Cutter polishing equipment with good polishing effect

A technology for cutting tools and equipment, applied in the field of cutting tool grinding equipment, can solve the problems of not meeting people's needs, the grinding wheel cannot touch the cutting tool, affecting people's normal use, etc., and achieves the effect of simple structure, avoiding hard contact and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

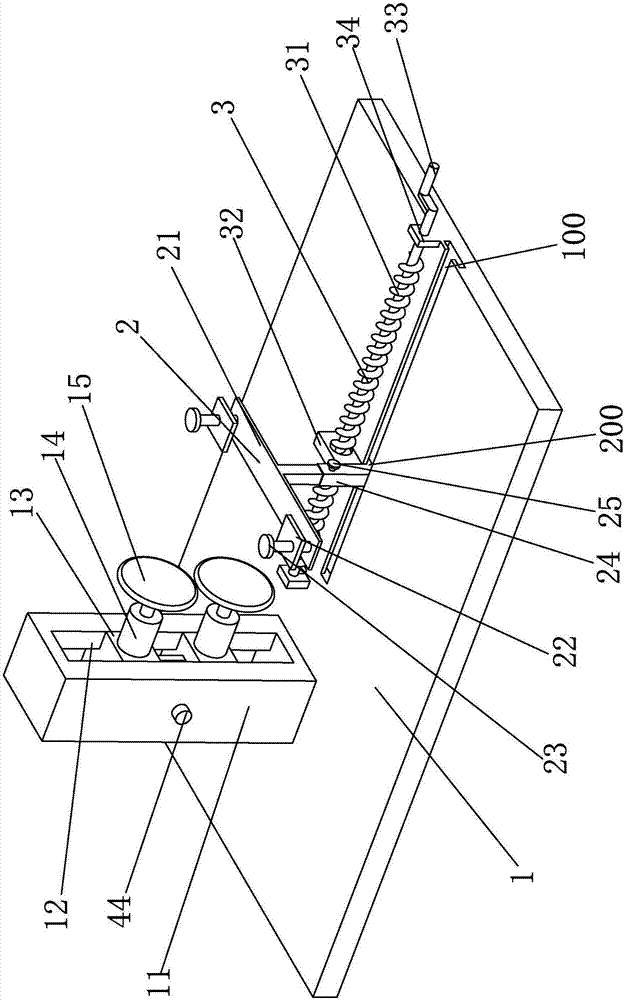

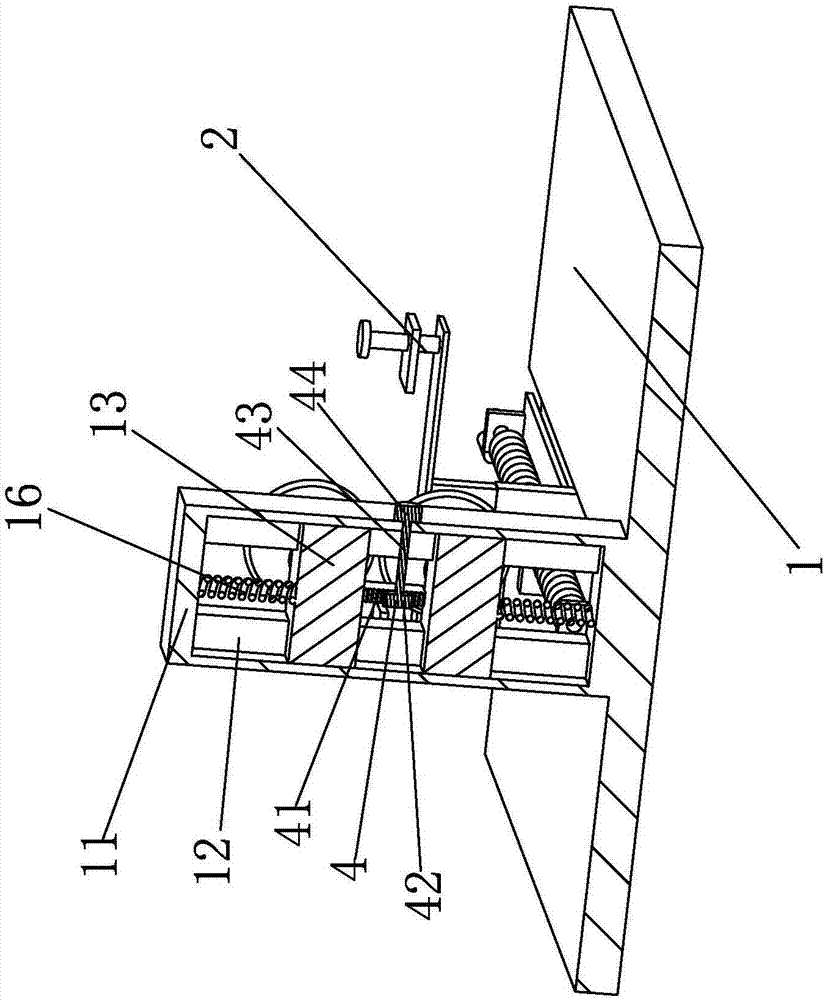

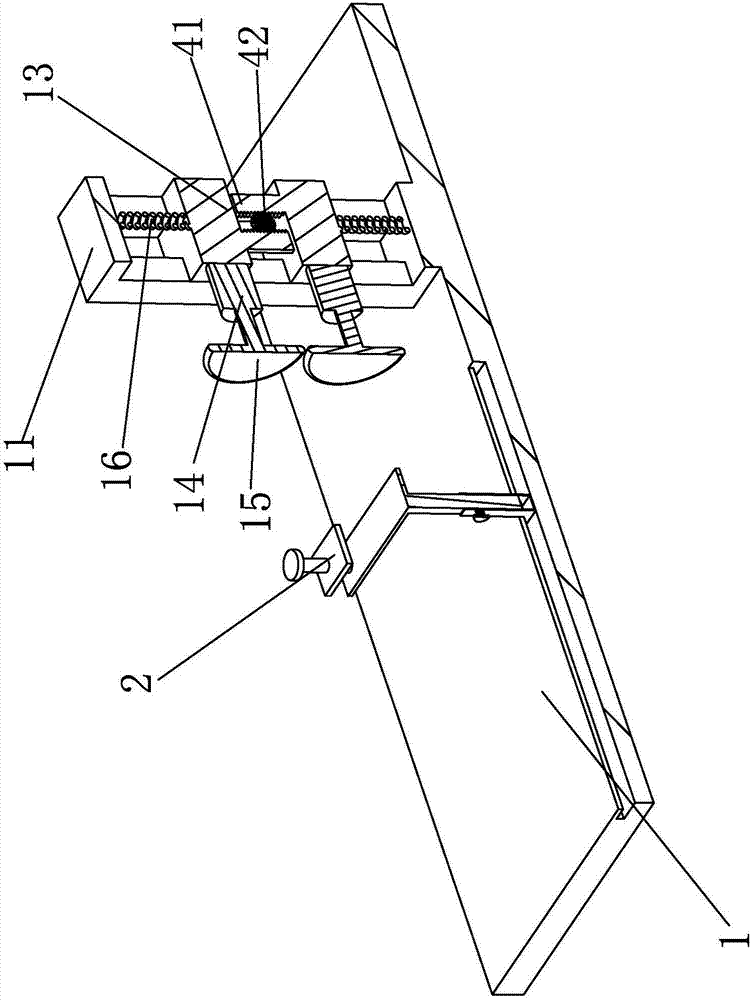

[0017] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

[0018] Such as Figures 1 to 3 The shown tool grinding equipment with good grinding effect includes a fixed seat 1, a fixed rod 11 is arranged on the fixed seat 1, and a moving groove 12 is arranged in the fixed rod 11. Symmetry is respectively provided with moving block 13 in the moving groove 12 of described moving block 13 front ends and is provided with motor 14, and is provided with grinding wheel 15 on the motor shaft of described motor 14, and between described moving block 13 and fixed bar 11 is provided with a push spring 16 that can push the moving block 13 toward the middle of the moving groove 12, and an adjustment device 4 that can adjust the distance between the two moving blocks 13 is provided between the two moving blocks 13. The fixing seat 1 at the front end of the grinding wheel 15 is provided with a fixing device 2 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com