Film covering and turnover integrated equipment and woven bag processing system

A film-coating and integrated technology, which is applied in the field of film-covering and flipping integrated equipment and woven bag processing systems, can solve the problems of high equipment cost and complicated operation, and achieve the effect of reducing equipment investment, reducing production costs, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

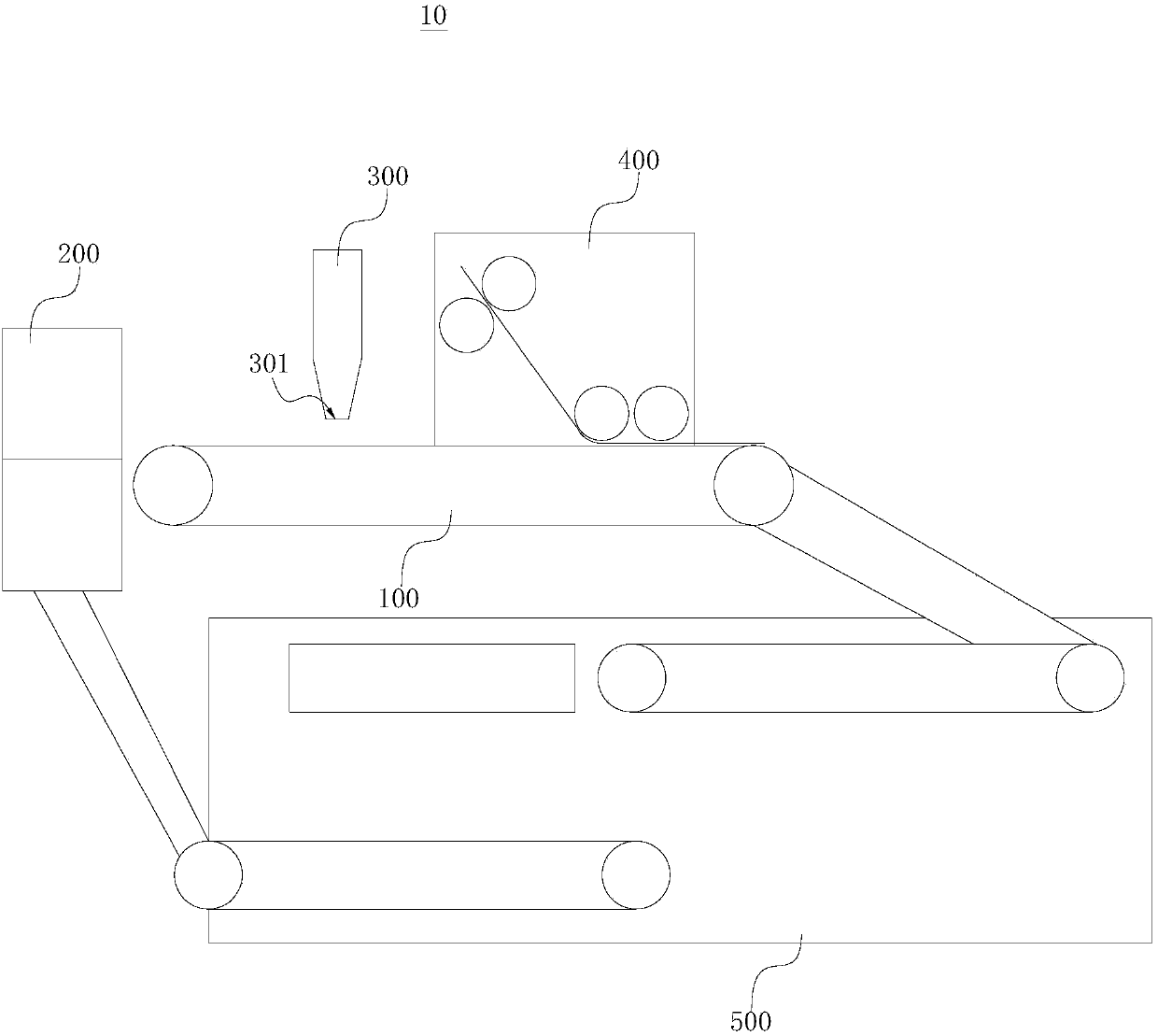

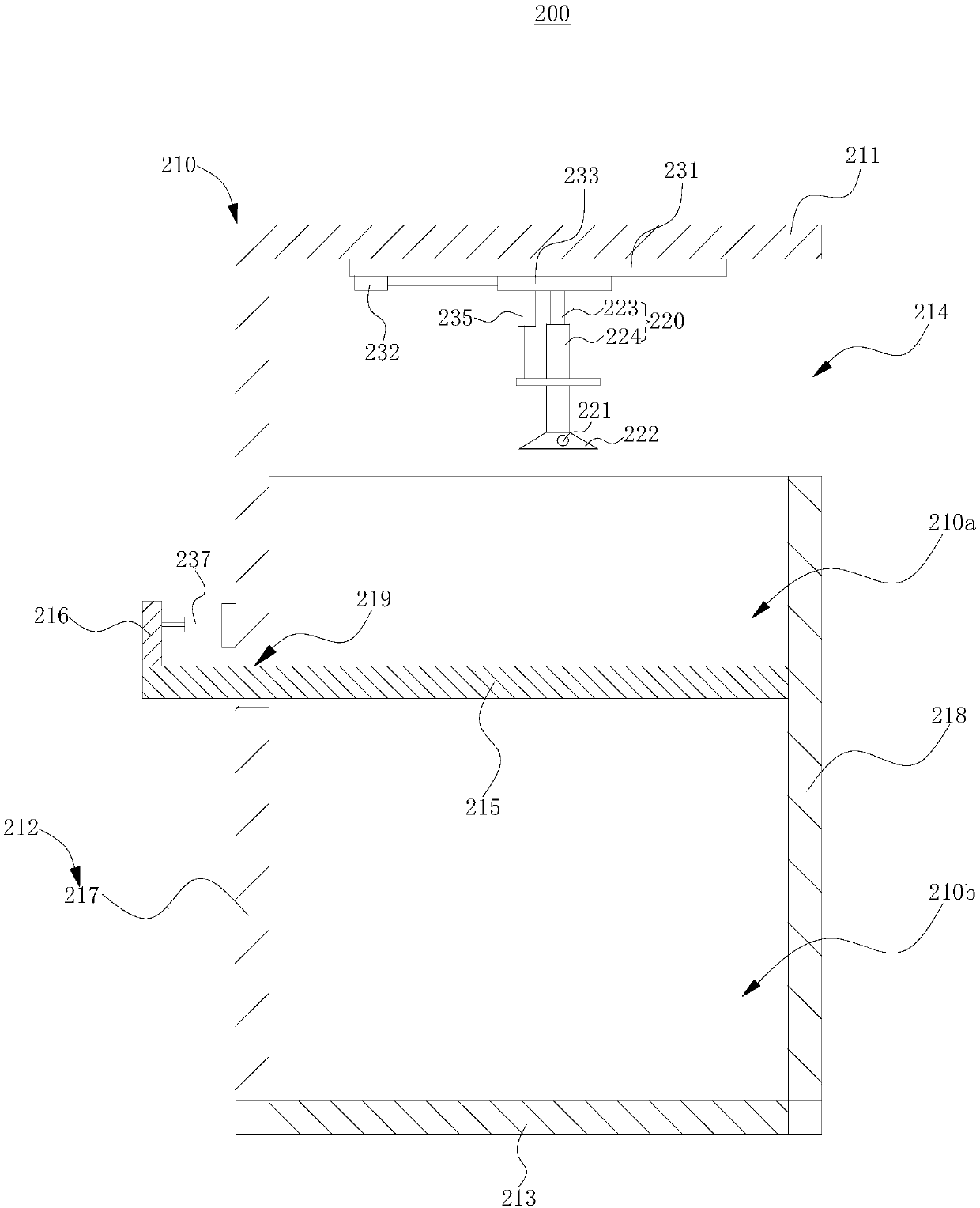

