Heat Treatment Technology of Large-scale Turbine Upper Crown Castings

A technology for water turbines and castings, applied in the field of large-scale water turbine processing, can solve the problems of small stress and difficult heat treatment of the upper crown, and achieve the effect of small stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

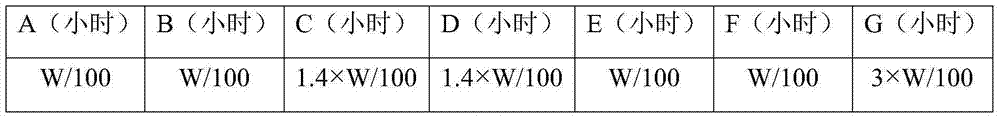

[0028] Take crowning for production of a hydropower station as an example:

[0029] Material: ZG06Cr13Ni5Mo;

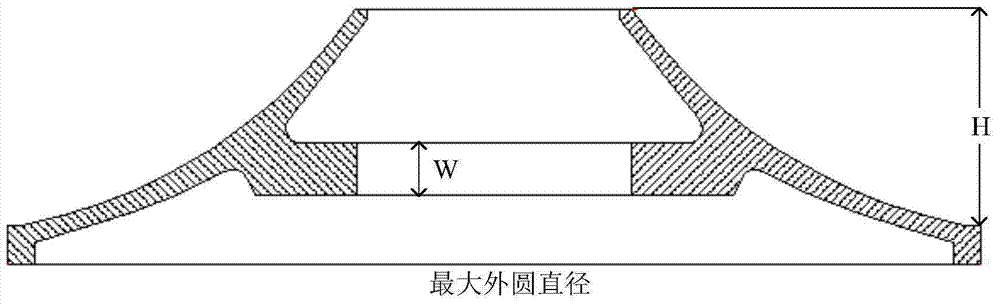

[0030] Crown Size: Maximum Outer Circle Diameter Height H=2445.2, W=500, H, W unit is mm.

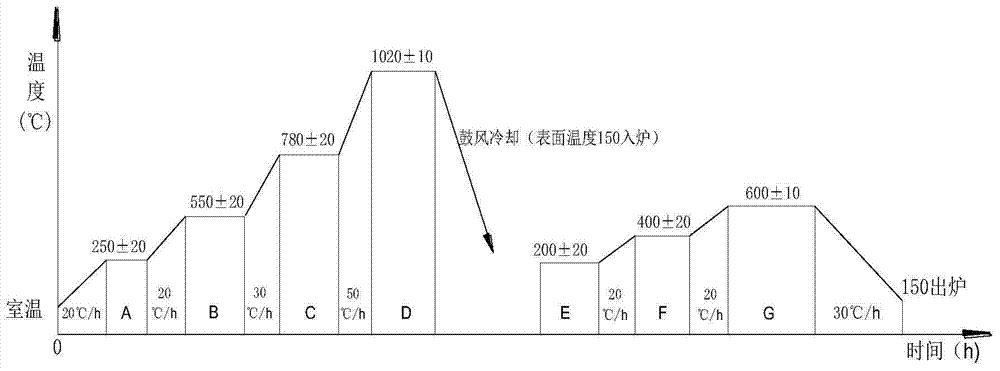

[0031] The crown heat treatment process is as follows:

[0032] 1) Select a trolley furnace with a trolley furnace surface size of 10m×10m;

[0033] 2) Furnace loading: install the upper crown after cleaning the molding sand on the furnace surface of the trolley, and support it with pad iron to ensure that the distance between the largest outer circular bottom surface of the upper crown and the furnace surface of the trolley is not less than 800mm, and the support of the upper crown casting There are no less than 5 points, and they are evenly distributed along the circumferential direction. There must be no overhead support points to prevent the deformation of the upper crown and ensure a good circulation of the furnace gas; then install four blowers around the furnace surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com