Method for adjusting pre-tightening force of angular contact bearing of indexing mechanism of positioning and orientating system

An angular contact bearing and preload adjustment technology, which is applied in the field of machinery, can solve problems such as inability to ensure consistent rotation resistance of the positioning and orientation system frame, unstable product quality, and damage to angular contact bearings, achieving low cost, eliminating manufacturing errors and , the effect of reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

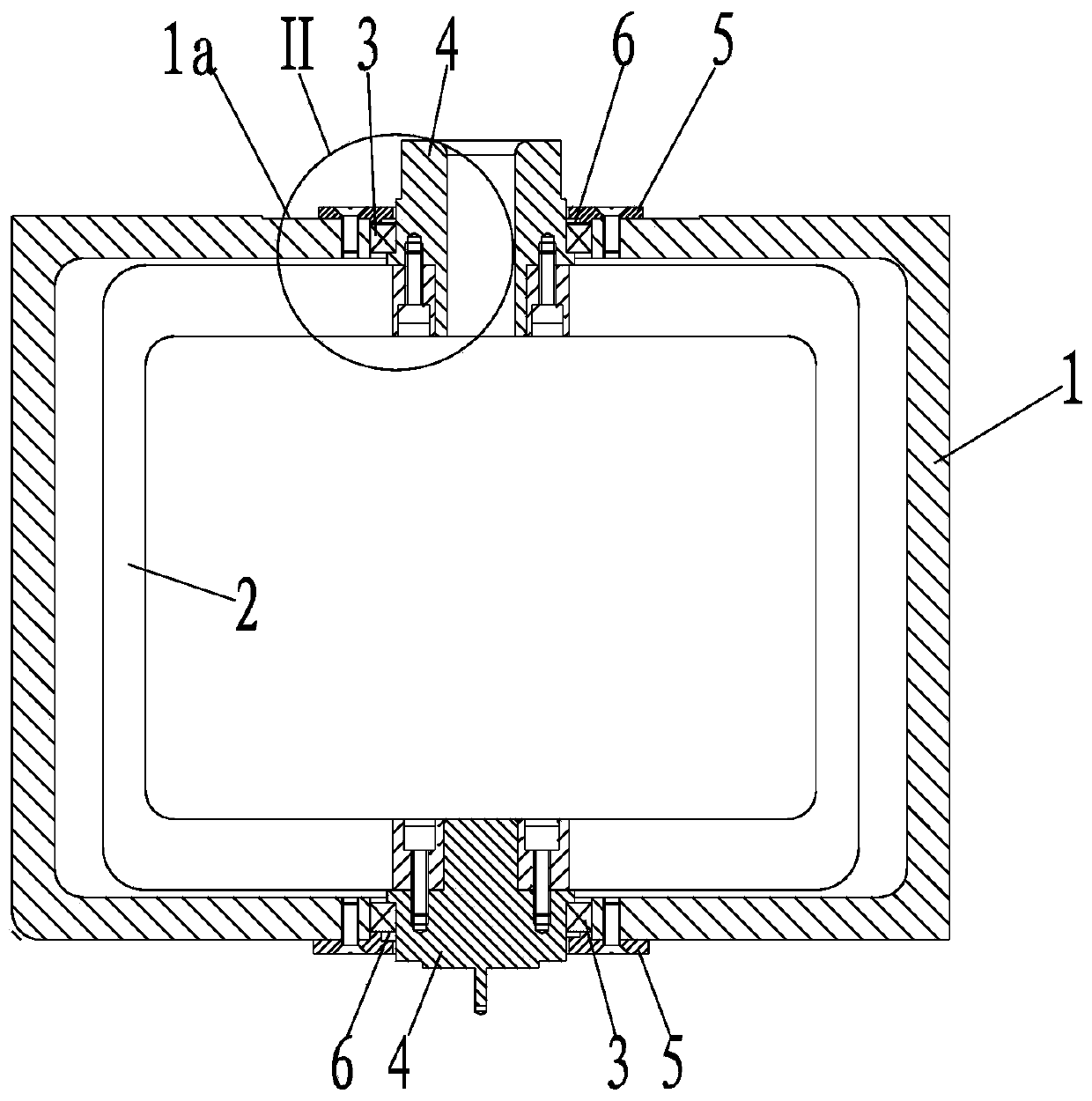

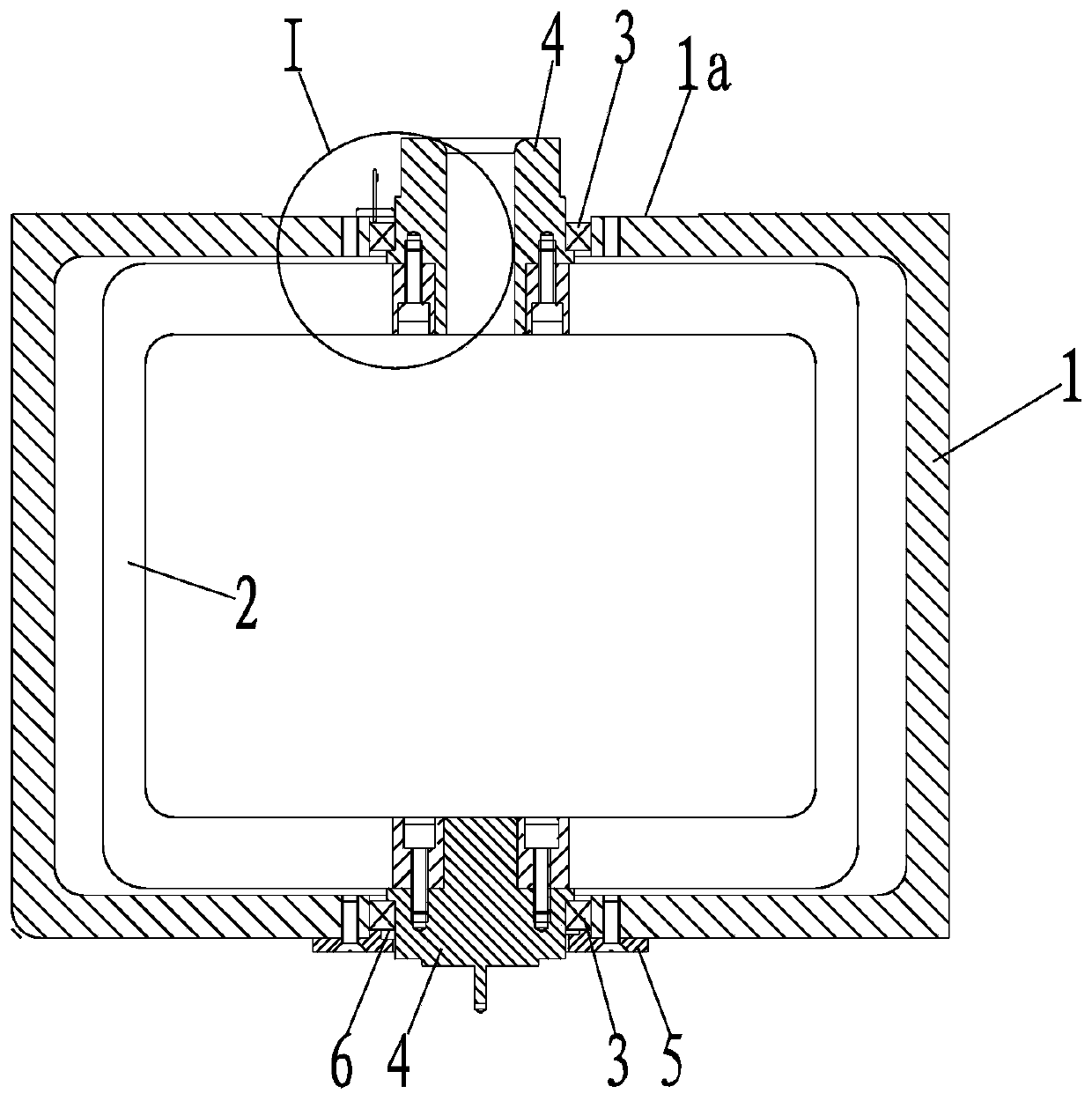

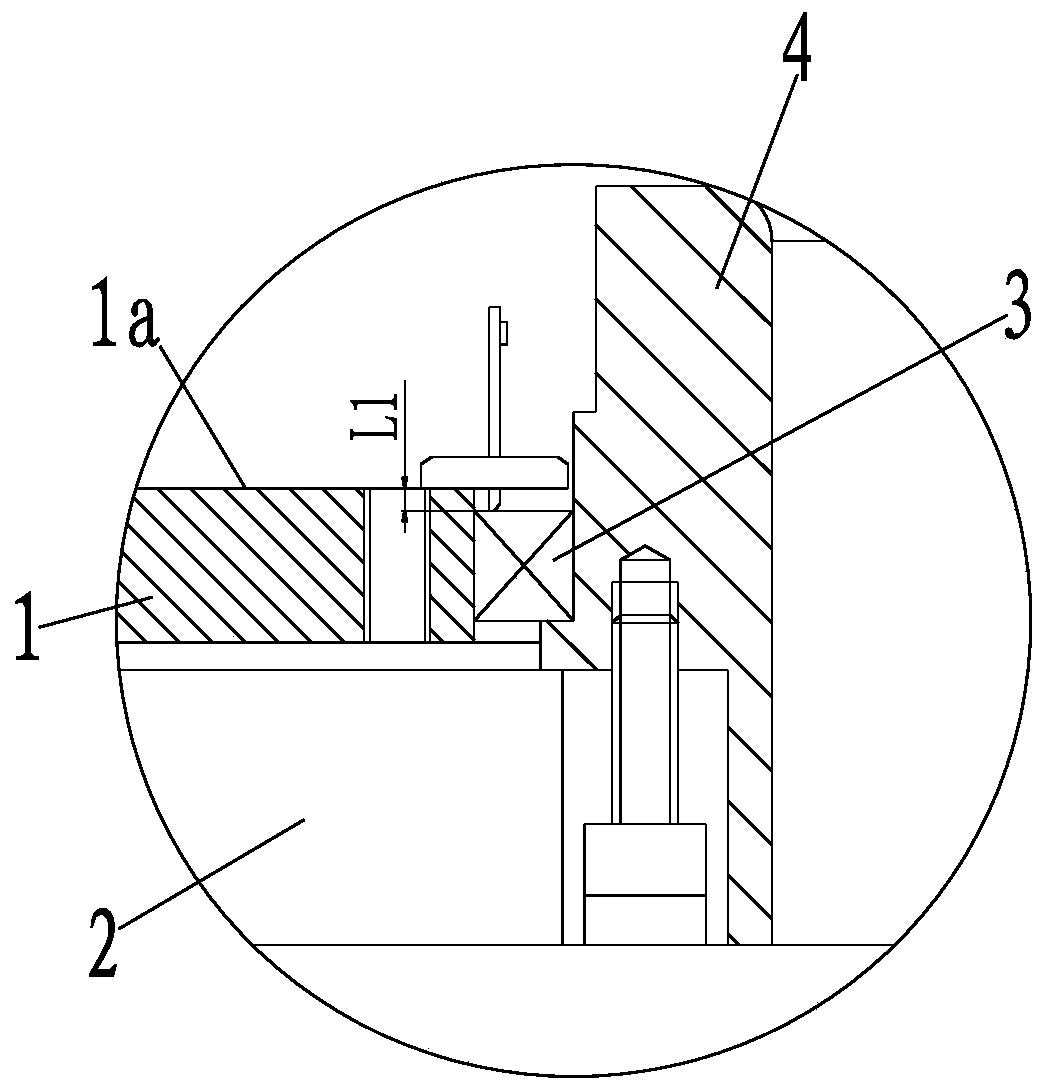

[0046] This embodiment provides a positioning and orientation system indexing mechanism angular contact bearing preload adjustment method, the positioning and orientation system indexing mechanism includes an outer frame 1 