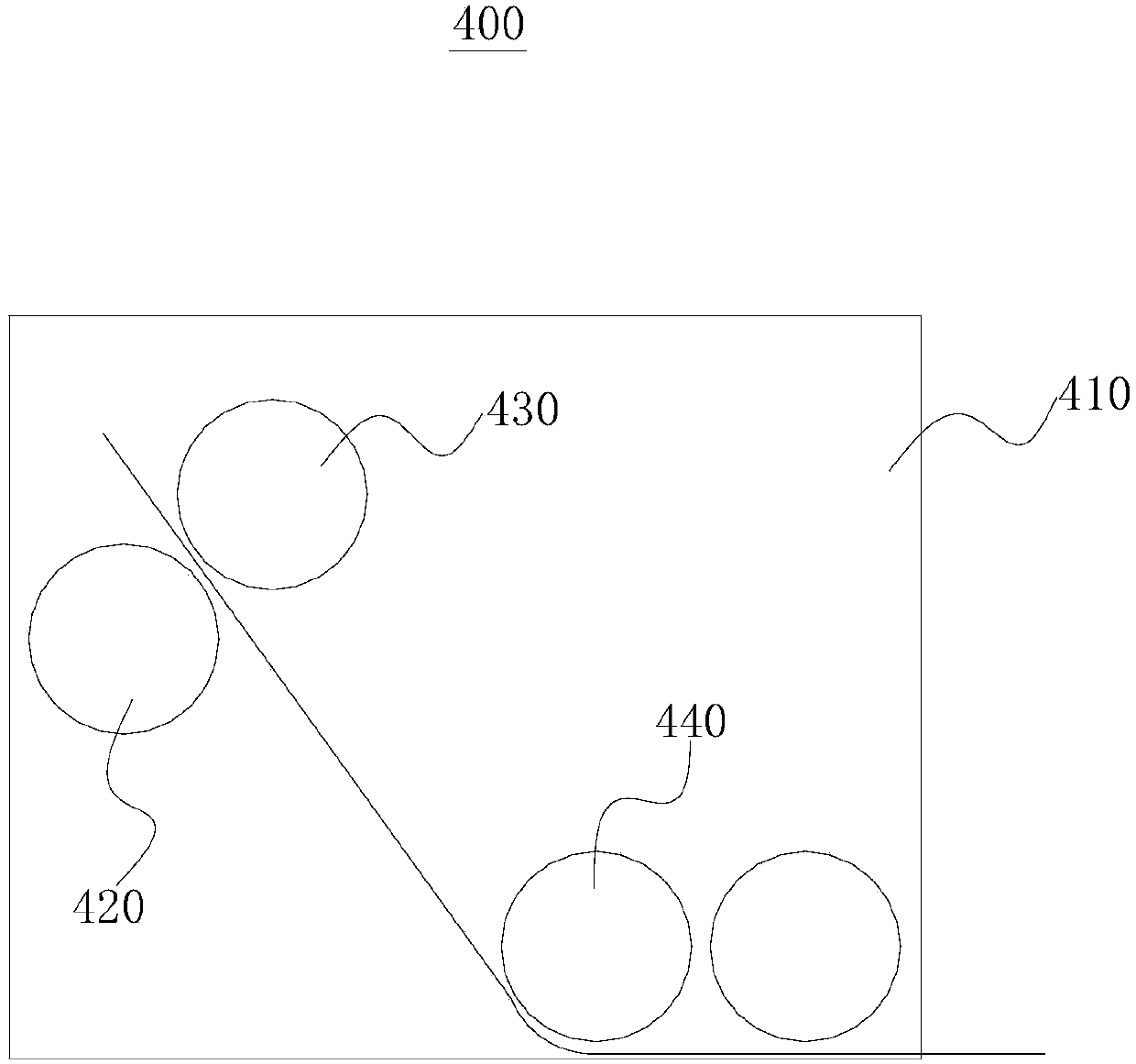

[0033] Please refer to figure 1 , the present embodiment provides a laminating and turning integrated equipment 10 , which includes a conveying device 100 , a feeding device 200 , a glue extruding device 300 , a film covering device 400 and a turning device 500 .

[0034] The conveying device 100 is used for conveying the woven bags to enter different processes, and the conveying device 100 can be a conveying belt structure, or a conveying roller structure. In this embodiment, it is preferable that the conveying device 100 is a conventional conveyor belt structure, and the feeding device 200 is arranged at the feeding end of the conveying device 100, and the feeding device 200 transports the captured woven bag to the feeding end of the conveying device 100 to complete the feeding Shipping in woven bags. The woven bag is sequentially transported to the extruding device 300 , the film covering device 400 and the turning device 500 along with the conveying device 100 , and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com