Patents

Literature

45results about How to "Consistent preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

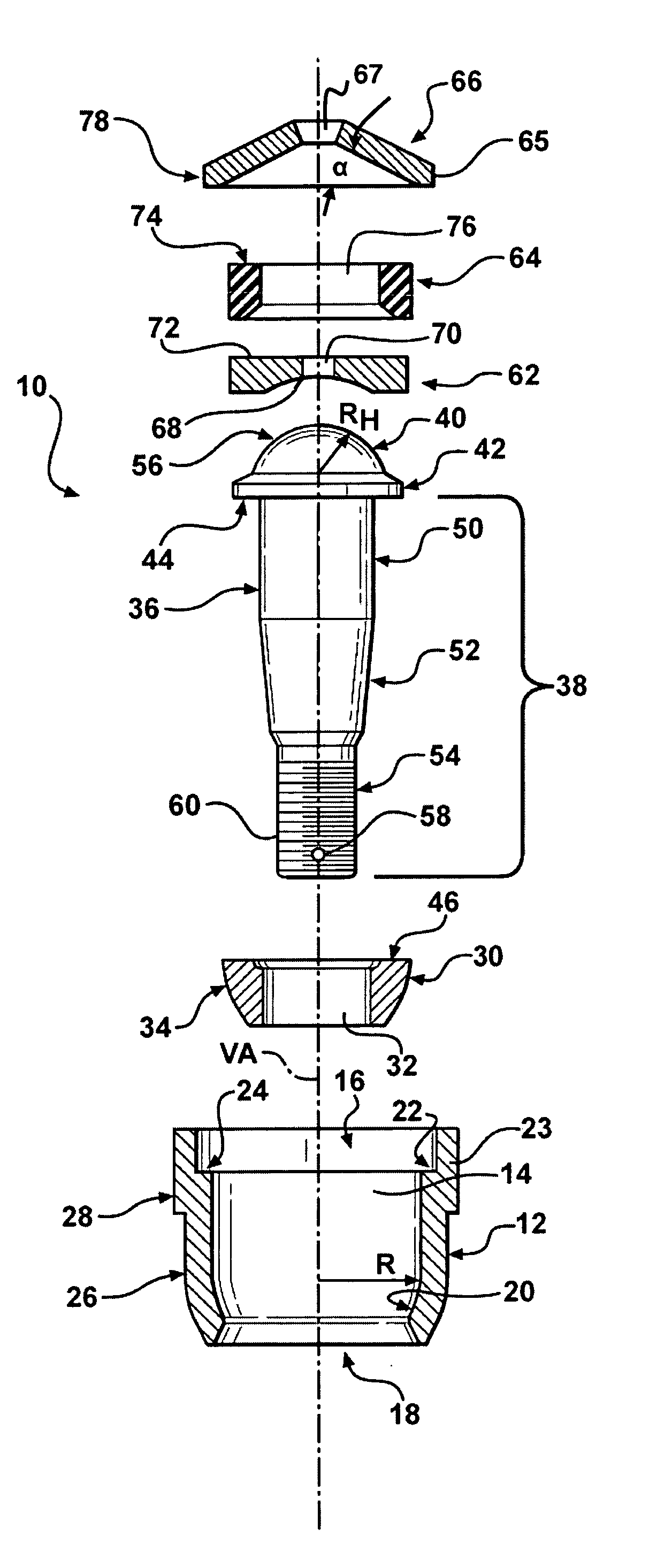

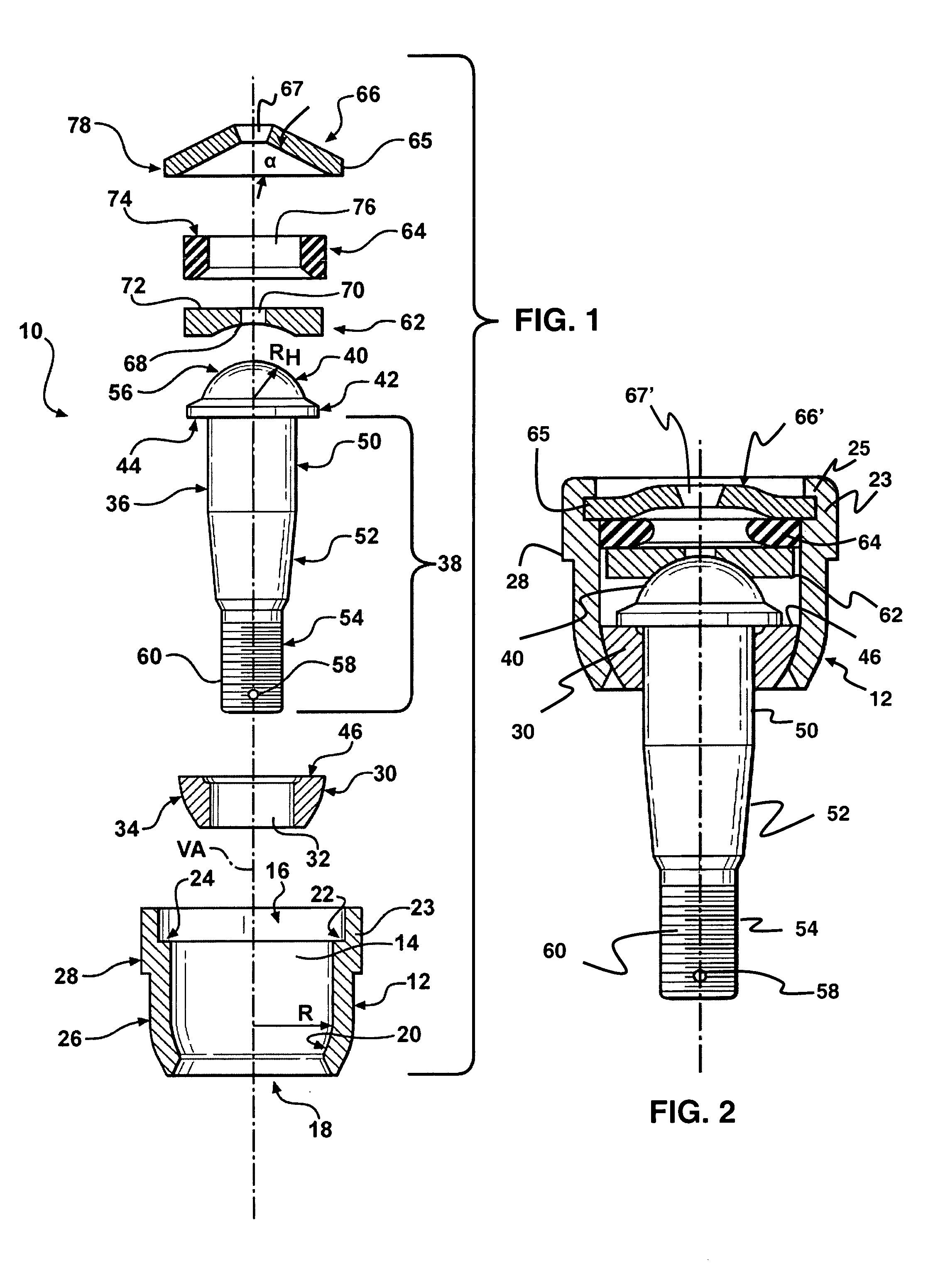

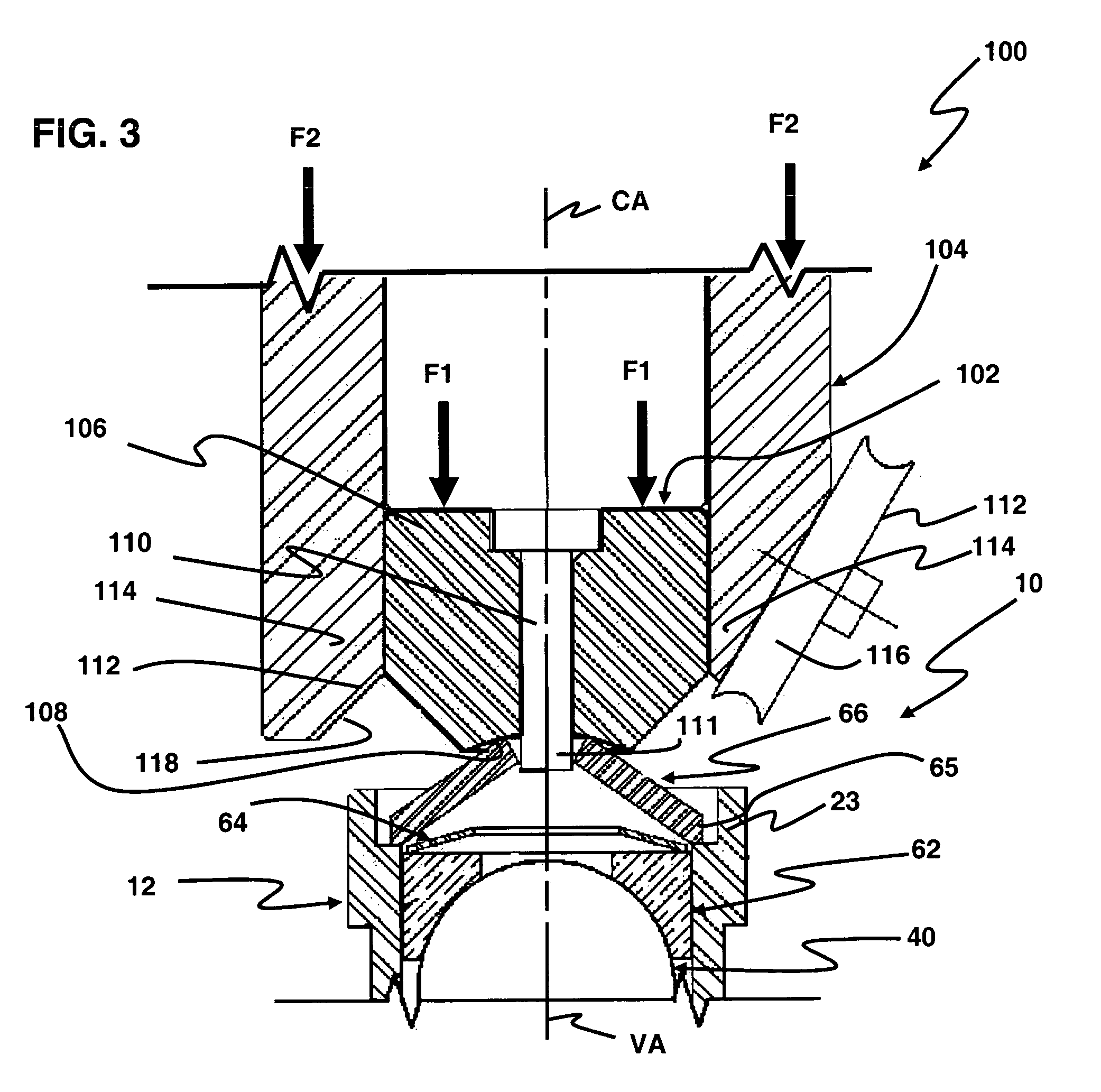

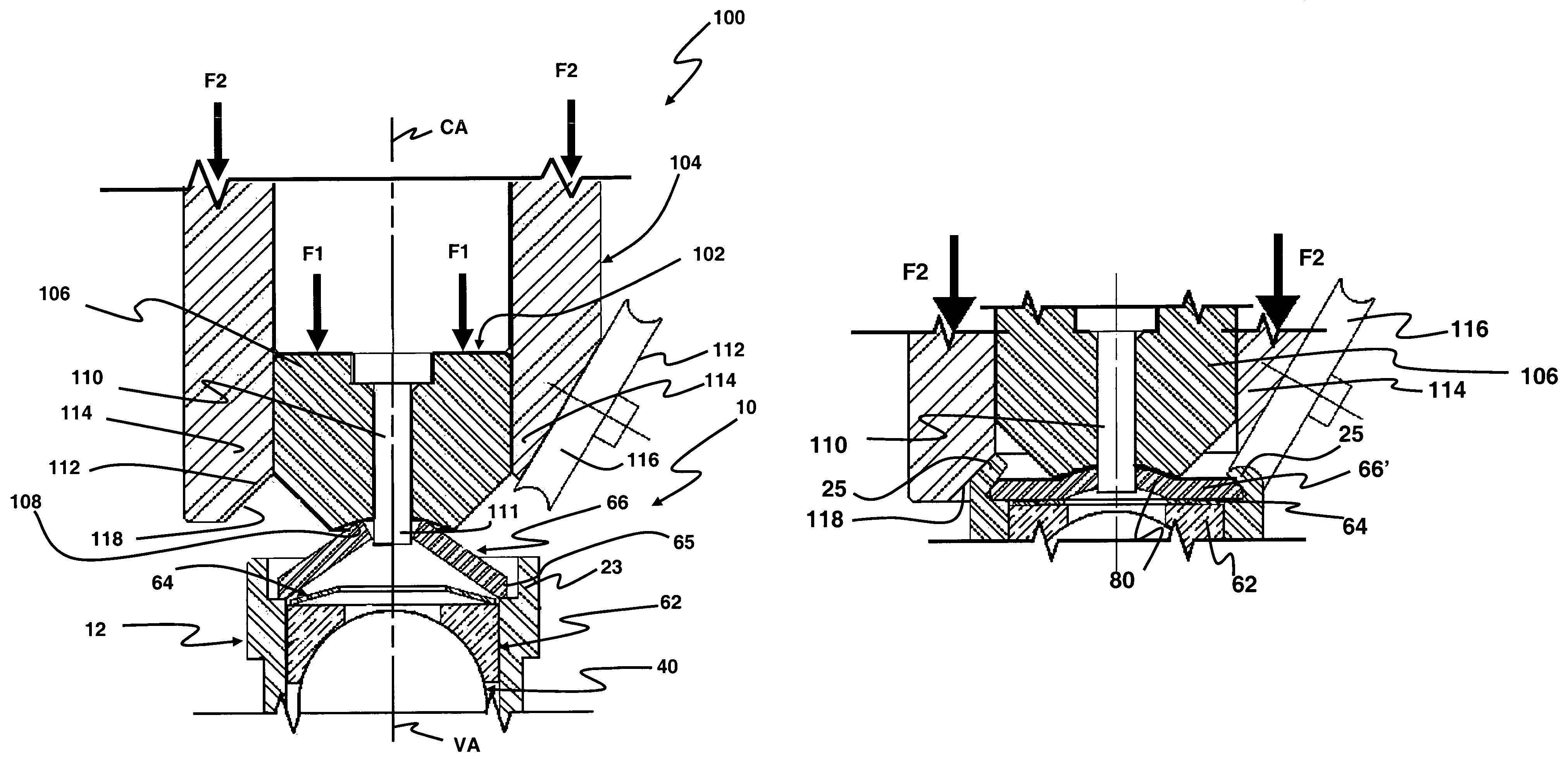

Method and apparatus for clearance adjusting cover plate closure

InactiveUS20050235476A1Good repeatabilityPrecise of of componentsCouplings for rigid shaftsPivotal connectionsEngineeringRepeatability

