Patents

Literature

53results about How to "Guaranteed Position Accuracy Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

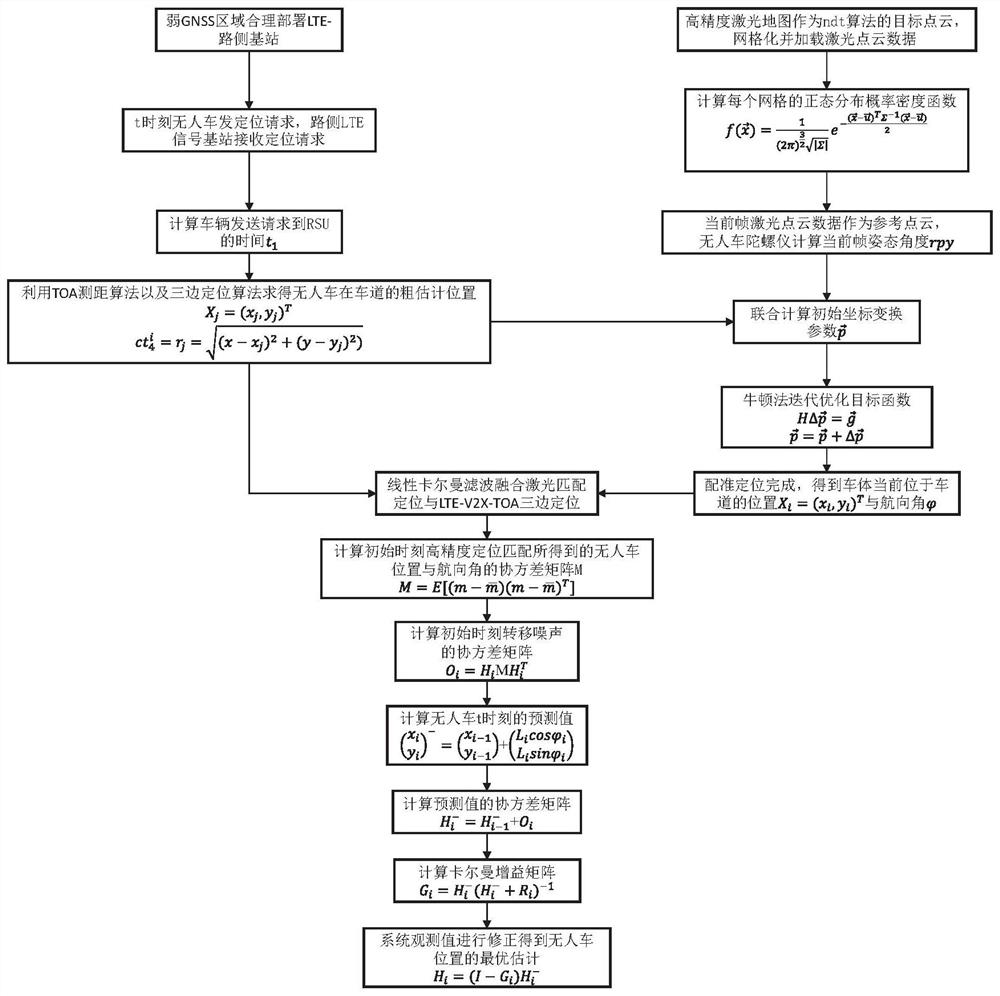

Vehicle integrated positioning method for advanced automatic driving V2X and laser point cloud registration

ActiveCN111949943AAlleviate positioning problemsLower deployment costsParticular environment based servicesNavigation by speed/acceleration measurementsPoint cloudRadar

The invention discloses a vehicle integrated positioning method for advanced automatic driving V2X and single vehicle laser radar point cloud feature matching and integration. The method comprises thesteps: enabling an unmanned vehicle to obtain the surrounding environment information in real time through a laser radar, and carrying out feature matching with an existing high-precision map, thereby achieving the local positioning of the vehicle on a lane; positioning the vehicle between the vehicle and a roadside LTE signal base station through an LTEV2X vehicle networking technology and a wireless positioning technology; by fully fusing the two positioning modes, achieving more accurate vehicle-road cooperative positioning. The technical characteristics of laser radar high-precision map feature matching and positioning in single-vehicle intelligence and the advantages of vehicle-road wireless communication positioning are fully utilized, the positioning problem of the unmanned vehiclein a weak satellite signal coverage area can be effectively solved, and the purpose of advanced automatic driving is achieved.

Owner:BEIHANG UNIV

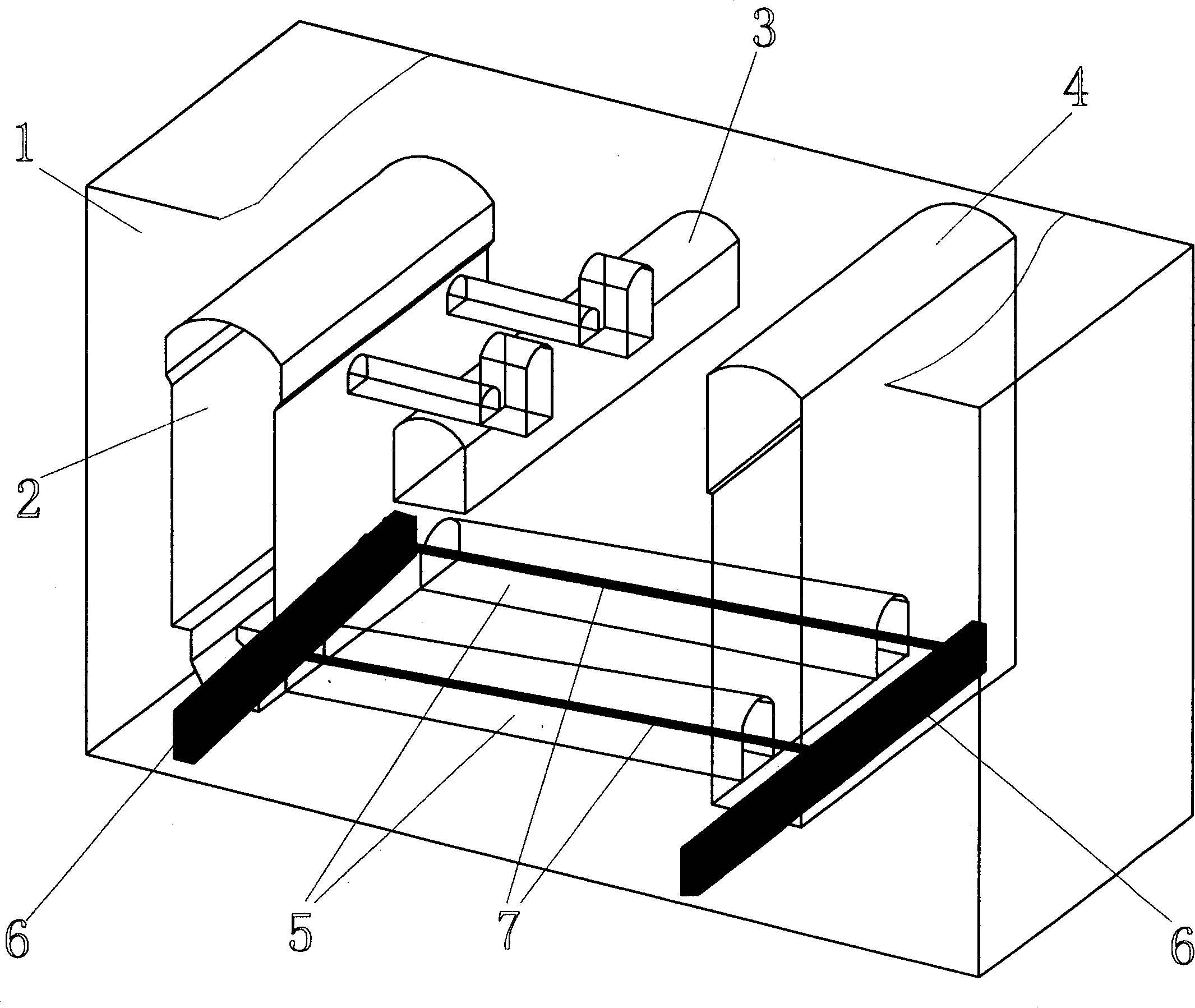

Method and special apparatus for excavation of concealed grotto in solid model test

InactiveCN1401861AAvoid severe distortionAvoid stressArtificial islandsFoundation testingThree stageEngineering

A method and special apparatus for excavating the concealed grotto in solid model experiment is disclosed. The axis marker shifted along with the preburied instrument is created in an absolute coordinate system. A locating method with three-stage transfer is used to convert the absolute locating system in absolute coordinate system to relative locating system. A special apparatus is desinged for excavation. Its advantages are eliminating the position error between concealed grotto and preburied instrument to maximum, and low cost.

