A quick-loading tool

A quick-installation and cutting tool technology, which is applied in the direction of drilling tool accessories, tool joints, manufacturing tools, etc., can solve the problems of poor installation convenience, low clamping accuracy, and poor rigidity of the tool body and tool handle, and achieve disassembly and assembly efficiency. High, high processing precision, strong rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

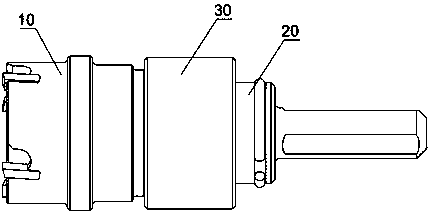

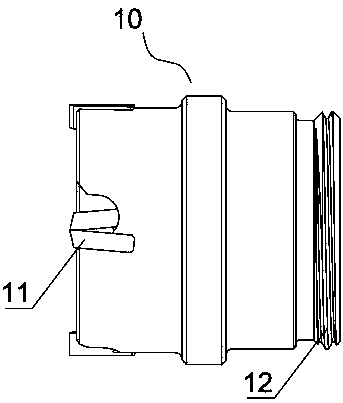

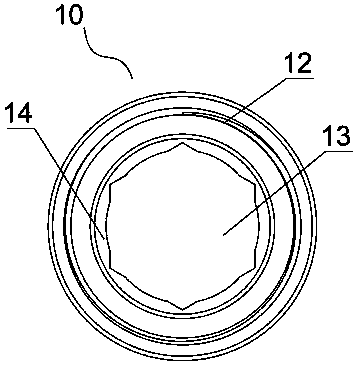

[0030] Such as figure 1 As shown, a quick-install tool in this embodiment includes a tool body 10 , a tool handle 20 and a fixing sleeve 30 . Such as figure 2 , image 3 As shown, one end of the cutter body 10 is provided with a cutting edge 11, and the other end is provided with an external thread 12, and one end of the cutter body 10 provided with the external thread 12 is provided with a connecting hole extending axially from the end face, and the connecting hole includes a column Shaped hole segment 14 and polygonal hole segment 13, and the inner diameter of the cylindrical hole segment 14 is not less than the circumscribed circle diameter of the polygonal hole segment 13, wherein the cylindrical hole segment 14 is located at the end of the cutter body near the external thread 12. It should be noted that the cross-section of the above-mentioned polygonal hole segment can be a polygonal hole that is equally or unequally divided, and the number of specific edges is not li...

Embodiment 2

[0037] Such as figure 1 As shown, a quick-install tool in this embodiment includes a tool body 10 , a tool handle 20 and a fixing sleeve 30 . Such as figure 2 , image 3 As shown, one end of the cutter body 10 is provided with a cutting edge 11, and the other end is provided with an external thread 12, and one end of the cutter body 10 provided with the external thread 12 is provided with a connecting hole extending axially from the end face. The cross-sectional outer contour includes at least an arc segment and a straight line segment. Correspondingly, as Figure 7As shown, one end of the handle 20 is provided with a connecting section 25 matching the connecting hole and a limiting boss 23 , the outer diameter of the limiting boss 23 is larger than the outer diameter of the circumscribed circle of the connecting section 25 .

[0038] Such as Figure 8 As shown, the cross-sectional outer profile of the connecting section 25 includes at least an arc segment 251 and a stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com