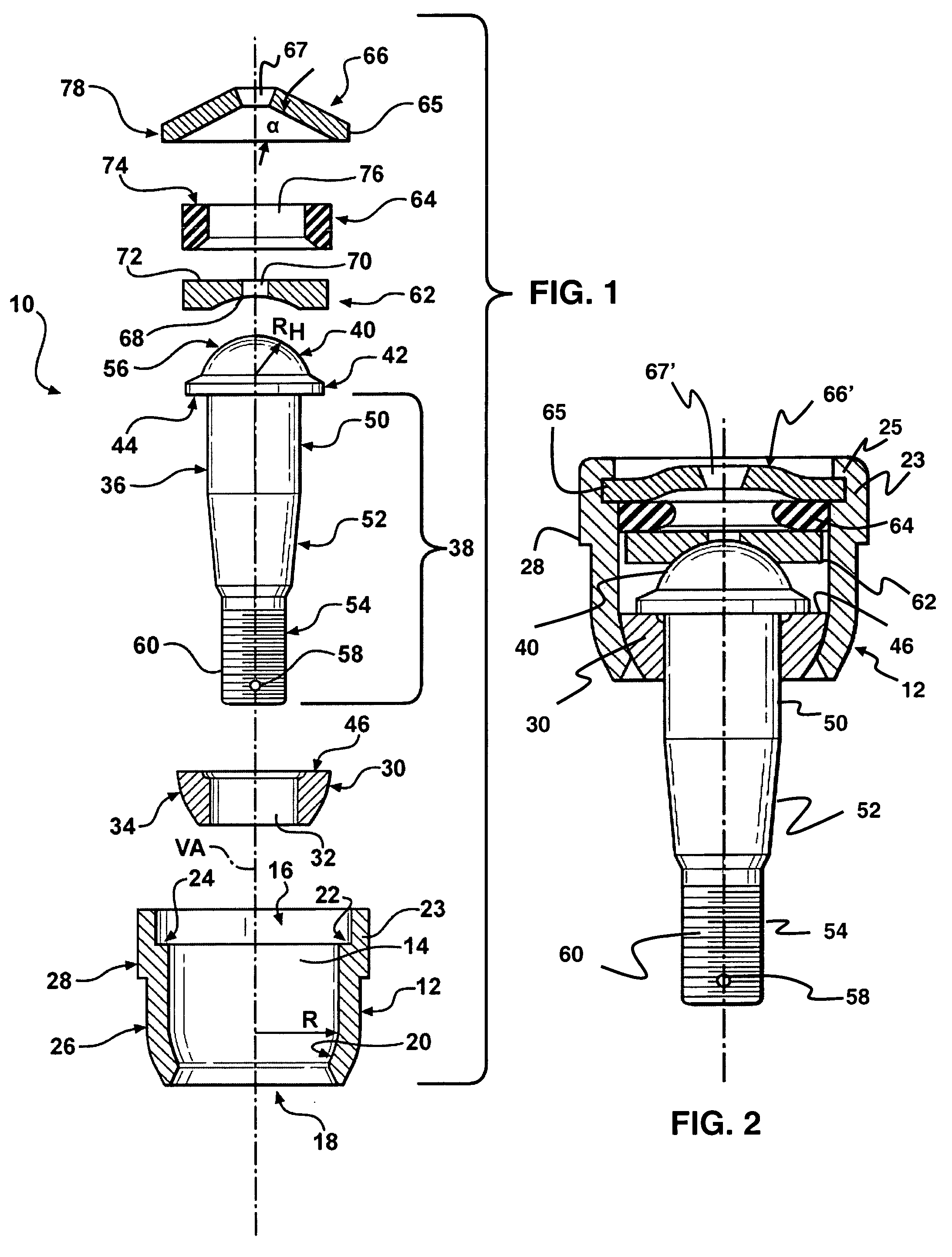

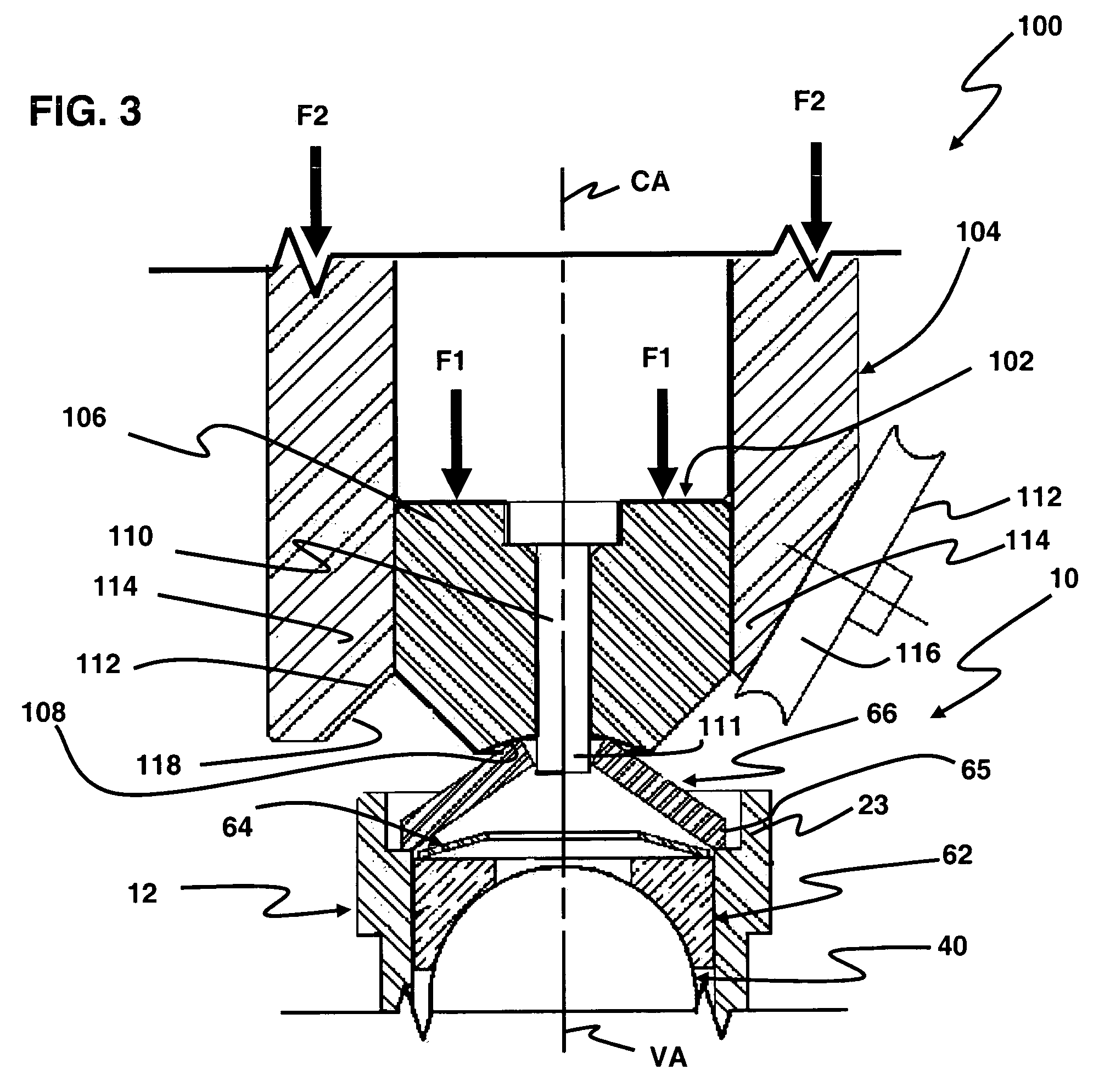

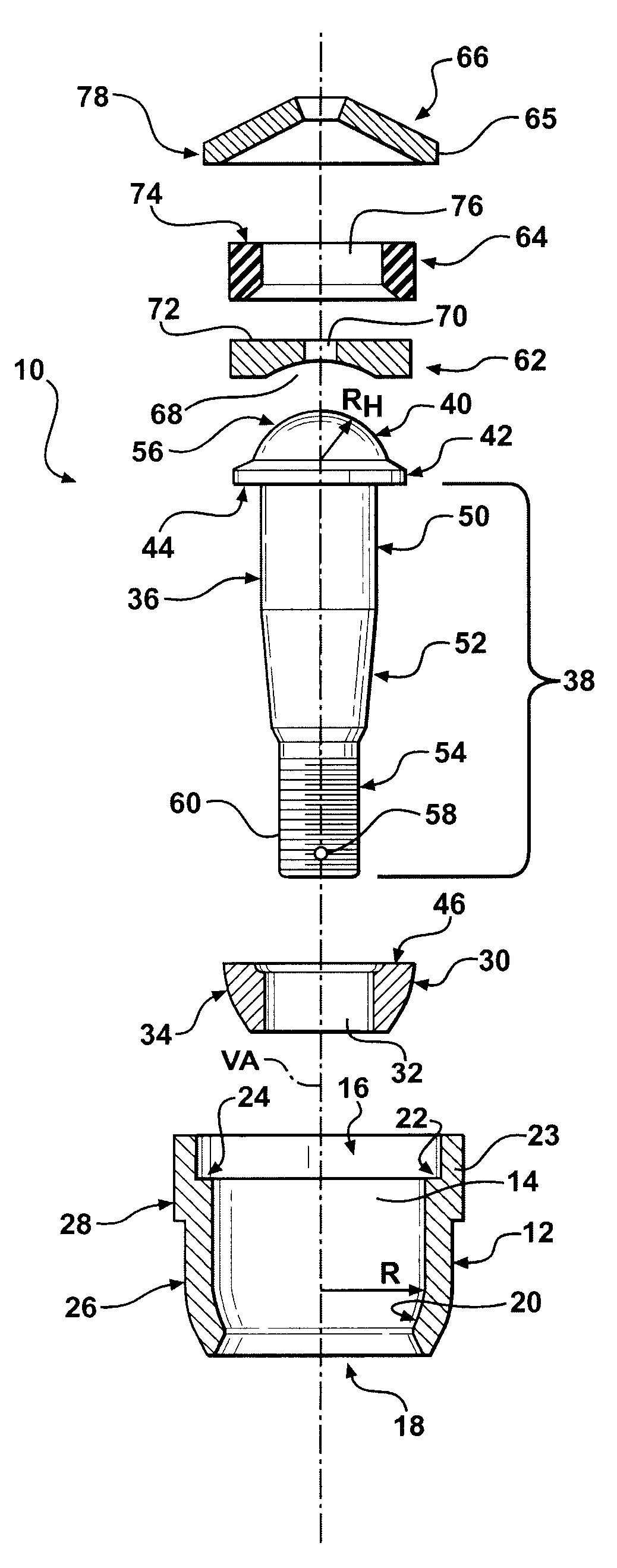

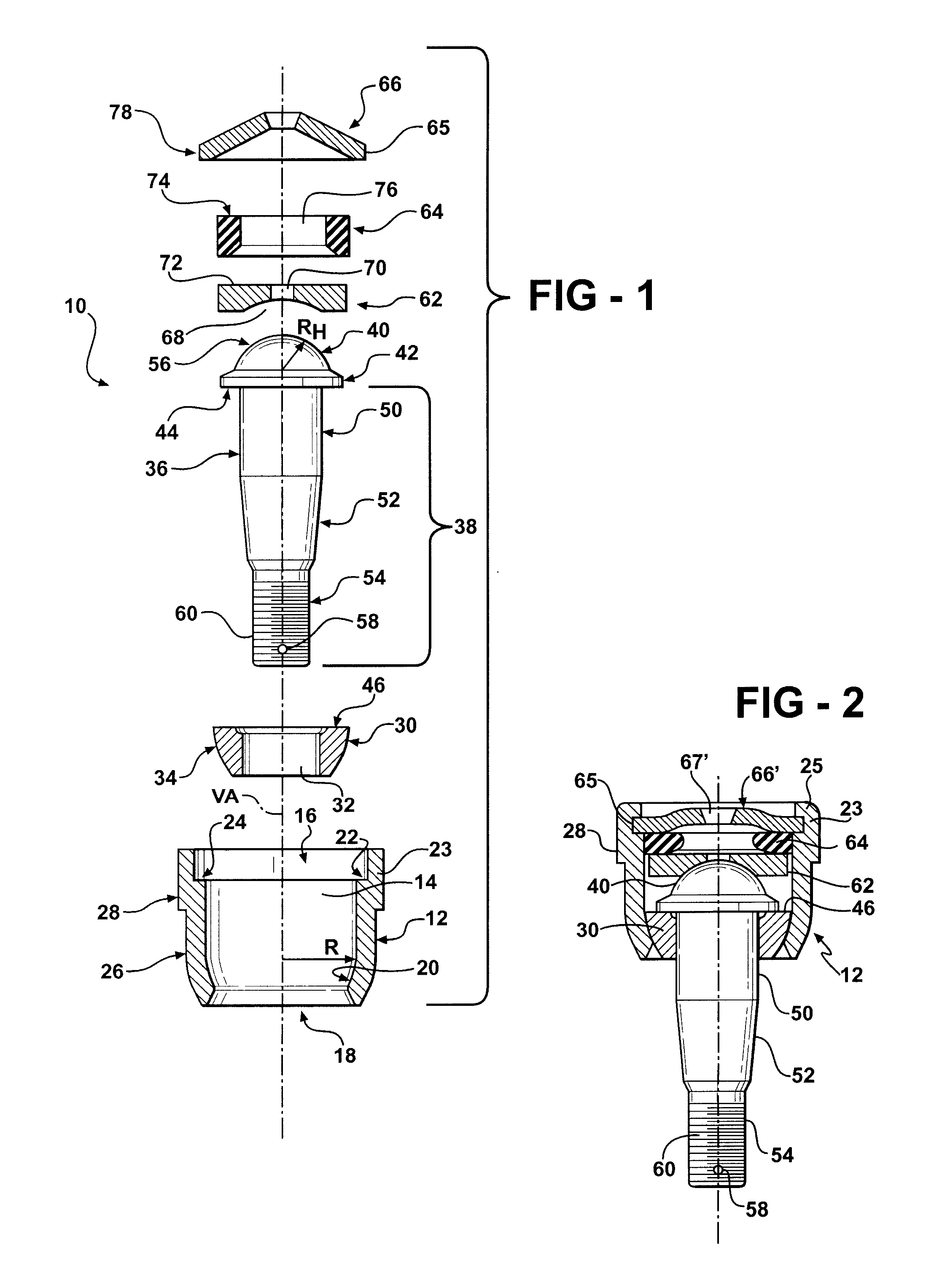

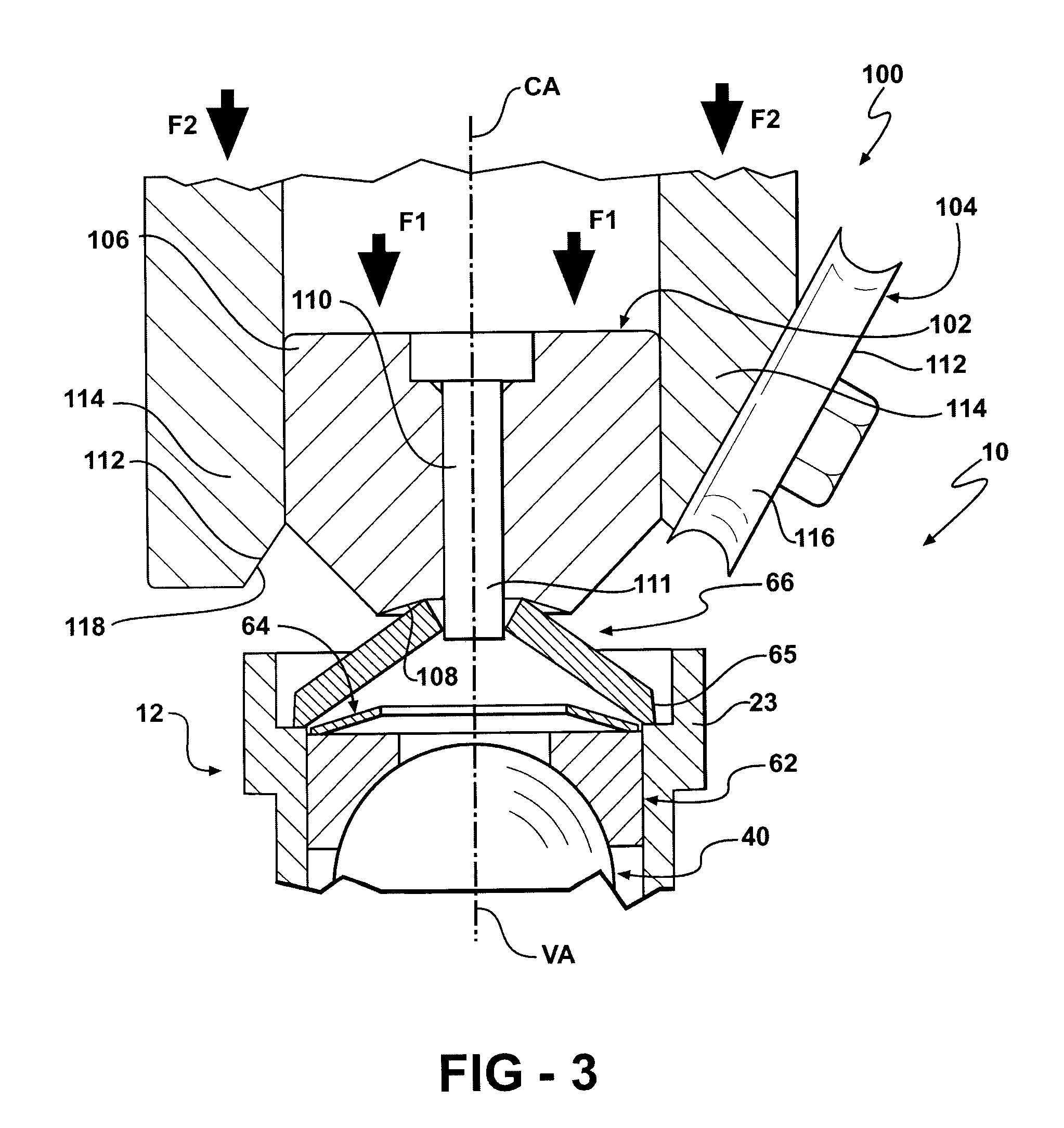

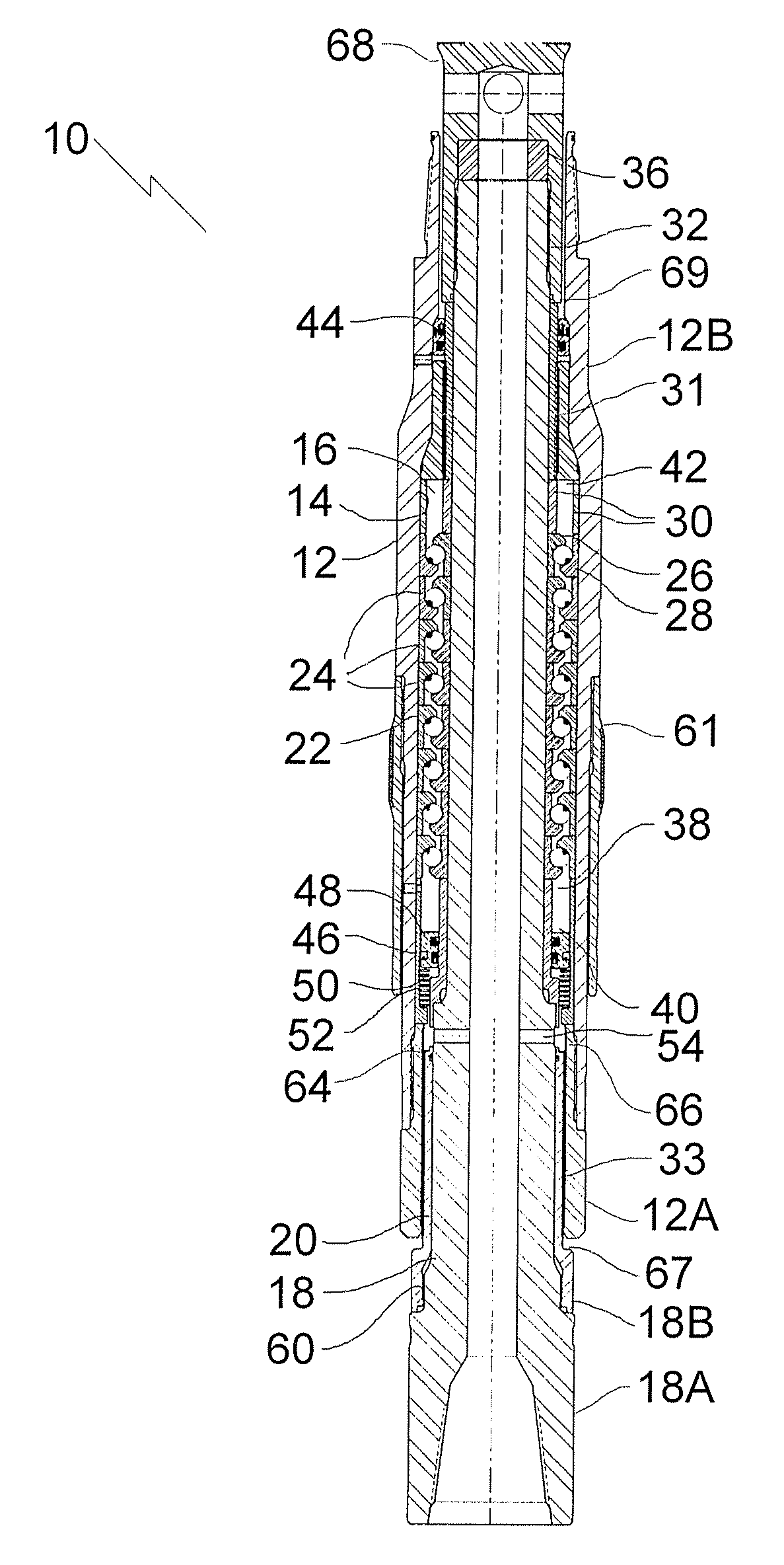

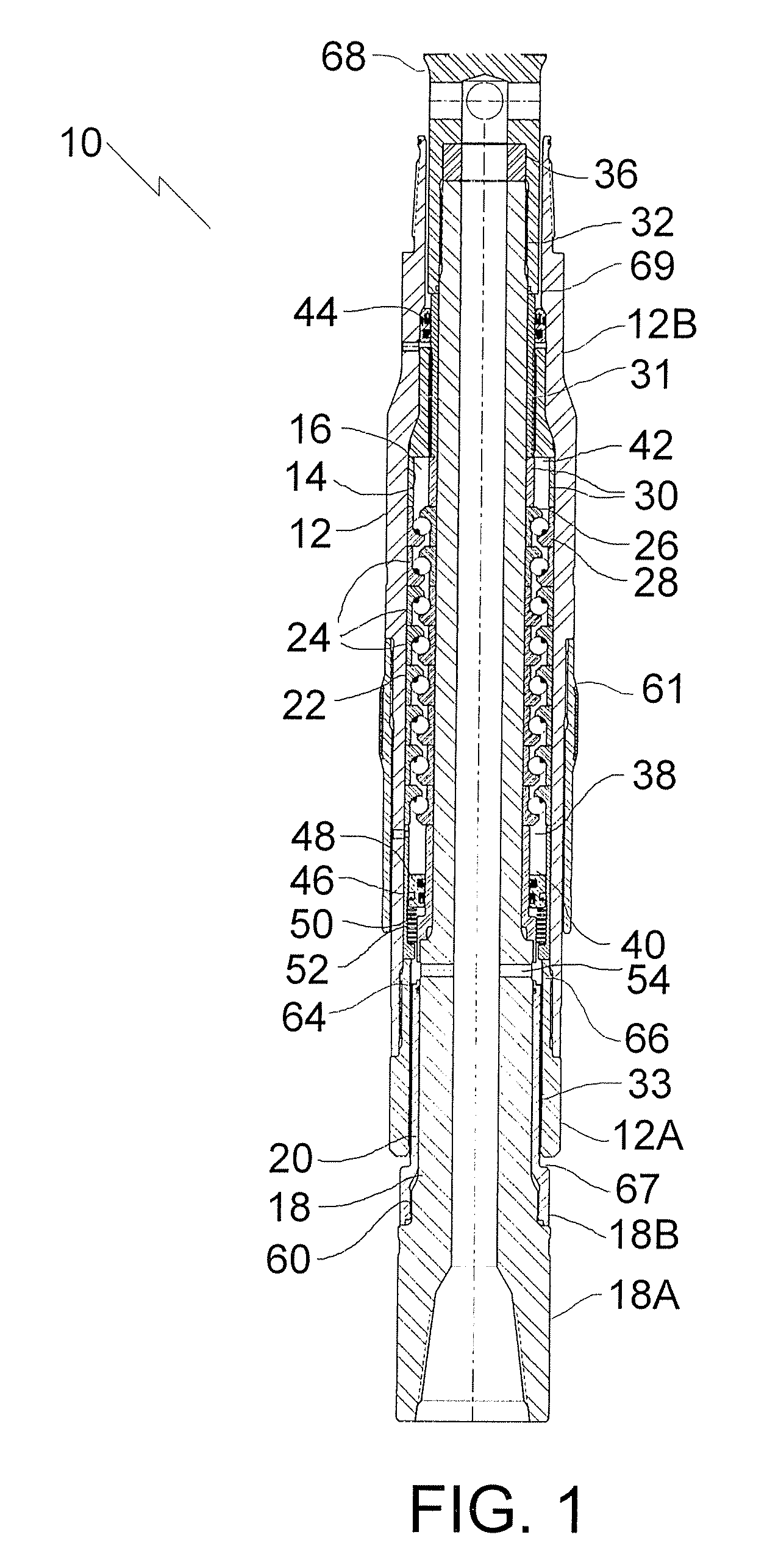

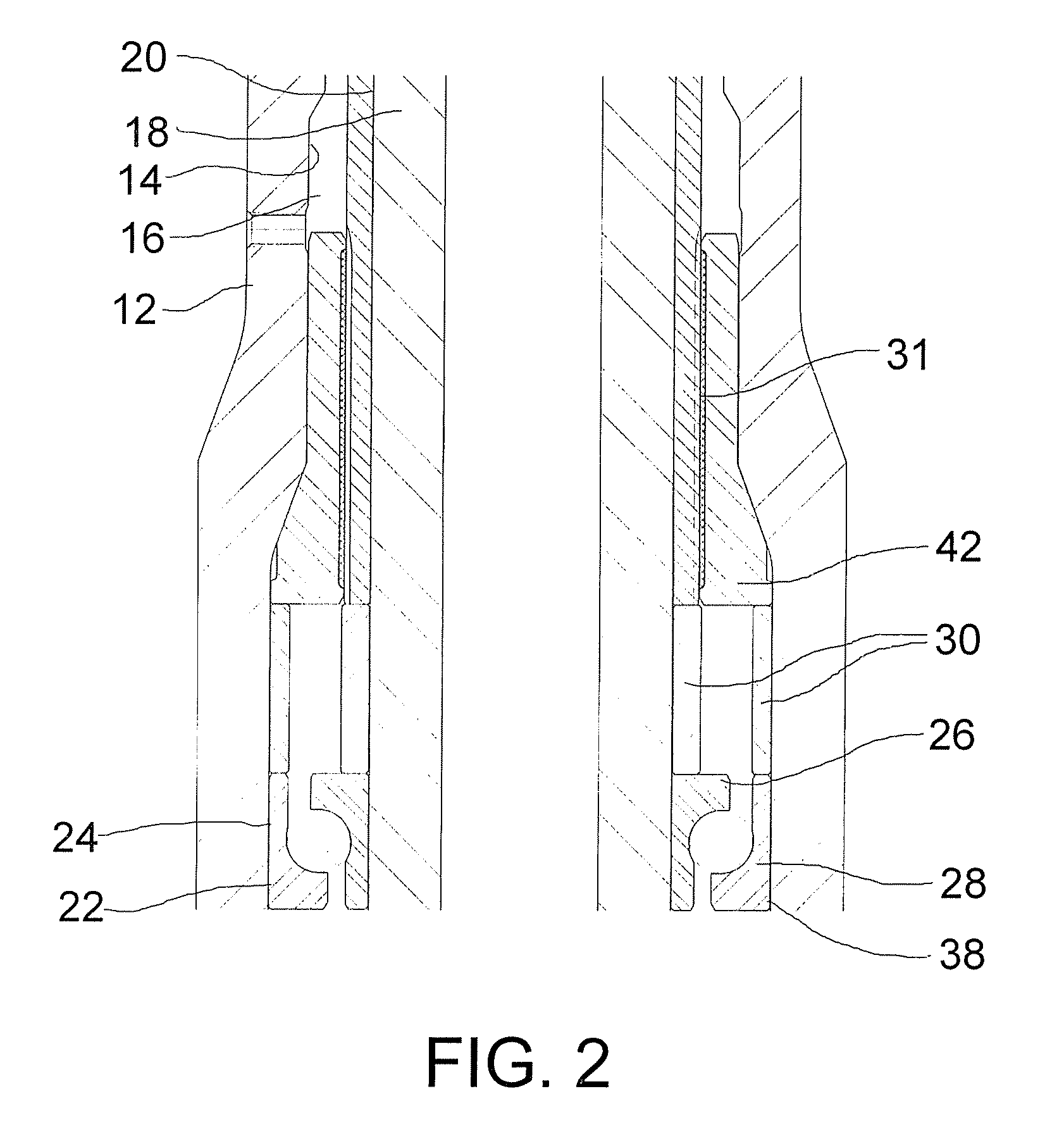

A ball and socket housing incorporating a thick housing wall of deformable material adjacent a central bore opening to provide a closure system utilizing a deformable cover-plate. The deformable cover-plate is formed to a desired configuration within the central bore to achieve a consistent internal socket preload. The cover-plate is deformed into the housing opening beyond an elastic limit to control resiliency or spring-back characteristics, thereby achieving a high-degree of repeatability and precise control of the ball and socket preload during the assembly process. The deformed cover-plate is retained in the socket housing at the cover-plate seat by swaged or rolling the perimeter of the housing to capture the perimeter of the deformed cover plate within the housing central bore opening.

Owner:FEDERAL MOGUL WORLD WIDE

Method for clearance adjusting cover plate closure

InactiveUS7421785B2Good repeatabilityPrecise of of componentsCouplings for rigid shaftsLarge fixed membersEngineeringMechanical engineering

A ball and socket housing incorporating a thick housing wall of deformable material adjacent a central bore opening to provide a closure system utilizing a deformable cover-plate. The deformable cover-plate is formed to a desired configuration within the central bore to achieve a consistent internal socket preload. The cover-plate is deformed into the housing opening beyond an elastic limit to control resiliency or spring-back characteristics, thereby achieving a high-degree of repeatability and precise control of the ball and socket preload during the assembly process. The deformed cover-plate is retained in the socket housing at the cover-plate seat by swaged or rolling the perimeter of the housing to capture the perimeter of the deformed cover plate within the housing central bore opening.

Owner:FEDERAL MOGUL WORLD WIDE

Method and apparatus for clearance adjusting cover plate closure

InactiveUS20080292391A1Good repeatabilityPrecise of of componentsCouplings for rigid shaftsPivotal connectionsRepeatabilityMechanical engineering

A ball and socket housing incorporating a thick housing wall of deformable material adjacent a central bore opening to provide a closure system utilizing a deformable cover-plate. The deformable cover-plate is formed to a desired configuration within the central bore to achieve a consistent internal socket preload. The cover-plate is deformed into the housing opening beyond an elastic limit to control resiliency or spring-back characteristics, thereby achieving a high-degree of repeatability and precise control of the ball and socket preload during the assembly process. The deformed cover-plate is retained in the socket housing at the cover-plate seat by swaged or rolling the perimeter of the housing to capture the perimeter of the deformed cover plate within the housing central bore opening.

Owner:FEDERAL MOGUL WORLD WIDE

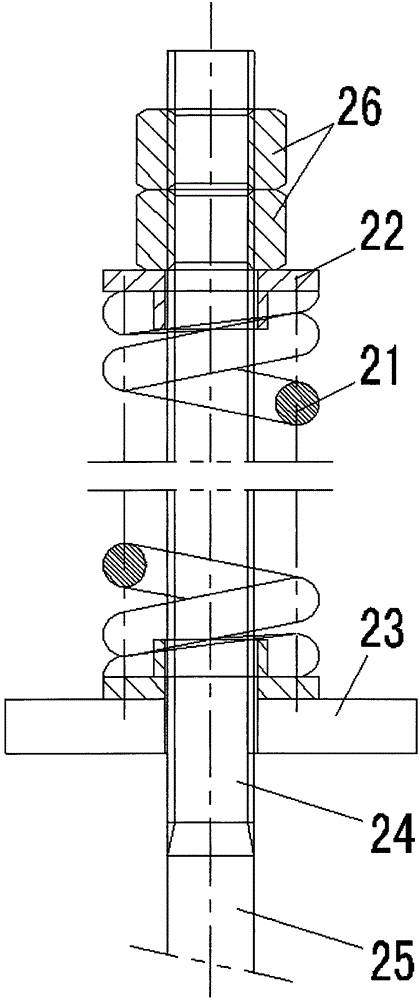

Method of providing a consistent preload on thrust bearings in a bearing assembly

A method of providing a consistent preload on thrust bearings in a bearing assembly. A first step involves placing against an inner race and an outer race of a bearing stack of tlirust bearings, deformable shims made from a material having a relatively flat stress-strain curve after its yield stress has been exceeded. A second step involves preloading the deformable shims beyond their yield point in situ until a predetermined preload tolerance is reached.

