Assembled offshore single-pile foundation construction platform and construction process thereof

A single-pile foundation and construction platform technology, which is used in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of long construction period, poor horizontal force resistance, and construction of construction platforms for outrigger ships to be placed and withdrawn. To achieve the effect of convenient subsea fixation, easy adjustment and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

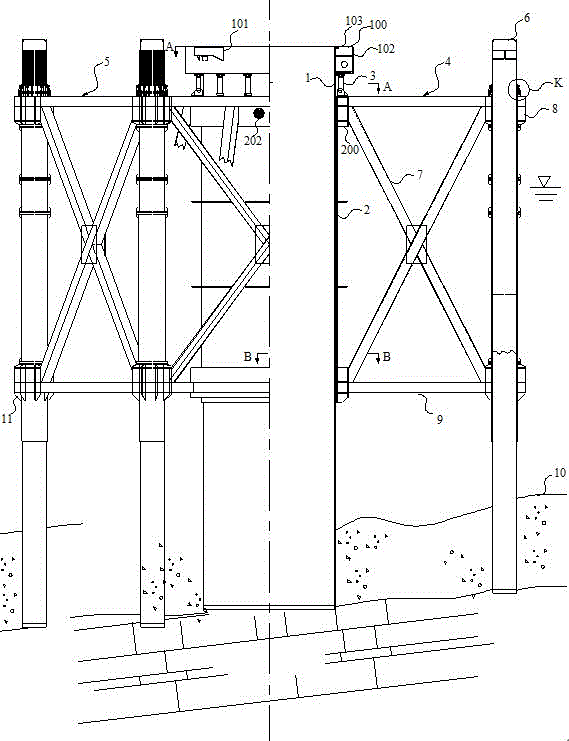

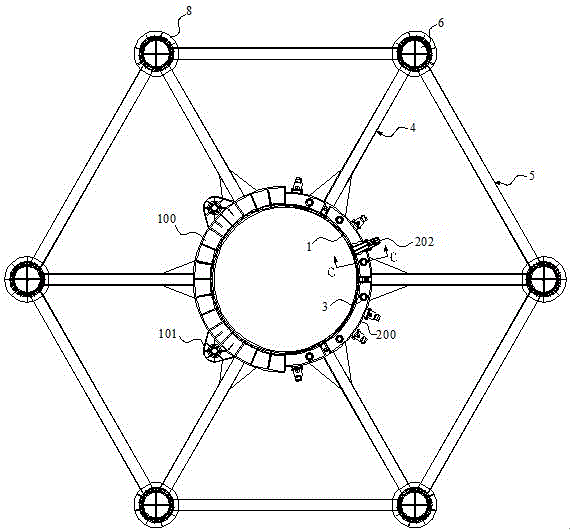

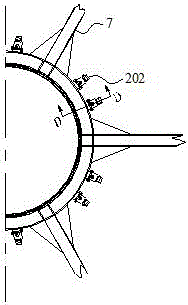

[0046] Such as Figures 1 to 6 As shown, an assembled offshore single-pile foundation construction platform includes a pile stabilization frame, a steel casing 1 and steel pipe piles 6, the center of the pile stabilization frame is provided with a positioning cylinder 2, and the outer uniform ring of the positioning cylinder 2 Set six installation sleeves 8, the installation sleeve 8 and the positioning cylinder 2 are fixedly connected through the radial truss 4, and the adjacent installation sleeves 8 are fixedly connected through the circumferential truss 5, the above-mentioned positioning cylinder 2, The installation sleeve 8, the radial truss 4 and the circumferential truss 5 together form a pile stabilizer. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com