Owner:TSINGHUA UNIV

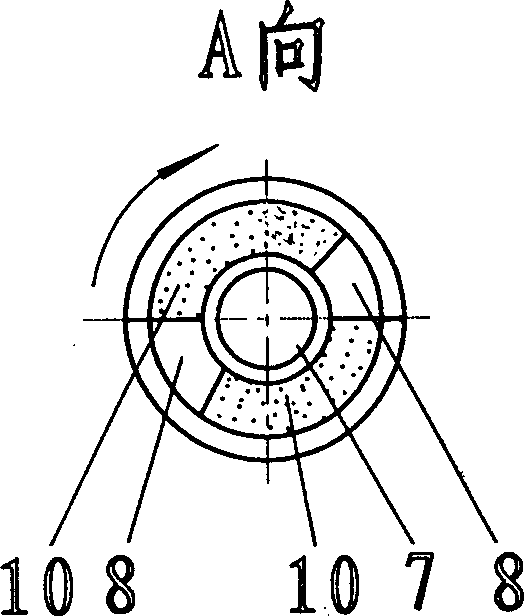

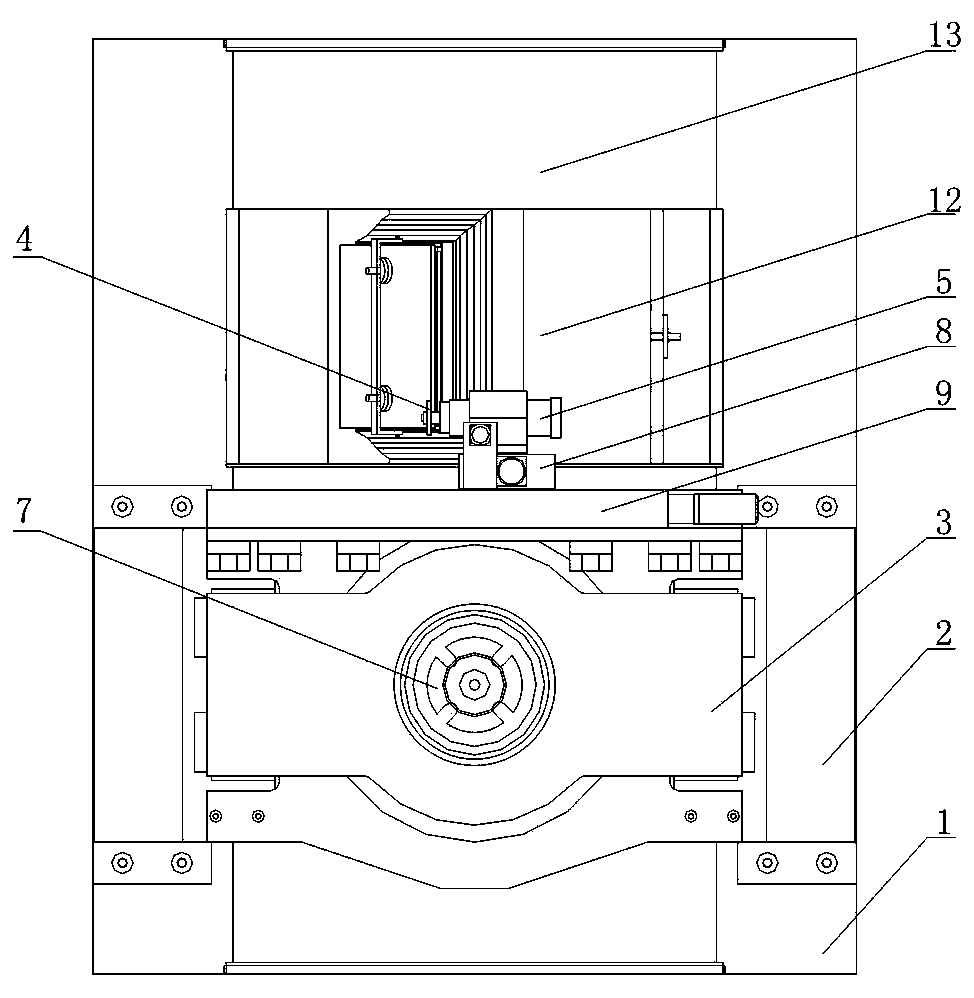

Angle workbench of high-precision combined tool

ActiveCN104551709AHigh precisionGuaranteed positioning accuracyLarge fixed membersPositioning apparatusEngineeringStructural engineering

The invention discloses an angle workbench of a high-precision combined too. The angle workbench of the high-precision combined tool comprises a lower foundation plate, an upper foundation plate, a supporting part and a connecting plate; the supporting plate is vertically fixed on the lower foundation plate; two lower V-shaped supporting blocks which have the same structure are arranged close to one side of the lower foundation plate; the supporting part comprises a rectangular supporting element and an upper V-shaped supporting block; the upper V-shaped supporting block is structured the same as the lower V-shaped supporting blocks, and a central line of the upper V-shaped blocking block is parallel to the center lines of the two lower V-shaped supporting blocks; three trimming shafts which have the same structure and are integrally connected with the upper foundation plate are arranged on one downward surface of the upper foundation plate; respectively positioned on the two lower V-shaped supporting blocks and one upper U-shaped supporting block. With the adoption of the structure above, the angle workbench of the high-precision combined tool has the advantages that the precision of the combined clamp is greatly improved; a plurality of surfaces of a workpiece can be processed and qualified by one-time positioning clamping, and therefore, the processing efficiency is increased, and the manufacturing cost is decreased.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