Owner:JOHNSON ORREN S

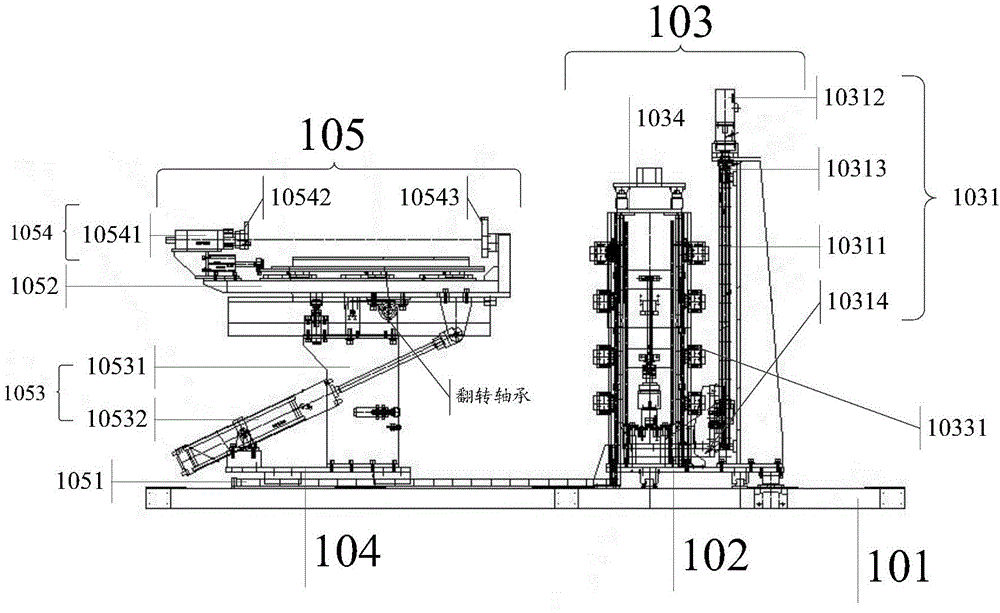

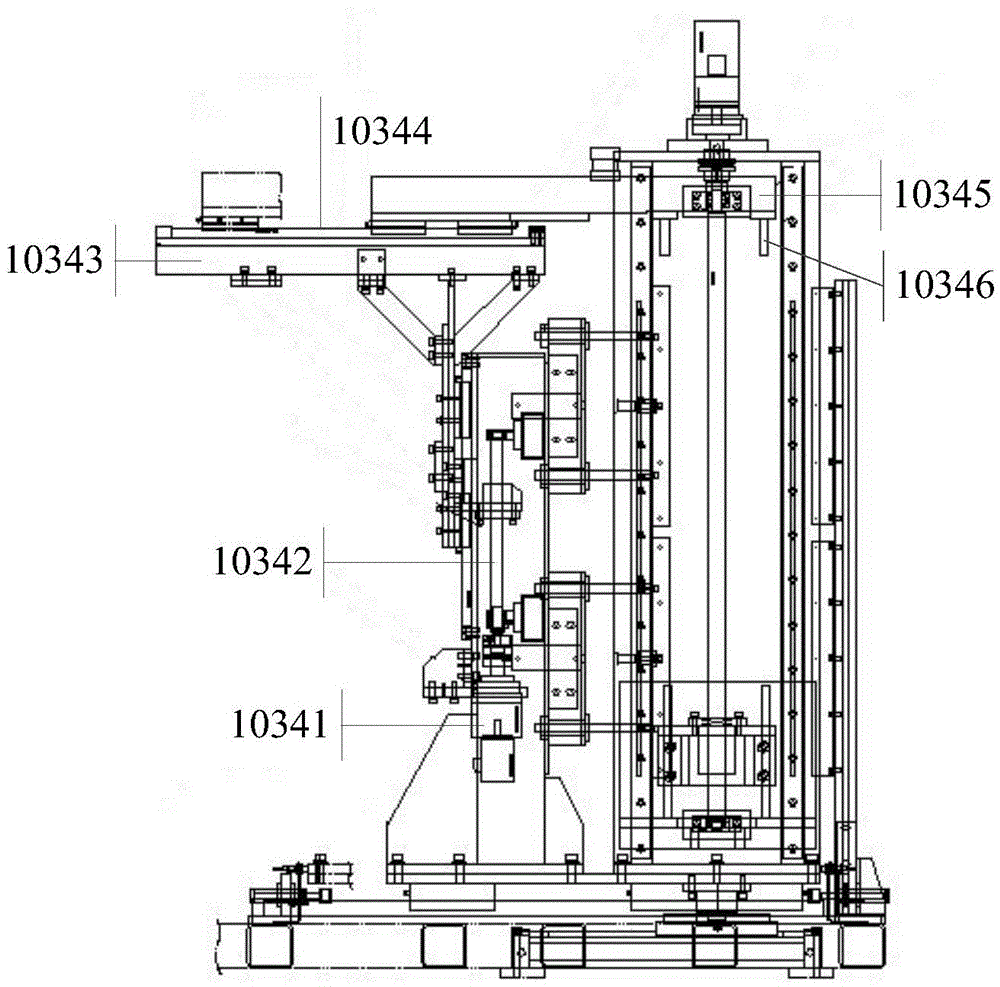

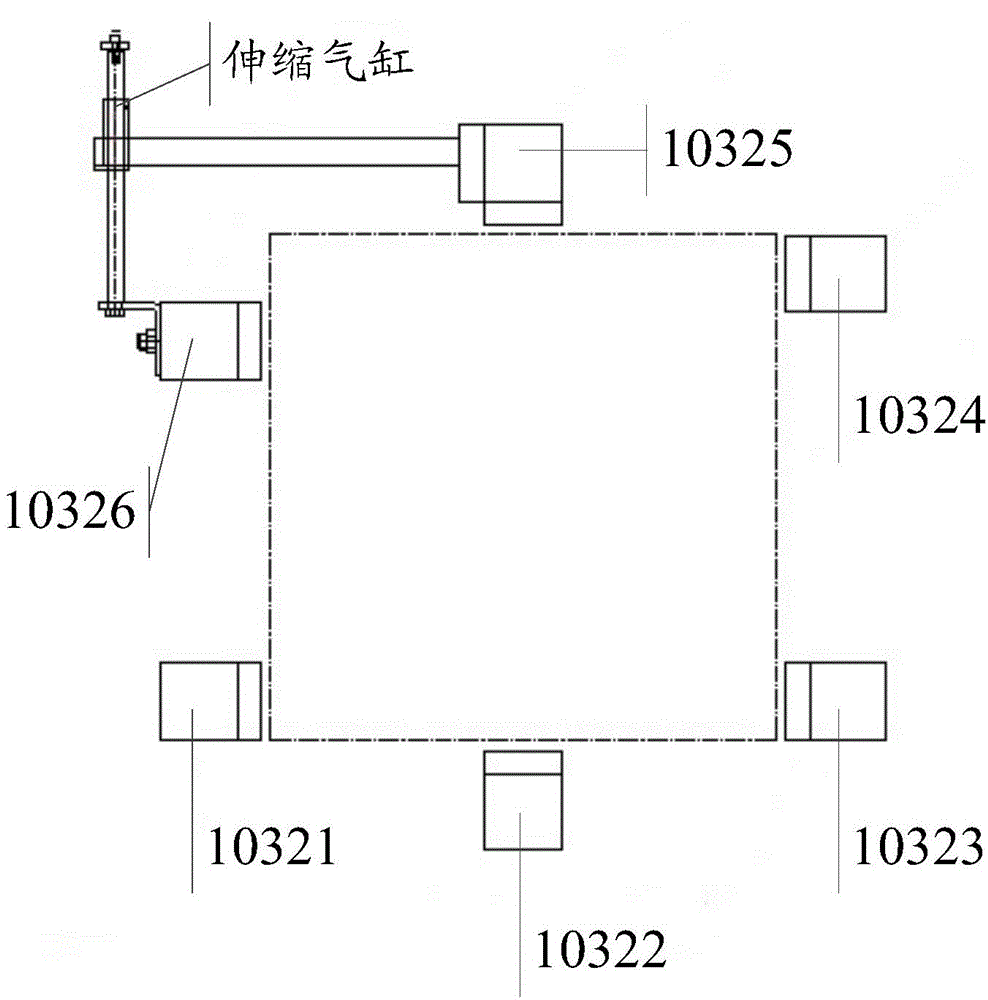

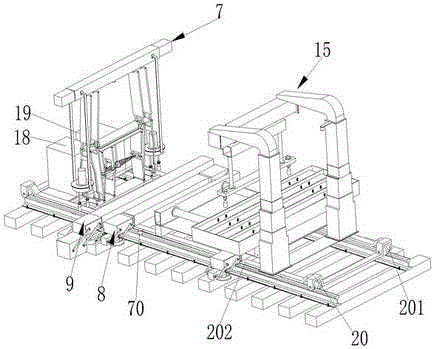

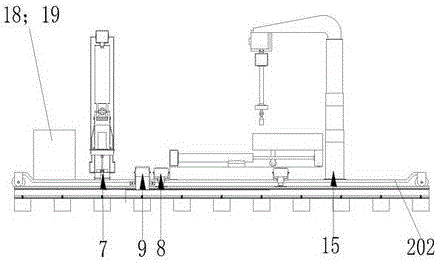

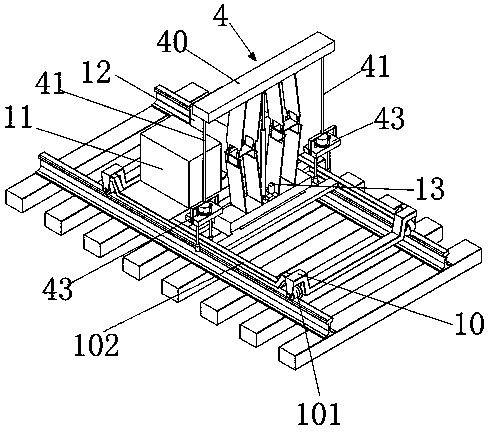

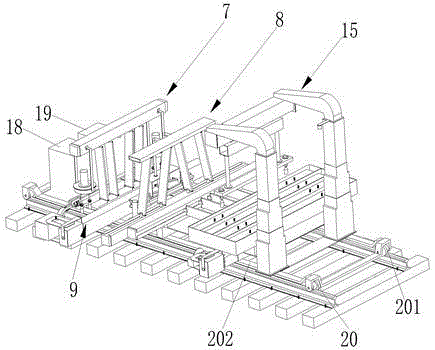

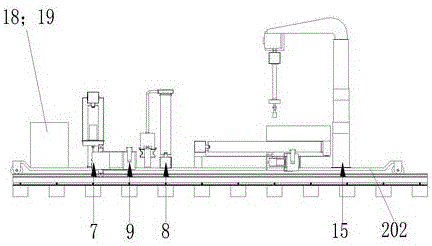

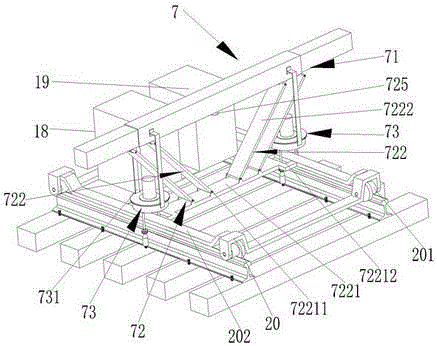

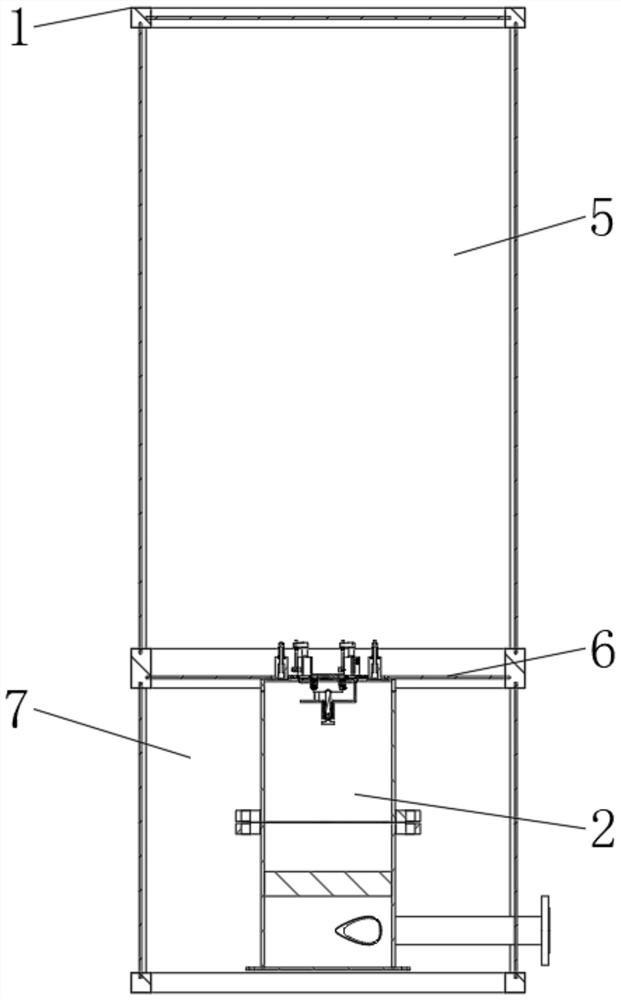

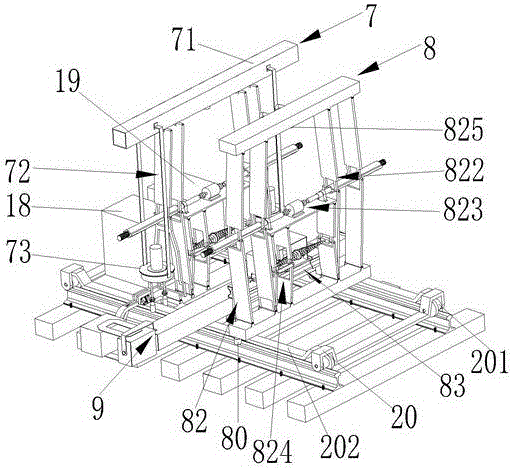

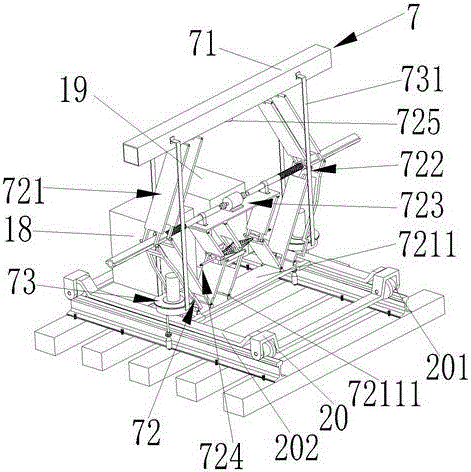

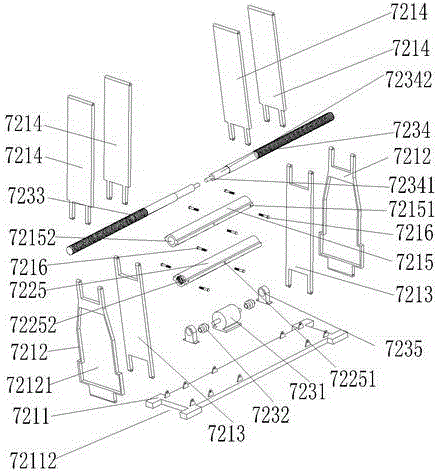

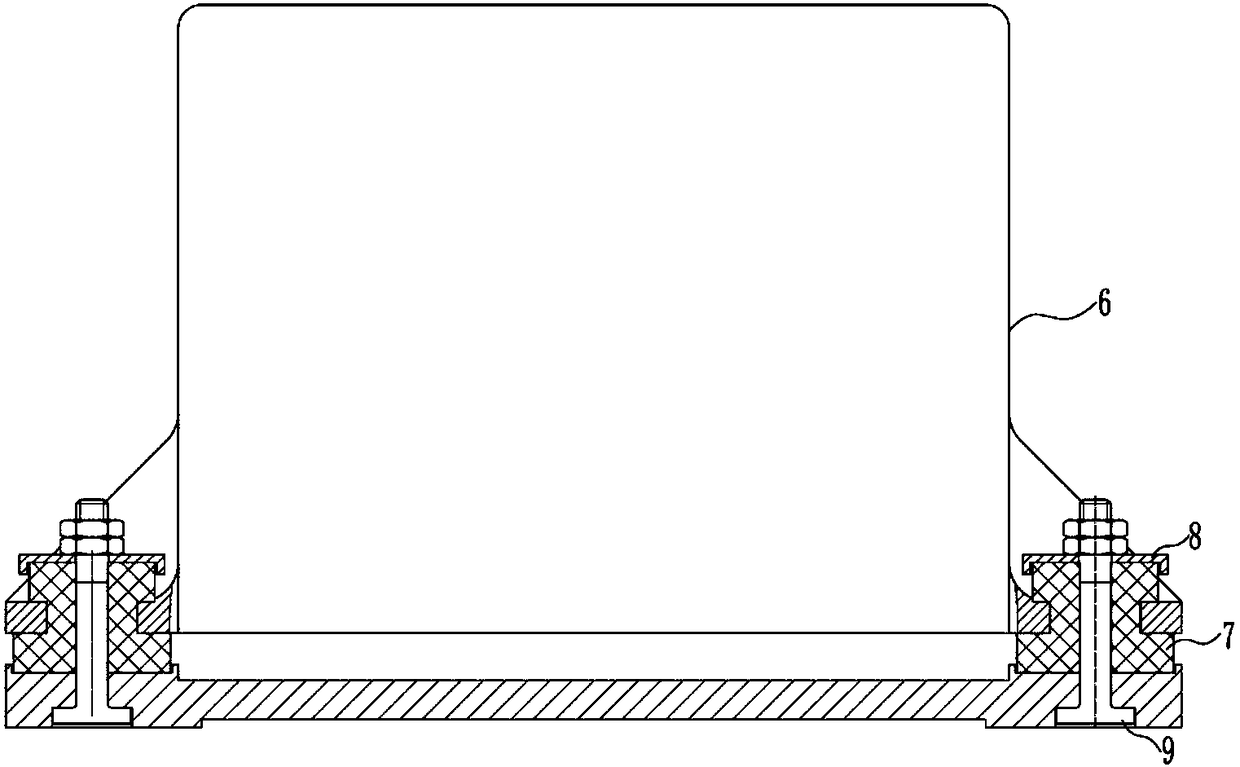

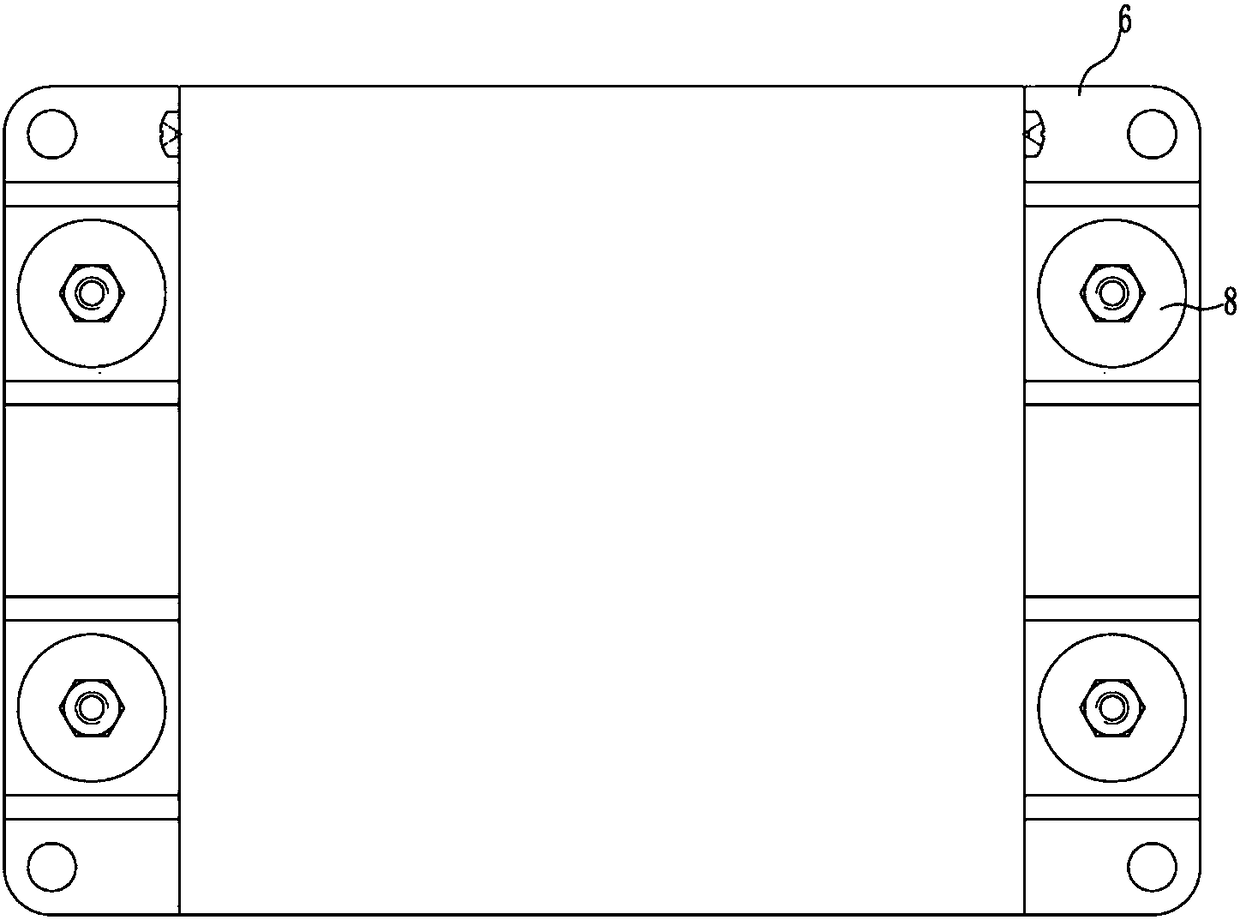

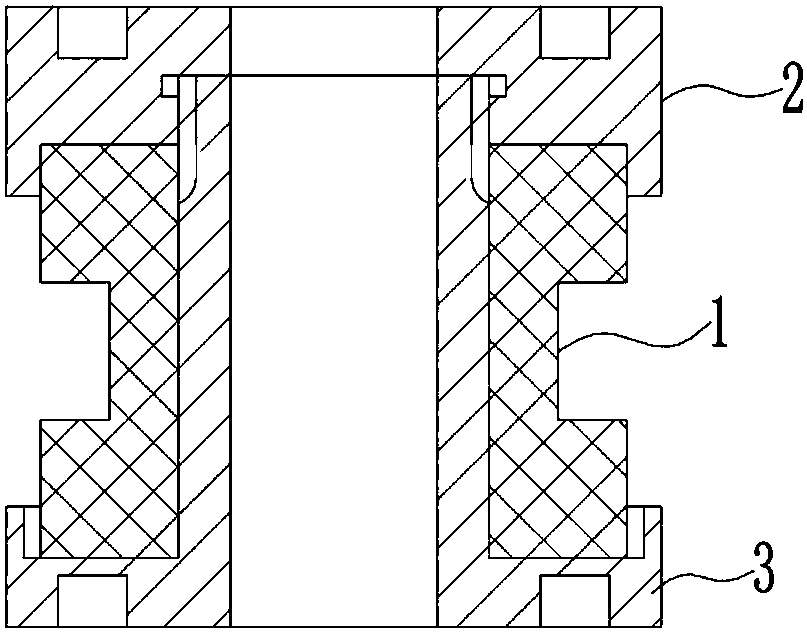

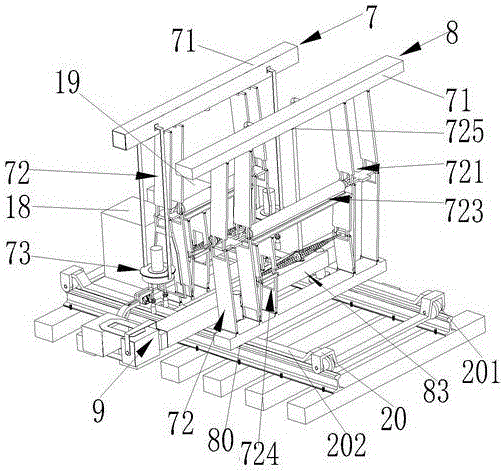

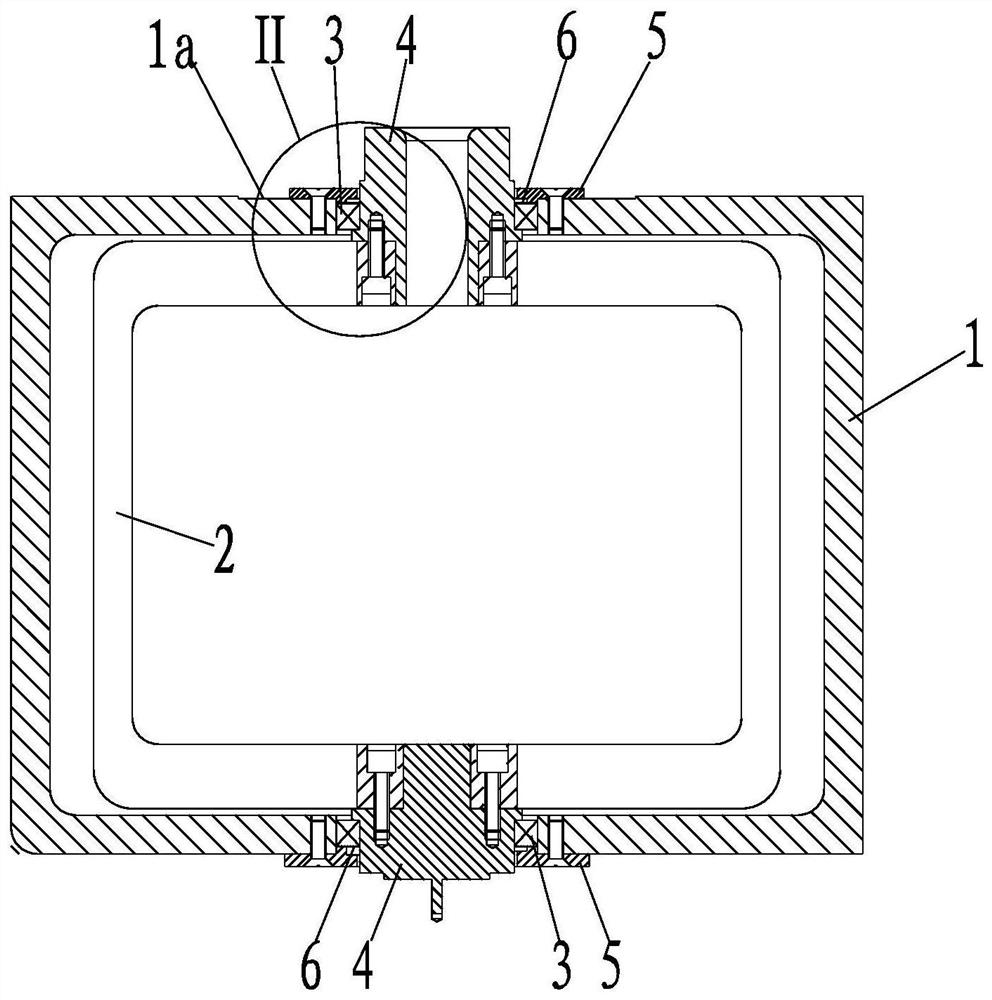

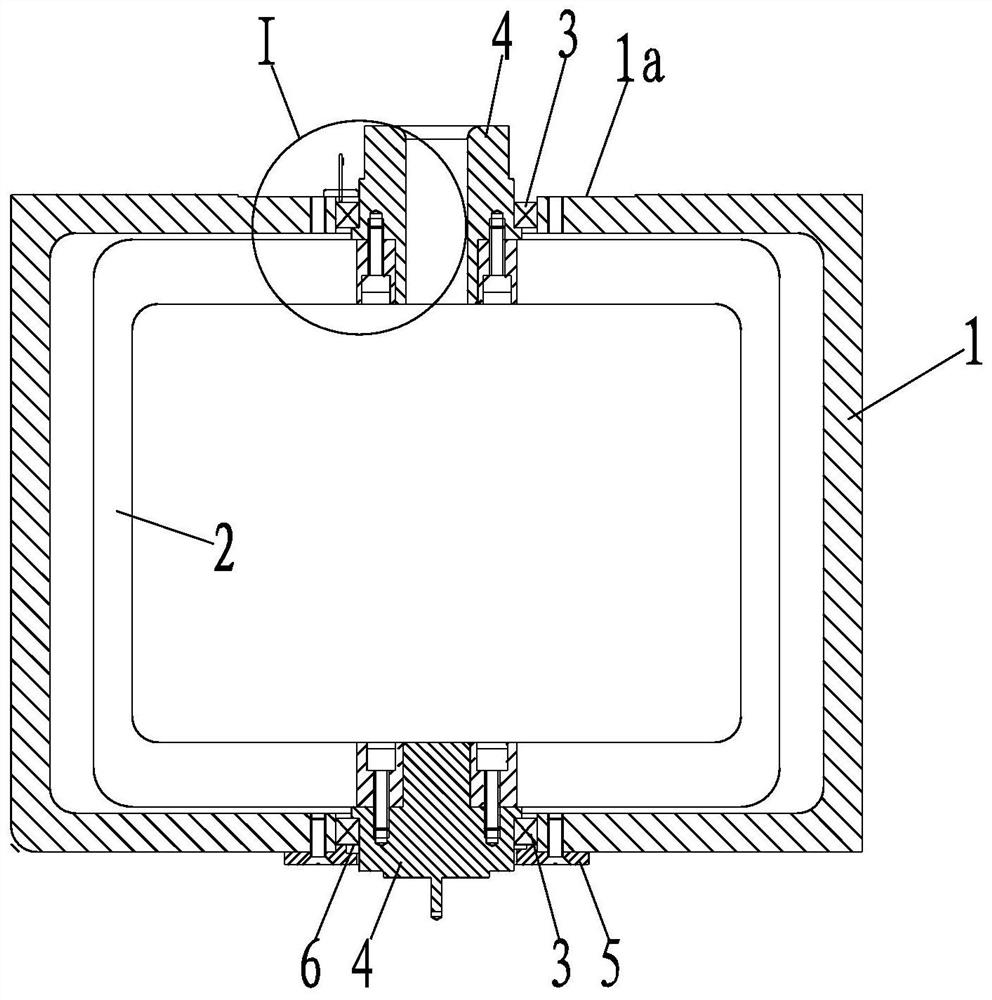

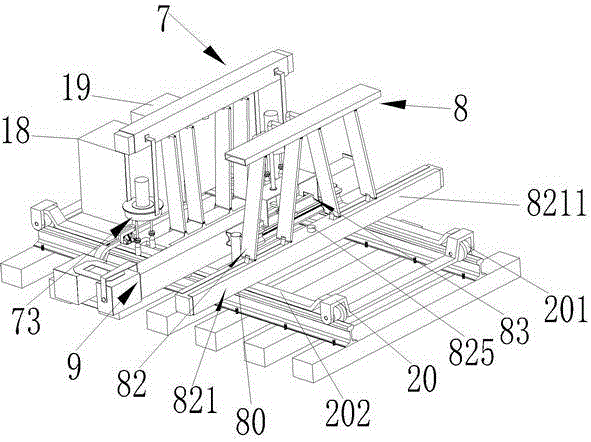

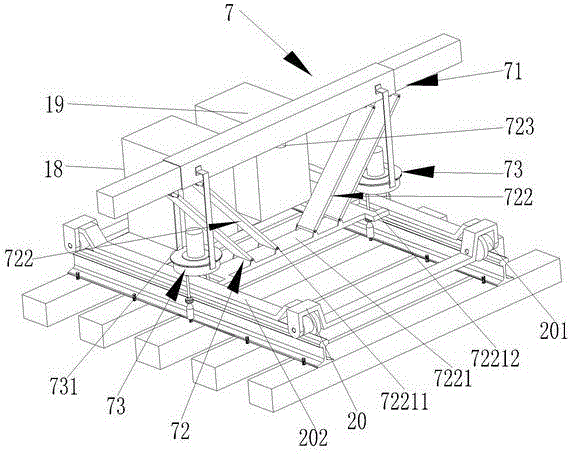

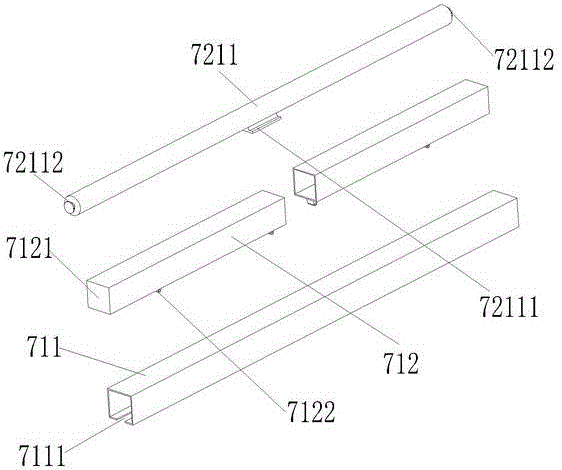

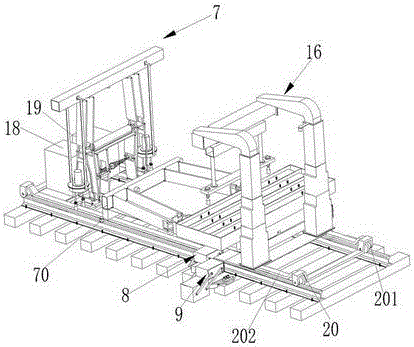

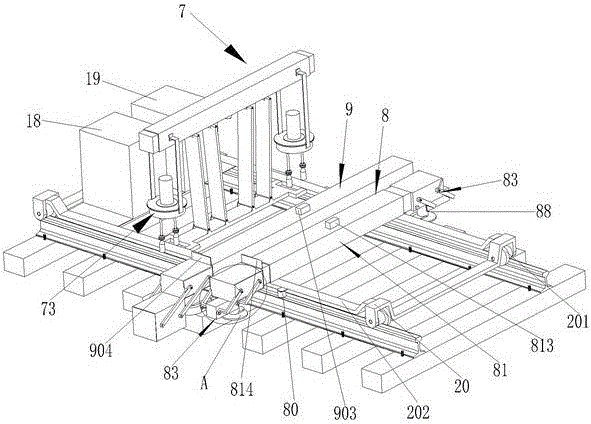

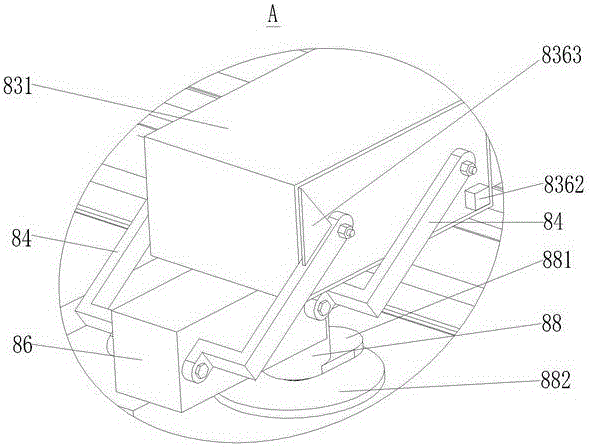

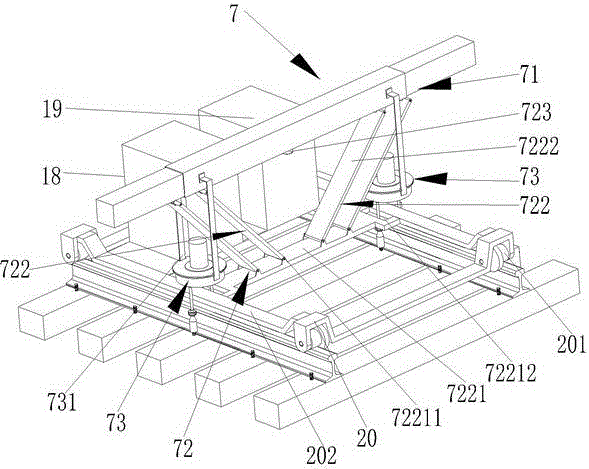

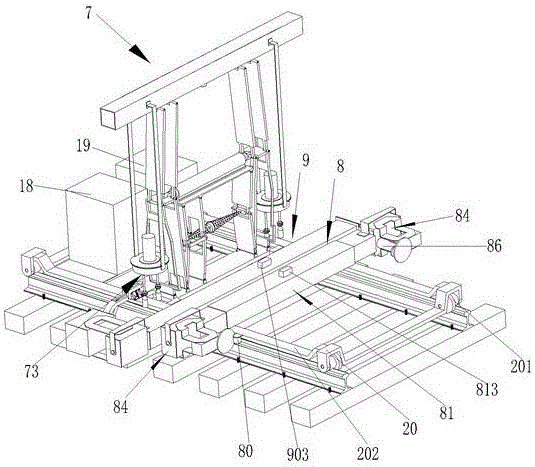

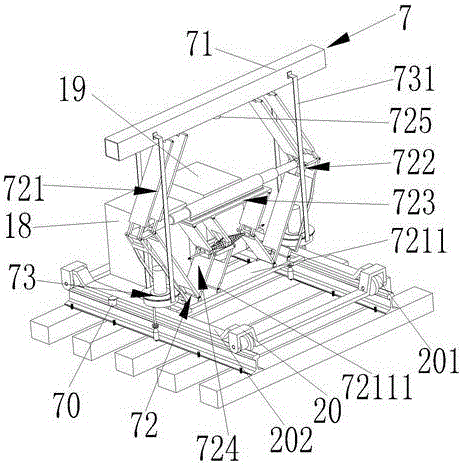

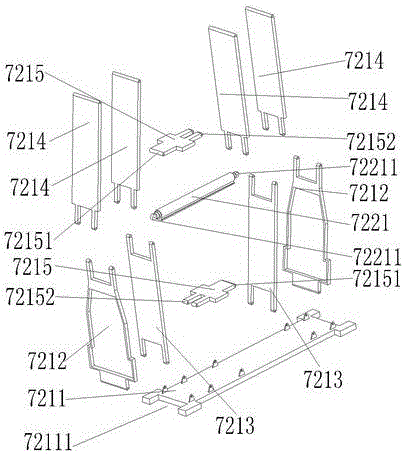

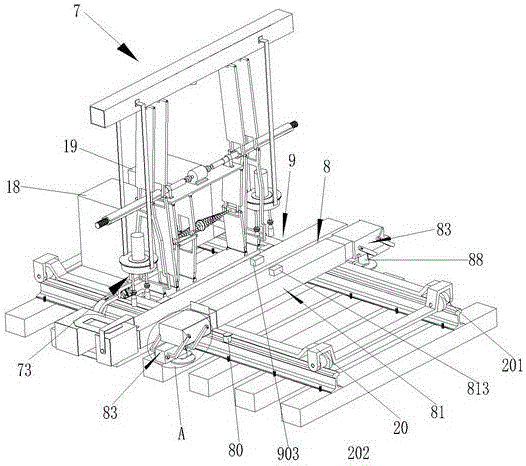

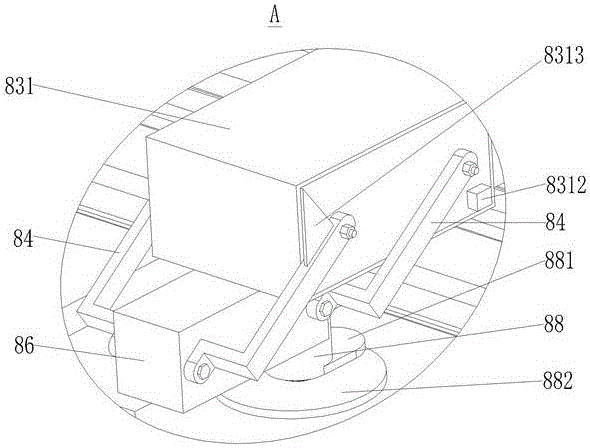

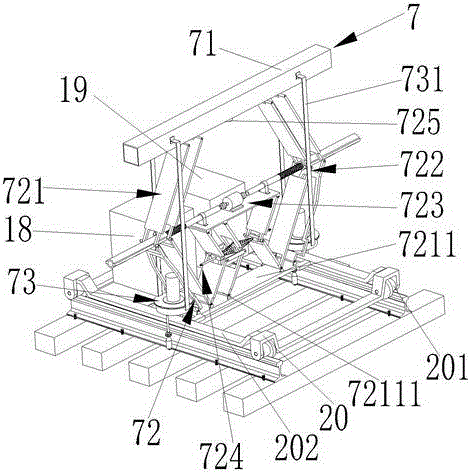

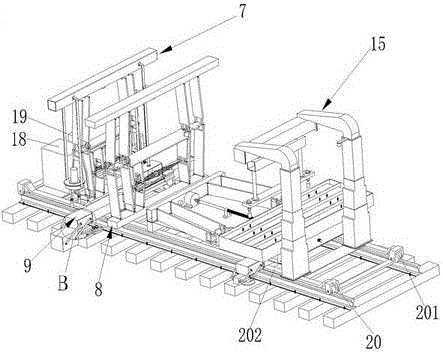

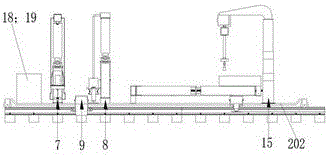

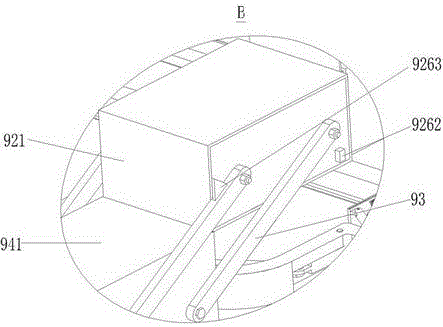

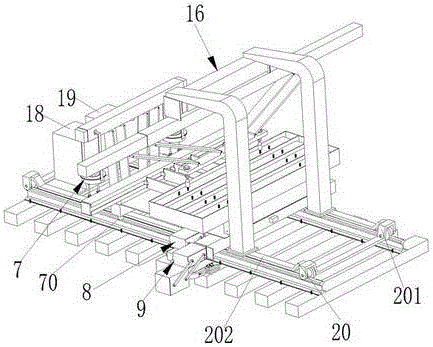

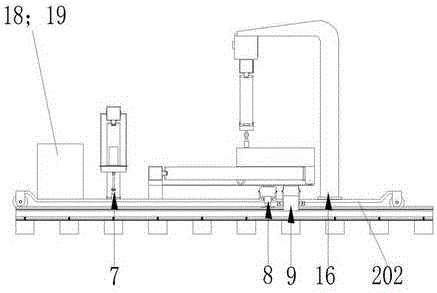

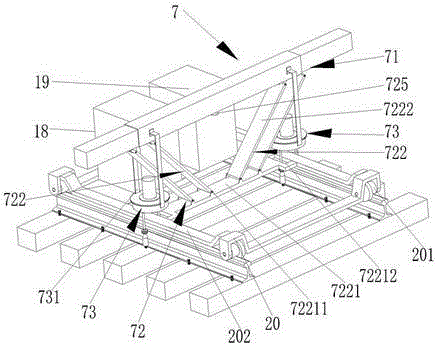

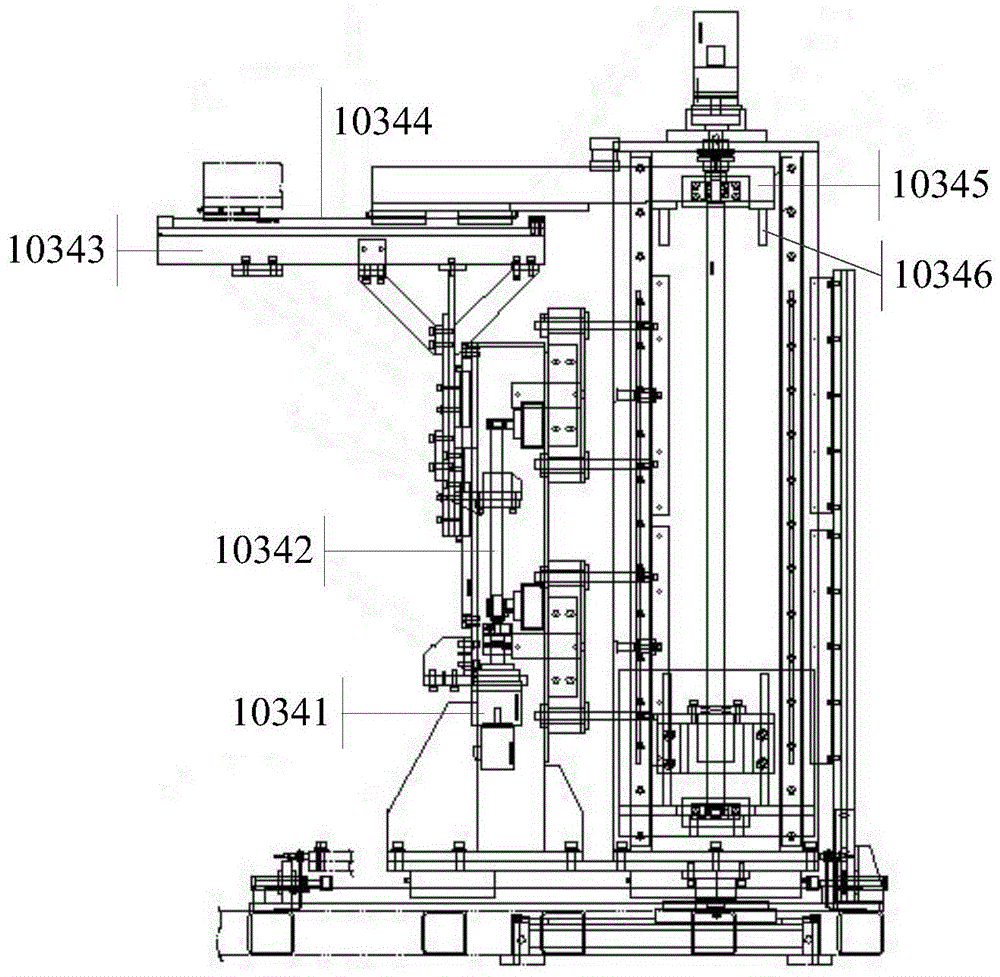

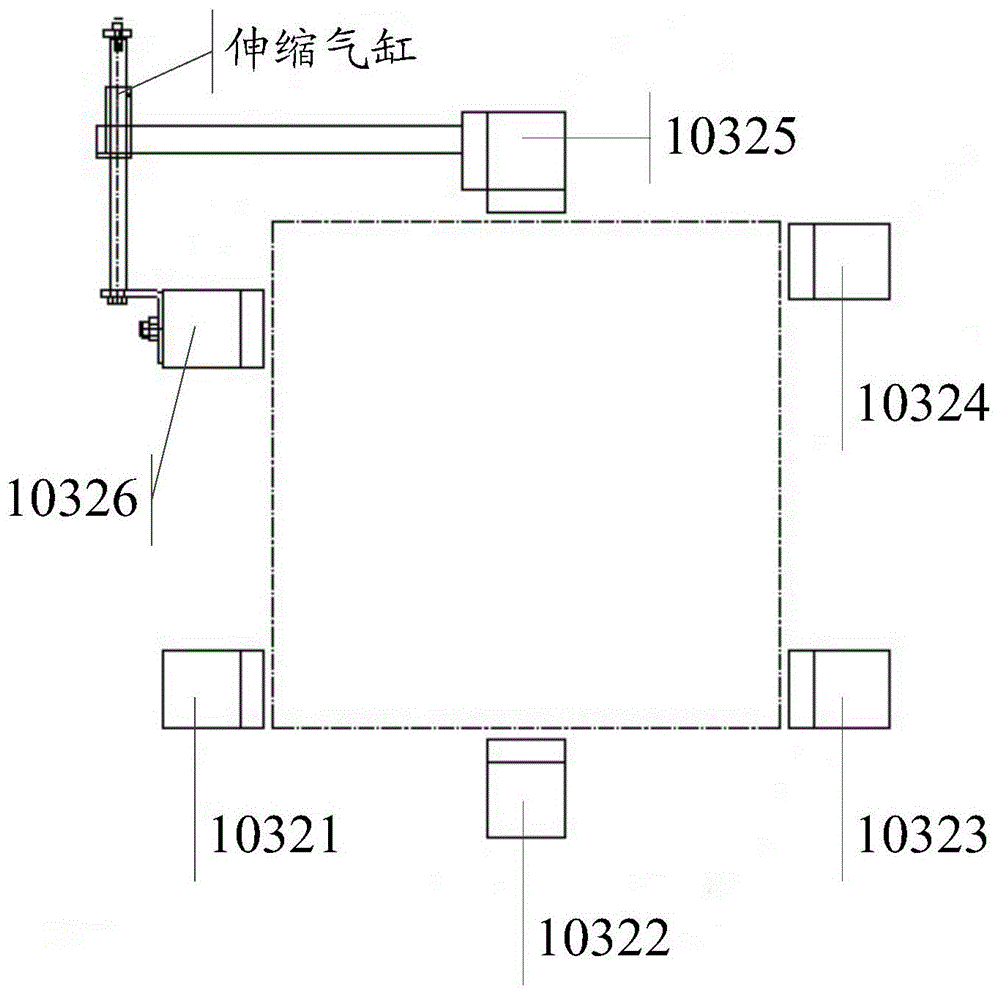

Battery stacking equipment

ActiveCN104157898AGuaranteed accuracyEnsure consistencyAssembling battery machinesFinal product manufactureBiochemical engineeringProtection mechanism

The invention discloses battery stacking equipment which comprises a frame; a first base plate arranged in the first part of the frame; a stacking positioning mechanism arranged on the first base plate and the first part; a second base plate arranged in the second part of the frame; and an automatic removal mechanism arranged on the second base plate; wherein the second part is different from the first part. The stacking positioning mechanism