An Axial Clearance Adjustment Structure at the High Temperature End of a Hall Thruster

A Hall thruster and axial clearance technology, applied in thrust reversers, machines/engines, and the use of plasma, etc., can solve the problems of insufficient compression resilience, difficult positioning, etc., to achieve easy assembly, reduce the number of parts, Achieve the effect of radial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

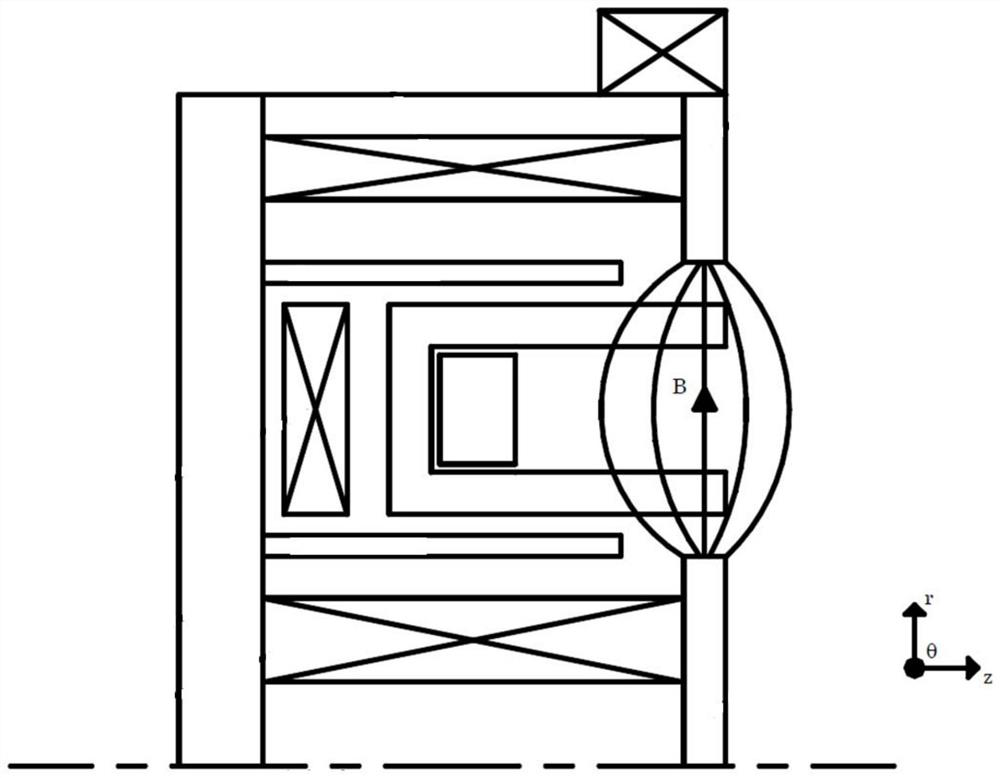

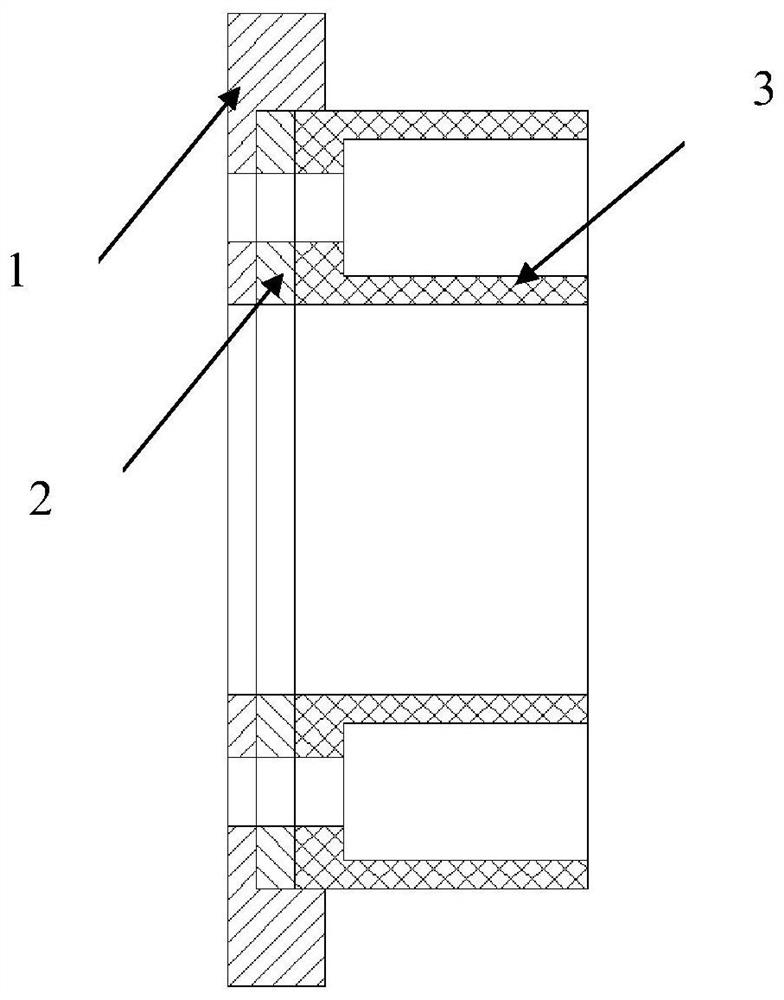

[0032] Such as Figure 3-9 As shown, an axial gap adjustment structure at the high temperature end of a Hall thruster of the present invention is composed of a metal base 1 , a metal rubber pad 2 and a ceramic channel 3 . The three parts are arranged coaxially, and the metal rubber pad 2 is fixed in the groove of the metal base 1 . The three realize stable and reliable connection with other parts in the Hall thruster through screws.

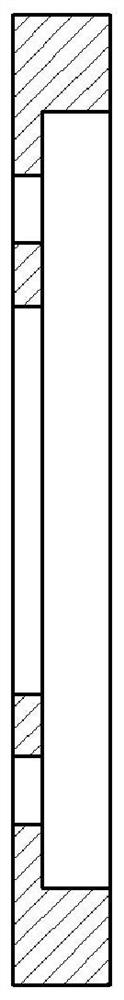

[0033]The metal base 1 is a ring structure, including a first cylindrical surface, a second cylindrical surface, a third cylindrical surface, a first end surface, a second end surface and a third end surface. The first cylindrical surface is the cylindrical surface with the largest diameter in the metal base 1, and its diameter is D1. The third cylindrical surface is the cylindrical surface with the smallest diameter in the metal base 1, and its diameter is D3. The diameter of the second cylindrical surface is D2. The relationship among D1, D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com