Permeable concrete based on coal gangue and preparation method thereof

A technology of permeable concrete and coal gangue, applied in the field of building materials, can solve the problem of not using coal gangue at the same time, and achieve the effects of saving natural crushed stone and cement resources, increasing binding capacity and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

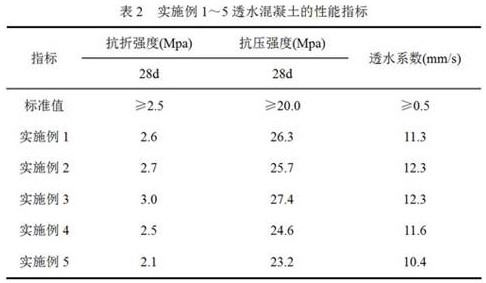

[0036] The ratio of raw materials used to prepare permeable concrete in Examples 1-5 of the present invention is shown in Table 1.

[0037]

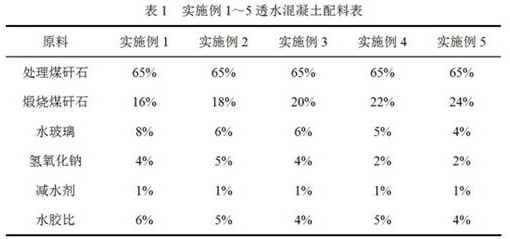

[0038] After testing, the flexural strength, compressive strength and water permeability coefficient measurement data of the permeable concrete test blocks prepared in Examples 1-5 after 28 days of standard curing are shown in Table 2.

[0039]

[0040] It can be seen from Table 2 that the flexural strength, compressive strength, and water permeability coefficient of the permeable concrete prepared in Examples 1 to 5 of the present invention are all within the standard value range compared with the standard value of permeable concrete for construction, and meet the standard for construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com