comprises a stacking actuator, a workpiece aided positioning mechanism, a guide bar fixing protection mechanism and a pressurization mechanism which cooperate with each other to ensure the accuracy and consistency of battery modules in the process of combining the battery modules into a battery pack, the automatic removal mechanism can avoid impact or shock of the combined battery pack in the process of manual carrying, and ensures the accuracy and consistency of the battery pack, so that the technical problem that various battery pack combining methods and equipment in the prior art are uneven in the accuracy and consistency improvement of the battery modules can be solved, and the battery stacking equipment can meet the needs of production.

Owner:HUBEI MECHANICAL & ELECTRICAL INST EQUIP MFG

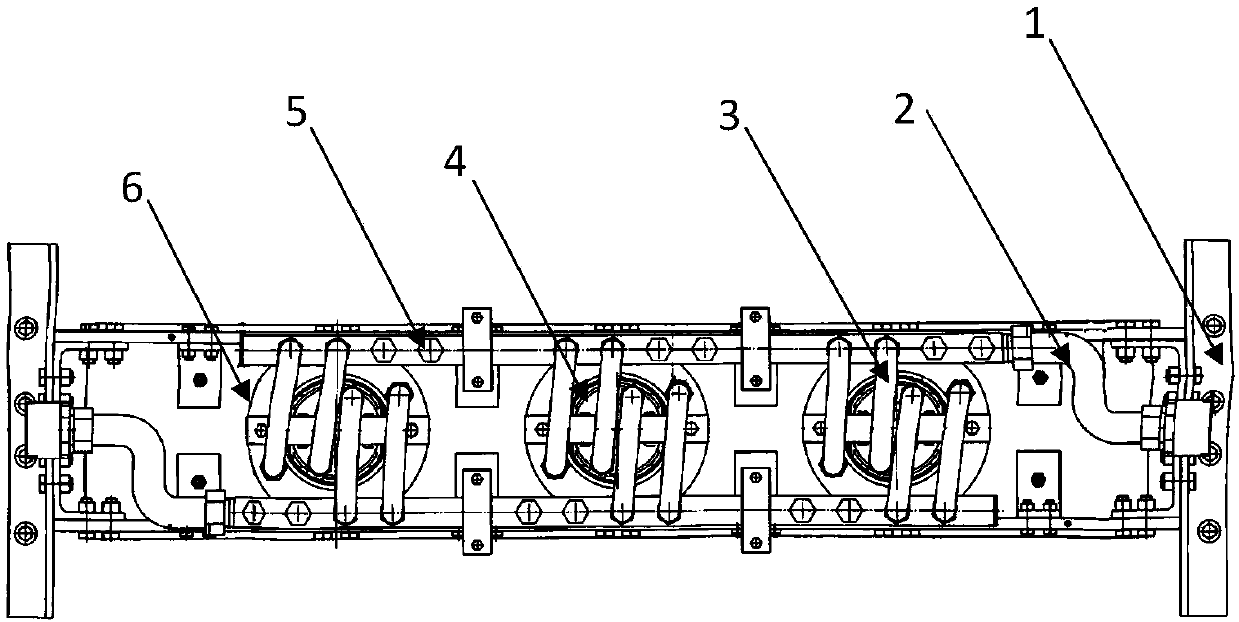

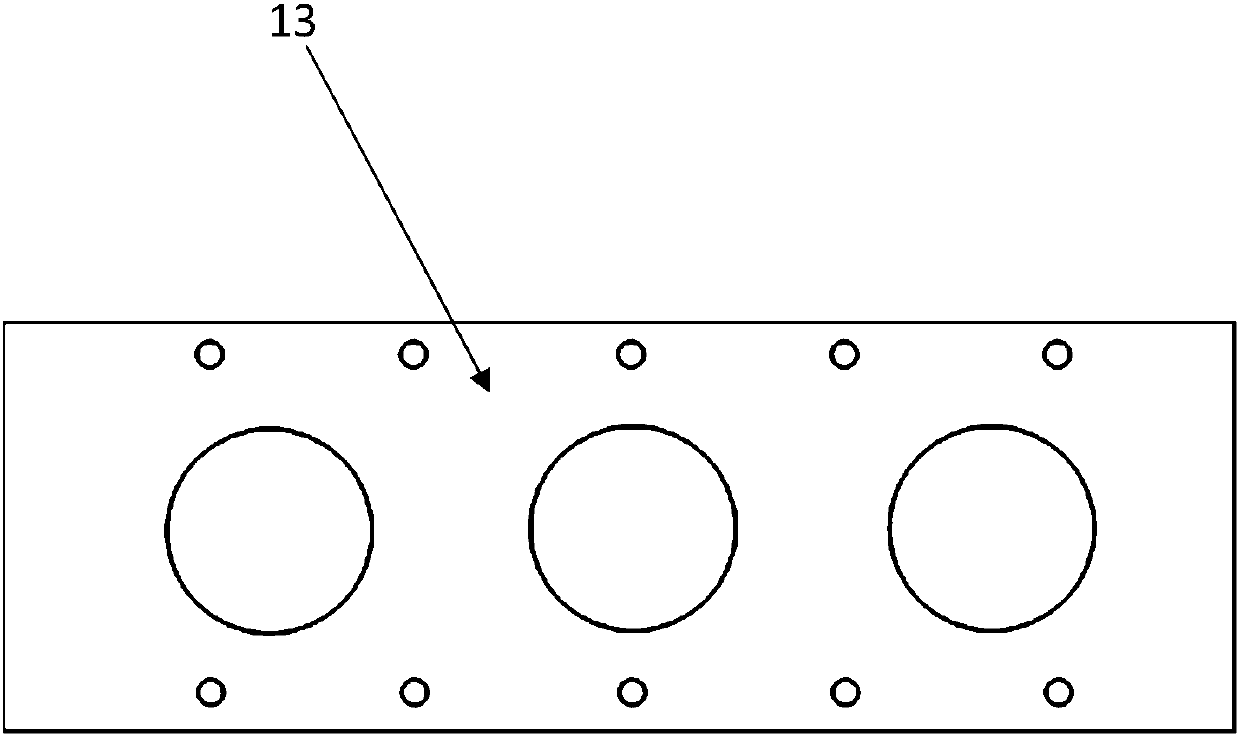

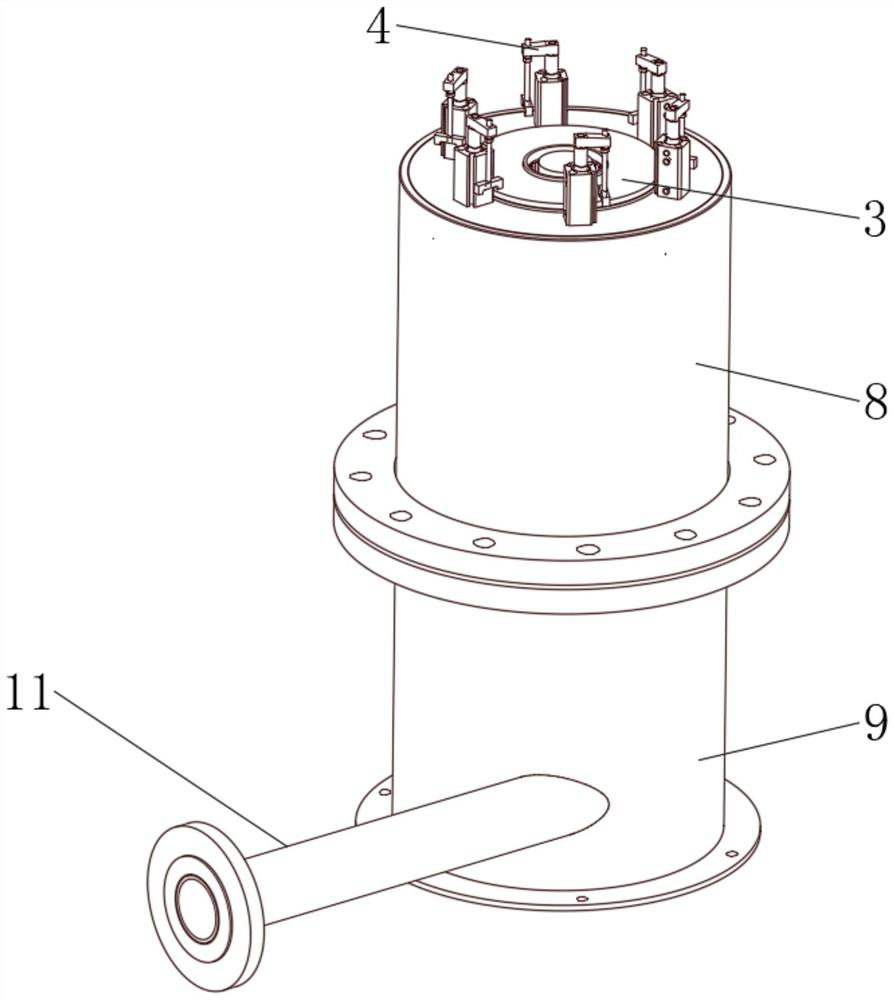

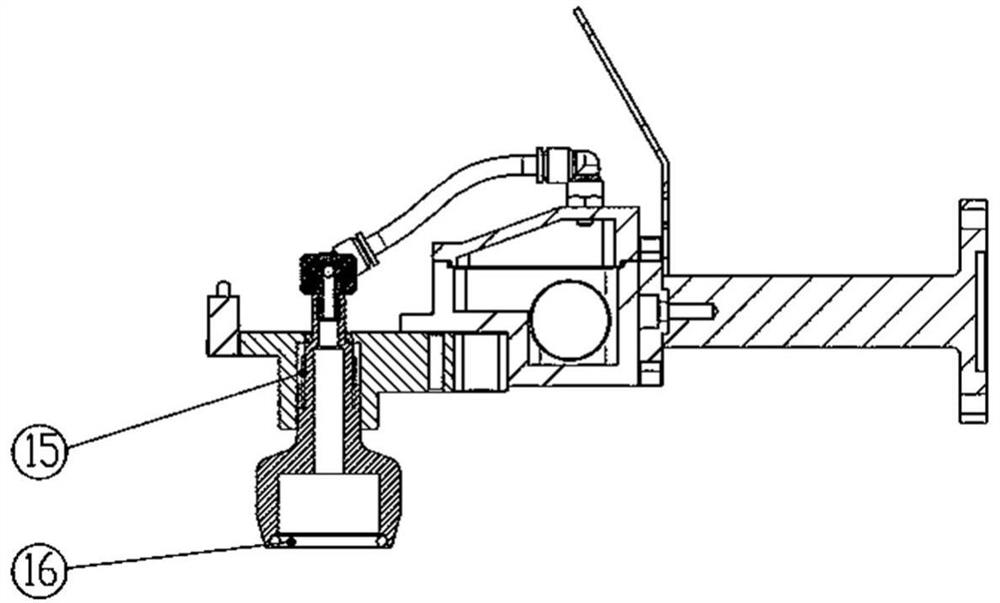

Thermal fatigue test device of piston

InactiveCN107917797AGuaranteed reliabilityGuarantee authenticityMachine part testingThermal fatigueThermal insulation

The invention discloses a thermal fatigue test device of a piston. The thermal fatigue test device is composed of a support frame, a non-standard piston tool, a tested piston, branch cooling water pipes, a thermal insulation board, and a main cooling water pipe. With the non-standard piston tool, the mechanical constraint of the tested piston on actual assembling condition is simulated completely;on the basis of cooperation of the cooling pipes, the thermal insulation board, and an external heating device, the temperature field of the tested piston on the actual working condition is simulatedcompletely. Thermal fatigue testing of pistons with different numbers is realized by flexible cooperation of the support frame and the tool. With the thermal fatigue test device disclosed by the invention, the actual assembling condition and cooling environment of the piston can be simulated fully; the arrangement condition can be adjusted flexibly based on the number of the tested pistons; the progress of the thermal fatigue test of the piston is controlled reasonably; the usage energy is optimized; and the credibility of the thermal fatigue test result of the piston is enhanced substantially.

