Polyethylene all-plastic ball valve formed by hot melt socket welding

A technology of socket welding and plastic ball valves, which is applied to valve details, valve devices, valve shell structures, etc., can solve the problems of small pre-tightening force on the sealing surface, affecting the pre-tightening force and large pre-tightening force on the sealing surface of the valve ball, etc. , to achieve the effect of keeping the preload consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

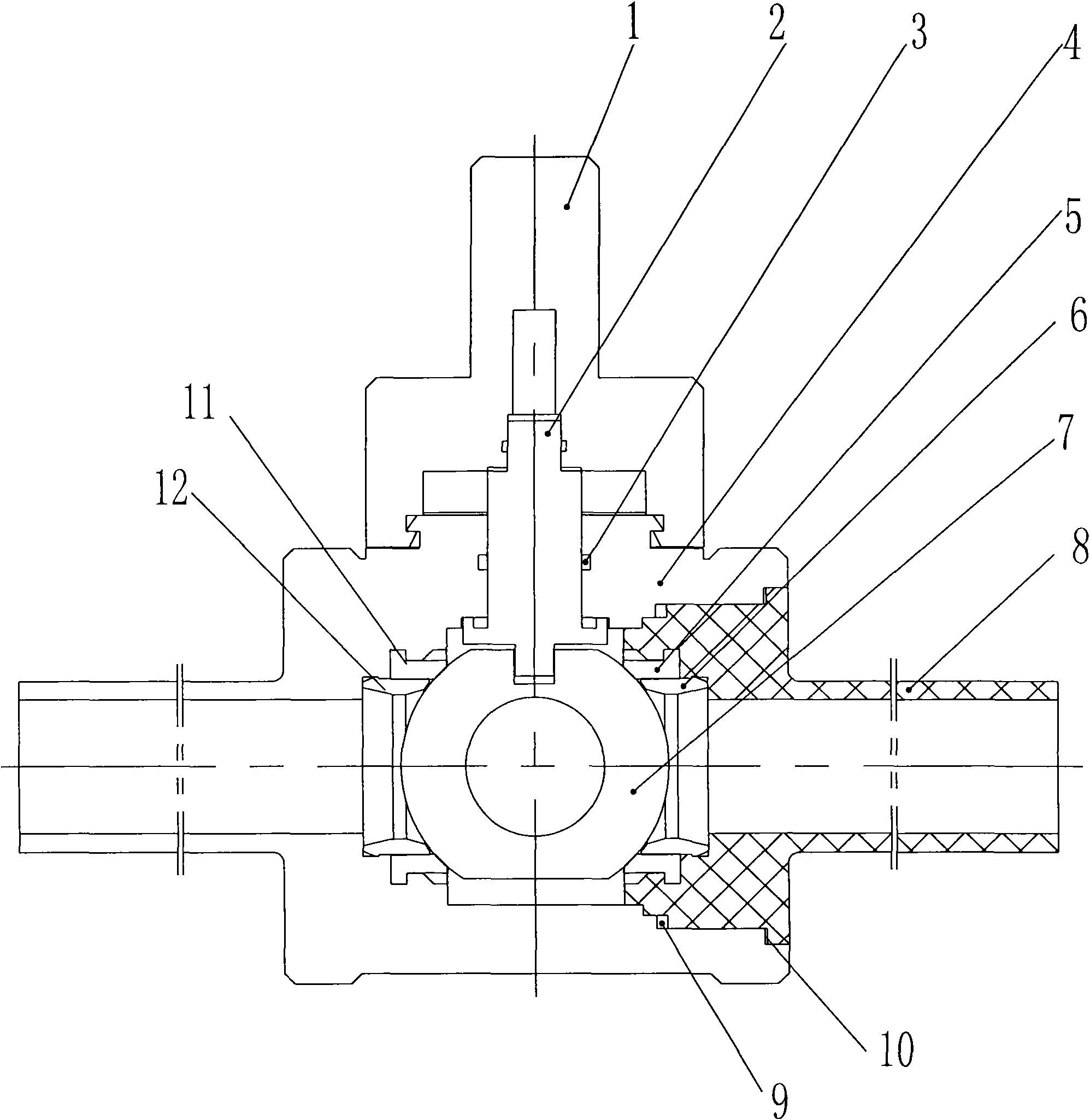