and an inner frame 2, the outer frame 1 and the inner frame 2 The angular contact bearing 3 and the rotating shaft 4 are flexibly connected between them, and a bearing end cover 5 is press-fitted on the outer frame 1 corresponding to the position of the angular contact bearing 3. The method for adjusting the preload of the angular contact bearing includes the following steps:

[0047] 1) Using a digital display depth micrometer to measure the height difference between the inner and outer rings at more than 3 different positions of the angular contact bearing 3 and taking the average value to obtain h;

[0048]2) Using a digital display depth micrometer to measure the depth from the end surface of the outer ring of the angular contact bearing 3 to the mounting...

Embodiment 2

[0058] This embodiment provides a method for adjusting the pretightening force of the angular contact bearing 3 whose model is 7012C-2RS. The design reference value of the rotational static friction force M of the angular contact bearing 3 is 260g. In this embodiment, there are two angular contact bearings 3, and the preload adjustment method of the two angular contact bearings 3 is the same, and only the preload adjustment method of one angular contact bearing 3 is specifically described here. The indexing mechanism of the positioning and orientation system includes an outer frame 1 and an inner frame 2, the outer frame 1 and the inner frame 2 are flexibly connected through the angular contact bearing 3 and the rotating shaft 4, and the outer frame 1 corresponds to the The position of the angular contact bearing 3 is press-fitted with a bearing end cover 5, and the method for adjusting the pretightening force of the angular contact bearing comprises the following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com