Owner:ZHEJIANG UNIV

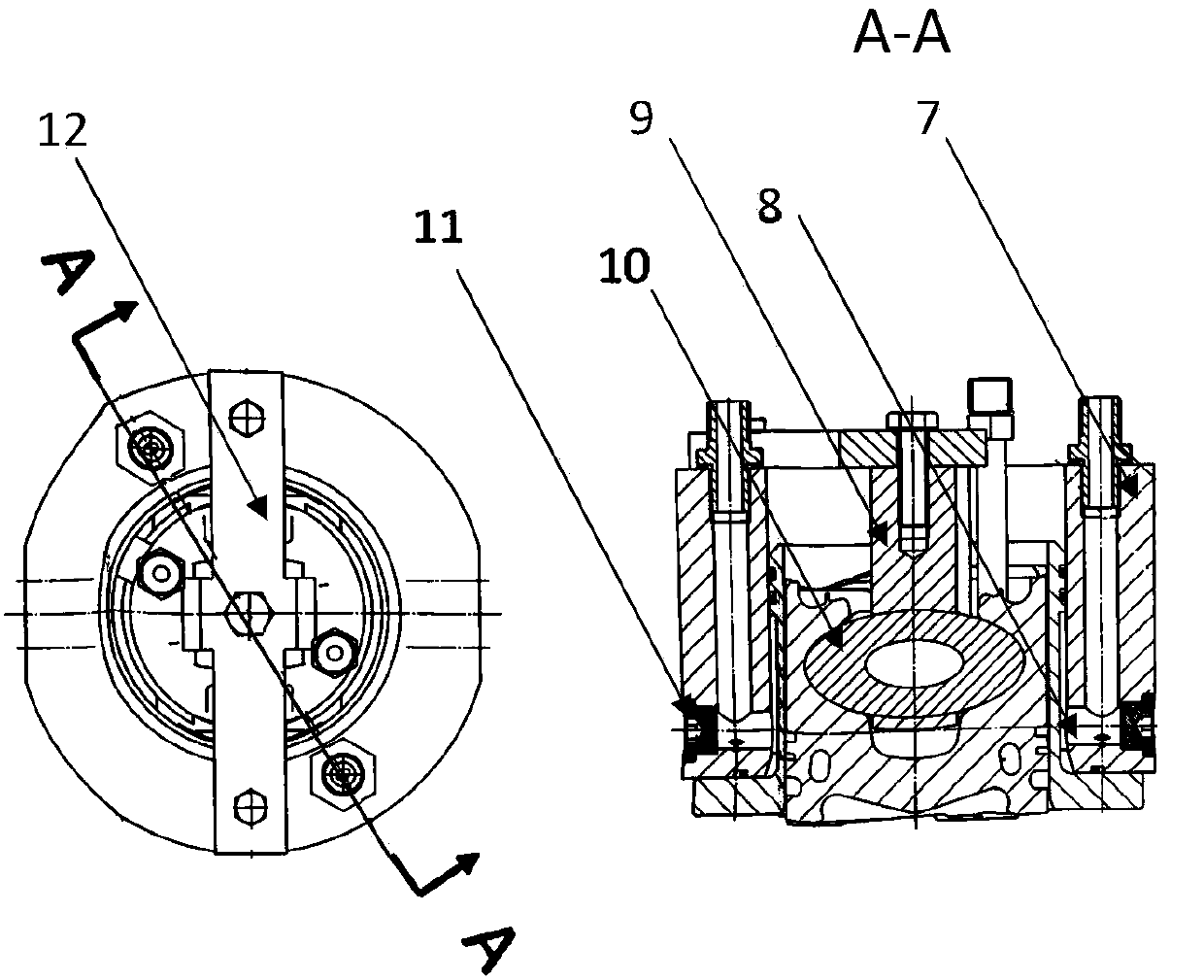

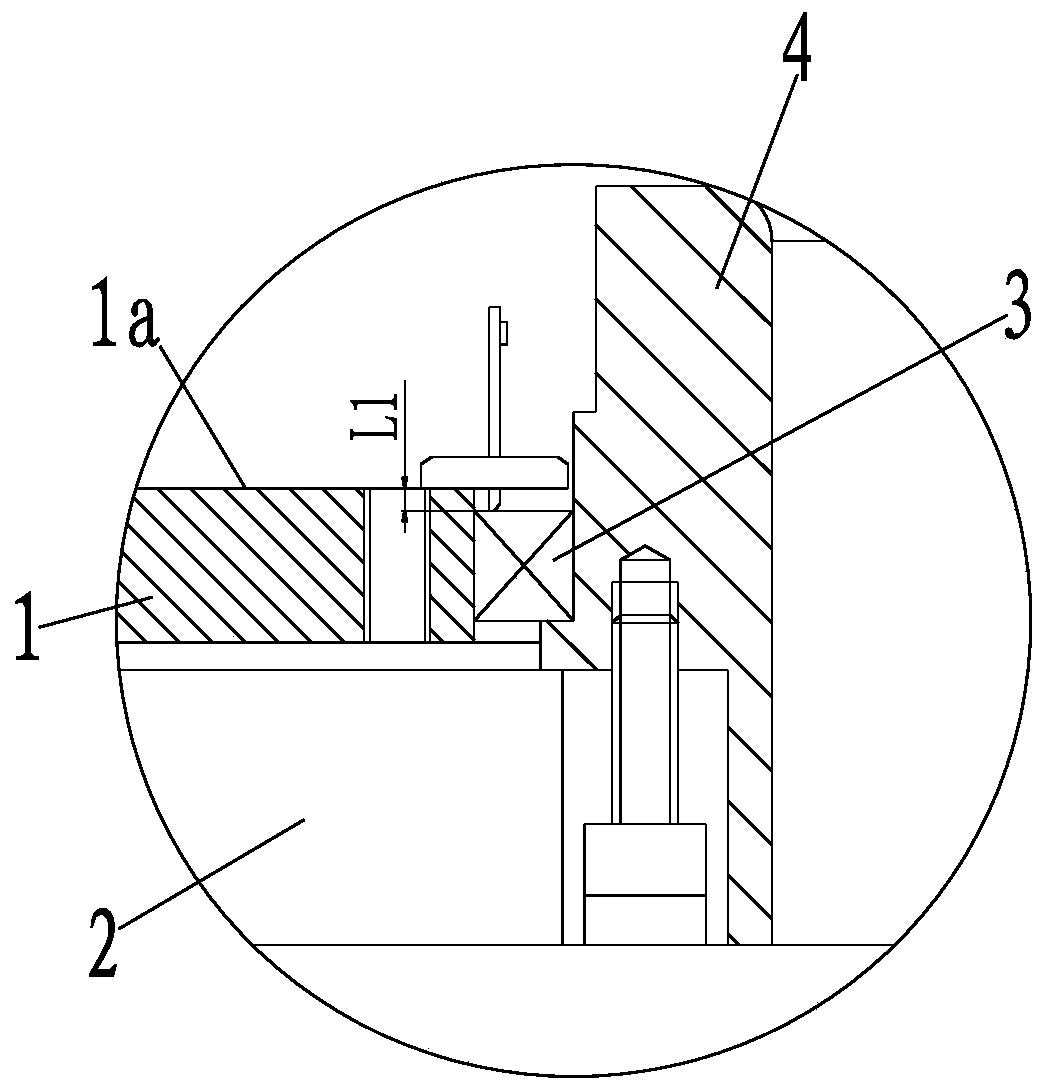

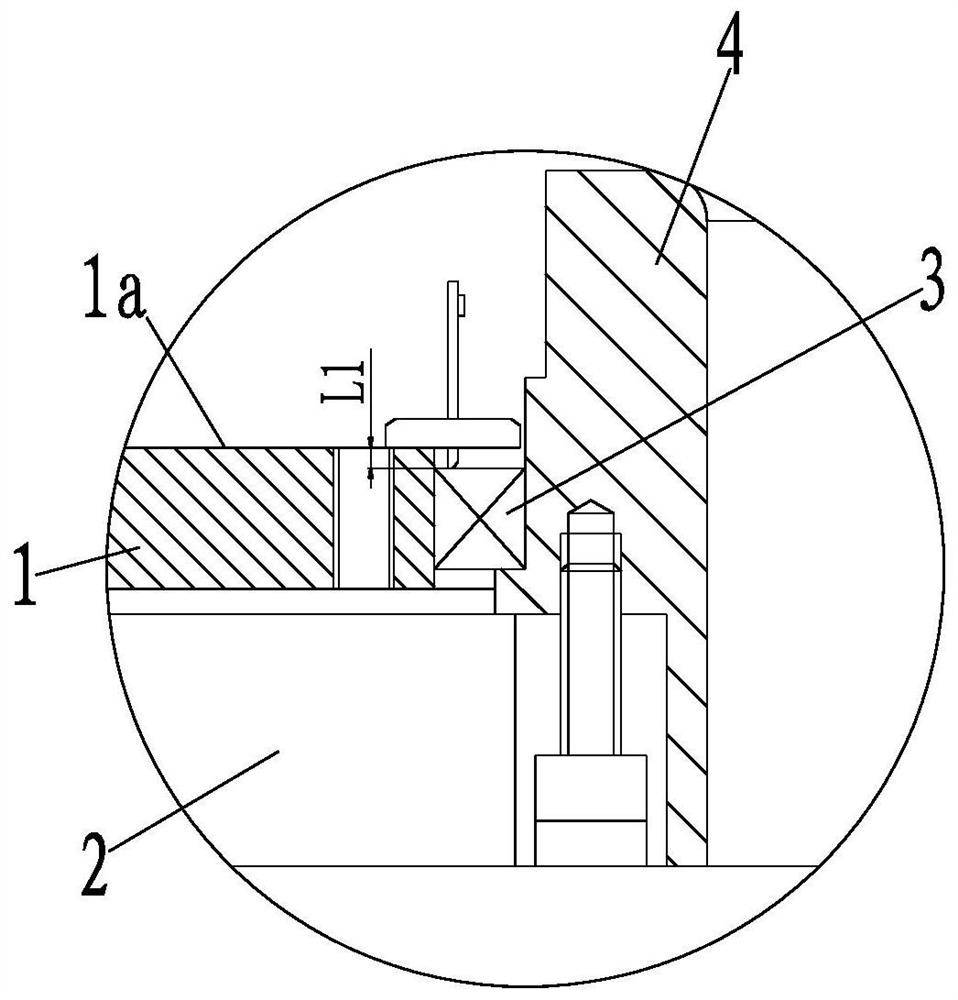

Method for adjusting pre-tightening force of angular contact bearing of indexing mechanism of positioning and orientating system

ActiveCN109945767AConsistent preloadReduce damage rateMechanical depth measurementsMechanical thickness measurementsEngineeringHeight difference

The invention discloses a method for adjusting the pre-tightening force of an angular contact bearing of an indexing mechanism of a positioning and orientating system. The method comprises the following steps: step one, measuring a height difference h between inner and outer rings of an angular contact bearing; step two, measuring a depth L1 from the outer ring end face of the angular contact bearing to the mounting surface of the outer frame; (3), measuring a height difference L2 between a step pressing surface and a mounting end surface of a bearing end cover before assembling; (4), carryingout match grinding of the step pressing surface of the bearing end cover before assembling with a set match grinding value; (5), making an annular aluminum foil pad with the thickness of 0.01mm underthe conditions of enabling the outer diameter of the annular aluminum foil pad to be smaller than the outer diameter of the outer ring of the angular contact bearing and the inner diameter of the annular aluminum foil pad to be larger than the inner diameter of the inner ring of the angular contact bearing; and (6), mounting at least one annular aluminum foil pad on the end surface of the angularcontact bearing and compressing the bearing end cover after match grinding on the annular aluminum foil pad to realize contact between the mounting end face of the bearing end cover and the outer frame. The method is suitable for a positioning and orientating system.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

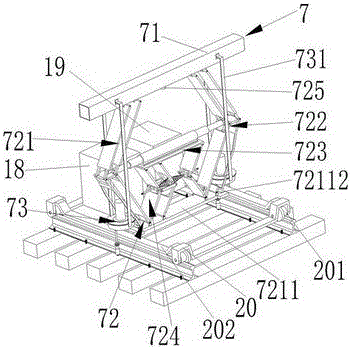

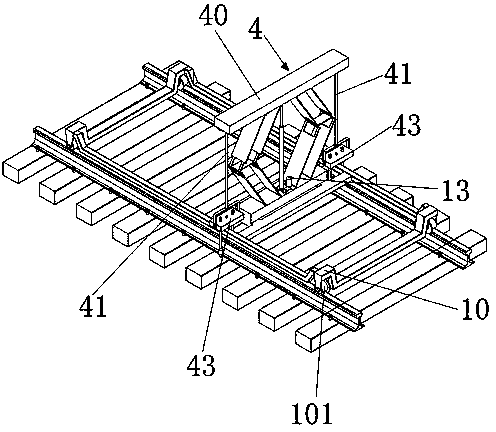

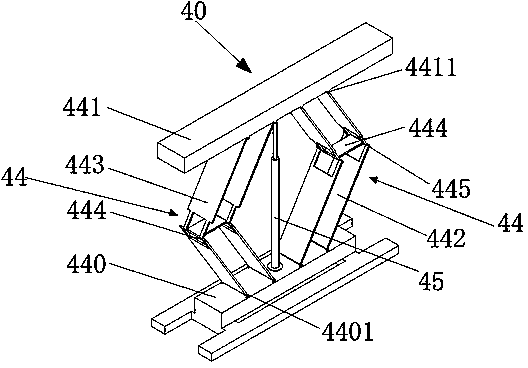

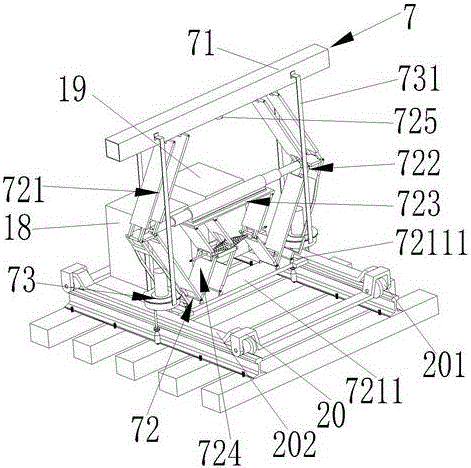

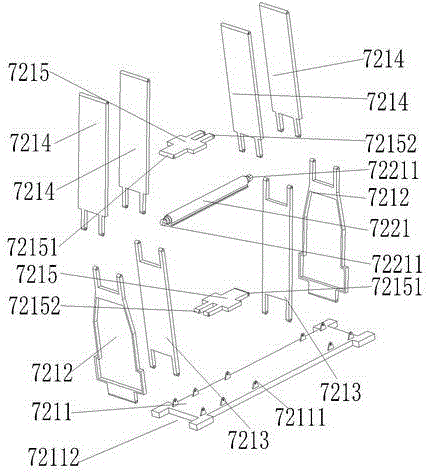

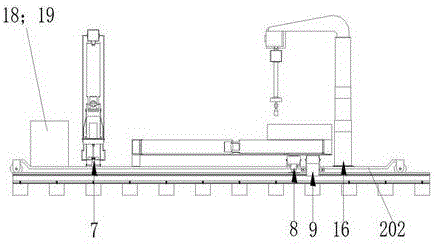

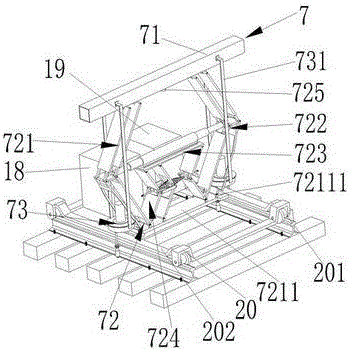

Sleeper changing machine having swing rail-lifting device

InactiveCN106320110AQuickly align to working positionConsistent preloadTrack superstructureRailway track constructionEngineeringMechanical engineering

The invention discloses a sleeper changing machine having a swing rail-lifting device. The sleeper changing machine consists of a synchronous four-nut mounting-dismounting device, a rail-lifting device, a sleeper turning, pushing and pulling device, a sleeper hoisting device, a generator, a hydraulic system, a control system box and a rail car. The rail car is provided with multiple trundles and two longitudinal beams, the synchronous four-nut mounting-dismounting device, the rail-lifting device, the sleeper turning, pushing and pulling device, the sleeper hoisting device, the generator, the hydraulic system and the control system box are arranged on the two longitudinal beams of the rail car, and the rail car is dragged by an engineering vehicle. The device can rapidly align a working device to a working position, achieves synchronous four-nut mounting and dismounting and makes four nuts consistent in pre-tightening force, prolongs the service life of bolts, ensures the sleeper and steel rail connecting reliability, performs rapid sleeper hoisting and placement works, is suitable for linear and curved railway section sleeper changing work, is simple and compact in structure, convenient to operate and high in sleeper changing work efficiency and is automatically controlled, and the sleeper turning, pushing and pulling device is an integrated device.

Owner:KUNMING UNIV

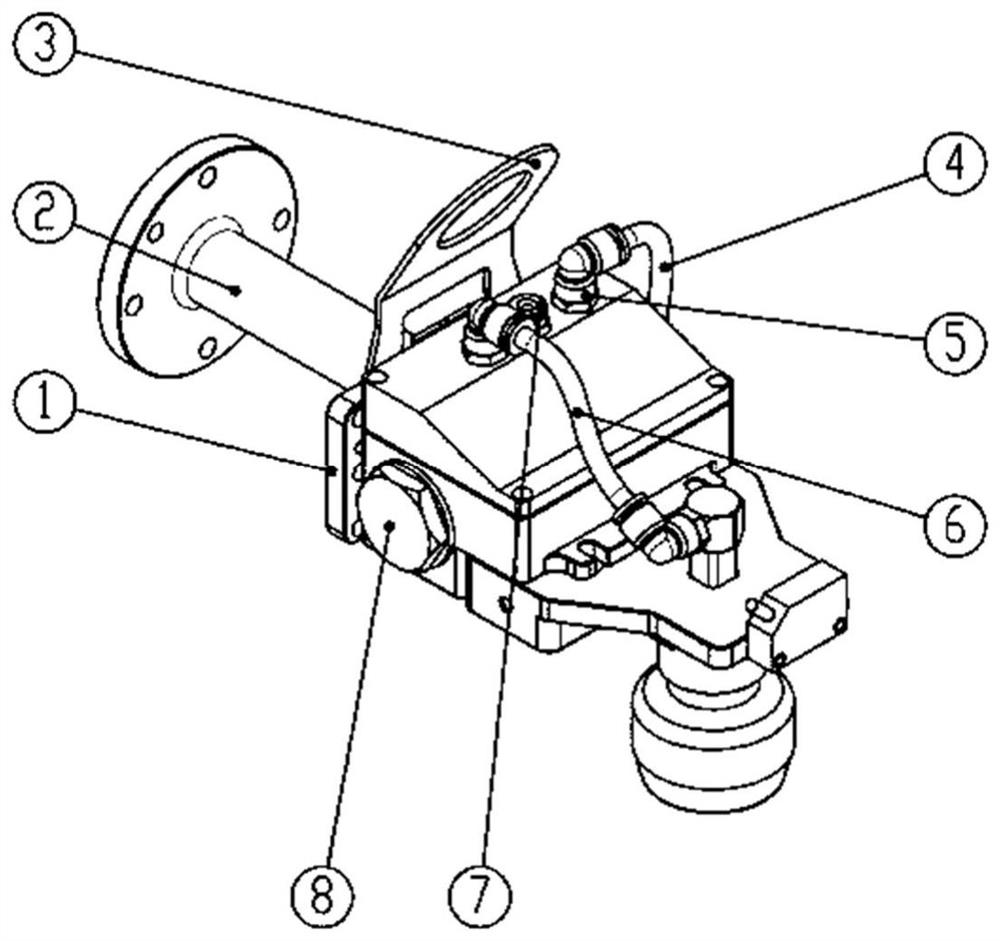

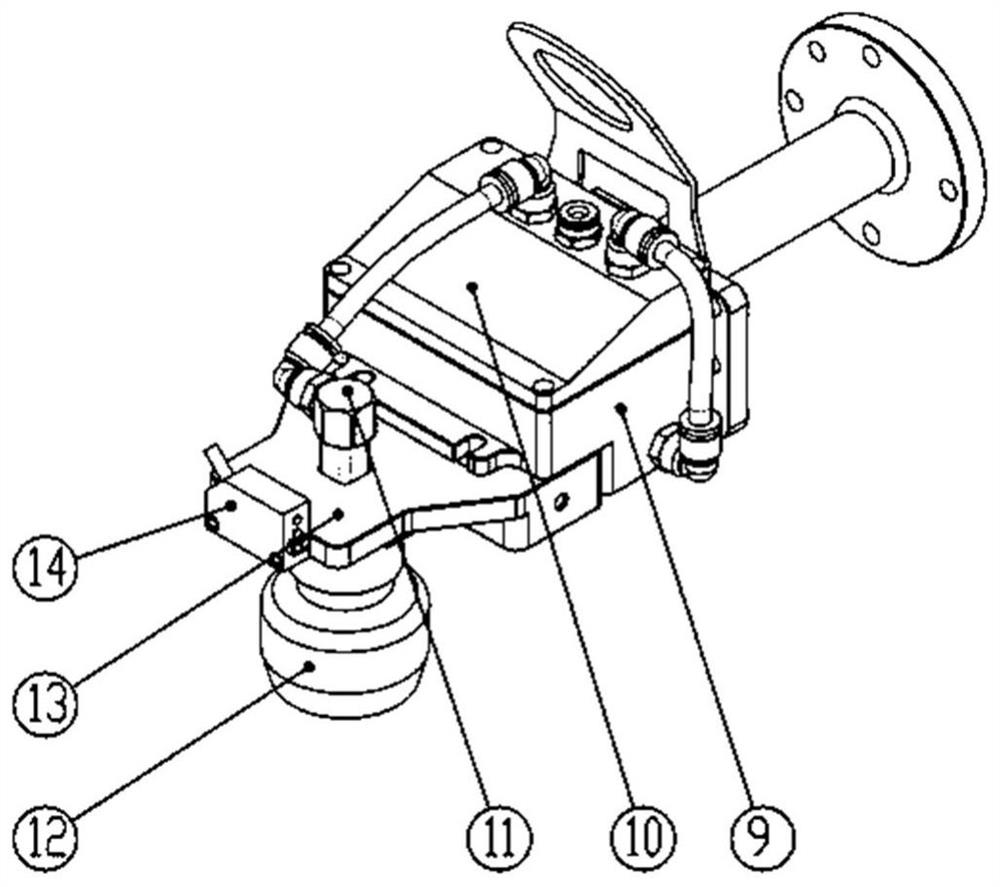

Sleeper four nut synchronization assembly and disassembly device

InactiveCN104179099AImprove work efficiencyConsistent preloadRailway track constructionTruckAutomatic control

The invention discloses a sleeper four nut synchronization assembly and disassembly device. The sleeper four nut synchronization assembly and disassembly device is composed of a four nut synchronization assembly and disassembly device, a rail car, an electric generator, a hydraulic system case, a camera component and a monitor, wherein four trundles and two longitudinal beams are installed on the rail car, the four nut synchronization assembly and disassembly device, the electric generator and the hydraulic system case are arranged on two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the monitor is arranged in a cab of a tractor truck, the electric generator provides power to an oil pump, and an oil tank, an oil pump and various hydraulic valves are installed in the hydraulic system case. The sleeper four nut synchronization assembly and disassembly device can adapt to sleeper nut assembly and disassembly work at straight and curve rail segments, can rapidly align four magnetic inner hexangular sockets to four bolts of a sleeper, saves time and is high in work efficiency due to the fact that four nuts are synchronously assembled and disassembled, conveniently achieves the purpose that pre-tightening force of the four nuts is consistent, improves fatigue life of the bolts, guarantees reliability of a connection between the sleeper and a steel rail, easily achieves program automatic control, and is convenient to operate.

