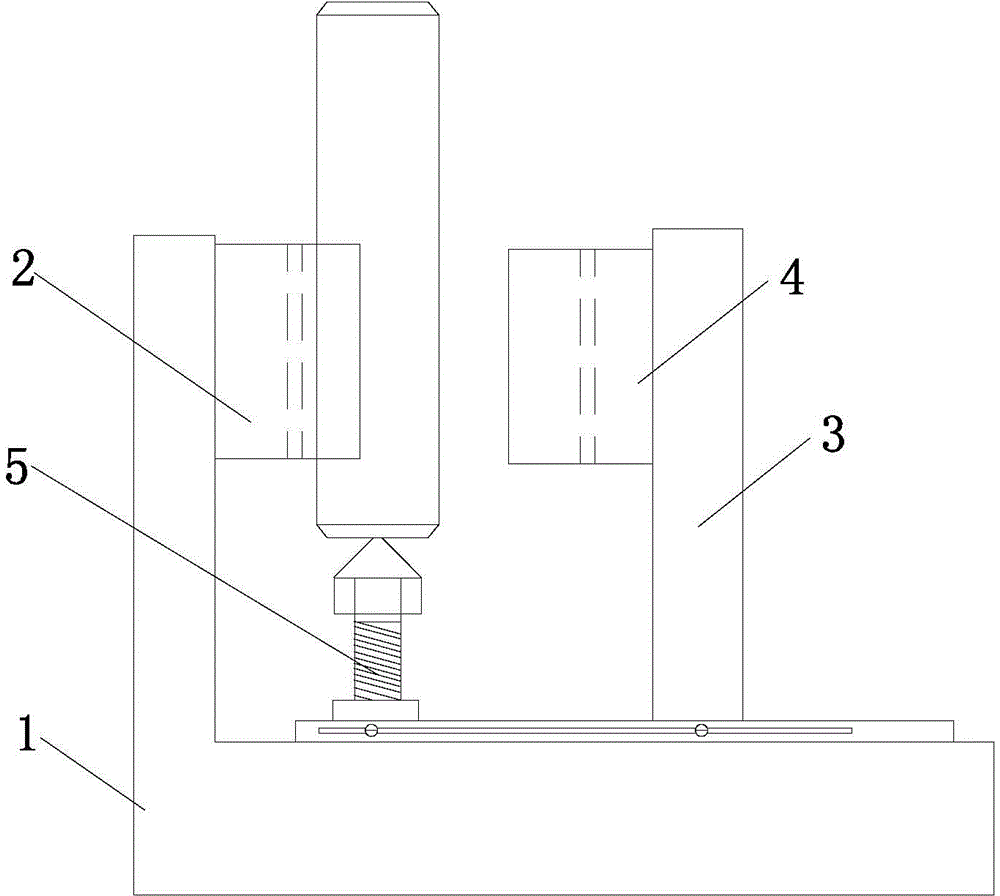

Large-outer-diameter pin clamp

A technology with large outer diameter and pin shaft, applied in the field of mechanical clamping, can solve the problems of pin shaft runout, error, clamping difficulty, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

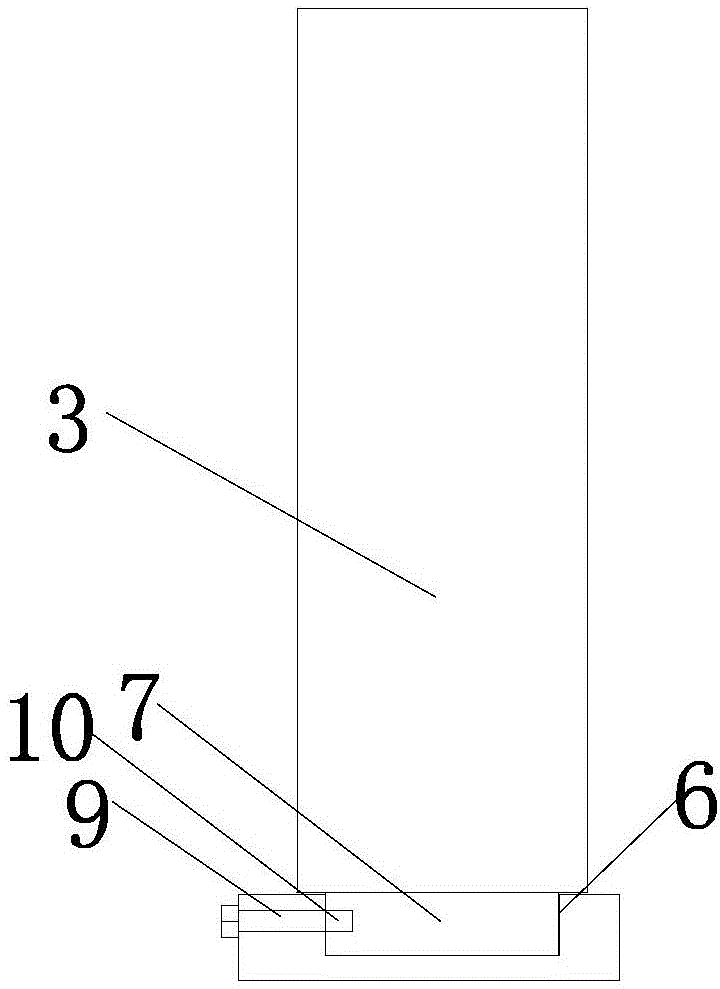

Embodiment 2

[0016] The side wall of the chute is provided with strip slots 9 along the length direction. By arranging the bar-shaped slots and cooperating with the bolts, when it is necessary to lock the positions of the first and second sliders, it is only necessary to tighten the bolts so that the ends of the bolts are against the first and second sliders.

Embodiment 3

[0018] A first screw hole 10 used in conjunction with a bar-shaped slot is provided on the side wall of the first slide rail. By providing the first screw hole, when it is necessary to lock the positions of the first and second sliders, it is only necessary to screw the screw into the first screw hole, and the screw connection is relatively stable.

Embodiment 4

[0020] A second screw hole used in conjunction with the bar-shaped slot is provided on the side wall of the second slide rail. By providing the second screw hole, when it is necessary to lock the positions of the first and second sliders, it is only necessary to screw the screw into the second screw hole, and the screw connection is relatively stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com