Pneumatic anti-breakage grasping claw for eggs and grasping method thereof

A technology of claws and eggs, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of egg position changes, egg placement postures are not uniform, eggs are not positioned accurately, etc., to prevent repeated feeding, improve efficiency, Guaranteed continuity of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

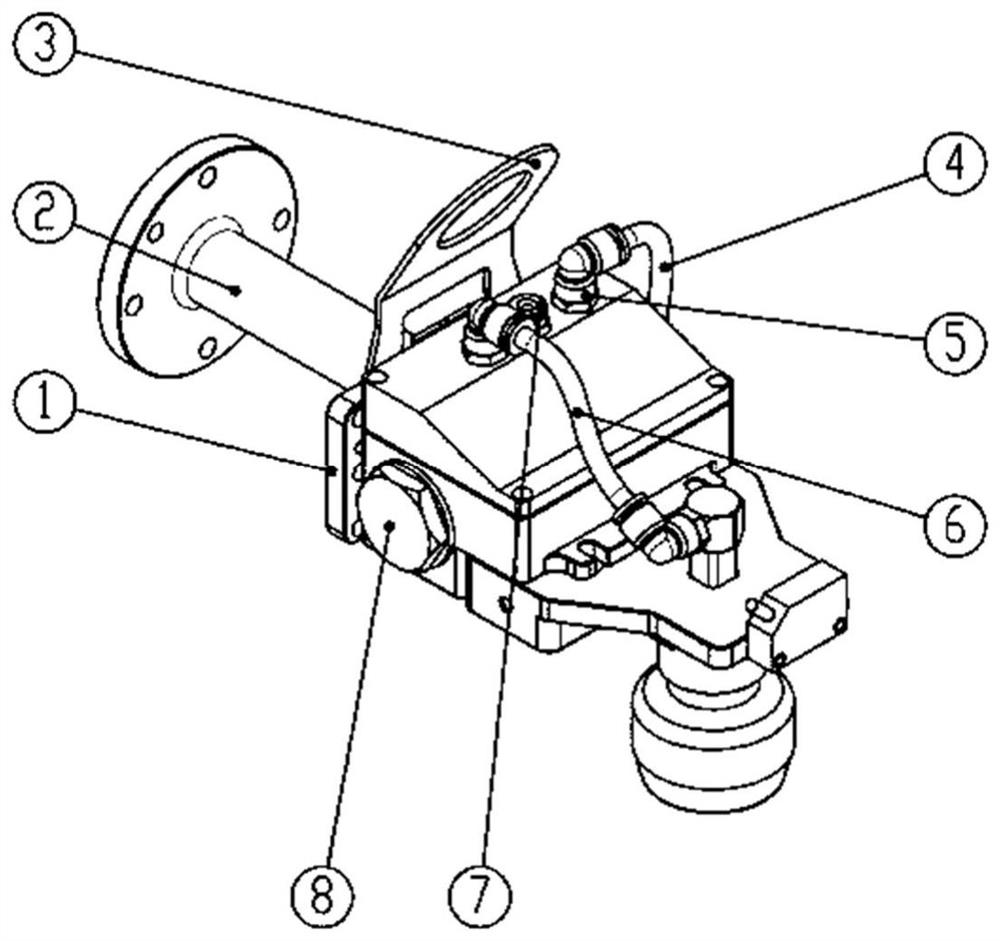

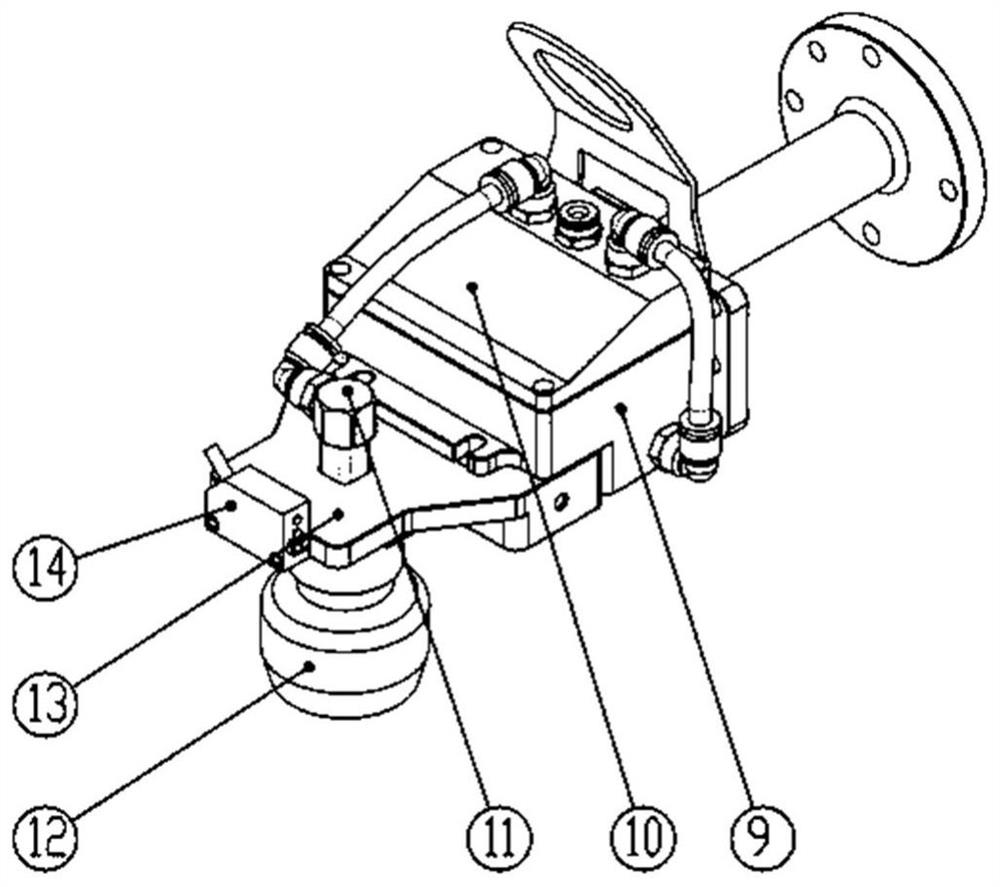

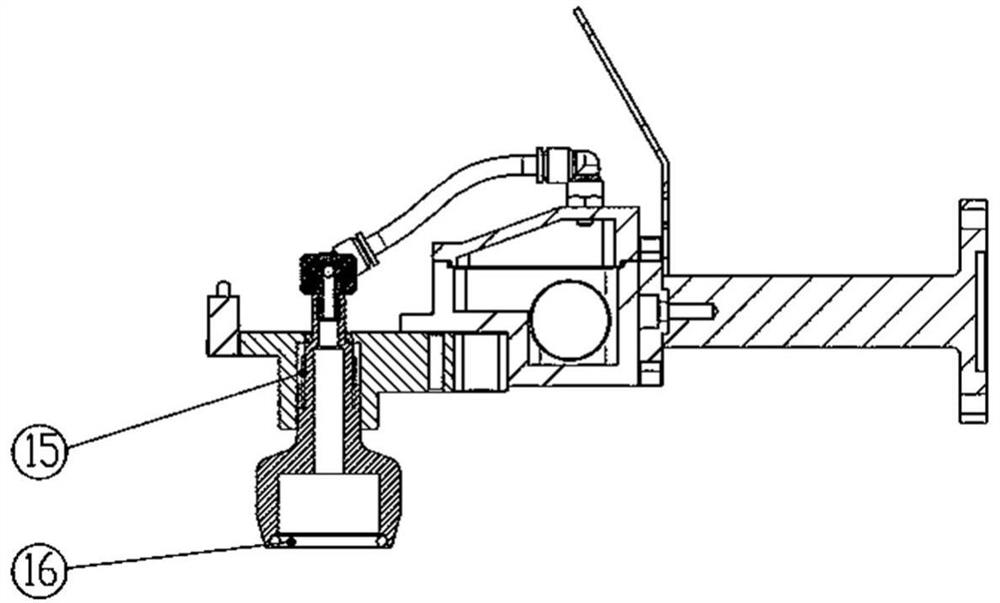

[0028] see Figure 1-4 , The grasping claw of the present invention is mainly composed of three groups of functional blocks: egg grasping, egg liquid collection, and material level detection.

[0029] Among them, the claw installation base plate 1, the claw connecting rod 2 and the pipeline support 3 are assembled to form a connecting mechanism for grabbing eggs, which are used to connect the six-axis robot and the grabbing claw of the present invention; the egg liquid collection box 9, the egg The egg liquid collection box cover 10 and the liquid level mirror 8 are assembled to form an egg liquid collection box assembly, wherein the mounting surface of the egg liquid collection box 9 and the egg liquid collection box cover 10 needs to be coated with sealant to ensure the airtightness of the cavity of the box body; Claw 12, bracket plate 13, photoelectric se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com