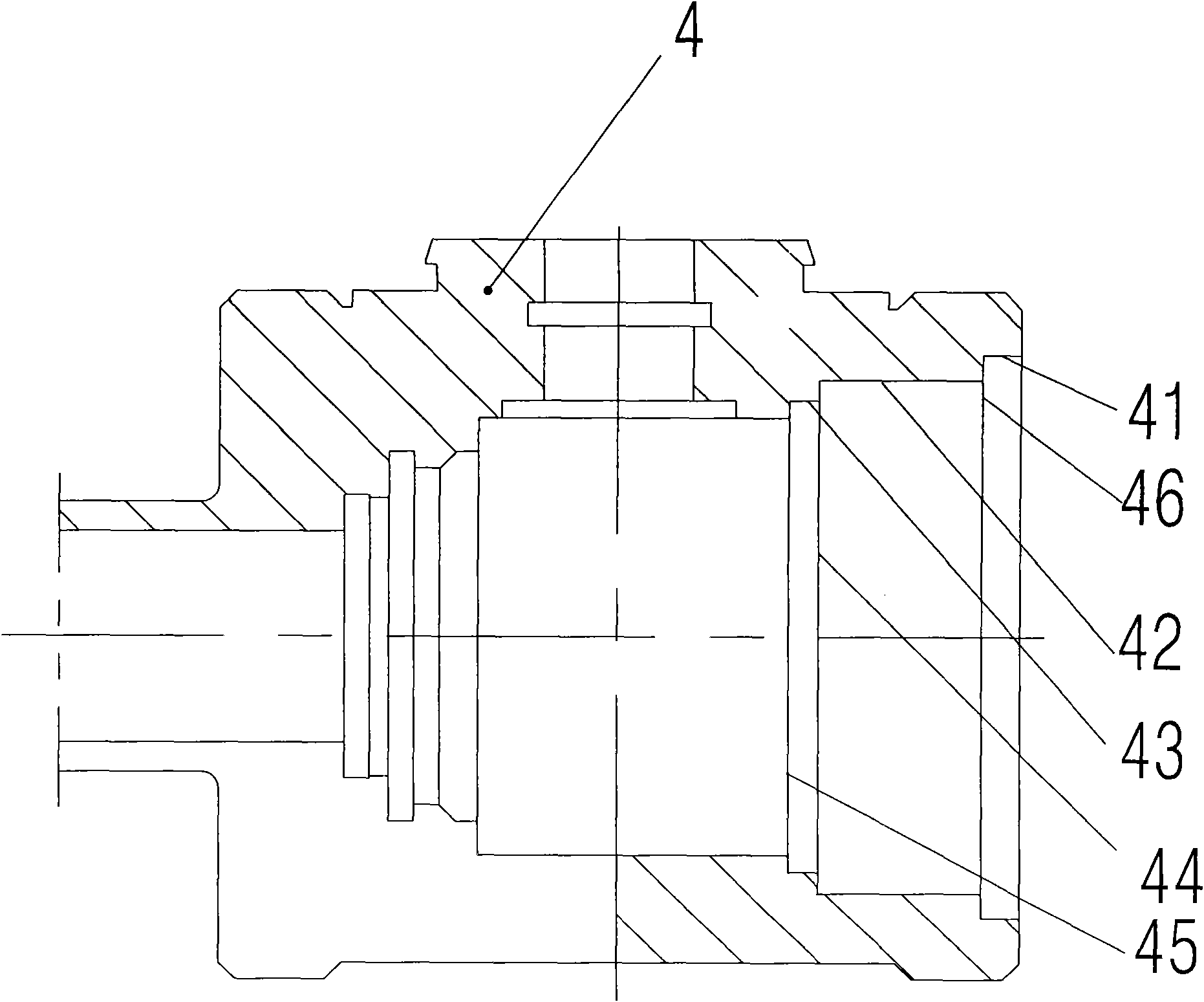

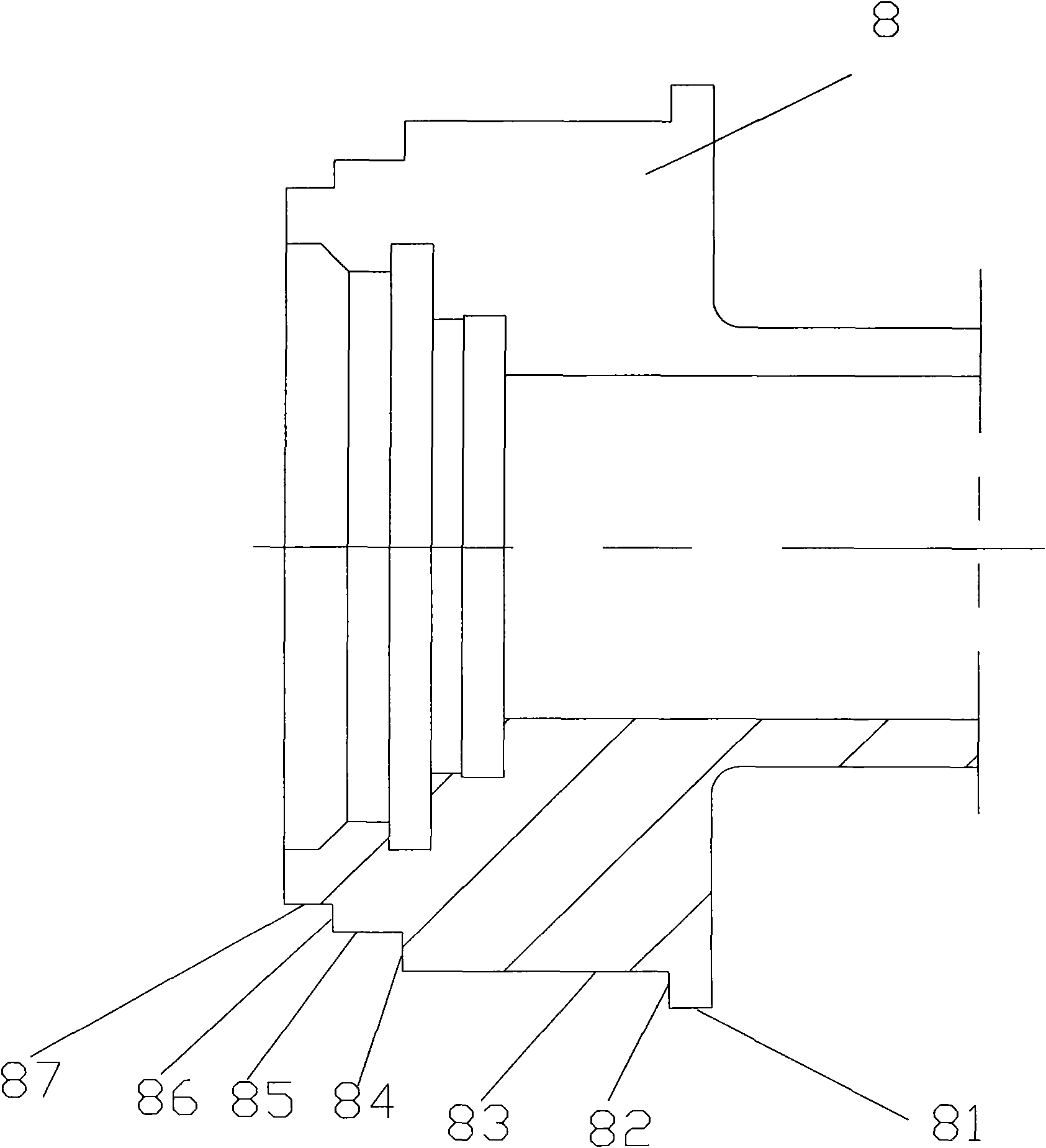

[0018] like figure 1 , a hot-melt socket welded polyethylene all-plastic ball valve, including a valve cap 1, a valve stem 2, a valve body 4, a valve ball 7, a connecting seat 8, a first valve ball seal ring 11, a second valve ball seal ring 5. The valve ball 7 is set in the valve body 4, and the valve ball 4 is provided with a valve stem 2 for rotating the valve ball 7, and a valve stem axis sealing ring 3 is provided between the valve stem 2 and the valve body 4; the first valve The ball sealing ring 11 is fixed on the side of the valve body 4 with the connecting pipe through the nesting of the first sealing ring installation ring 12 and the valve body 4, so as to realize the sealing between the connecting pipe end of the valve body 4 and the valve ball 7; the second valve ball The sealing ring 5 is nested in the tube of the connecting seat 8 through the second sealing ring mounting ring 6 to realize the sealing between the connecting seat 8 and the valve ball 7 . The socke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com