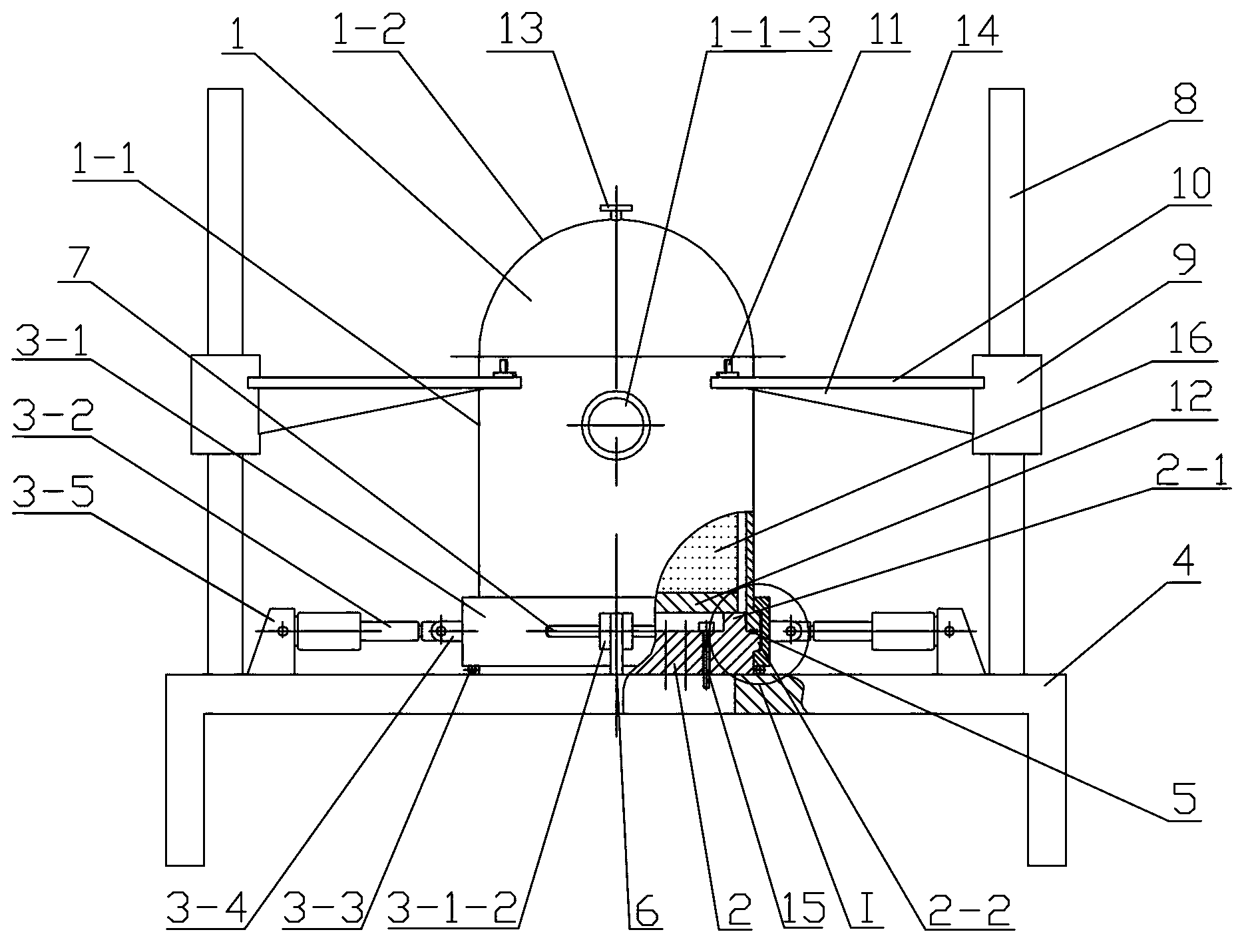

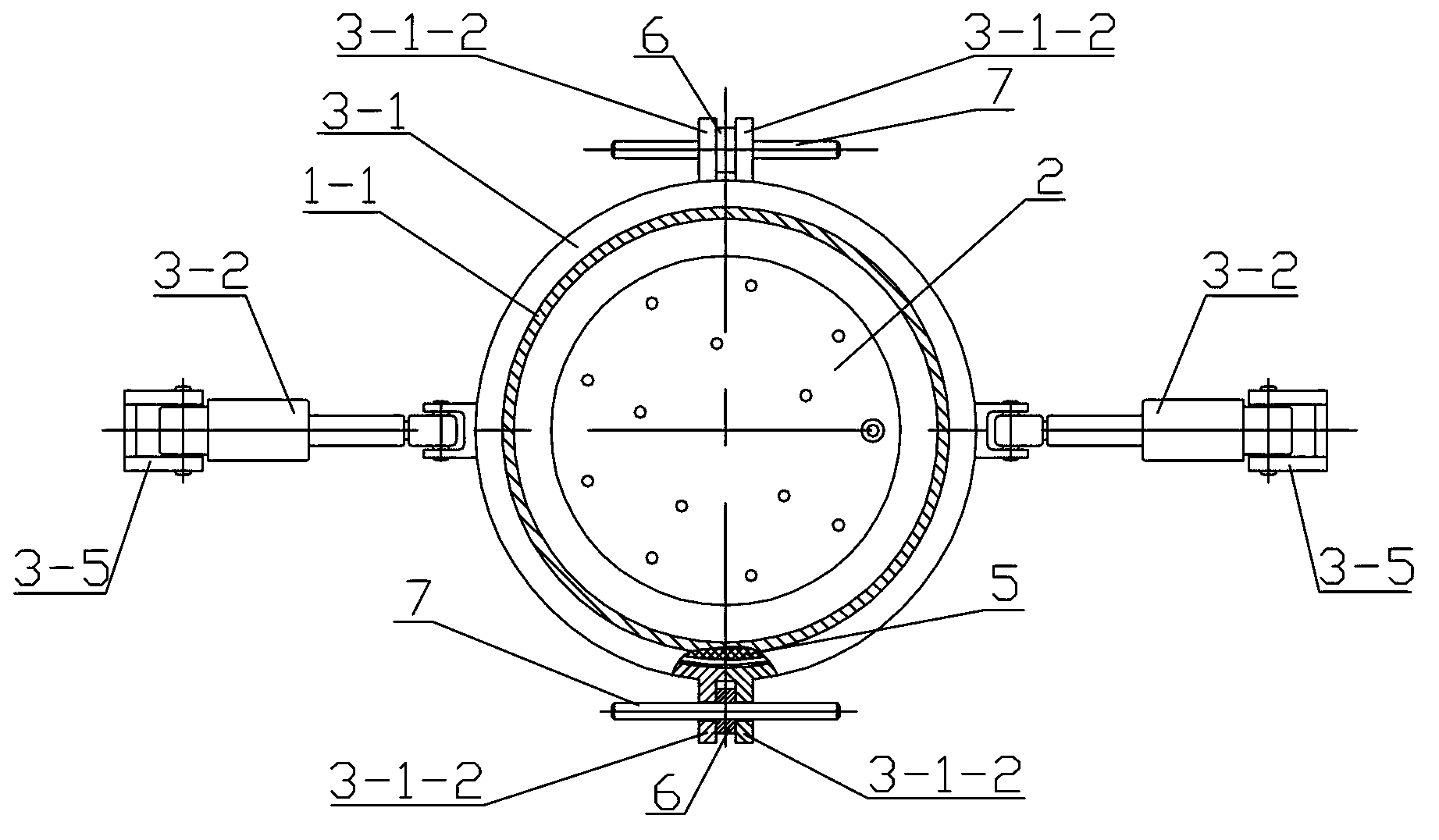

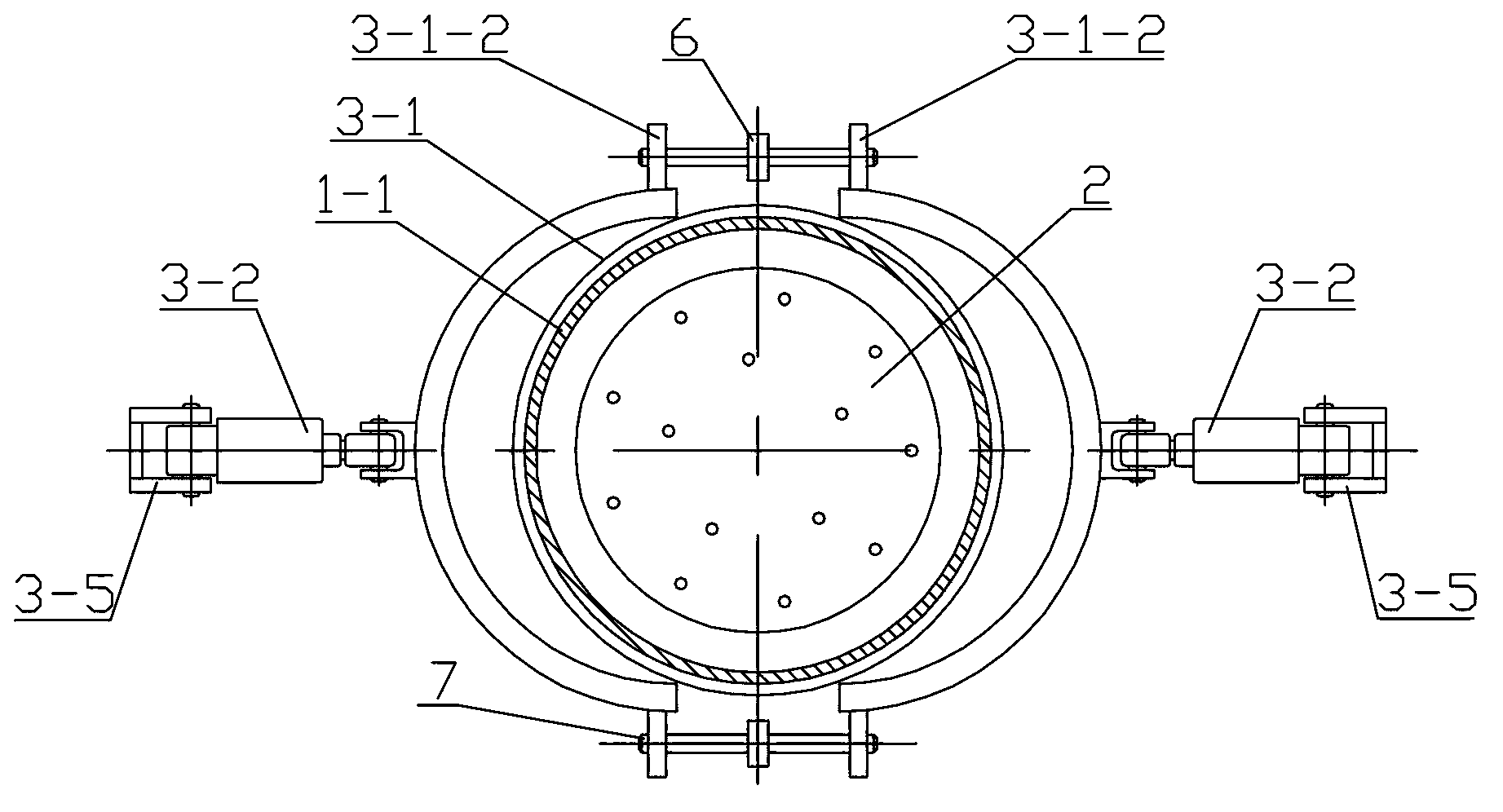

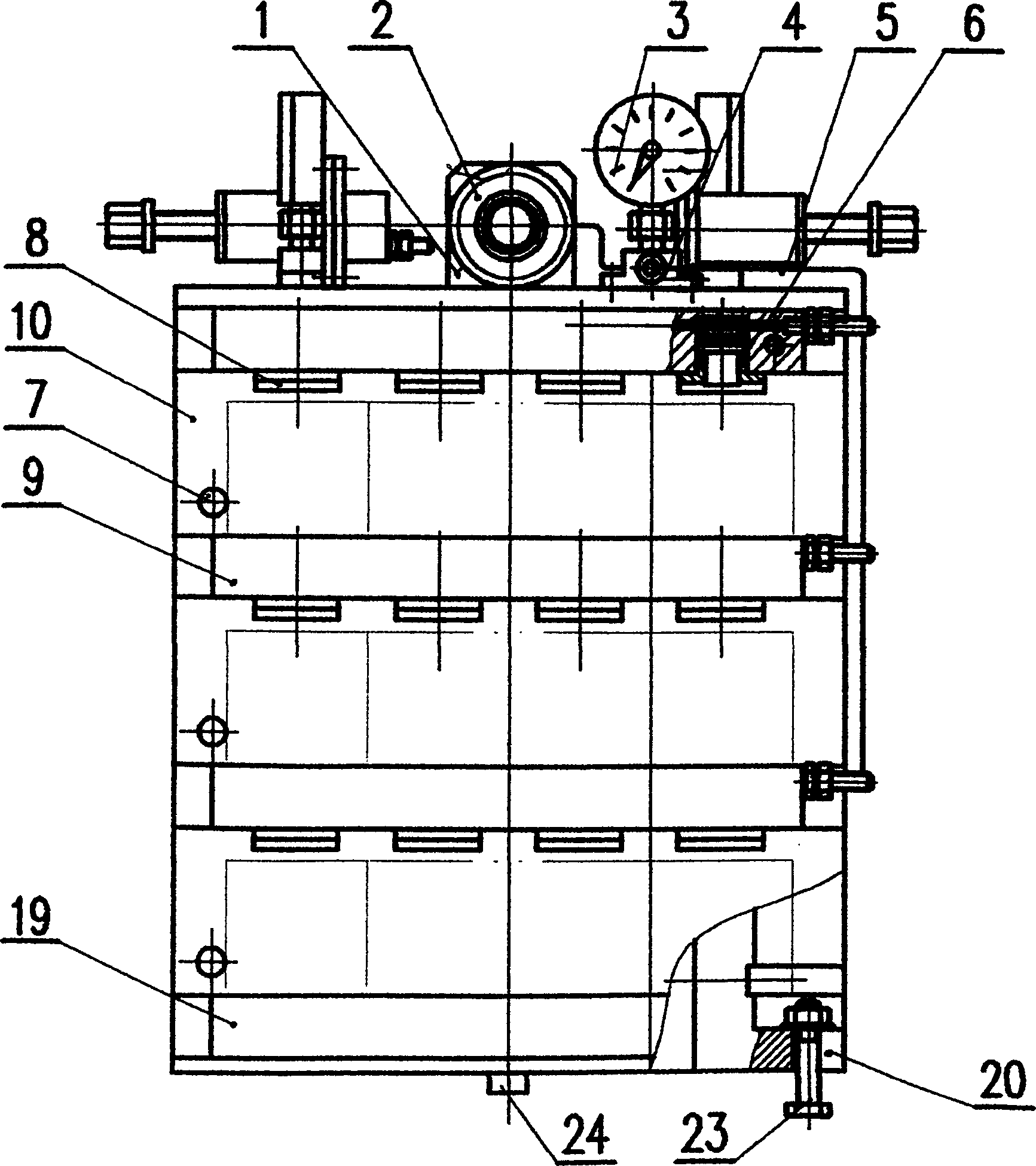

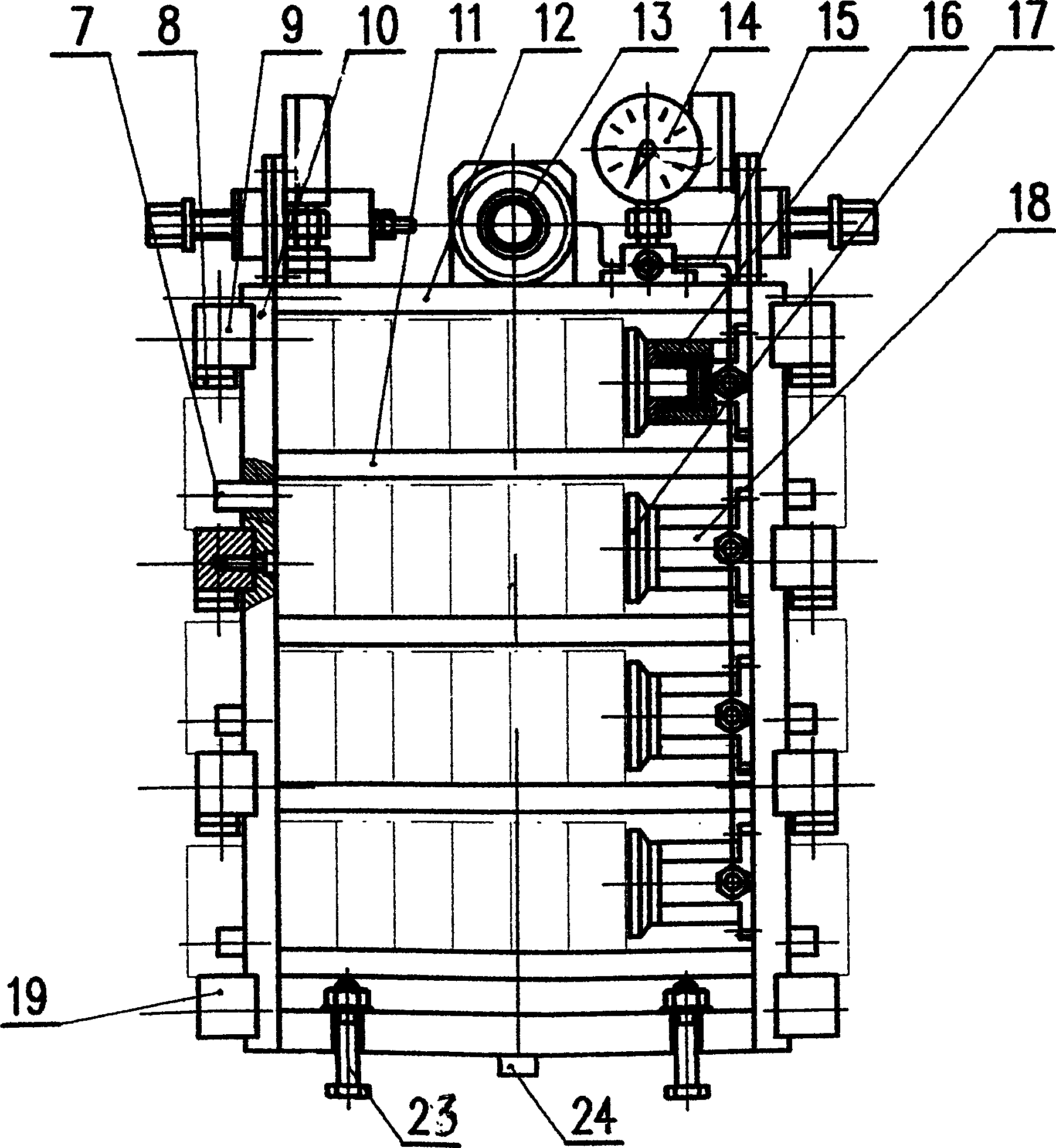

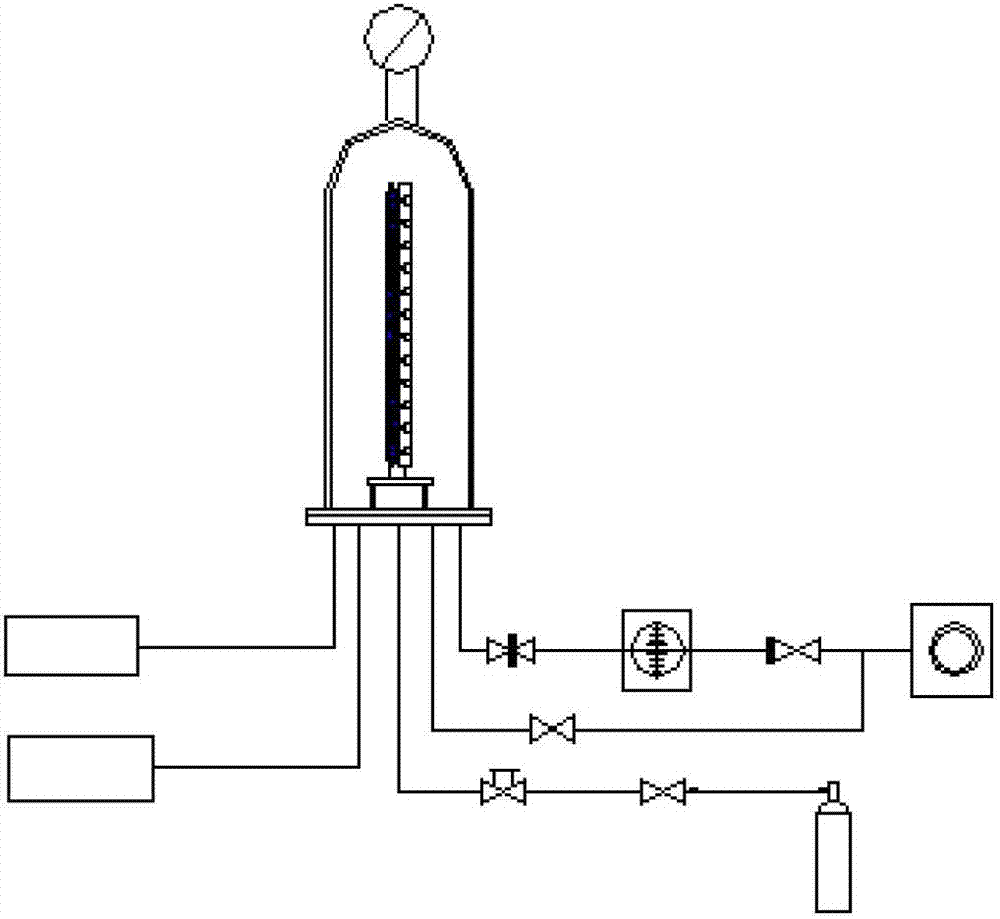

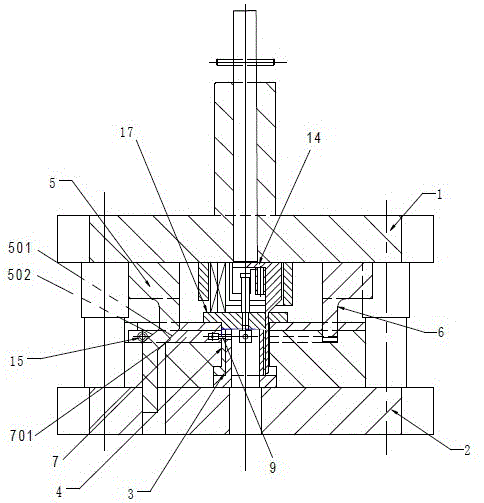

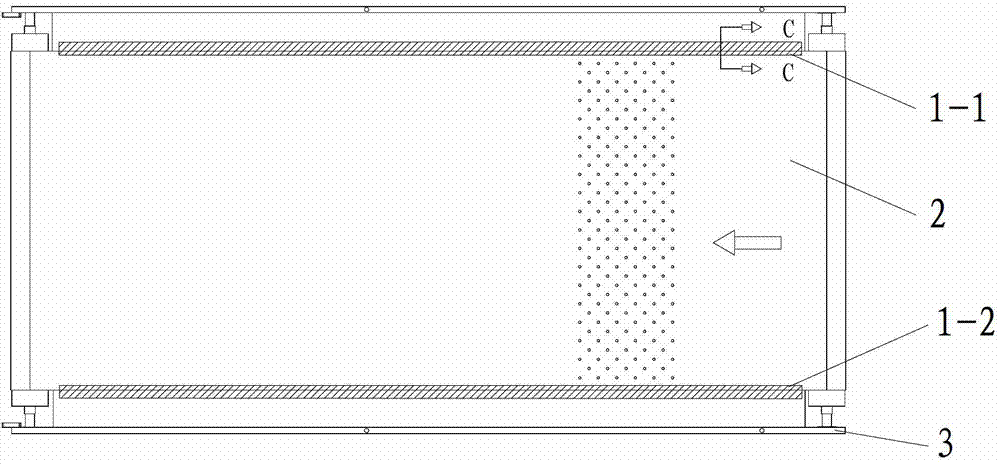

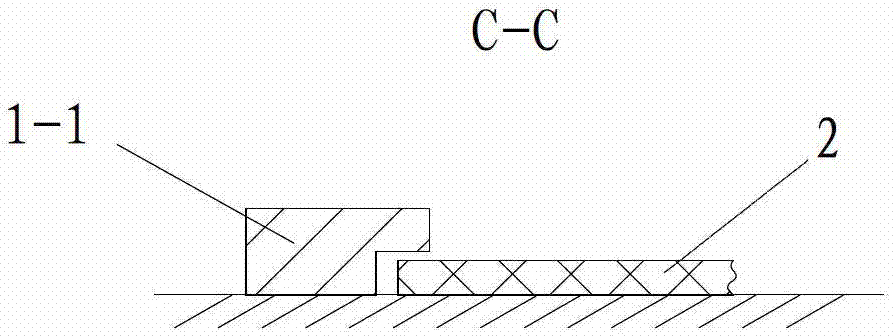

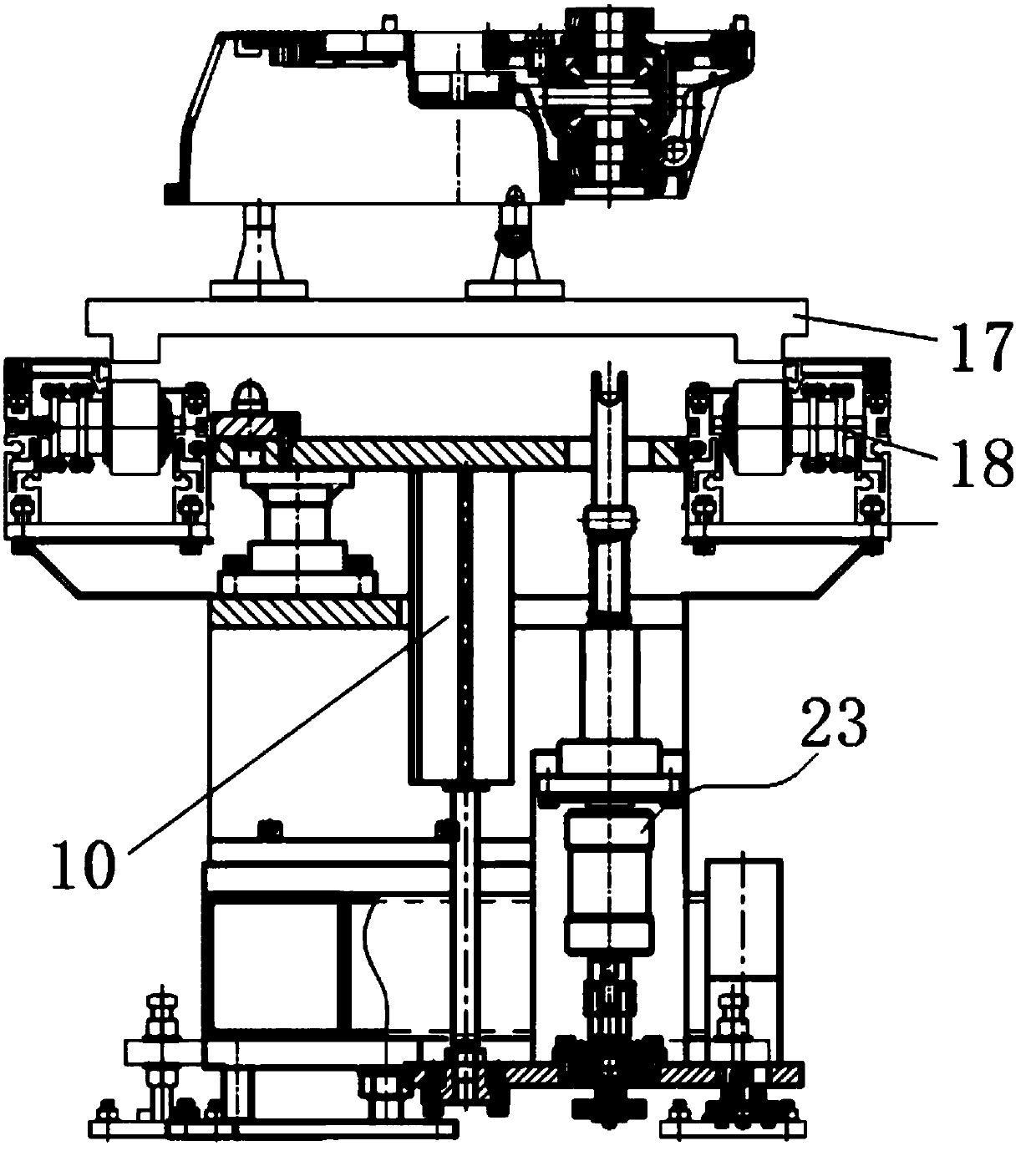

Welding experiment chamber for simulating medium-pressure liquid or gas environment

The invention disclose a welding experiment chamber for simulating a medium-pressure liquid or gas environment, and relates to an underwater welding experiment chamber. The welding experiment chamber aims to solve the problems that for the existing experimental equipment for simulating underwater welding, components in a chamber are not easy to replace, the applicability is poor, the simulated pressure for simulating a welding experiment is low, and only a single pressure medium is available. A chamber bottom is arranged on the upper end face of a platform support; a plurality of chamber penetrating connectors are uniformly arranged in the chamber bottom; a chamber body is arranged above the chamber bottom; two semicircular hoops are buckled to form a ring; two side walls of a trapezoidal groove are tightly matched with an upper inclined plane and a lower inclined plane; an oil cylinder support is fixedly connected with the upper end face of the platform support; two lifting guide rails are symmetrically arranged on the outer side of the oil cylinder support by adopting the vertical center line of the chamber body as a reference; each lifting guide rail is provided with a lifting oil cylinder; four lugs are uniformly distributed on the external wall at the upper end of a barrel; one end of each lifting support is connected with one of the lifting oil cylinders; the other end of each lifting support is connected with two of the four lugs; and a welding platform is arranged on an annular boss. The experiment chamber is used for simulating the underwater welding.

