Hot pickled mustard tuber slicing device

A slicing device and slicing technology, which is applied in metal processing and other directions, can solve the problems of difficult holding and mustard, and achieve the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

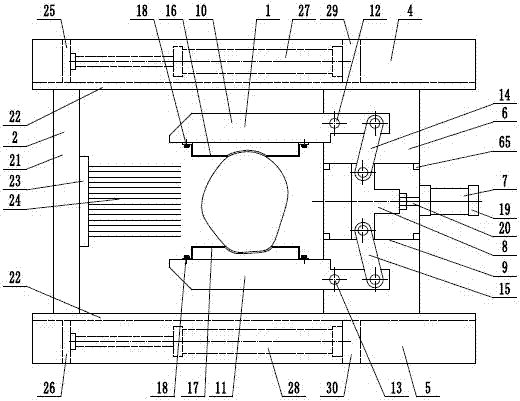

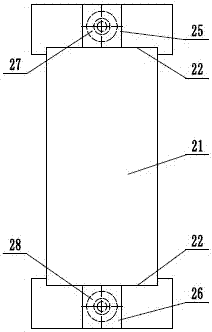

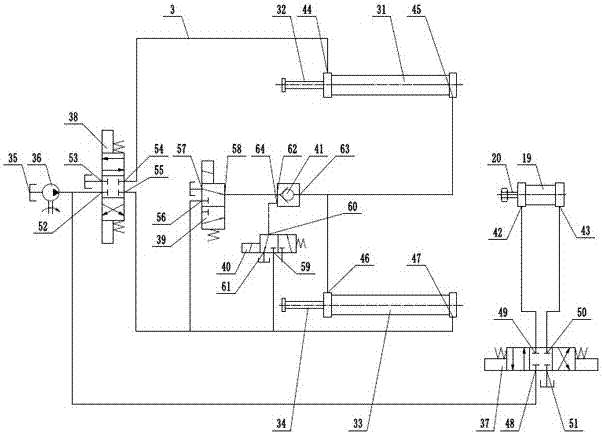

[0014] Such as figure 1 , figure 2 with image 3Shown, a kind of mustard slicing device, it comprises clamping mechanism 1, slicing mechanism 2, hydraulic drive mechanism 3, and described clamping mechanism 1 comprises upper beam 4, lower beam 5, clamping frame 6, driving oil cylinder 7, T-shaped slide block 8, slide block guide rail 9, upper jaw 10, lower jaw 11, upper bearing pin 12, lower bearing pin 13, upper connecting rod 14, lower connecting rod 15, clamping spring leaf 16 on the Π shape, Under the Π-shaped clamping spring leaf 17 and fastening screw 18, the upper beam 4 and the lower beam 5 are parallel to each other, the clamping frame 1 is fixed between the upper beam 4 and the lower beam 5, and the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com