Full mold casting smoke treatment device

A technology for flue gas treatment and solid casting, applied in foundry equipment, manufacturing tools, transportation and packaging, etc., can solve problems such as deteriorating the production environment of the workshop, affecting the health of workers, and being difficult to use on a large scale, to protect the environment, The effect of uniform extraction and health assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

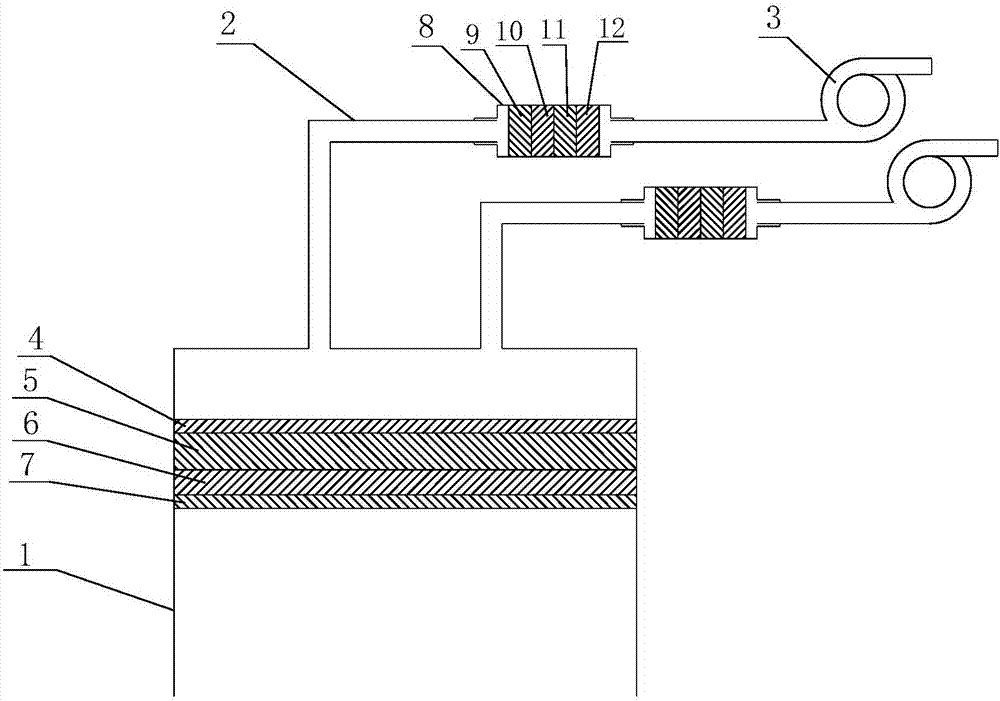

[0015] Such as figure 1 As shown, the present invention provides a full mold casting flue gas treatment device, which is used for flue gas treatment in the full mold casting process. The device comprises an air extraction cover box 1, and the shape of the air extraction cover box 1 is not limited. Here, a cube is used as an example to describe in detail. The bottom of the air extraction cover box 1 is open, and the four sides and the top are integrated. During use, the air extraction cover box 1 is covered on the solidified mold, mainly covering the open riser and the air outlet.

[0016] The top of the air extraction cover box 1 is connected with at least one air extraction pipe 2, preferably two, and here are two air extraction pipes 2 as an example for specific description, the air extraction pipe 2 is connected with the exhaust fan 3 respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com