Owner:HARBIN INST OF TECH

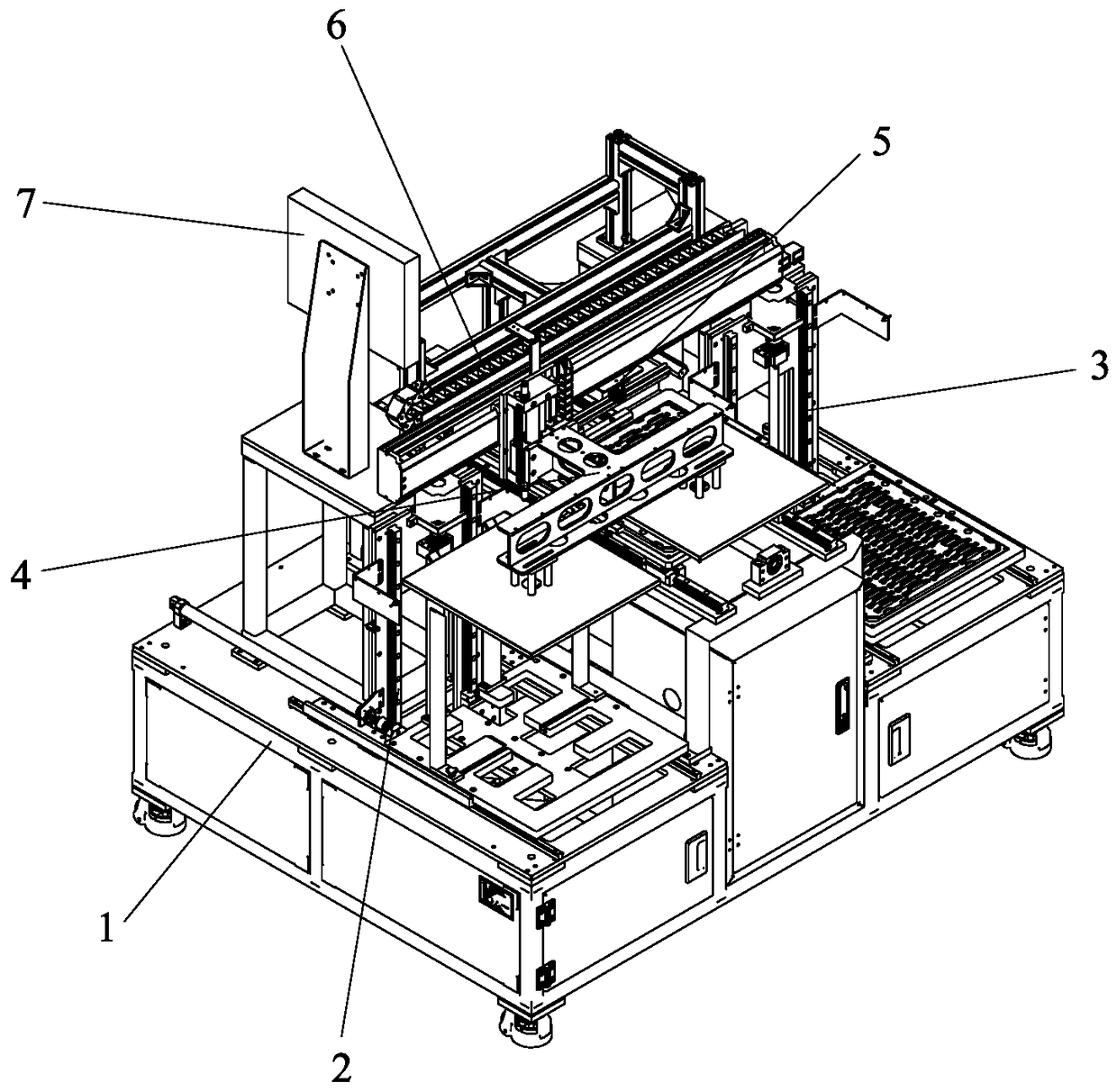

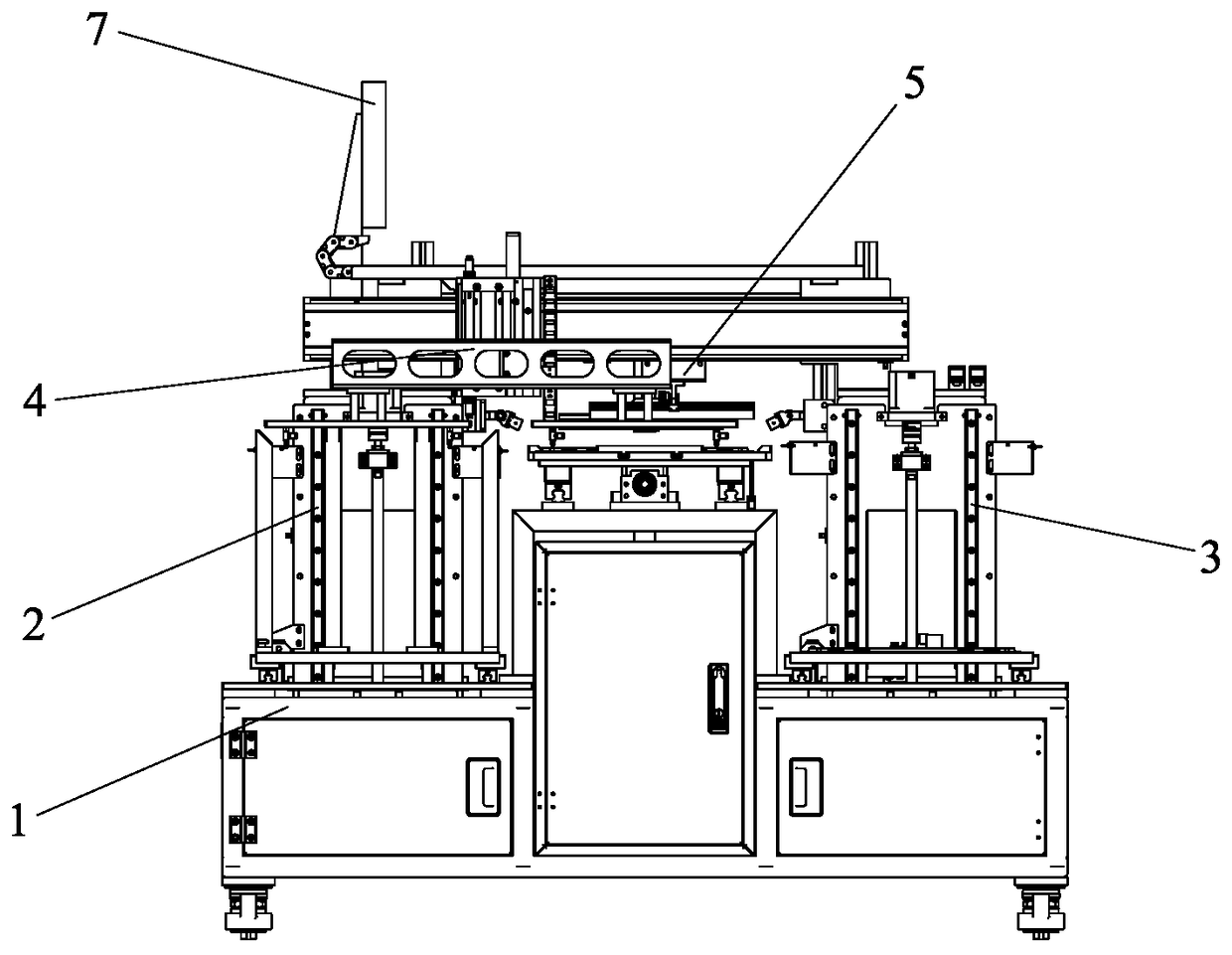

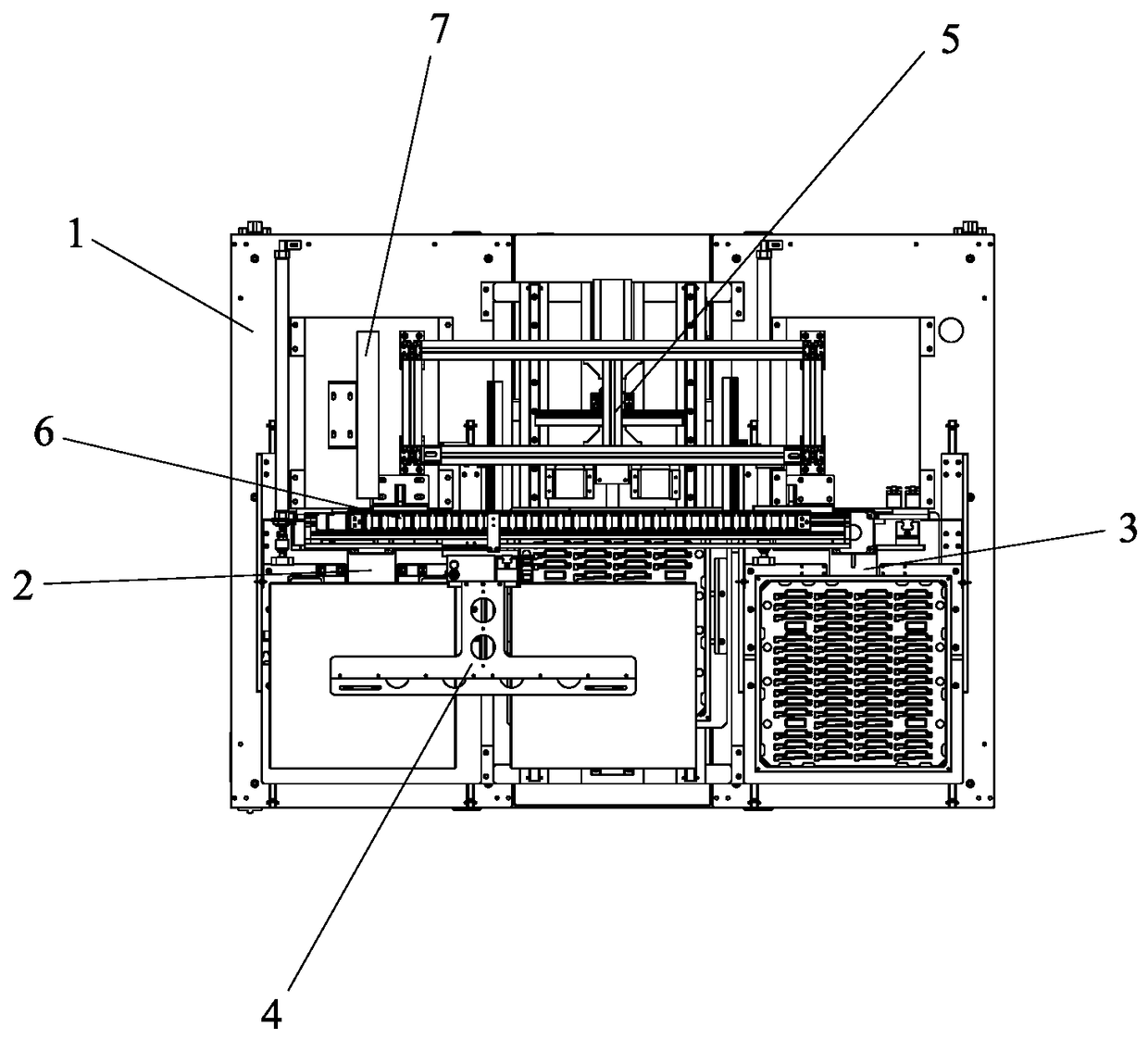

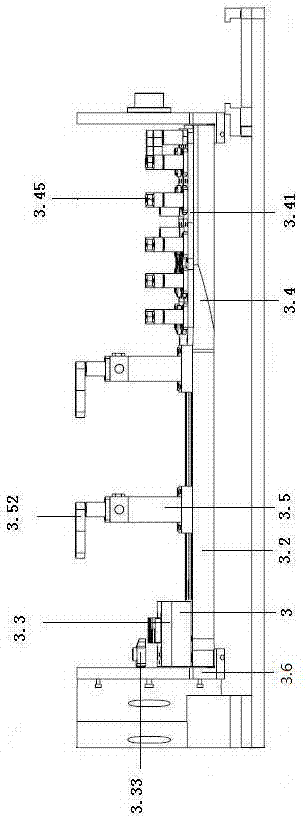

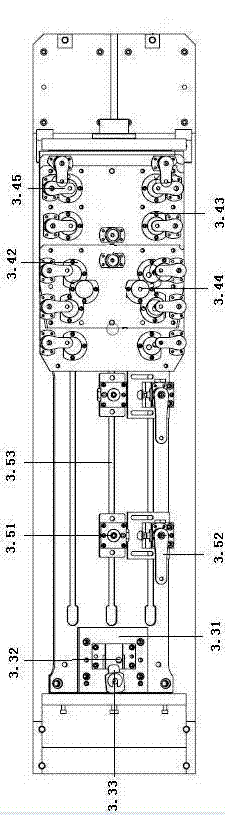

Character 2D code detection device

ActiveCN108861627APrevent outflowImprove detection efficiencyConveyorsStacking articlesCcd cameraComputer science

The invention discloses a character 2D code detection device. The character 2D code detection device comprises a rack, a feeding material disk caching mechanism, a discharging material disk caching mechanism, a suction cup mechanism, a detection mechanism and an NG product getting mechanism. The feeding material disk caching mechanism and the discharging material disk caching mechanism are fixed to the left and right sides of the rack correspondingly. The detection assembly is fixed to the middle area of the rack. The suction cup mechanism is fixed to the feeding material disk caching mechanism, the discharging material disk caching mechanism and the detection mechanism and located above a to-be-detected assembly. The NG product getting mechanism is fixed to the location behind the suctioncup mechanism. The character 2D code detection device conducts large-area detection on a whole material disk through a high-precision large-view CCD camera and effectively improves the detection efficiency and the product detection accuracy. The mechanisms are driven to act through a motor used in cooperation with a lead screw and linear guide rails or a cylinder used in cooperation with the linear guide rails, and the requirements for stability and position accuracy in the motion process are ensured; the feeding or discharging waiting time can be effectively reduced through the feeding material disk caching mechanism and the discharging material disk caching mechanism, and the production efficiency is improved.

