Cutting device for straightening and cutting machine

A cutting device and cutting machine technology, applied in the field of mechanical shearing mechanism, can solve the problems of cutting knife damage, jumping, frequent cutting knife replacement, etc., and achieve the effect of improving quality and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

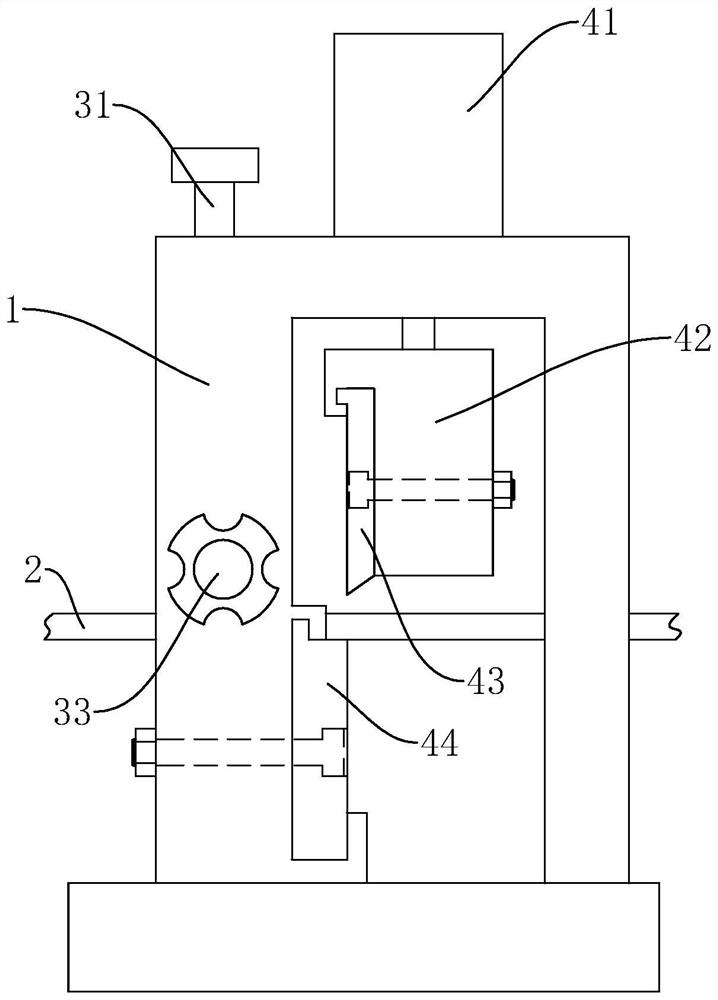

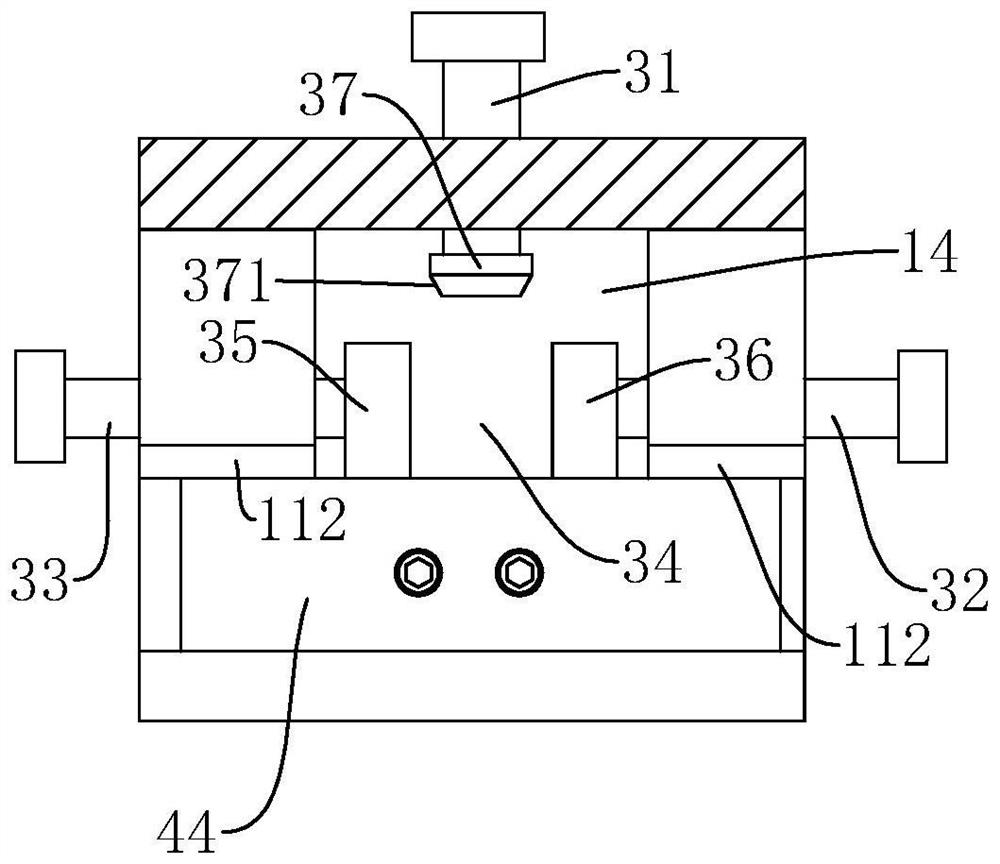

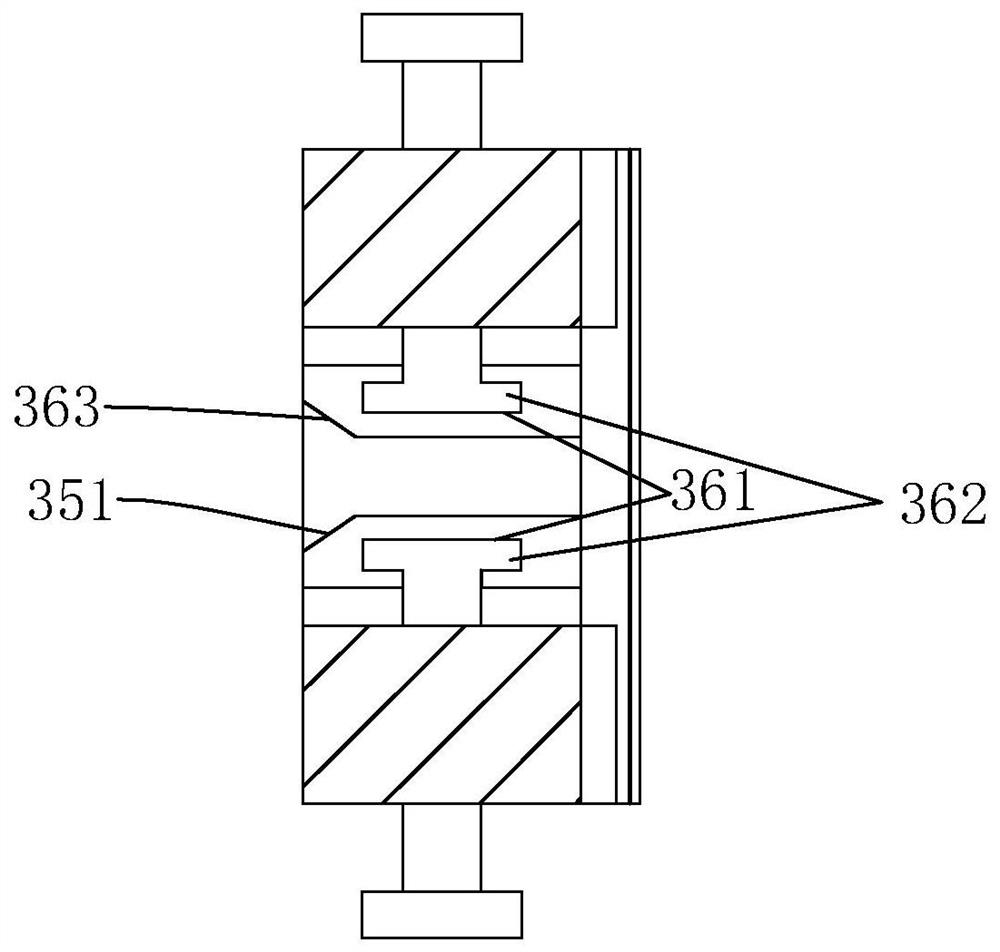

[0022] combine Figure 1 to Figure 5 The cutting device of the straightening and cutting machine of the present invention will be further described.

[0023] A cutting device for a straightening and cutting machine is characterized in that it includes a frame body 1, a workpiece limiting mechanism, a fixed knife 44 and a moving knife mechanism.

[0024] The frame body 1 includes a top plate 12 , vertical plates 11 and support columns 13 located on the left and right sides of the top plate 12 , and the vertical plate 11 has a workpiece channel 14 .

[0025] The workpiece limiting mechanism includes a left adjusting rod 32, a right adjusting rod 33 and an upper adjusting rod 31; On the right side wall and the top wall, and the first ends of the left adjusting rod 32, the right adjusting rod 33 and the upper adjusting rod 31 are all positioned in the workpiece channel 14 and form a limiting channel 34, and the second end is positioned at the outside of the vertical plate 11, Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com