Owner:KUNMING UNIV

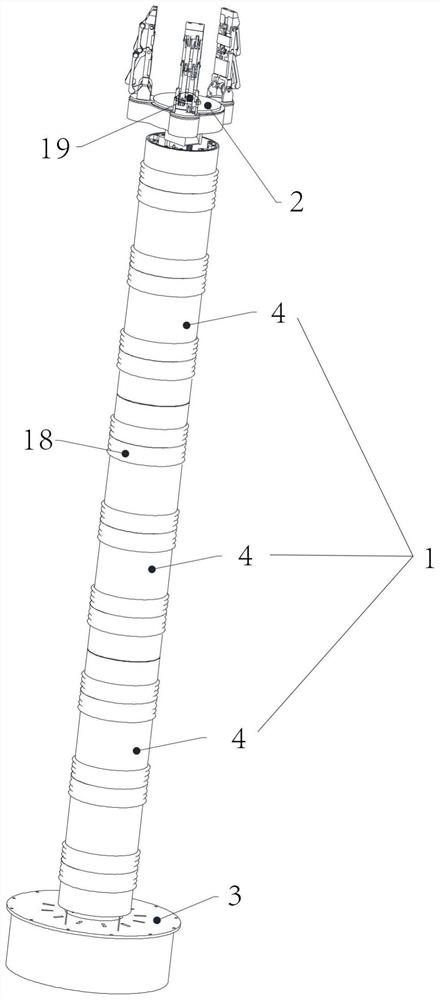

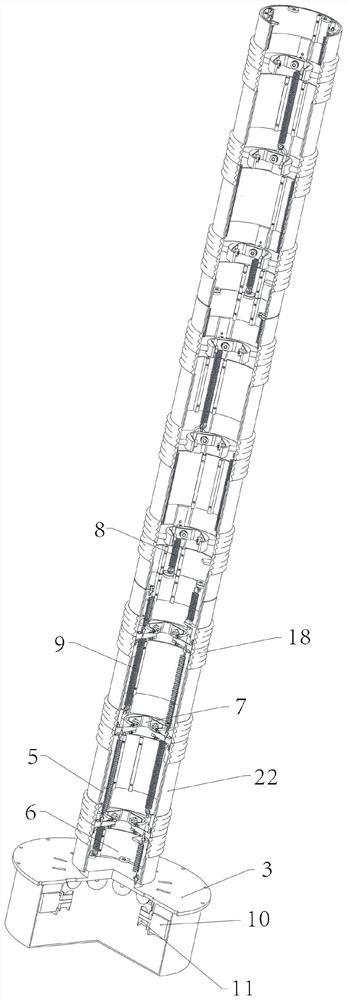

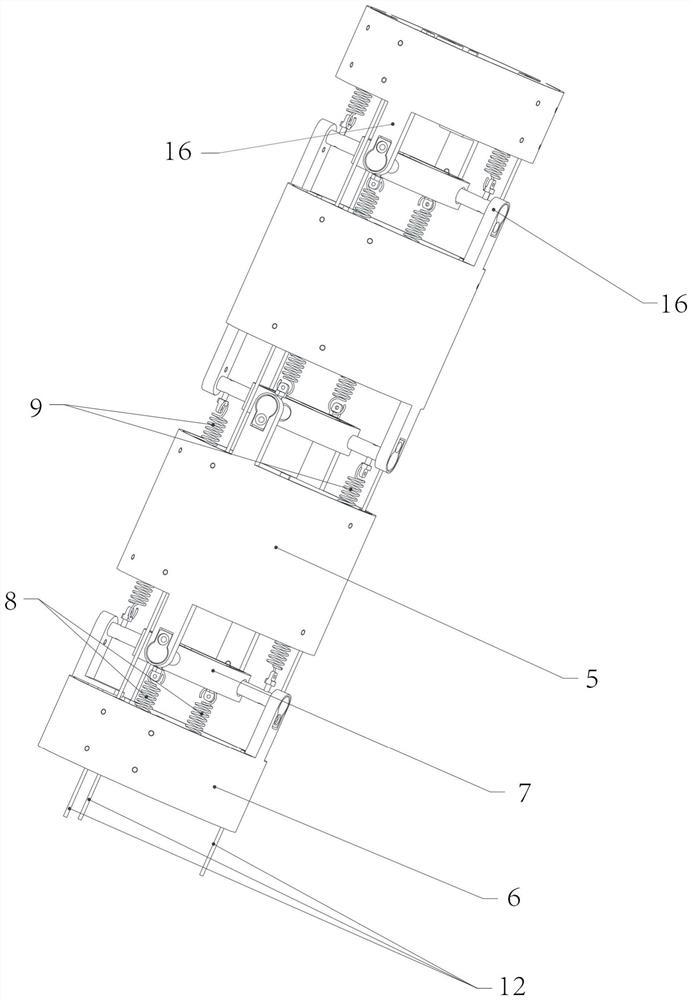

Rigid-flexible coupling hyper-redundant intelligent sensing mechanical arm and using method thereof

PendingCN114227660AModularity hasStrong adaptability to space environmentProgramme-controlled manipulatorJointsControl engineeringElectric machinery

The rigid-flexible coupling hyper-redundant intelligent sensing mechanical arm comprises a mechanical arm body, an operation device and a driving mechanism are arranged at the front end and the rear end of the mechanical arm body respectively, and the mechanical arm body is formed by sequentially connecting a plurality of bending units; each bending unit comprises a plurality of middle sections connected in sequence, base sections are arranged at the two ends of each middle section, the base sections and the middle sections are of hollow cylindrical structures, the base sections and the middle sections are movably connected through cross hinges, and every two adjacent middle sections are movably connected through cross hinges; the driving mechanism comprises a plurality of driving motors, reels are arranged on rotating shafts of the driving motors, a plurality of tendon ropes are arranged in the bending unit, one ends of the tendon ropes are fixed to the front end of the bending unit, and the other ends of the tendon ropes are connected with the reels respectively. The mechanical arm has the advantages of modularization, super-redundancy self-adaption, high space environment adaptability, measurable tail end pose, perceptible external contact and the like, and can be used for capturing and grabbing non-cooperative and cooperative targets and internal investigation of complex cavities.

Owner:BEIJING INST OF SPACECRAFT SYST ENG +1

Machine automatic rapid sleeper-changing device

InactiveCN106498819AQuickly align to working positionConsistent preloadTrack superstructureRailway track constructionAutomatic controlControl system

The invention discloses a machine automatic rapid sleeper-changing device. The device is composed of a four-nut synchronous assembling / disassembling device, a first track hoisting device, a track-transferring and sleeper pulling-pushing device, a sleeper overhead-hoisting device, a power generator, a hydraulic system and control system box and a track car, wherein multiple truckles and two carlings are arranged on the track car; the four-nut synchronous assembling / disassembling device, the first track hoisting device, the track-transferring and sleeper pulling-pushing device, the sleeper overhead-hoisting device, the power generator and the hydraulic system and control system box are arranged on the two carlings of the track car; and the track car is towed by an engineering truck. The device disclosed by the invention can rapidly align a working device with a working position; four nuts can be synchronously assembled / disassembled, so that the pre-tightening forces of the four nuts are consistent, the fatigue life of a bolt is prolonged, and the connection reliability of the sleeper and a steel rail is guaranteed; the sleeper can be rapidly overhead-hoisted and placed to work; the device is adapted to the sleeper-changing work of linear and curve track sections; the track-transferring and sleeper pulling-pushing device is an integrated device; the device is simple and compact in structure, realizes automatic control, and is convenient for operation, and sleeper-changing working efficiency is high.

Owner:KUNMING UNIV

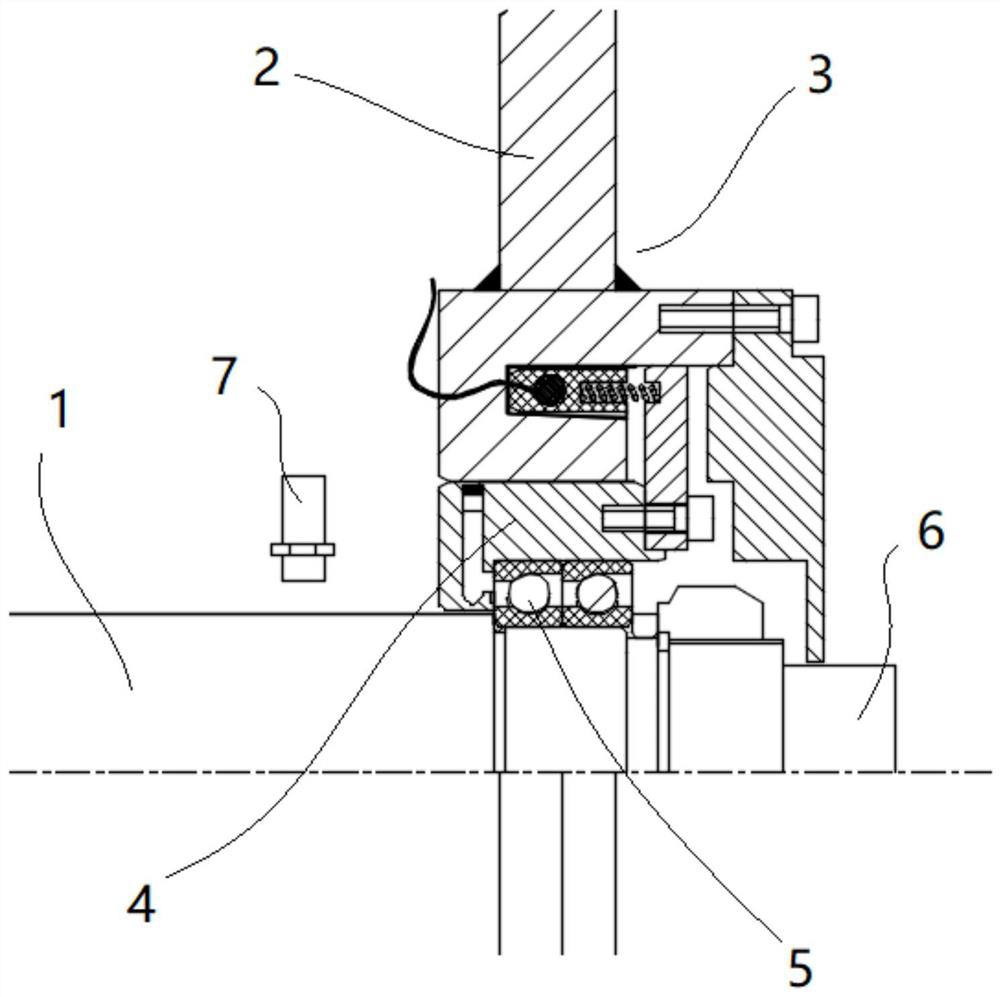

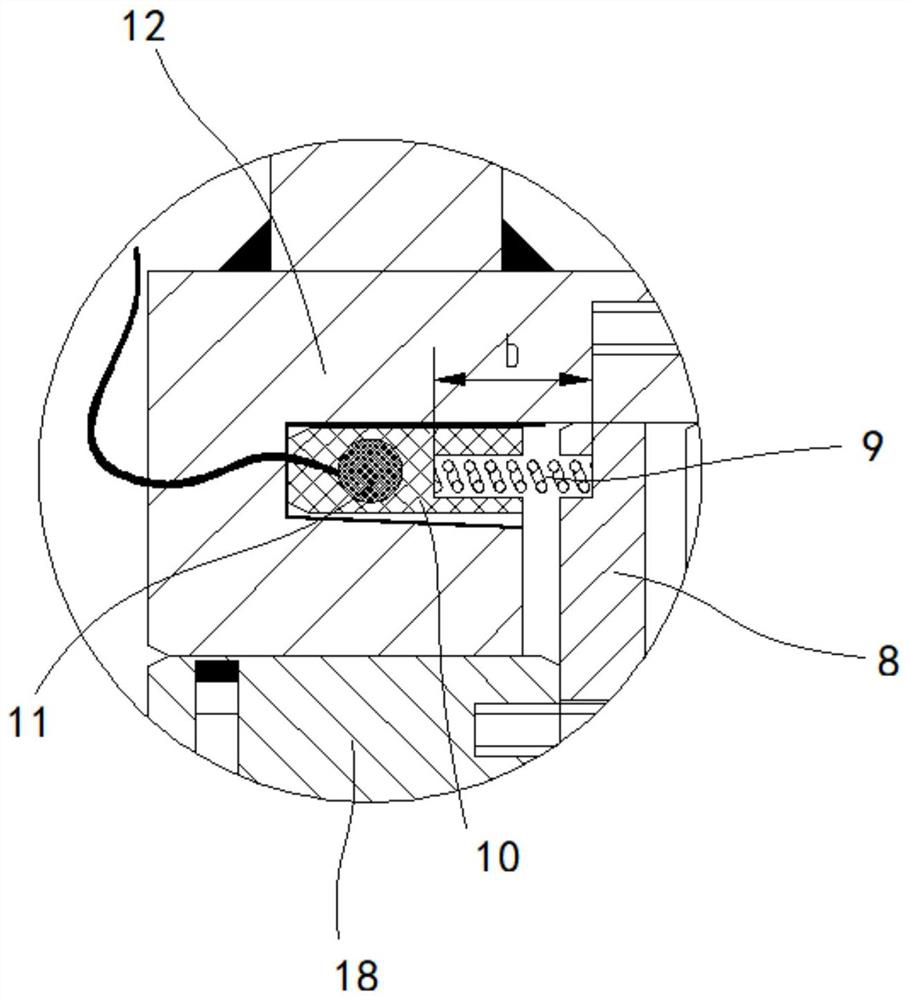

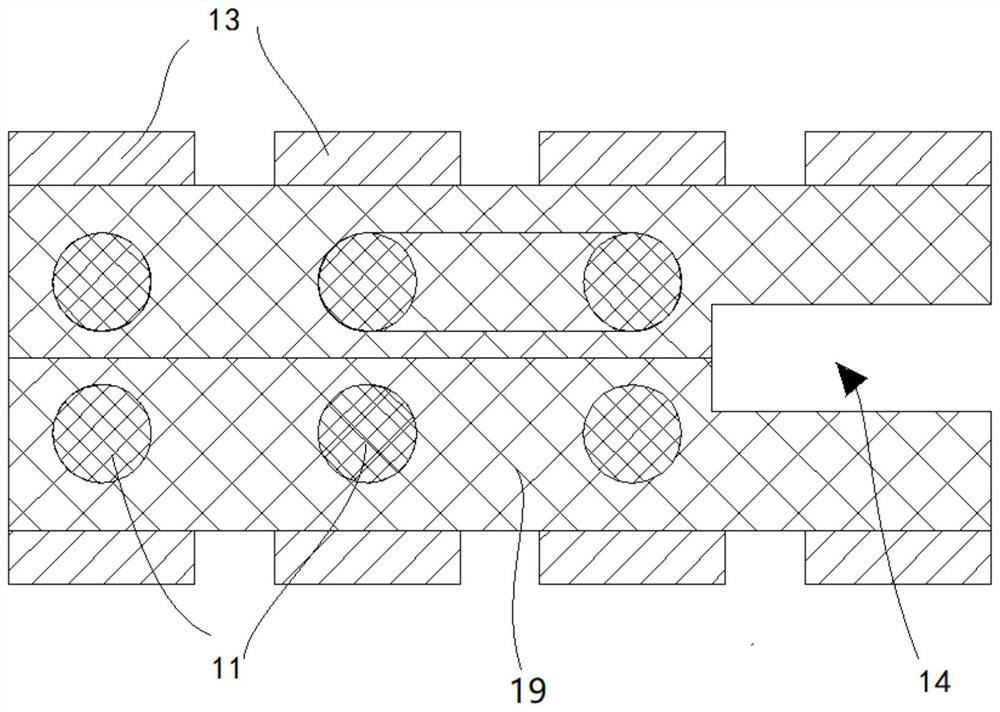

Motor

ActiveCN113659759AExtrusion force decreases or disappearsReduce compression deformationSupports/enclosures/casingsElectric machineEngineering

The invention relates to high-speed rotating equipment, in particular to a motor. The motor provided by the invention comprises a rotor, a bearing, a bearing seat, a shell assembly, a base and an elastic piece; the rotor is provided with an extending end and a tail end which are opposite; the bearing sleeves the rotor and is close to the tail end; the bearing seat is matched with the shell assembly and abuts against the end face of one side, close to the extending end, of the bearing; the base is matched with the shell assembly; the elastic piece can generate elastic force in the axial direction of the rotor; the elastic piece is provided with a first end and a second end which are opposite in the elastic force direction, the first end is matched with the base, and the second end is matched with the bearing seat; and a heating piece is arranged in the base, the base can be heated to expand in the elastic force direction of the elastic piece, and the base can be cooled to retract in the direction opposite to the expansion direction. The pretightening force between the bearing and the bearing seat can be adjusted when the rotor rotates.

Owner:TIANJIN EMAGING TECH

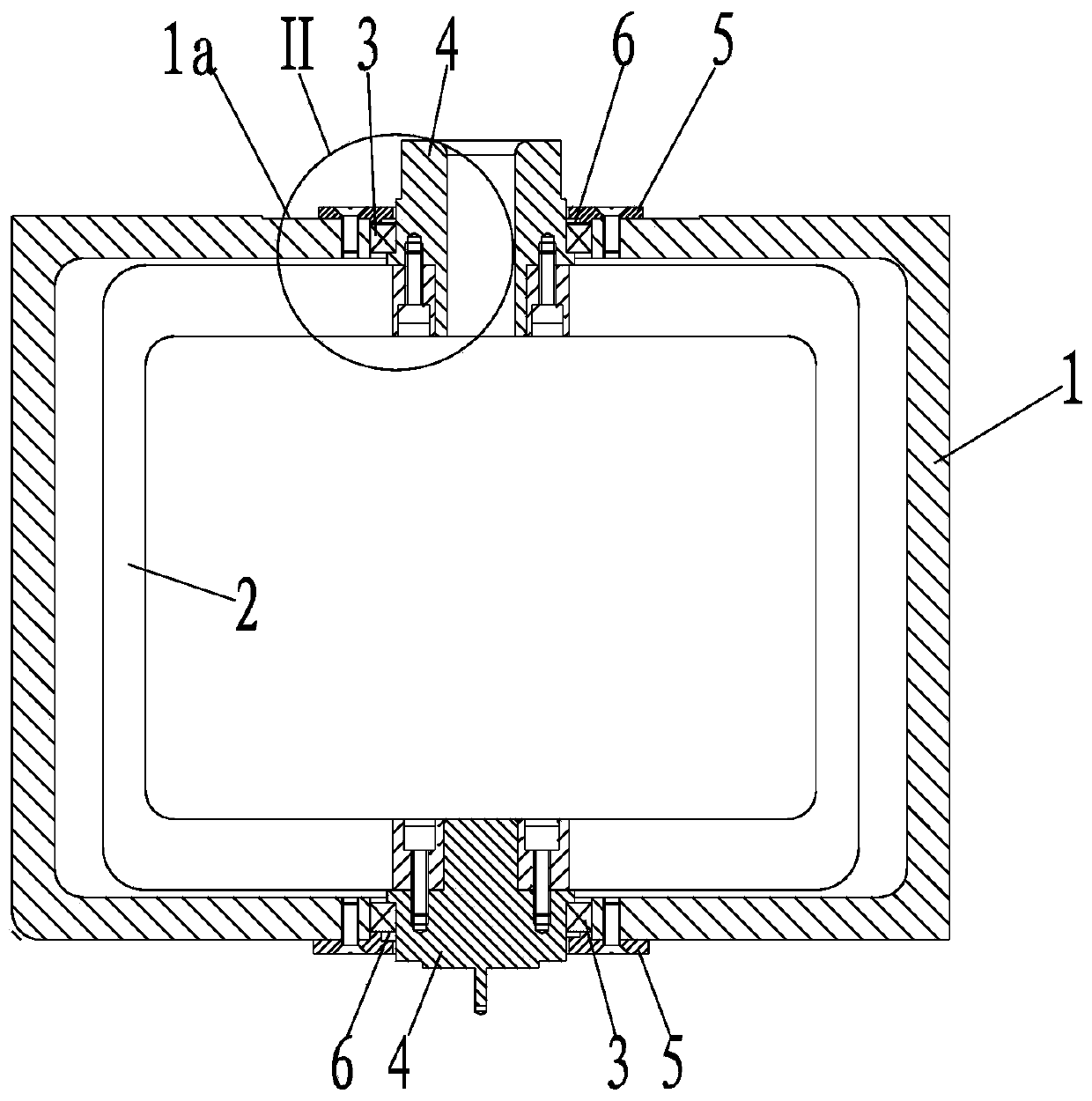

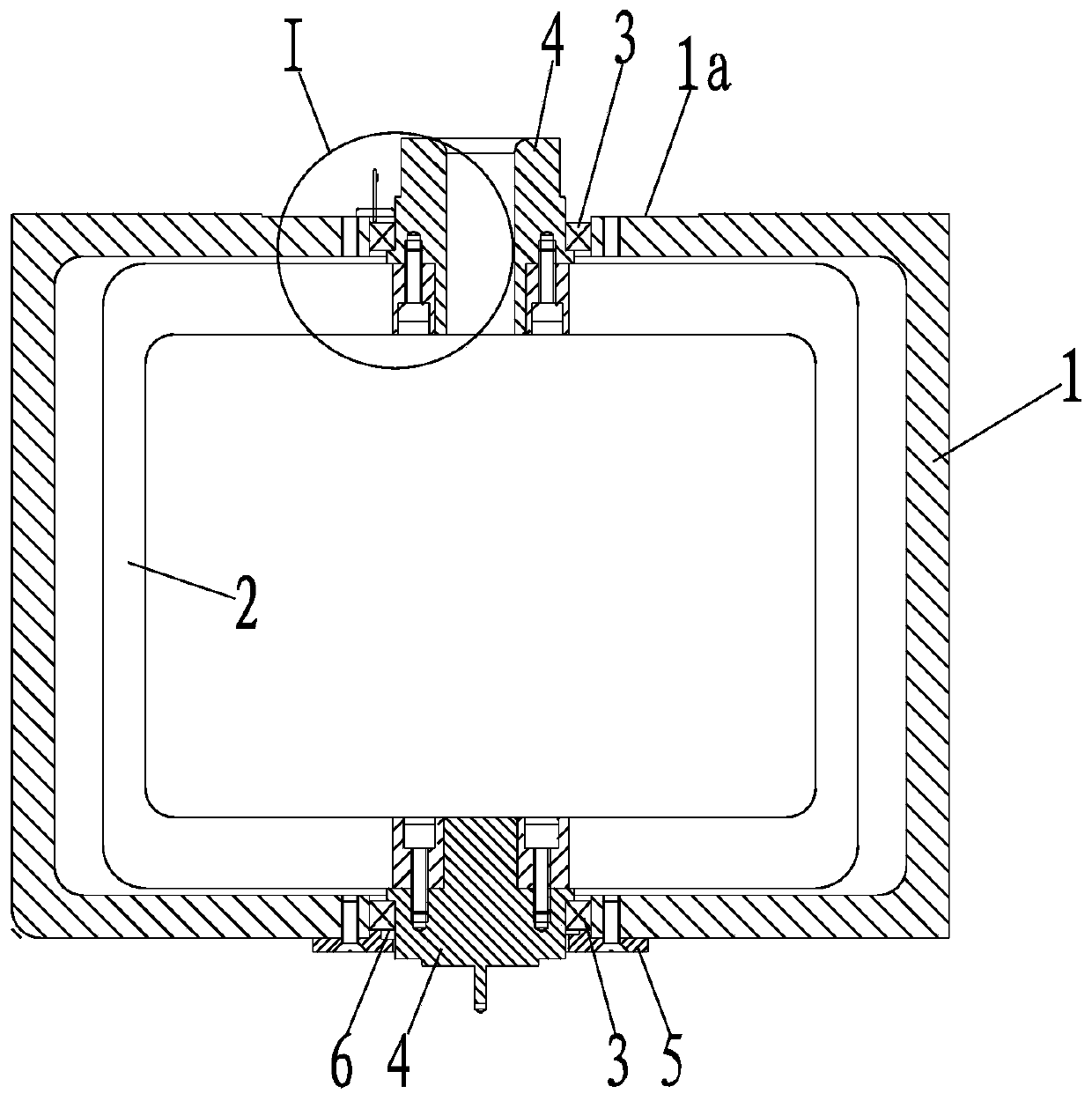

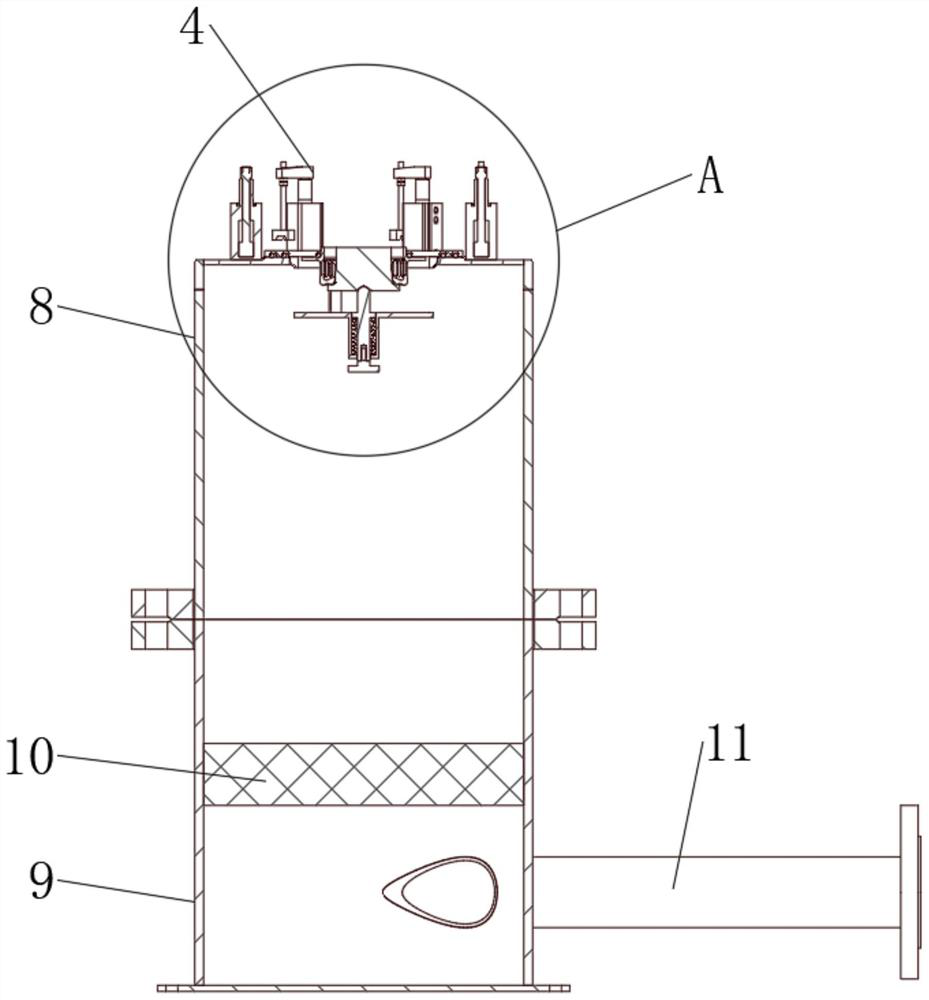

Tool for measuring air flow of swirler of combustion chamber of gas turbine

InactiveCN114018346ASimple structureWide range of workVolume meteringVolume/mass flow by dynamic fluid flow effectCombustion chamberGas turbines

The invention provides a tool for measuring the air flow of a swirler of a combustion chamber of a gas turbine, and relates to the technical field of gas turbine combustion chamber swirler air flow measurement. The tool for measuring the air flow of the swirler of the combustion chamber of the gas turbine comprises an isolation cabinet body, a gas collection tank, a swirler mounting plate and a pneumatic mounting module, a middle partition plate is fixedly connected to the interior of the isolation cabinet body, and the gas collection tank is fixedly connected to the inner bottom of the isolation cabinet body; the swirler mounting plate is fixedly connected to the upper surface of the gas collecting tank, and the upper surface of the gas collecting tank is located on the periphery of the swirler mounting plate and fixedly connected with the pneumatic mounting module. The invention aims to improve the air flow measurement precision of the swirler, reduce the problem of measurement value fluctuation caused by atmospheric environment disturbance, air inlet disturbance, pressure measurement disturbance and the like, and meanwhile, through the automatic pressing device, the assembly speed is improved, and meanwhile, the pretightening force after each time of installation is ensured to be consistent.