Owner:XIAMEN HONGXIN ELECTRON TECH +1

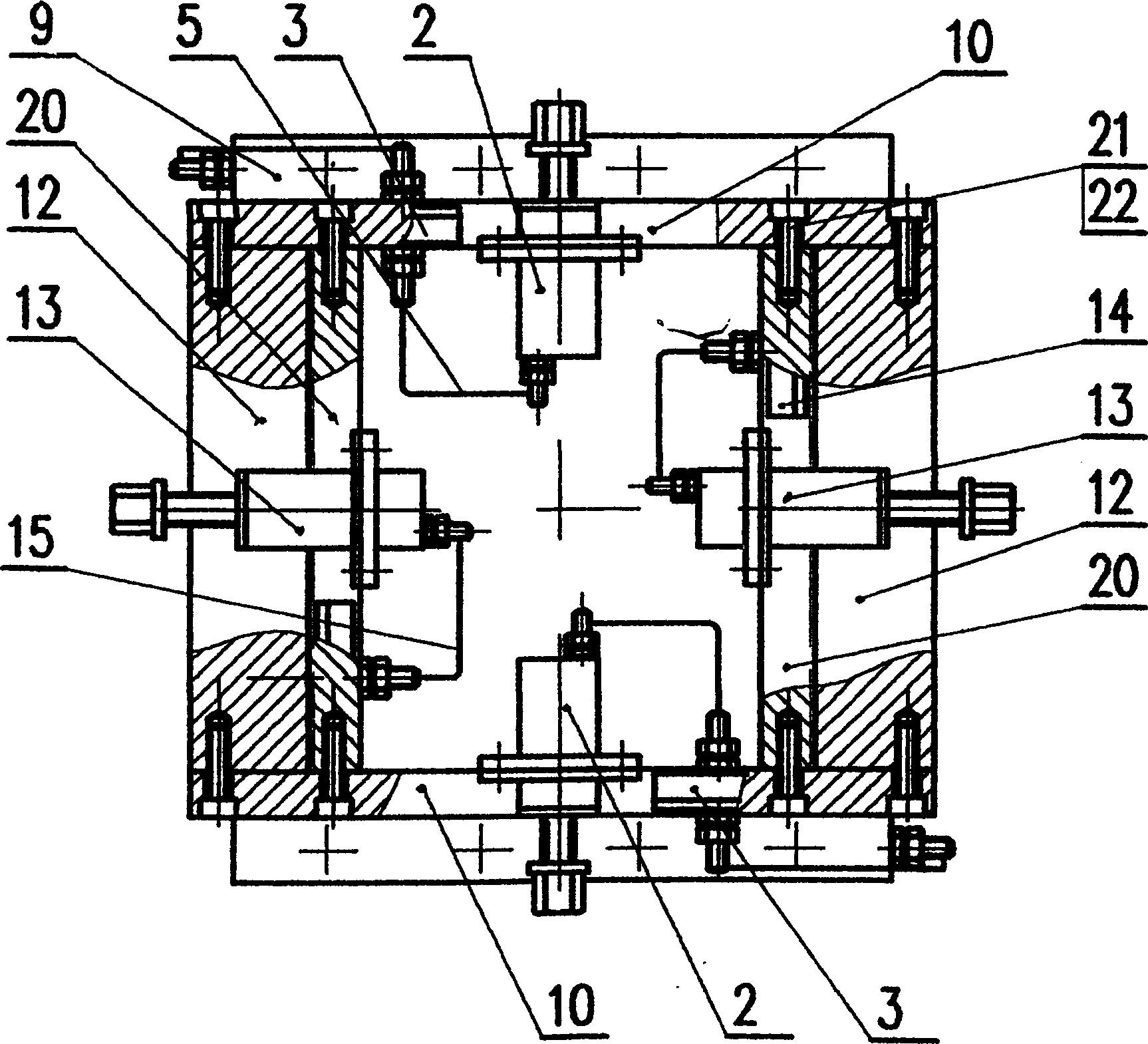

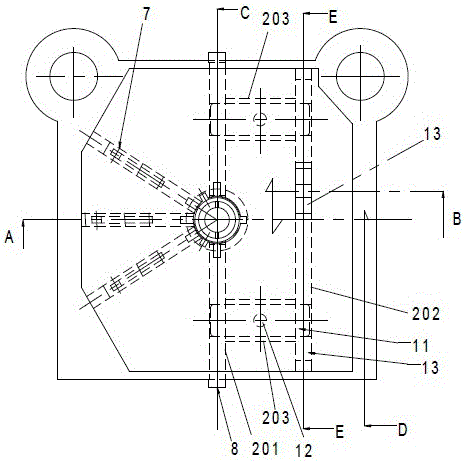

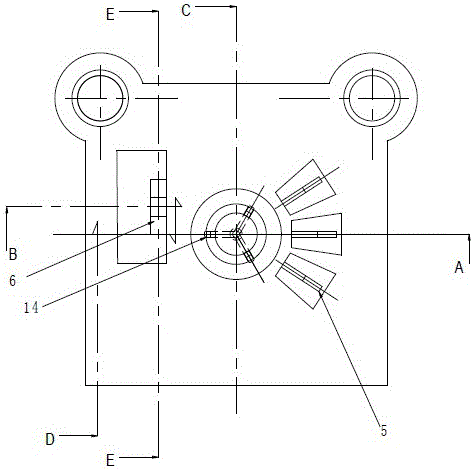

Processing method for hexahedral valve assembling block parts and clamp thereof

InactiveCN1593842AExpand clampingLarge processing areaPositioning apparatusMetal-working holdersEngineeringSwitching time

The invention relates to process for blocking accessory of cubic valves and the clump, which both belongs to the field of processing blocking accessory of cubic valves for hydraulic pressure controlling valve. The sets vertical quadrate clump box that has four faces on two revolving workbench of the chief horizontal processing table. Then set the six faces of the cubic valves to the four faces of the clump box. To finish the horizontal process and hole process of the six faces of the cubic valves through the revolving of quadrate clump box and the atomically tool switching of horizontal processing table. Processing, setting up and using of the invention are simple, so it needs only one step and lesser tool switching time to finish the horizontal process and hole process of the six faces of the cubic valves so that to product with high efficiency and high quality.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

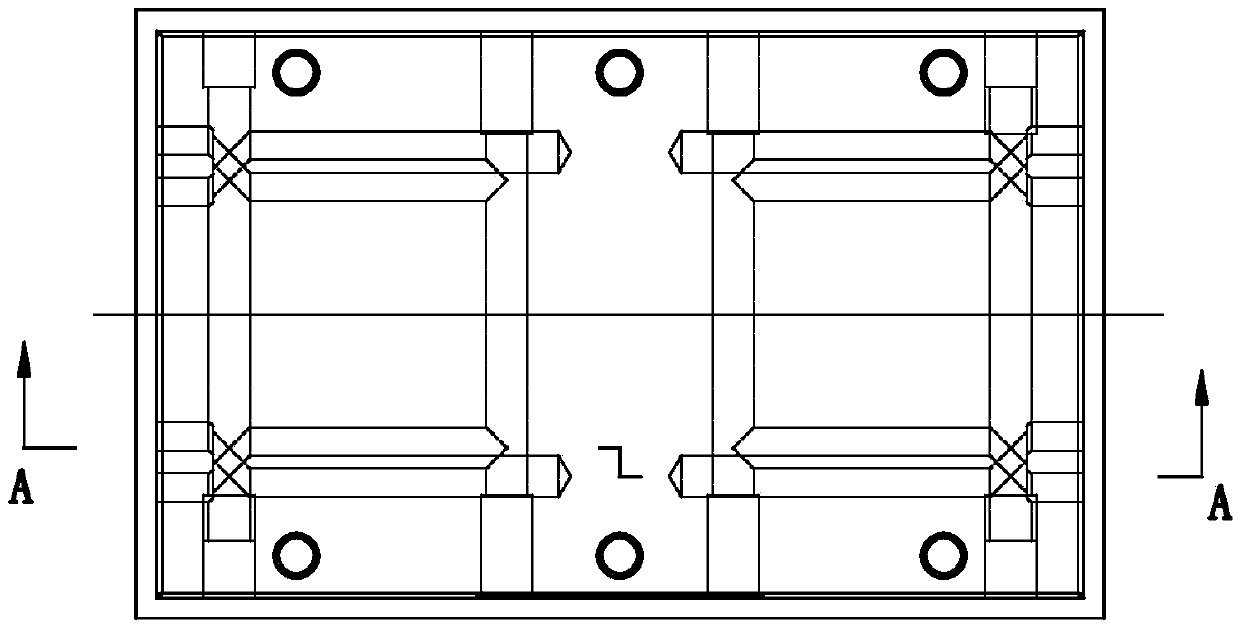

Processing technique of core inserts and cavity inserts

ActiveCN104191547AGuarantee mold clamping accuracyMeet appearance requirementsManufacturing technologyBiomedical engineering

The invention discloses a processing technique of core inserts and cavity inserts, belonging to the technical field of mold manufacturing. The processing technique comprises the following steps: providing a whole blank of a core insert and a cavity insert; processing a precise locating hole in the whole blank; cutting the whole blank at a remnant material reserving position in the middle position of the whole blank; assembling the back surfaces of the cut core insert and the cut cavity insert oppositely, precisely locating to fix the positions of the core insert and the cavity insert and clamping to fix the core insert and the cavity insert; processing four side walls and the cutting surface of each of the core insert and the cavity insert; disassembling the core insert and the cavity insert and processing the thicknesses of the core insert and the cavity insert respectively; and processing according to the precise locating hole access in the subsequent work procedures. The processing technique can ensure the mold clamping precision of the cavities of the core insert and the cavity insert, and can reduce the processing and assembling errors caused by the conventional mode and can meet the requirement on the appearance of the high-precision products.

