Molded stator, molded electric motor, and air conditioner

A technology for molded stators and stators, which is applied in the fields of molded motors, air conditioners, and molded stators, and can solve problems such as difficult detection of rotor positions and motor inoperability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

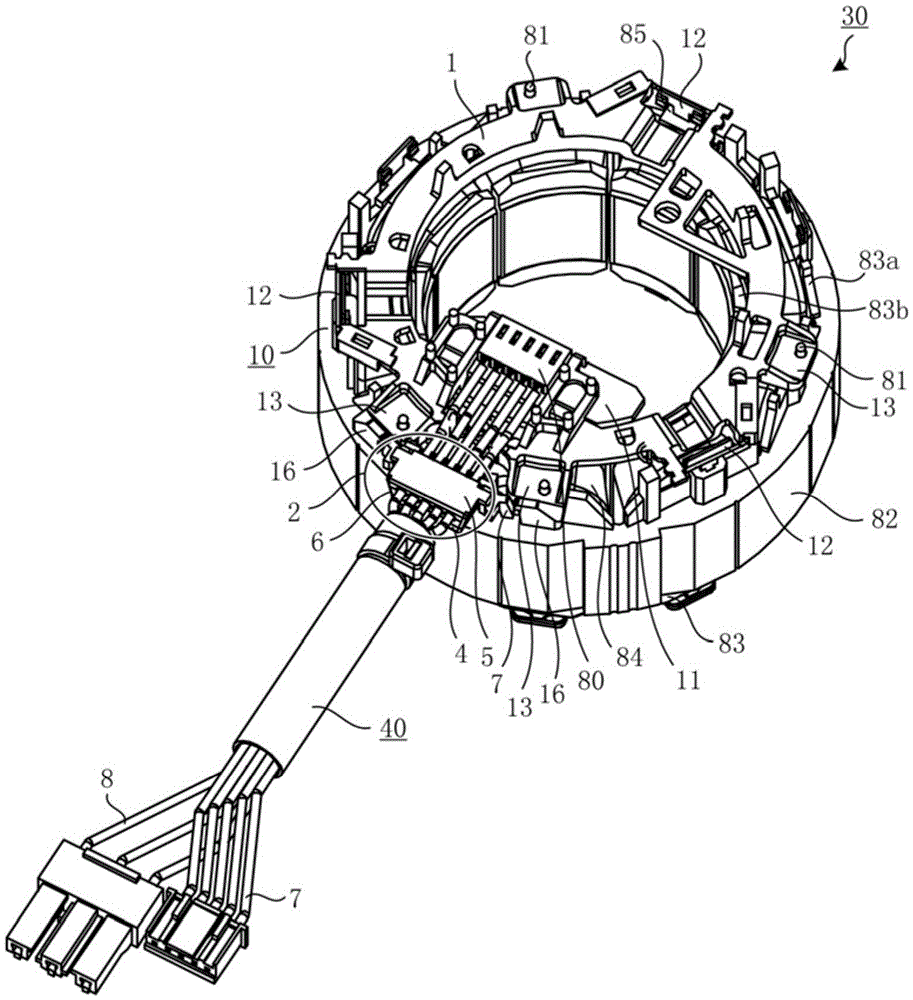

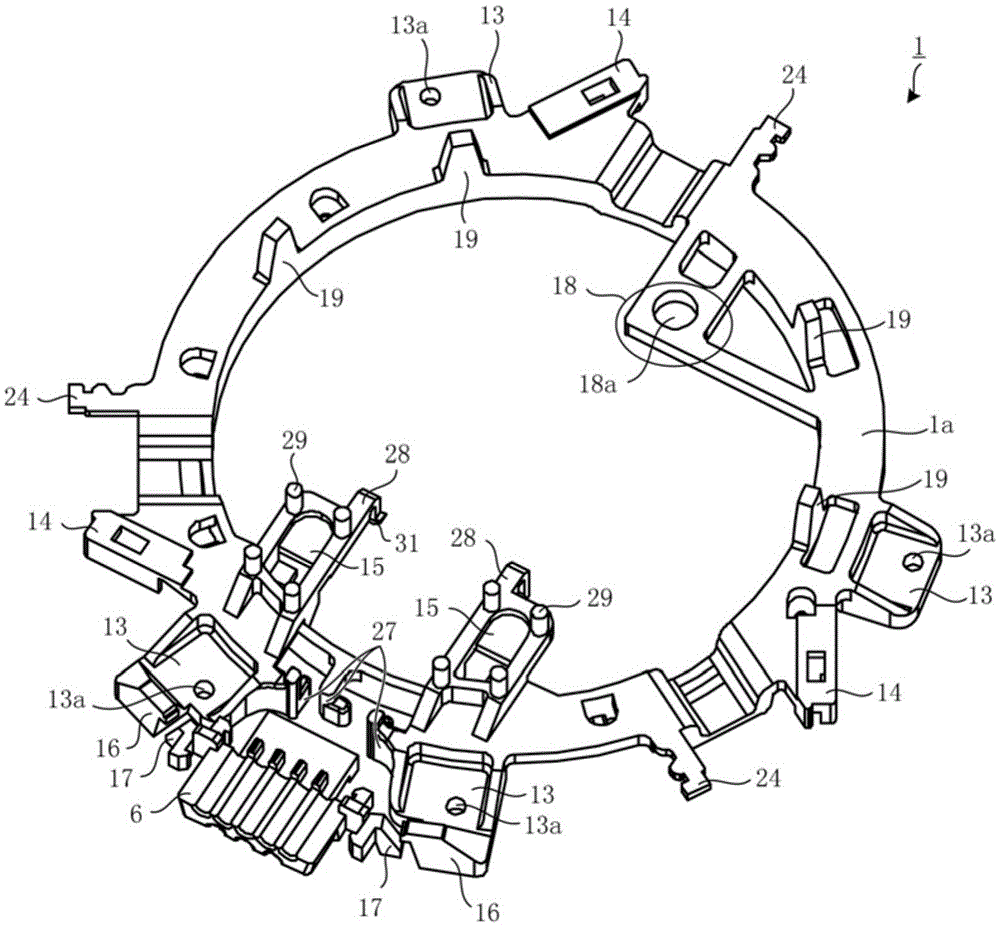

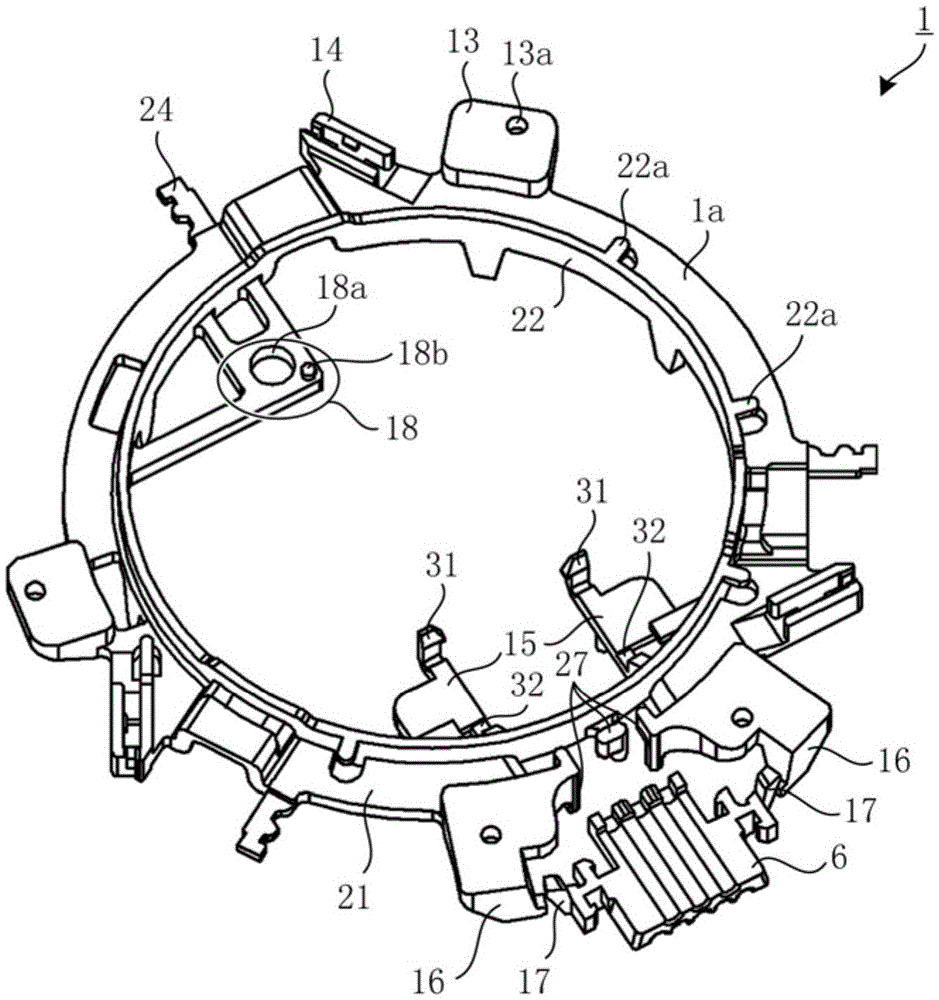

[0085] figure 1 It is a perspective view looking at the stator assembly of the electric motor concerning embodiment of this invention from the board|substrate side. figure 2 yes figure 1 A perspective view of the lead wiring assembly shown. image 3 It is viewed from the back (other side) figure 2 Perspective view of the wiring components shown. Figure 4 yes figure 2 An enlarged view of the lead wire terminal holding part of the lead wire wiring component shown. Figure 5 yes figure 2 This is an enlarged view of the lead-out member included in the lead wire wiring member and its surroundings. Image 6 yes figure 2 An enlarged view of the substrate holding portion and its surroundings included in the lead wiring component shown. Figure 7 is from with Image 6 An enlarged view of the substrate holder and its surroundings viewed from different directions. Figure 8 is a perspective view of the sensor substrate. Figure 9 It is a perspective view of the lead wire w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com