Owner:苏州泽志流体技术有限公司

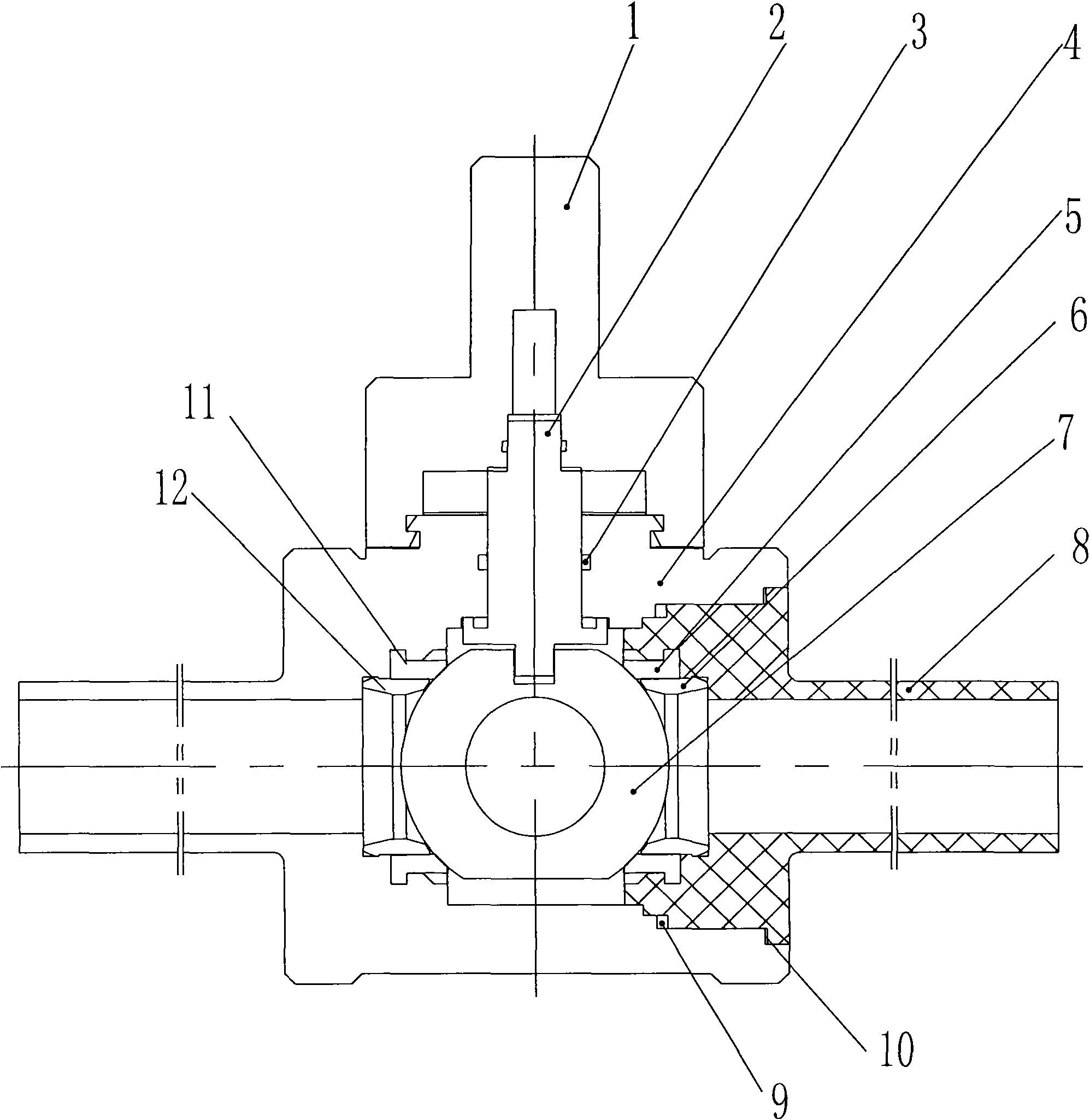

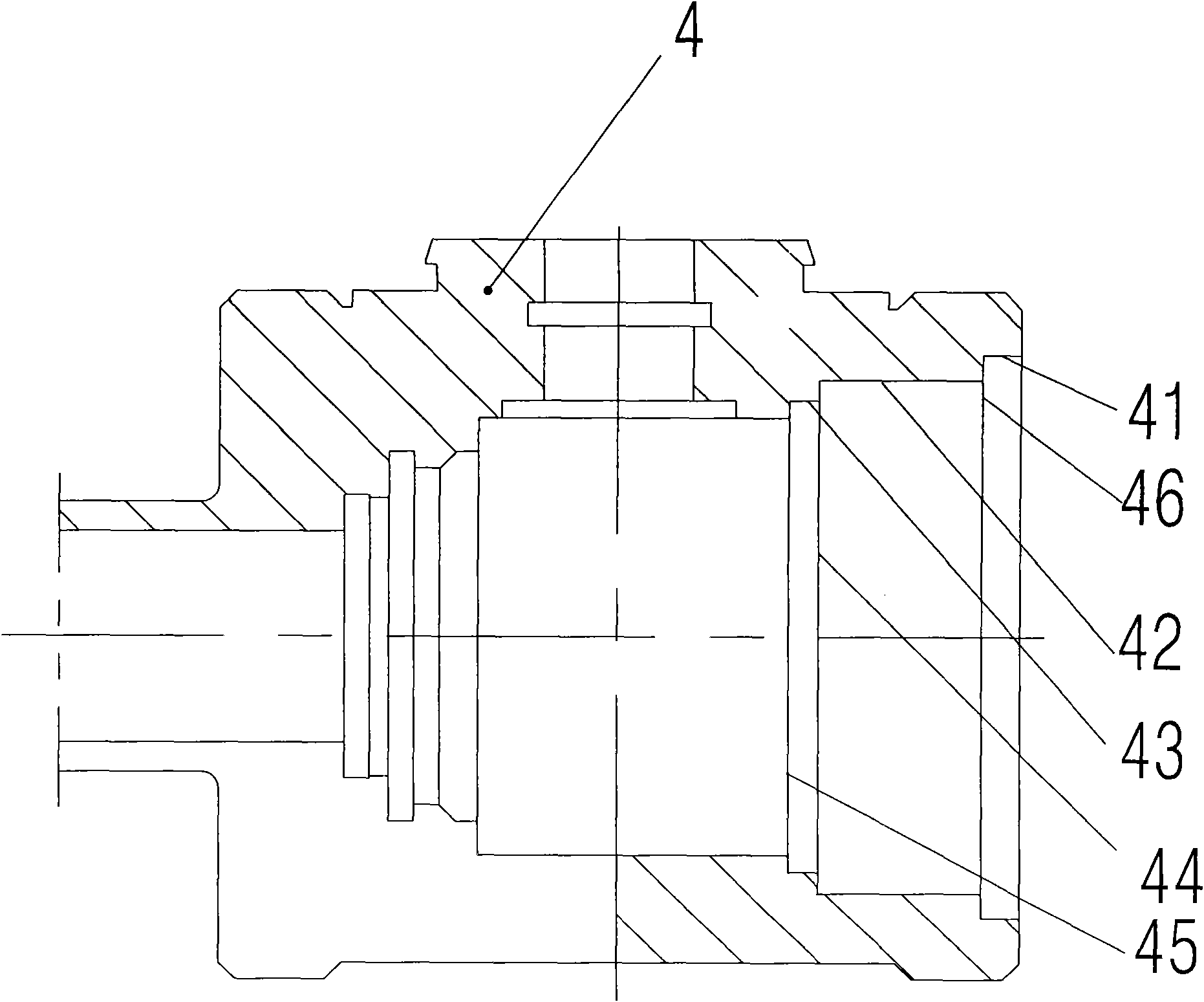

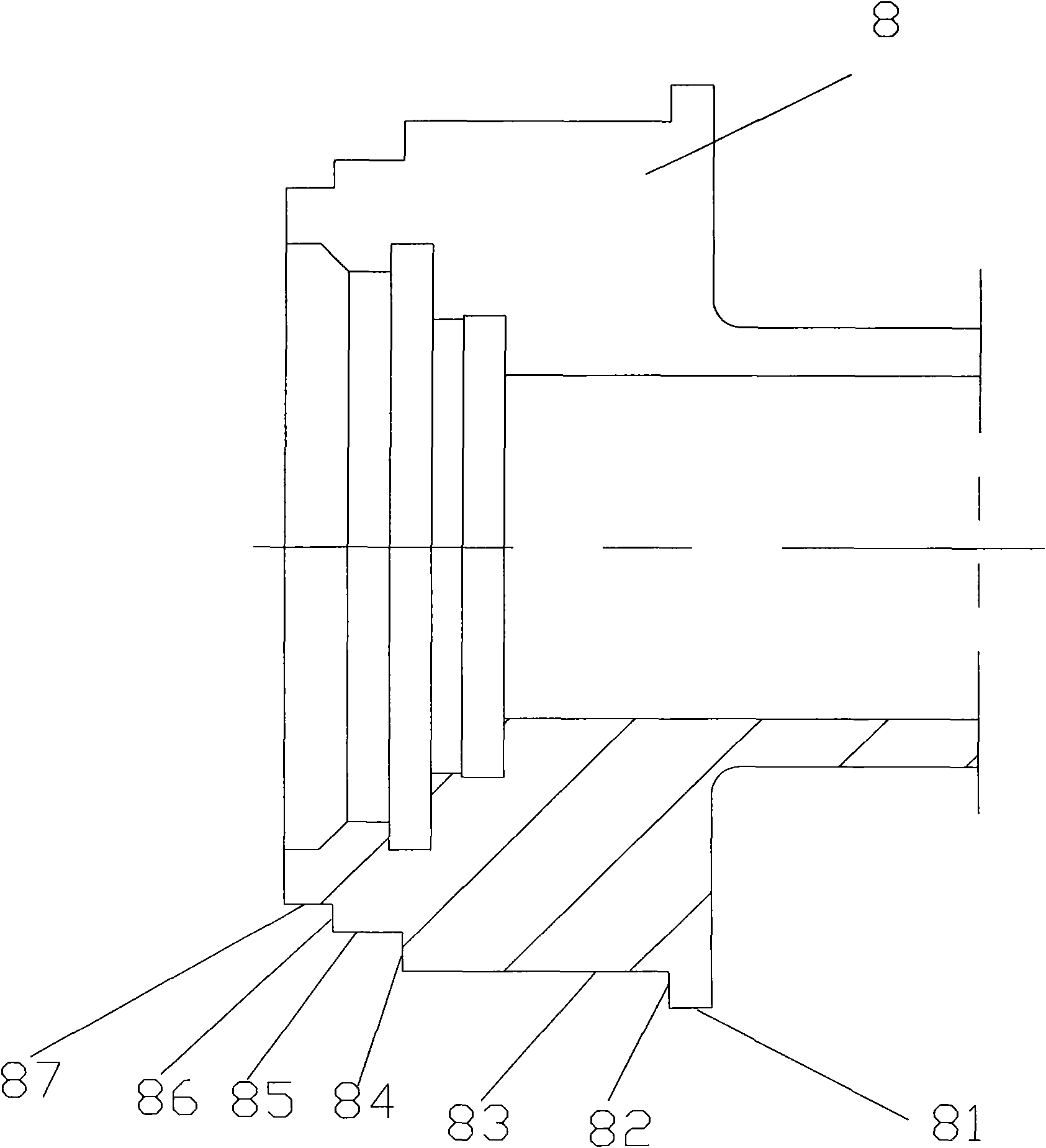

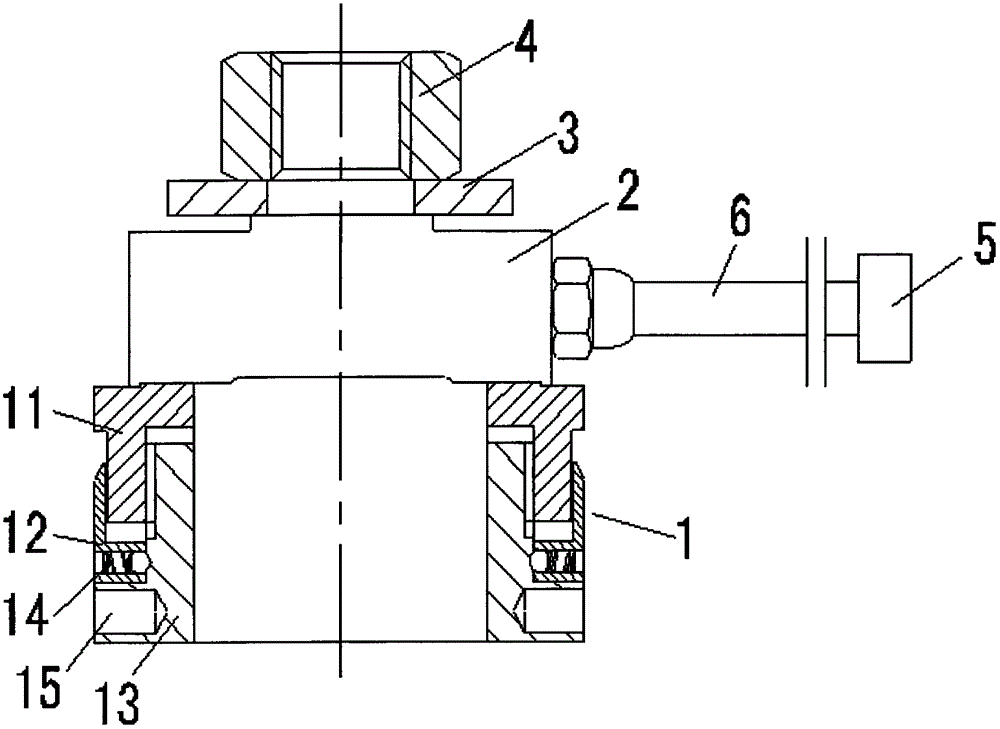

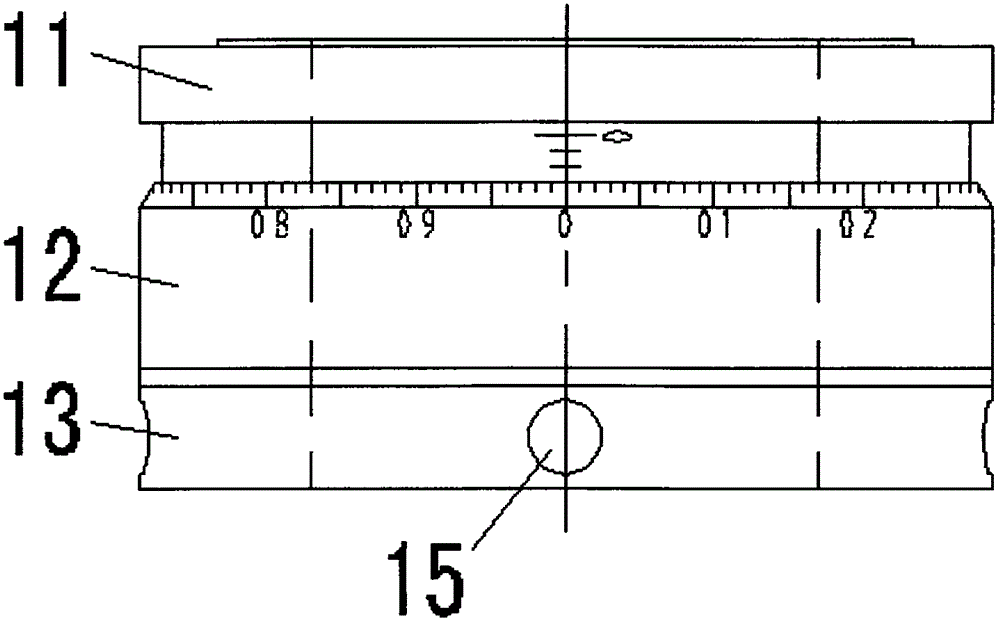

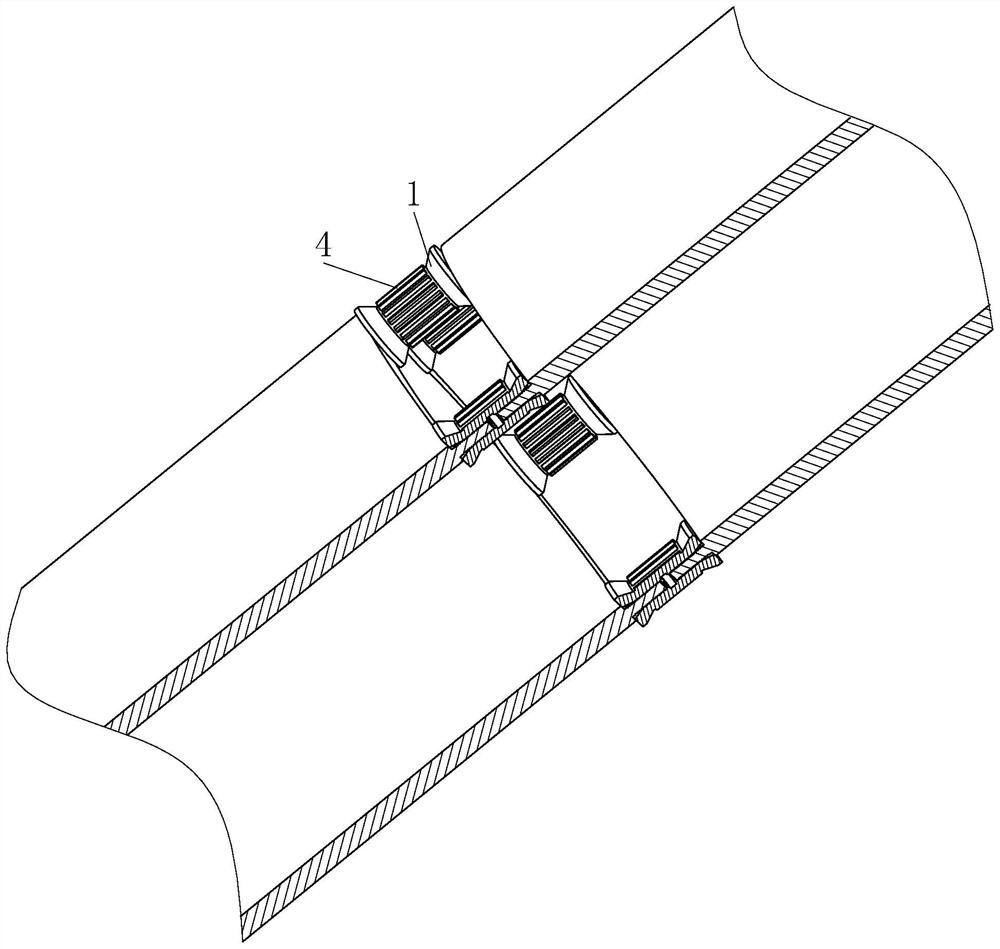

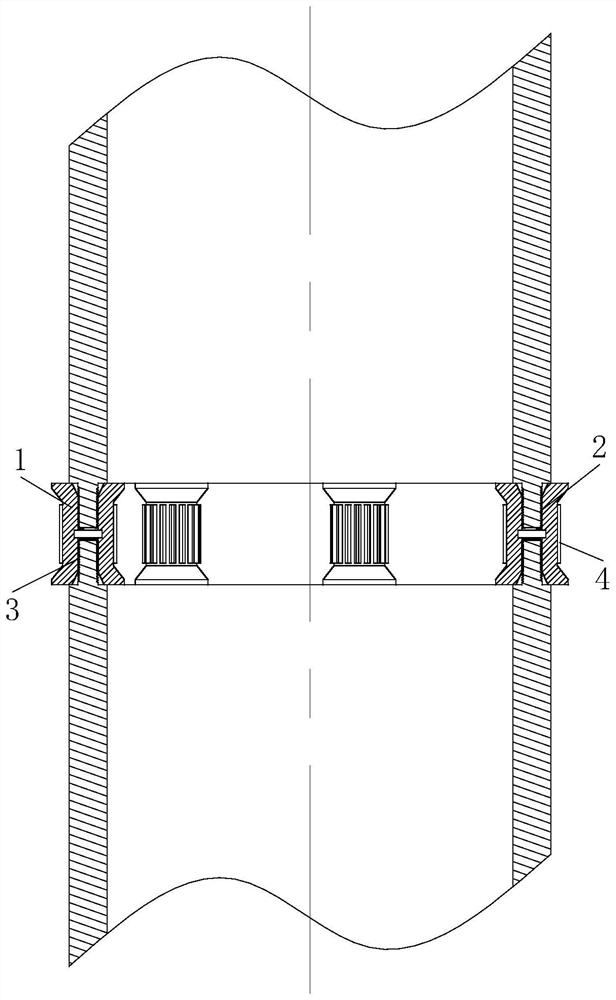

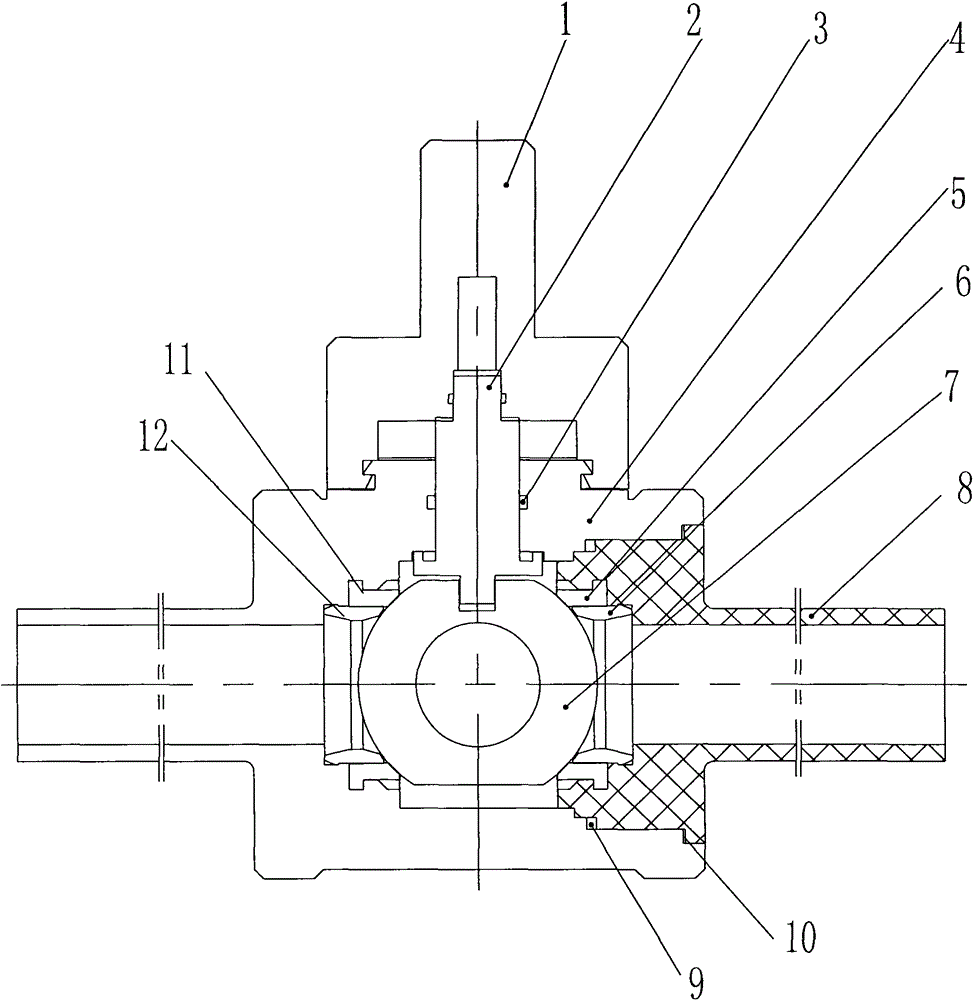

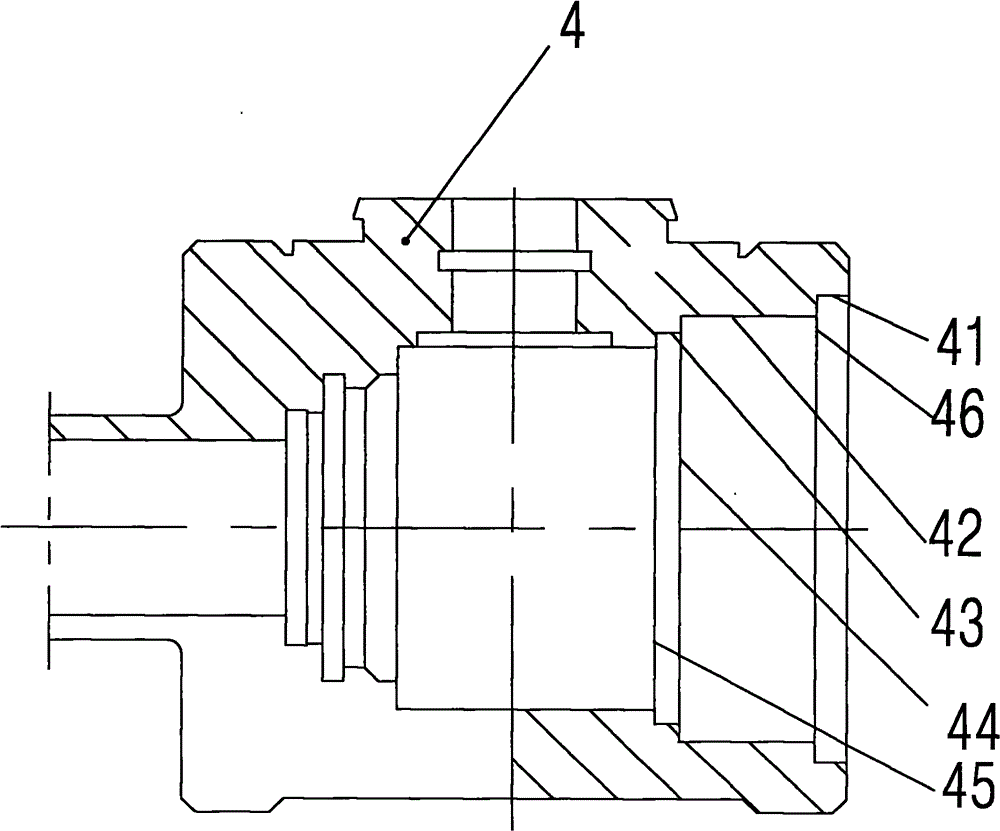

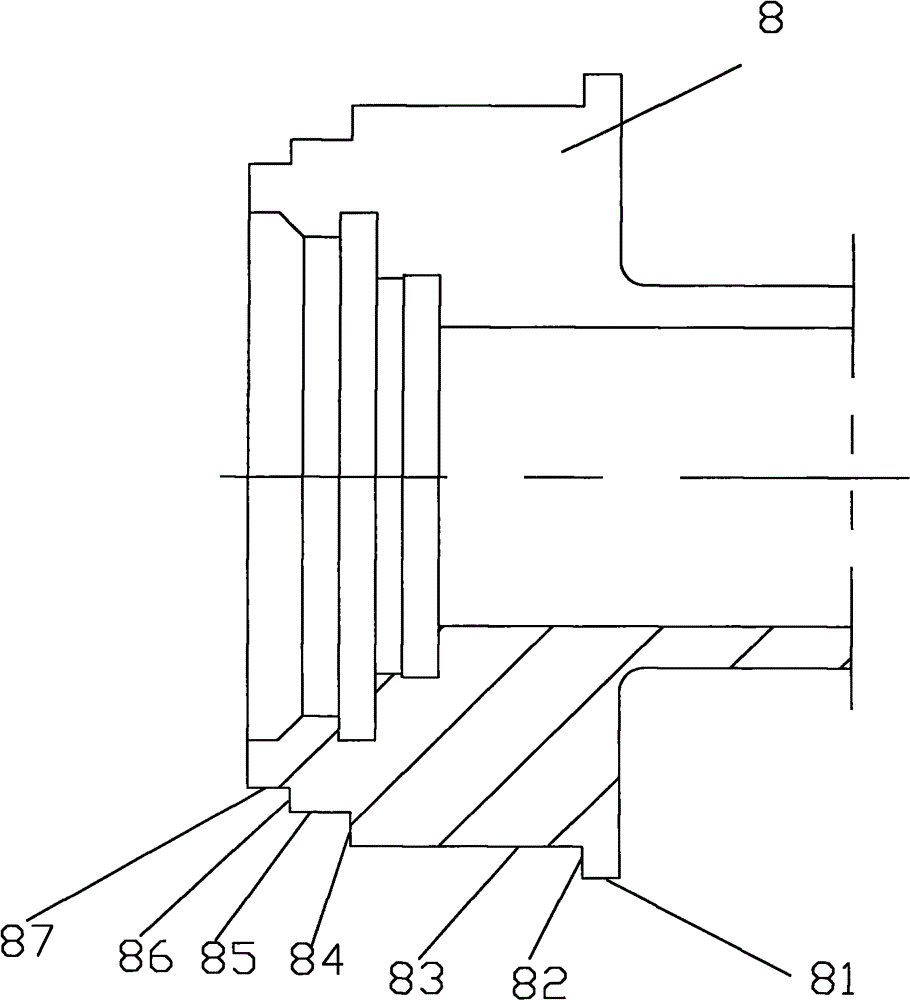

Polyethylene all-plastic ball valve formed by hot melt socket welding

ActiveCN101581376AConsistent preloadAchieve radial positioningSpindle sealingsPlug valvesBall valvePolyethylene

The invention relates to a pipeline cut-off valve, in particular to a polyethylene all-plastic ball valve formed by hot melt socket welding. The ball valve comprises a valve rod, a valve body, a valveball, a stub tube, a first valve ball sealing ring and a second valve ball sealing ring, wherein, the valve ball is arranged in the valve body, and the valve rod which rotates the valve ball is arranged thereon; the first valve ball sealing ring is fixed between the valve body and the valve ball, and the second valve ball sealing ring is fixed between the stub tube and the valve ball; the stub tube and the valve body are in hot melt socket-type connection, the inner surface of the insertion chamber of the valve body is provided with a melt glue surface of the valve body, and the outer surfaceof the stub tube is provided with a melt glue surface of the stub tube; and the valve body is matched with the stub tube and is provided with an axial positioning structure used for positioning the axial depth of the stub tube inserted into the valve body. The axial positioning structure of the invention guarantees the axial depth of the stub tube inserted into the valve body, thereby guaranteeing the axial spacing of sealing faces formed by the two valve ball sealing rings, and enabling the pretightening force of each sealing face to be consistent with the designed pretightening force.

