A battery stack device

A kind of equipment and battery technology, which is applied in the direction of battery assembly, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of uneven effect of battery modules, and achieve consistency, accuracy and consistency, and guarantee The effect of preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiment of the present invention provides a battery stacking device, which solves the technical problem that various methods or devices for combining battery packs in the prior art can achieve uneven effects on improving the accuracy and consistency of battery modules, and realizes To ensure the technical effect of accuracy and consistency between battery modules in the battery pack.

[0047] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

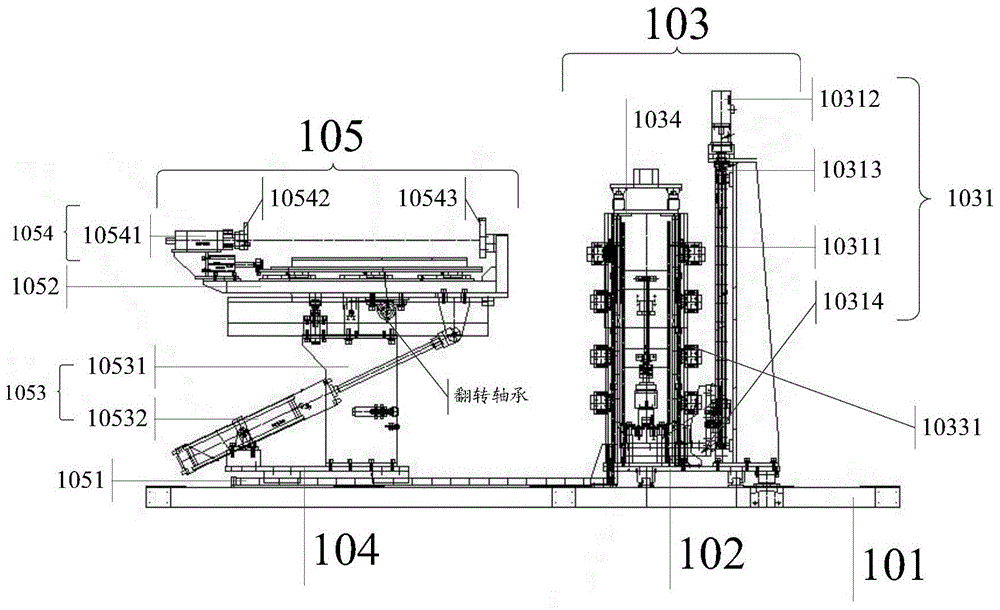

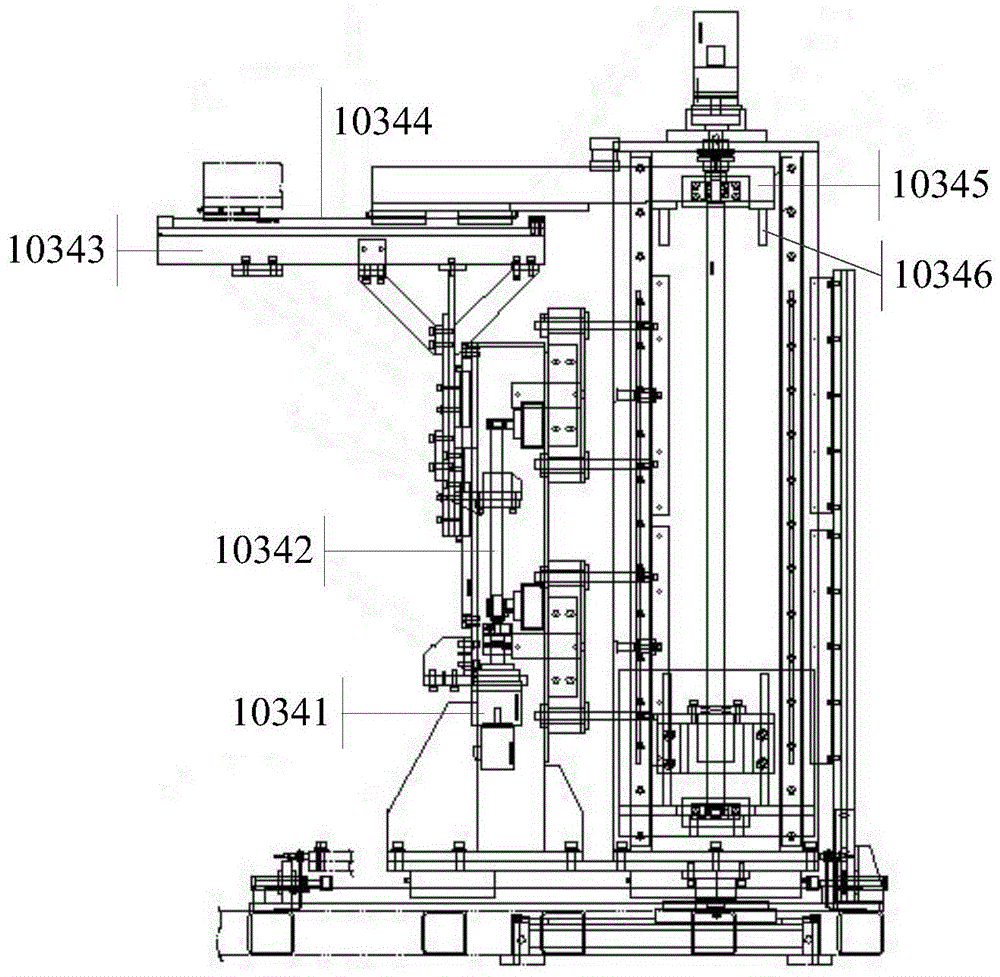

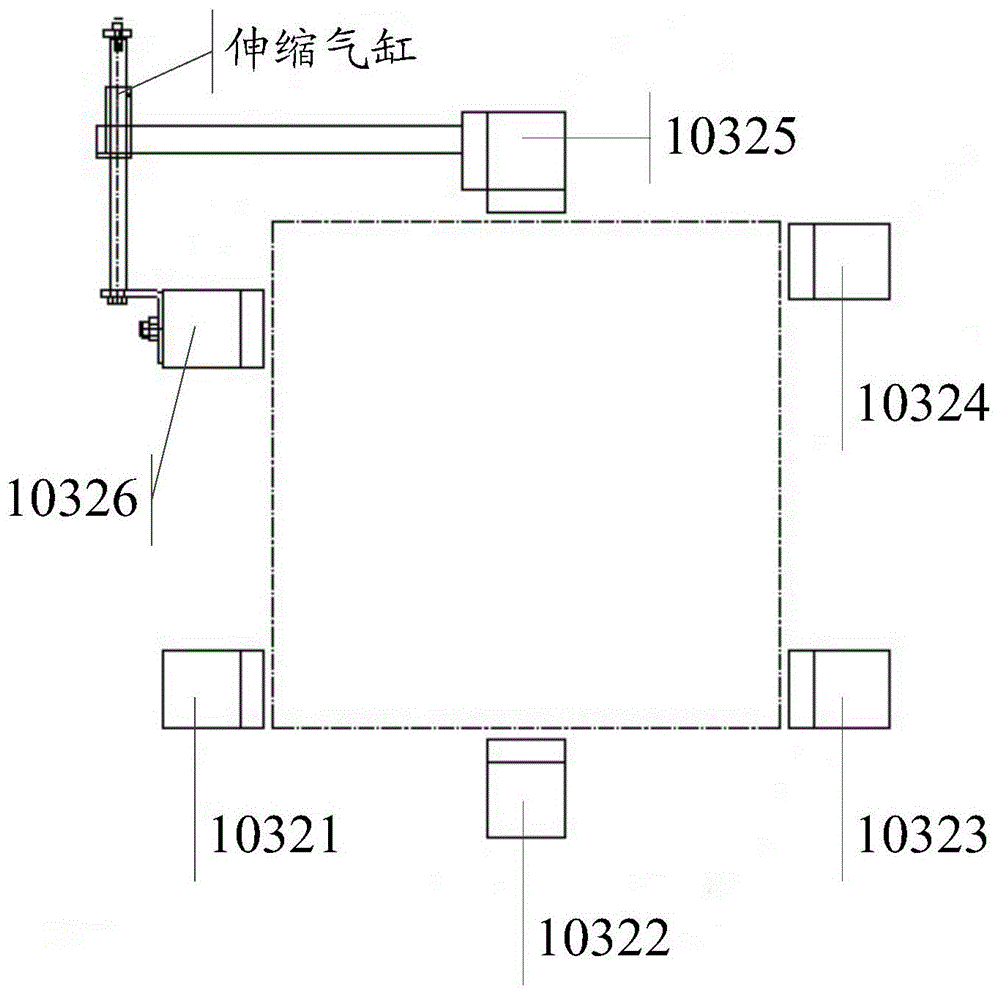

[0048] An embodiment of the present invention provides a battery stack device, please refer to figure 1 , figure 1 is the front view of the battery stack device provided by the embodiment of the present invention, such as figure 1 As shown, the battery stack device includes:

[0049] Rack 101;

[0050] The first bottom plate 102 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com