Radial locking floating cable

A floating and cable technology, applied in electrical components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of poor extrusion resistance of the structure, inflexible use, increased usage, etc., to increase the extrusion resistance , Stable structure, and improved anti-extrusion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

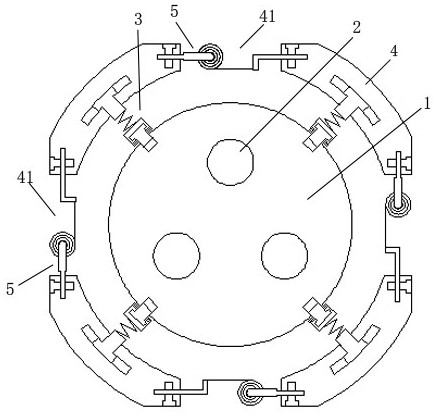

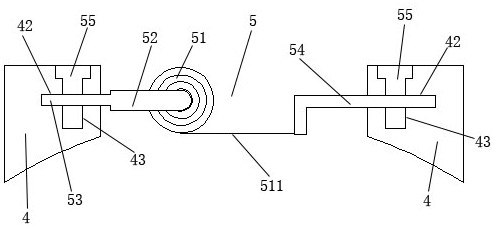

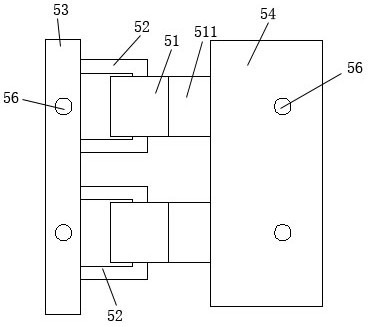

[0021] Such as Figures 1 to 4 As shown, a radially locked floating cable includes a cable inner core 1, a wire group 2, an outer shell 4, an expansion mechanism 5, and a radial locking mechanism 3; the cross section of the outer shell 4 is a ring structure; the cable The inner core 1 is installed in the inner center of the outer shell 4; a plurality of wire groups 2 are installed inside the inner core 1 of the cable; a plurality of radial locking mechanisms 3 are evenly installed around the inner periphery of the outer shell 4; the radial locking mechanism 3 includes a sliding plate 31, a spring 32, a connecting block 33, and a rotating screw head 34; the outer shell 4 is evenly provided with a plurality of arc-shaped engagement grooves 47; the inner sides of the arc-shaped engagement grooves 47 are respectively slid and engaged A sliding pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com