Nonlinear large-aperture optical element clamping device capable of achieving definite value axial load application

A technology for optical components and axial loads, which is applied in workpiece clamping devices, optical components, optics, etc., can solve the problems of harmonic conversion efficiency drop and deformation, and achieve the effect of improving harmonic conversion efficiency and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

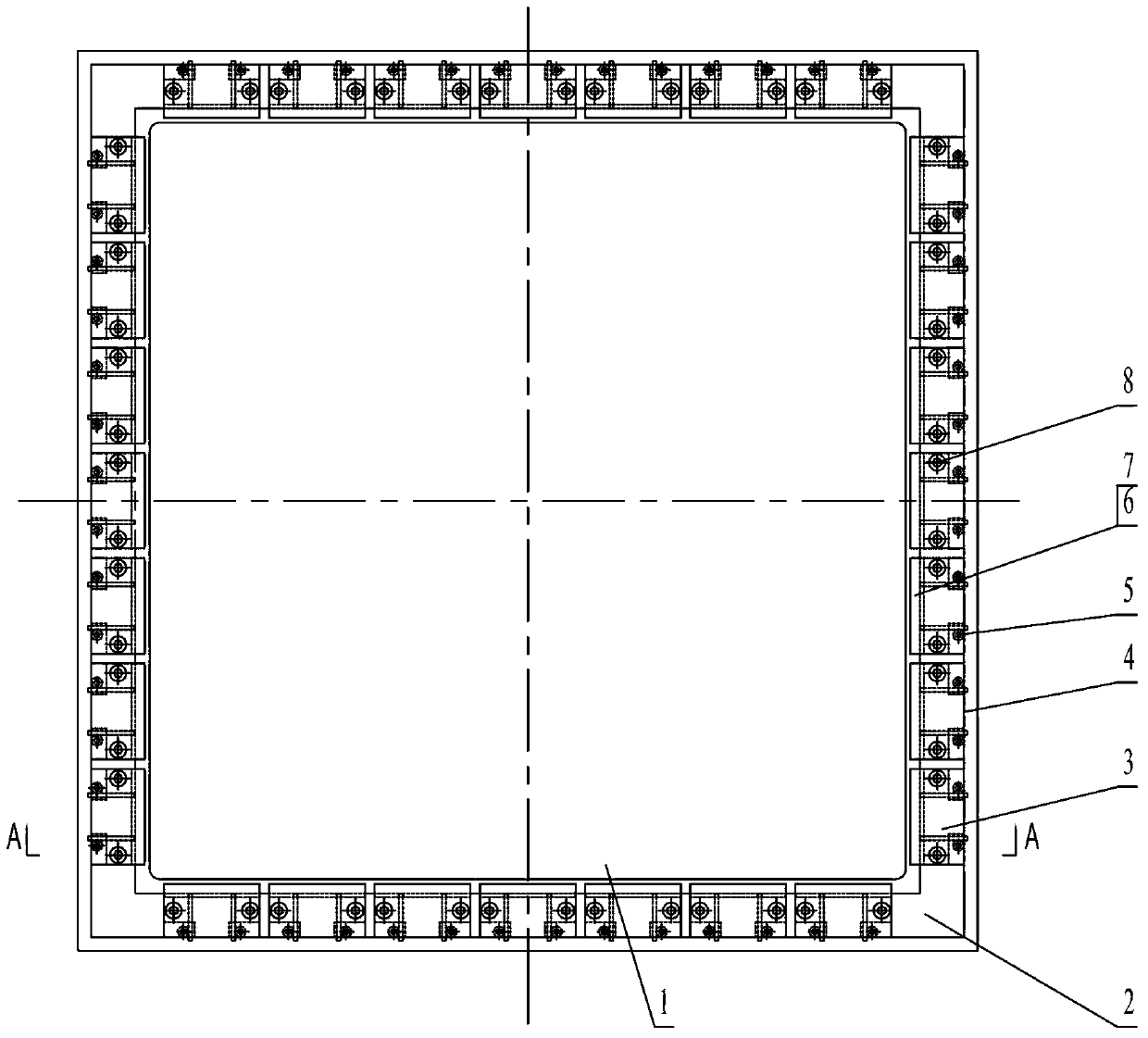

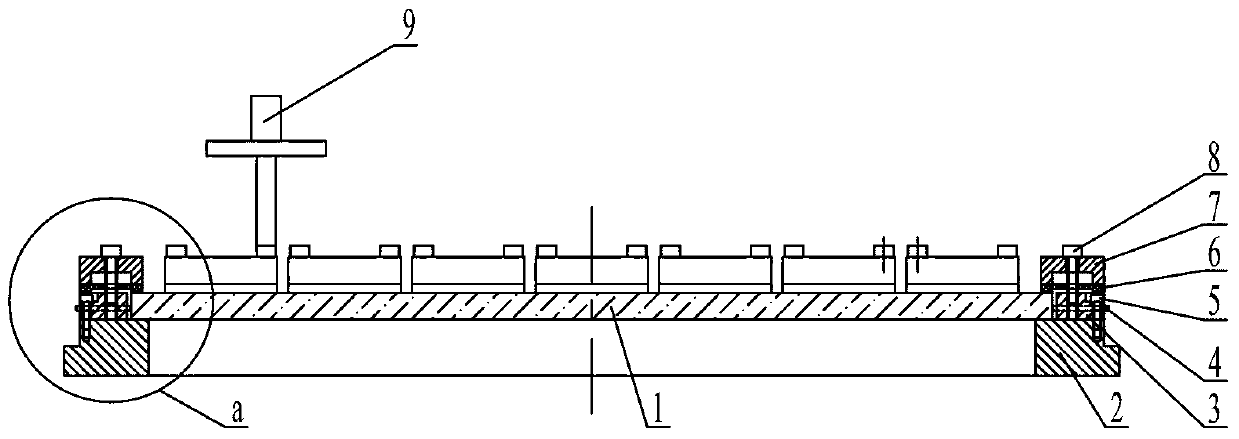

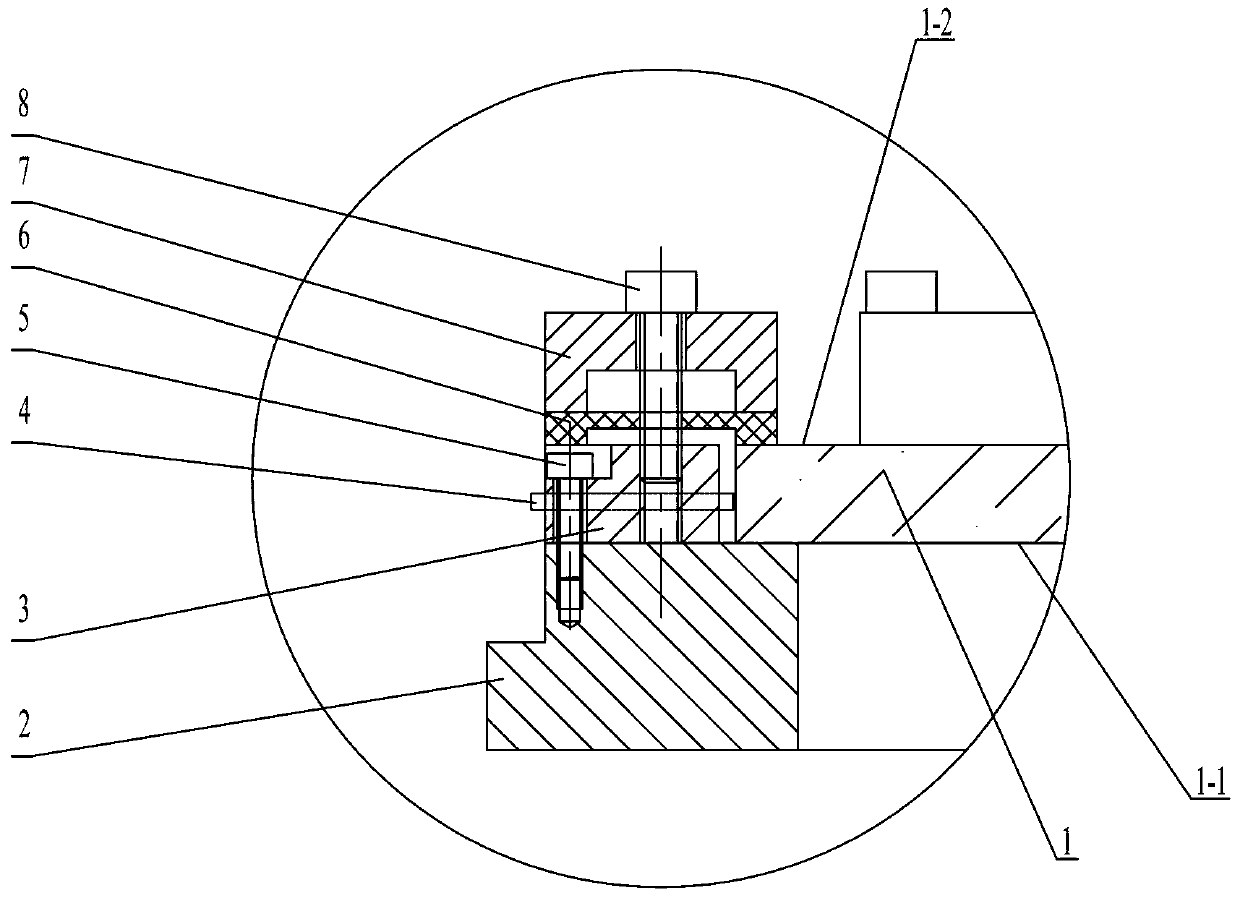

[0011] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment. The clamping device for nonlinear large-aperture optical elements that realizes the application of a constant axial load in this embodiment includes a support frame 2, a plurality of positioning edge blocks 3, a plurality of rubber nails 4, and a plurality of elastic pressure pieces 6 , a plurality of rigid pressing pieces 7, a plurality of loading screws 8 and a torque wrench 9, the nonlinear large-aperture optical element 1 is placed on the support frame 2, and the backlight surface 1-1 of the nonlinear large-aperture optical element 1 is surrounded by the support Frame 2 contacts, and the support frame 2 supports it within a certain range around the backlight surface of the nonlinear large-diameter optical element 1 to realize the axial positioning of the nonlinear large-diameter optical element 1; multiple positioning devices are installed around the support frame 2 Side blocks...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 2 The present embodiment will be described. The torque wrench 9 of the present embodiment is a dial-type torque wrench. Such setting facilitates the one-to-one correspondence between the torque of the torque wrench and the axial force of the applied screw, and through the fixed value torque output of the torque wrench, the fixed value axial load application of the nonlinear large-diameter optical element is realized. Other compositions and connections are the same as in the first embodiment.

[0013] The dial-type torque wrench in the above embodiment can be a torque wrench with a model number of FTD2CN-S and an accuracy of 3% produced by Tohnichi Corporation of Japan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com