Owner:GUANGDONG LIANSU TECH INDAL

Tension detection device for elevator wire rope

ActiveCN104276469BHigh precisionConsistent preloadTension measurementElevatorsEngineeringPressure sensor

Owner:SUZHOU BALANCE ELEVATOR TECH CO LTD

Sleeper replacement device with four-nut synchronous disassembly and assembly function

InactiveCN106400624AAutomatic Quick AlignmentConsistent preloadRailway track constructionPush and pullAutomatic control

The invention discloses a sleeper replacement device with a four-nut synchronous disassembly and assembly function. The sleeper replacement device is composed of a sleeper four-nut synchronous disassembly and assembly device body, a rail lifting device, a sleeper transferring, pushing and pulling device, a generator, a hydraulic system, a control system box and a rail car. The rail car is provided with four castors and two longitudinal beams. The sleeper four-nut synchronous disassembly and assembly device body, the rail lifting device, the sleeper transferring, pushing and pulling device, the generator and the hydraulic system are arranged on one of the two longitudinal beams of the rail car. The control system box is arranged on the other longitudinal beam of the rail car. The rail car is pulled by a construction vehicle. By the adoption of the sleeper replacement device with the four-nut synchronous disassembly and assembly function, the working device can be made to be aligned with the working position automatically; synchronous disassembly and assembly of four nuts can be achieved, the four nuts are the same in pretightening force, the fatigue life of bolts is prolonged, and the connecting reliability of a sleeper and a steel rail is guaranteed; the sleeper replacement device can adapt to the related operations of sleeper replacement of linear and curved rail sections; and the sleeper transferring, pushing and pulling device is an integrated device, and the sleeper replacement device is simple and compact in structure, automatic in control, convenient to operate and high in sleeper replacement efficiency.

Owner:KUNMING UNIV

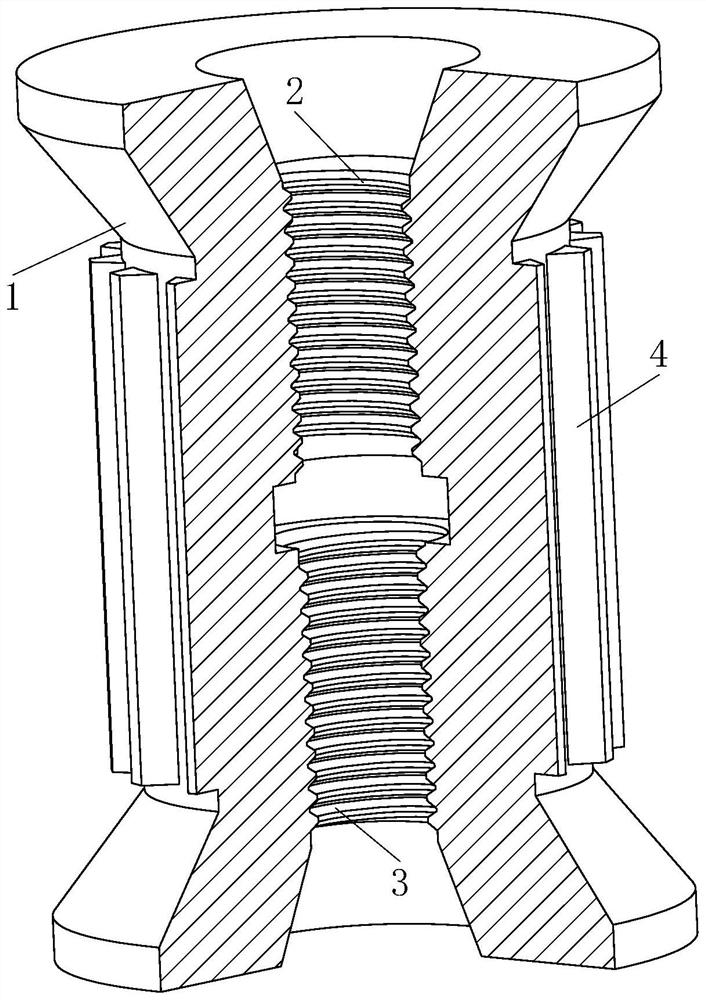

Rubber vibration absorber

PendingCN108533656AConsistent preloadImprove vibration damping effectShock absorbersEngineeringInverted-T shape

The invention belongs to the technical field of rubber vibration isolation, and particularly relates to a rubber vibration absorber. According to the rubber vibration absorber, the problems that the size of appearance structure of vibration absorber system is large and the pre-tightening amount of each vibration absorber of the vibration absorber system is not easy to control of an existing product are solved. The vibration absorber comprises a rubber vibration absorber pad, a pressing cover and a support shaft, wherein the pressing cover and the supporting shaft are arranged at the two ends of the rubber vibration absorber pad respectively; the supporting shaft is of an inverted T-shape, a mounting boss is arranged at the large end of the supporting shaft, an external thread is arranged at the small end of the supporting shaft, and a through hole penetrating through the axis of the supporting shaft is formed in the middle of the supporting shaft; the rubber vibration absorber pad is cylindrical, the longitudinal section of the rubber vibration absorber pad is in an I-shape, and a supporting shaft mounting hole penetrating through the axis of the supporting shaft is formed in the middle of the supporting shaft; a stepped hole is formed in the pressing cover, the stepped hole comprises a first mounting hole and a second mounting hole which are coaxially arranged, wherein the diameter of the first mounting hole is equal to the aperture of the through hole, the aperture of the second mounting hole is matched with the outer diameter of the small end of the supporting shaft, andan inner thread is arranged in the second mounting hole; and the supporting shaft penetrates through the supporting shaft mounting hole from bottom to top and extends into the second mounting hole and is in threaded connection to the pressing cover and the thread.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Automatic machine for sleeper replacement

InactiveCN106436503AAutomatic Quick AlignmentConsistent preloadRailway track constructionAutomatic controlControl system

The invention discloses an automatic machine for sleeper replacement. The automatic machine consists of a sleeper four-screw nut synchronous mounting and dismounting device, a sleeper lifting device, a sleeper turning and pushing device, a power generator, a hydraulic system, a control system box and a track trolley, wherein the track trolley is provided with four foot wheels and two longitudinal beams; the sleeper four-screw nut synchronous mounting and dismounting device, the sleeper lifting device, the sleeper turning and pushing device, the power generator, the hydraulic system and the control system box are arranged on the two longitudinal beams of the track trolley; the track trolley is tracked by a mobile machinery shop. By adopting the automatic machine, a working device can be automatically aligned to a working position, synchronous mounting and dismounting of four screw nuts can be achieved, the pre-tightening force of the four screw nuts can be accordant, the fatigue service life of a bolt can be prolonged, and the connection reliability of the sleeper and a steel rail can be ensured; the automatic machine is applicable to related operation that sleepers on straight line or curved line rail sections are replaced; the sleeper turning and pushing device is an integrated device which is simple and compact in structure, automatic to control, convenient to operate and high in sleeper replacement working efficiency.

Owner:KUNMING UNIV

Pneumatic anti-breakage grasping claw for eggs and grasping method thereof

A pneumatic egg shatterproof grasping claw and its grasping method adopts a cylindrical hollow grasping claw, a buffer gasket is provided at the entrance edge of the cavity, and a vacuum negative pressure source is externally connected to the tail end of the grasping claw , the grasping claw is connected to the egg liquid collection box through the vacuum connection pipeline, the egg liquid collection box can suck the broken eggs under the action of negative pressure and separate the egg liquid from the air, the egg liquid stays in the egg liquid collection box, and the air Enter the vacuum negative pressure source; the grasping claw is installed on the support plate, the support plate is fixed on one side of the egg liquid collection box, and the other side of the egg liquid collection box is connected to the mechanical arm; the support plate is installed The photoelectric sensor detects the position of the egg through the photoelectric sensor. The invention aims at the problems such as fragility, no positioning surface and relatively difficult rigid positioning in the clamping process existing in the automatic carving of eggs, and realizes the automatic grasping, handling and clamping of eggs, and the operation is reliable and stable.

Owner:西安精雕软件科技有限公司

A method for adjusting the pretightening force of an angular contact bearing of an indexing mechanism in a positioning orienting system

ActiveCN109945767BConsistent preloadReduce damage rateMechanical depth measurementsMechanical thickness measurementsEngineeringHeight difference

The invention discloses a method for adjusting the pretightening force of an angular contact bearing of an indexing mechanism of a positioning and orientation system, which comprises the following steps: (1) measuring the height difference h of the inner and outer rings of the angular contact bearing; Depth L1 to the mounting surface of the outer frame; (3) Measure the height difference L2 between the step press-fit surface of the bearing end cover before assembly and the installation end surface; (4) The step press-fit of the bearing end cover before assembly (5) Make a ring-shaped aluminum foil pad with a thickness of 0.01mm. The outer diameter of the ring-shaped aluminum foil pad is smaller than the outer diameter of the outer ring of the angular contact bearing, and the inner diameter of the ring-shaped aluminum foil pad is larger than that of the inner ring of the angular contact bearing. (6) Install at least one ring-shaped aluminum foil pad on the end face of the angular contact bearing, and press the ring-shaped aluminum foil pad with the ground bearing end cover. At this time, the installation end face of the bearing end cover and the outer frame are installed face fit. Suitable for positioning and orientation systems.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

Sleeper replacement device based on mechanical-electrical-hydraulic integration

InactiveCN106192627AConsistent preloadImprove fatigue lifeTrack superstructureRailway track constructionPush and pullAutomatic control

The invention discloses a sleeper replacement device based on mechanical-electrical-hydraulic integration. The device is composed of a four-nut synchronous assembling and disassembling device for a sleeper, a rail-lifting device, a sleeper rotating, pushing and pulling device, an electric generator, a hydraulic system, a control system box and a rail car. The rail car has four trundles and two longitudinal beams. The four-nut synchronous assembling and disassembling device for the sleeper, the rail-lifting device, the sleeper rotating, pushing and pulling device, the electric generator, the hydraulic system and the control system box are arranged on the two longitudinal beams of the rail car. The rail car is pulled by an engineering vehicle. The sleeper replacement device based on mechanical-electrical-hydraulic integration has following beneficial effects: the device is capable of automatically aligning a working device to the working position and capable of synchronously assembling and disassembling four nuts such that pre-stress force of the four nuts is the same and fatigue life of bolts is prolonged; reliability between the sleeper and steel rails is ensured; sleeper changing operation can be suitable for liner and curved rail segments; and the sleeper rotating, pushing and pulling device is an integrated device; and the device is simple and compact in structure, automatic in control, convenient in operation and high in sleeper changing efficiency.

Owner:KUNMING UNIV

Mechanical-electrical-hydraulic integrated sleeper replacement device

InactiveCN106522046AQuickly align to working positionConsistent preloadRailway track constructionAutomatic controlControl system

The invention discloses a mechanical-electrical-hydraulic integrated sleeper replacement device. The mechanical-electrical-hydraulic integrated sleeper replacement device is composed of a four-nut synchronous assembly and disassembly device, a rail lifting device, a rail switching and sleeper sliding device, a sleeper hoisting device, an electric generator, a hydraulic system and control system cabinet and a rail vehicle, wherein the rail vehicle is provided with a plurality of trundles and two longitudinal beams; the four-nut synchronous assembly and disassembly device, the rail lifting device, the rail switching and sleeper sliding device, the sleeper hoisting device, the electric generator and the hydraulic system and control system cabinet are arranged on the two longitudinal beams of the rail vehicle; and the rail vehicle is dragged by an engineering vehicle. By means of the mechanical-electrical-hydraulic integrated sleeper replacement device, a working device can be aligned at the working position quickly; four nuts are assembled and disassembled synchronously, so that the pretightening forces of the four nuts are coincident, the fatigue life of bolts is prolonged, and connection reliability of a sleeper and a steel rail is ensured; the sleeper is quickly hoisted and arranged; the device is suitable for sleeper replacement of linear and curved rail sections; and the rail switching and sleeper sliding device is an integrated device, the structure is simple and compact, automatic control is achieved, operation is convenient, and efficiency of sleeper replacement work is high.

Owner:KUNMING UNIV

Sleeper replacing machine with crossing sleeper and push-pull sleeper integration device

InactiveCN106498815AConsistent preloadImprove fatigue lifeRailway track constructionAutomatic controlControl system

The invention discloses a sleeper replacing machine with a crossing sleeper and push-pull sleeper integration device. The sleeper replacing machine comprises a sleeper four-nut synchronous dismantling and installing device, a sleeper lifting device, a crossing sleeper and push-pull sleeper device, a generator, a hydraulic system, a control system box and a track vehicle. The track vehicle is provided with four trundles and two longitudinal beams. The sleeper four-nut synchronous dismantling and installing device, the sleeper lifting device, the crossing sleeper and push-pull sleeper device, the generator, the hydraulic system and the control system box are arranged on the two longitudinal beams of the track vehicle, and the track vehicle is pulled by an engineering vehicle. According to the sleeper replacing machine, a working device is automatically aligned with the working position, synchronous dismantling and installation of four nuts can be achieved, so that pre-tightening force of the four nuts is consistent, the fatigue life of a bolt is improved, and sleeper and steel rail connection reliability is ensured. The sleeper replacing machine can adapt to relevant operation of straight line and curve rail section sleeper replacement, a crossing sleeper and a push-pull sleeper are an integrated device, and the sleeper replacing machine is simple and compact in structure, is controlled automatically and is convenient to operate and high in sleeper replacement working efficiency.

Owner:KUNMING UNIV

Mechanical-electrical-hydraulic integration sleeper replacement device

InactiveCN106223139AConsistent preloadImprove fatigue lifeRailway track constructionPush and pullAutomatic control

The invention discloses a mechanical-electrical-hydraulic integration sleeper replacement device. The mechanical-electrical-hydraulic integration sleeper replacement device is composed of a sleeper four-nut synchronous assembling and disassembling device, a rail lifting device, a sleeper rotating, pushing and pulling device, a generator, a hydraulic system and control system box and a rail car. The rail car is provided with four casters and two longitudinal beams. The sleeper four-nut synchronous assembling and disassembling device, the rail lifting device, the sleeper rotating, pushing and pulling device, the generator, and the hydraulic system and control system box are arranged on the two longitudinal beams of the rail car. The rail car is driven by an engineering car. By means of the mechanical-electrical-hydraulic integration sleeper replacement device, a working device can be automatically aligned to a working position, and four nuts can be synchronously disassembled and assembled, so that the pretightening force of the four nuts is consistent, the fatigue life of bolts is prolonged, and the connection reliability of a sleeper and steel rails is ensured; the mechanical-electrical-hydraulic integration sleeper replacement device can adapt to related work of sleeper replacement of linear and curved rail sections; the sleeper rotating, pushing and pulling device is an integrated device; and the structure is simple and compact, control is automatic, operation is convenient, and the sleeper replacement work efficiency is high.

Owner:KUNMING UNIV

Automatic sleeper replacing device

InactiveCN106381781AAutomatic Quick AlignmentConsistent preloadRailway track constructionAutomatic controlControl system

The invention discloses an automatic sleeper replacing device which is composed of a sleeper four-nut synchronous assembling and disassembling device, a rail lifting device, a sleeper-rotating and sleeper pushing-and-pulling device, a generator, a hydraulic system and control system cabinet and a rail car. The rail car is provided with four trundles and two longitudinal beams. The sleeper four-nut synchronous assembling and disassembling device, the rail lifting device, the sleeper-rotating and sleeper pushing-and-pulling device, the generator and the hydraulic system and control system cabinet are arranged on the two longitudinal beams of the rail car. The rail car is dragged by an engineering truck. According to the automatic sleeper replacing device, the working devices can be aligned with working positions automatically, four-nut synchronous assembling and disassembling can be achieved, pretightening force of four nuts is made consistent, the fatigue lives of bolts are prolonged, and connection reliability of sleepers and steel rails is guaranteed; the automatic sleeper replacing device can adapt to relevant operations for sleeper replacing of linear and curved railway sections; and the sleeper-rotating and sleeper pushing-and-pulling device is an integrated device, is simple and compact in structure, convenient to operate and high in sleeper replacing efficiency, and automatic control is achieved.

Owner:KUNMING UNIV

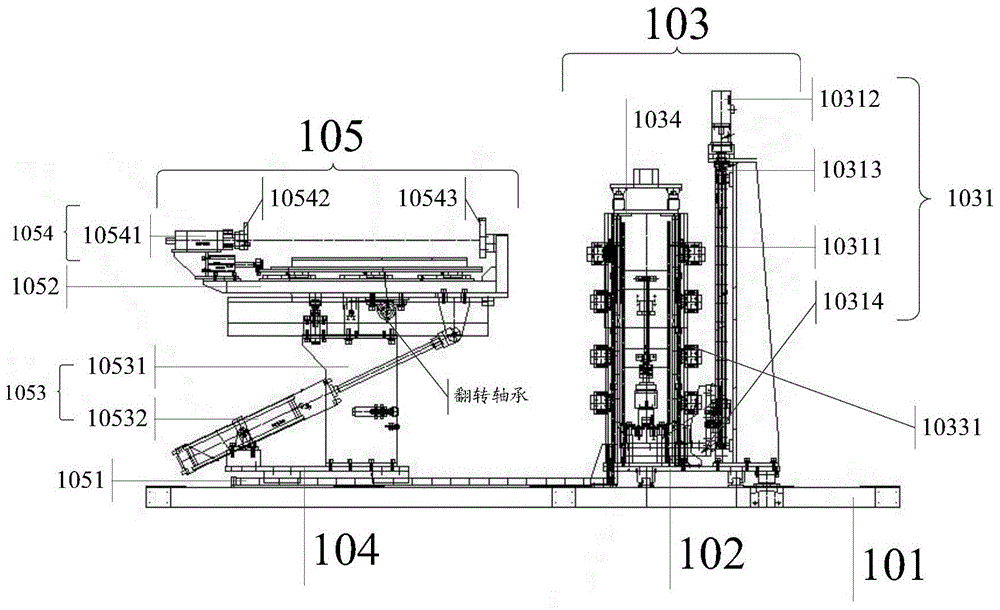

Mechanics-electronics-hydraulics-integrated sleeper replacing machine

InactiveCN106351089AQuickly align to working positionConsistent preloadTrack superstructureRailway track constructionAutomatic controlControl system

The invention discloses a mechanics-electronics-hydraulics-integrated sleeper replacing machine. The mechanics-electronics-hydraulics-integrated sleeper replacing machine is composed of a four-nut synchronous assembling-disassembling device, a first sleeper lifting device, a sleeper-transferring and sleeper-push-pull device, a sleeper hoisting transporting device, a power generator, a hydraulic system and control system cabinet and a rail car. The rail car comprises a plurality of castors and two longitudinal beams, the four-nut synchronous assembling-disassembling device, the first sleeper lifting device, the sleeper-transferring and sleeper-push-pull device, the sleeper hoisting transporting device, the power generator and the hydraulic system and control system cabinet are arranged on the two longitudinal beams of the rail car, and the rail car is drawn through an engineering van. According to the mechanics-electronics-hydraulics-integrated sleeper replacing machine, the working devices can be rapidly aligned with the working position; four nuts can be synchronously assembled or disassembled, pre-tightening force of four nuts is coincident accordingly, the fatigue life of bolts is prolonged, and the reliability of connection between sleepers and steel rails is guaranteed; rapid hoisting transporting and placing work of sleepers is achieved; the mechanics-electronics-hydraulics-integrated sleeper replacing machine adapts to sleeper replacement of linear and curved rail sections; the sleeper-transferring and sleeper-push-pull device is an integrated device, the structure is simple and compact, automatic control is achieved, operation is convenient, and the sleeper replacement working efficiency is high.

Owner:KUNMING UNIV

Telegraph pole connecting nut and tightening tool thereof

The invention belongs to the technical field of fasteners, and particularly relates to a telegraph pole connecting nut and a tightening tool thereof, the telegraph pole connecting nut comprises a main body, a first threaded section and a second threaded section; the screwing directions of the first threaded section and the second threaded section in the nut are set to be opposite, so that when the nut only needs to be rotated in one direction, the two threaded rods can move in the direction of the nut, then the two threaded rods are tightly connected with the nut, and the two threaded rods can be tightly connected with the nut through a special tool. According to the telegraph pole connecting device, the nuts are screwed, all the nuts are rotated at the same time when the nuts are screwed, all the nuts on the two telegraph poles move towards the middles of the nuts at the same time, it is guaranteed that the telegraph poles do not deflect in the connecting process, stress concentration at the connecting positions of the telegraph poles is avoided, and the stability of the connecting positions is improved; and meanwhile, all the nuts are screwed down at the same time, so that the connecting speed of the telegraph pole is higher, and the connecting efficiency is improved.

Owner:胡瑞国

Polyethylene all-plastic ball valve formed by hot melt socket welding

ActiveCN101581376BAchieving a sealed connectionAvoid the problem of different axesSpindle sealingsPlug valvesHot meltEngineering

The invention relates to a pipeline cut-off valve, in particular to a polyethylene all-plastic ball valve formed by hot melt socket welding. The ball valve comprises a valve rod, a valve body, a valveball, a stub tube, a first valve ball sealing ring and a second valve ball sealing ring, wherein, the valve ball is arranged in the valve body, and the valve rod which rotates the valve ball is arranged thereon; the first valve ball sealing ring is fixed between the valve body and the valve ball, and the second valve ball sealing ring is fixed between the stub tube and the valve ball; the stub tube and the valve body are in hot melt socket-type connection, the inner surface of the insertion chamber of the valve body is provided with a melt glue surface of the valve body, and the outer surfaceof the stub tube is provided with a melt glue surface of the stub tube; and the valve body is matched with the stub tube and is provided with an axial positioning structure used for positioning the axial depth of the stub tube inserted into the valve body. The axial positioning structure of the invention guarantees the axial depth of the stub tube inserted into the valve body, thereby guaranteeing the axial spacing of sealing faces formed by the two valve ball sealing rings, and enabling the pretightening force of each sealing face to be consistent with the designed pretightening force.

Owner:GUANGDONG LIANSU TECH INDAL

Sleeper replacing device with sleeper four-nut synchronous assembly and disassembly device

InactiveCN106436507AQuickly align to working positionConsistent preloadTrack superstructureRailway track constructionAutomatic controlControl system

The invention discloses a sleeper replacing device with a sleeper four-nut synchronous assembly and disassembly device. The sleeper replacing device is composed of the four-nut synchronous assembly and disassembly device, a sleeper lifting device, a retracking and sleep pushing and pulling device, a sleeper hoisting device, a power generator, a hydraulic system, a control system box and a track car. The track car is provided with multiple trundles and two longitudinal beams, the four-nut synchronous assembly and disassembly device, the sleeper lifting device, the retracking and sleep pushing and pulling device, the sleeper hoisting device, the power generator, the hydraulic system and the control system box are arranged on the two longitudinal beams of the track car, and the track car is dragged by an engineering van. A working device can be rapidly aligned with a working position; four-nut synchronous assembly and disassembly are achieved, the pretightening force of four nuts is consistent, the fatigue life of bolts is prolonged, and the reliability of the sleeper and steel rail connection is guaranteed; sleepers are rapidly hoisted and placed; the sleeper replacing device adapts to linear and curved rail road segment sleeper replacing work; the retracking and sleep pushing and pulling device is an integrated device, the structure is simple and compact, automatic control is achieved, operation is convenient, and sleeper replacing work efficiency is high.

Owner:KUNMING UNIV

A battery stack device

ActiveCN104157898BGuaranteed accuracyEnsure consistencyAssembling battery machinesFinal product manufactureProtection mechanismEngineering

Owner:HUBEI MECHANICAL & ELECTRICAL INST EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com