Owner:GOERTEK INC

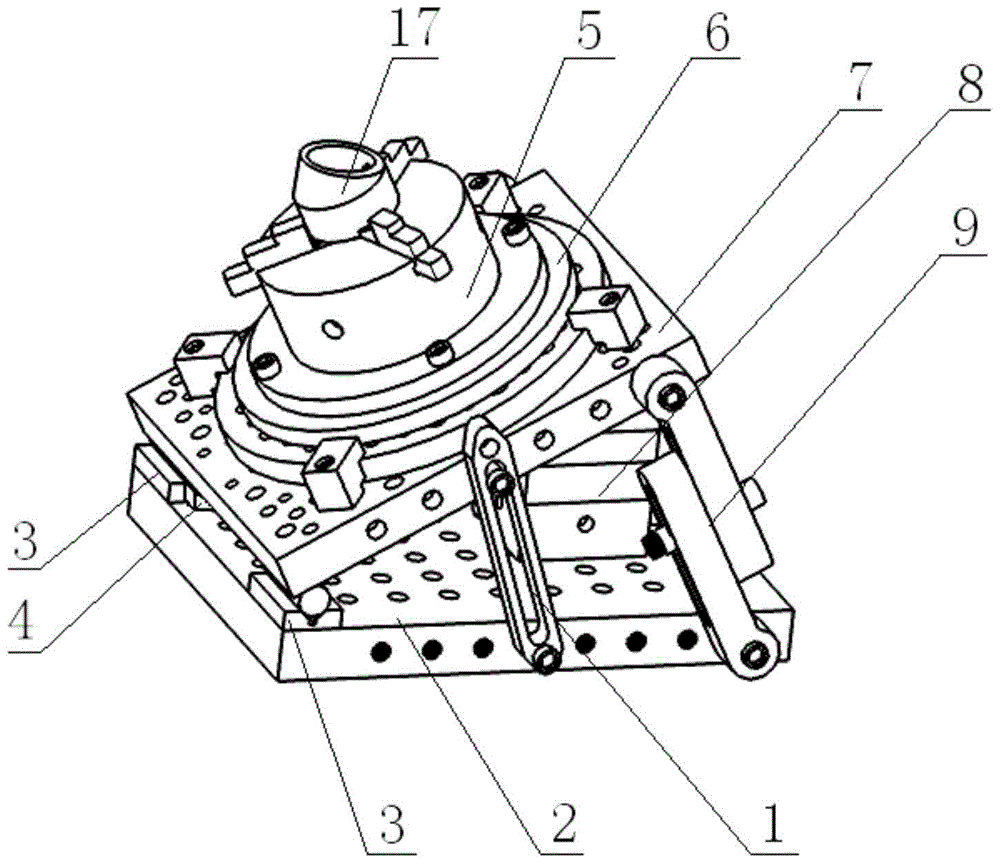

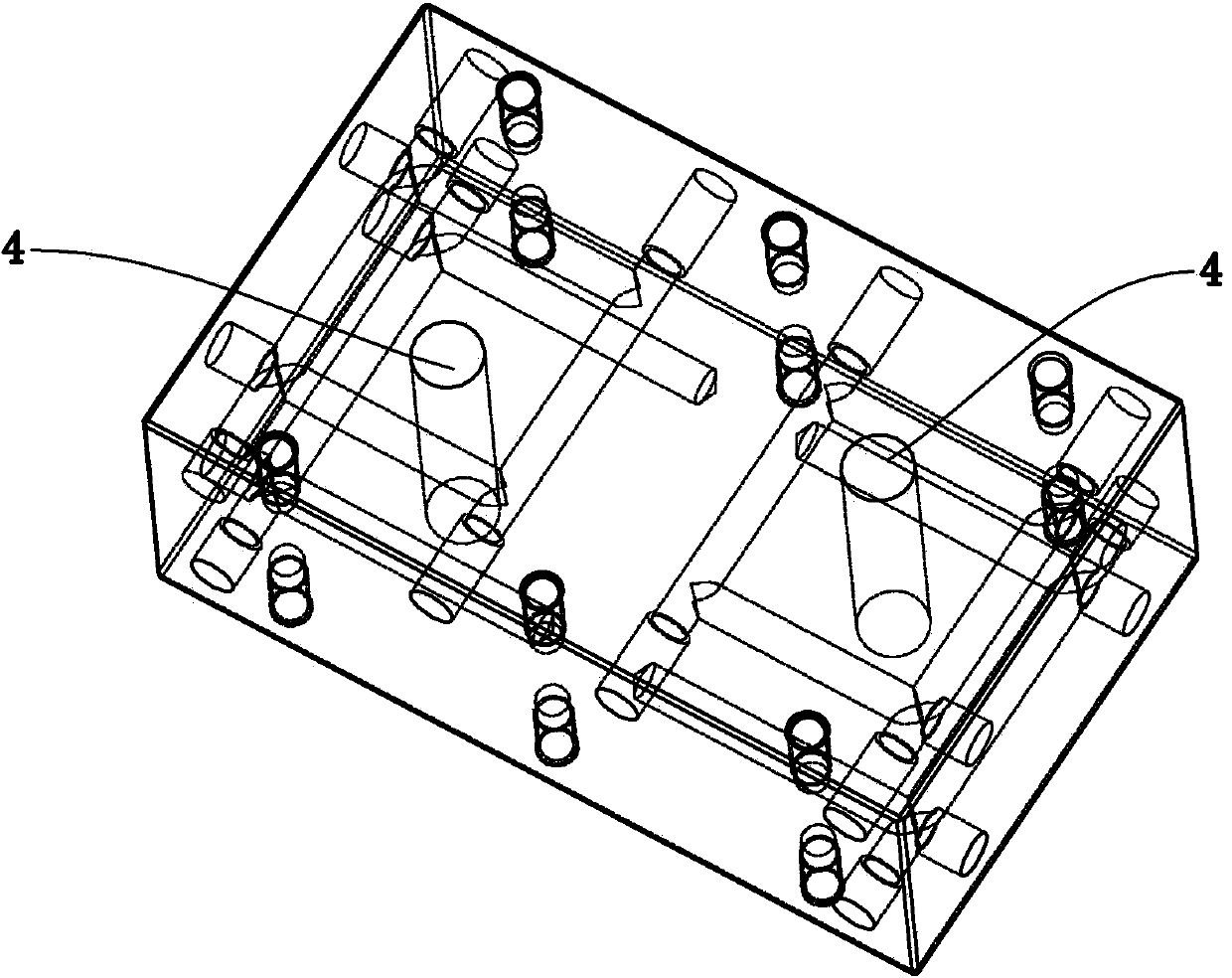

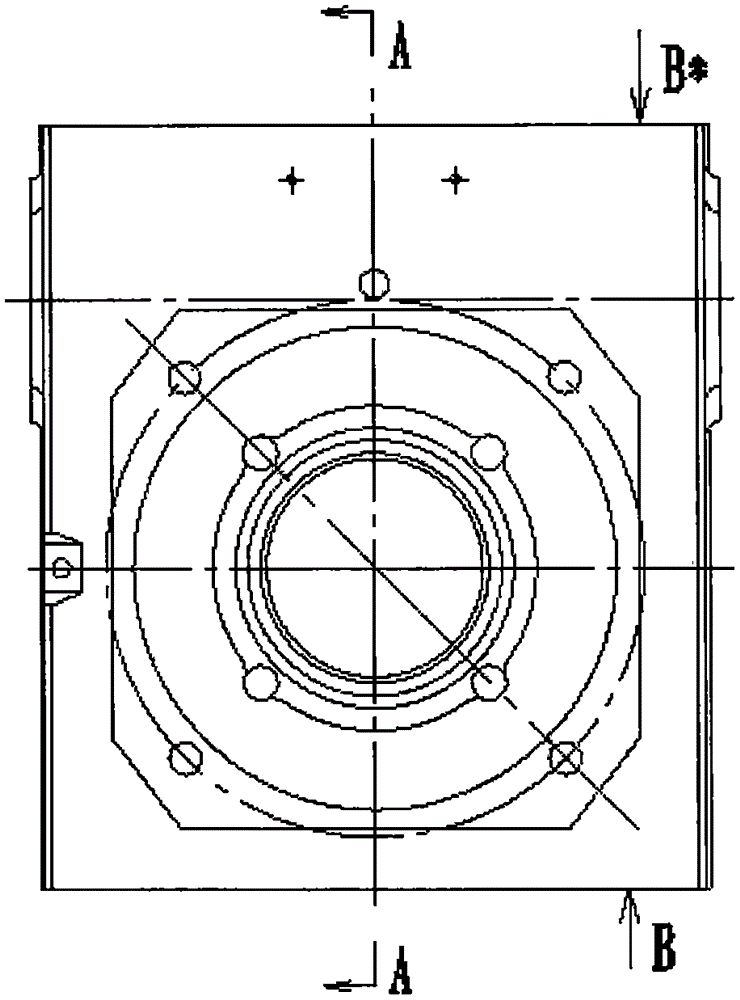

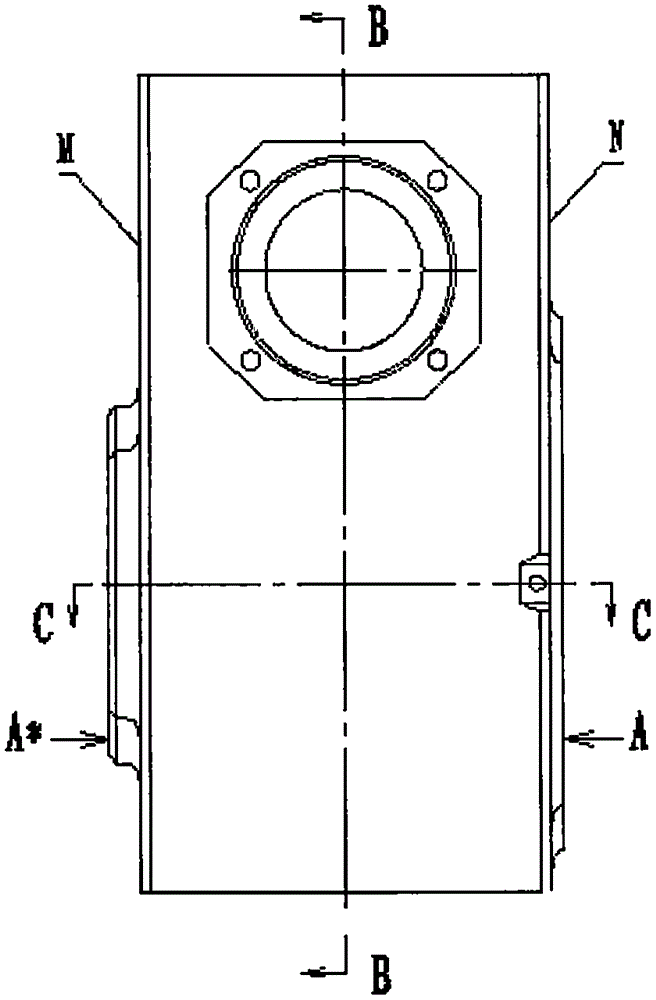

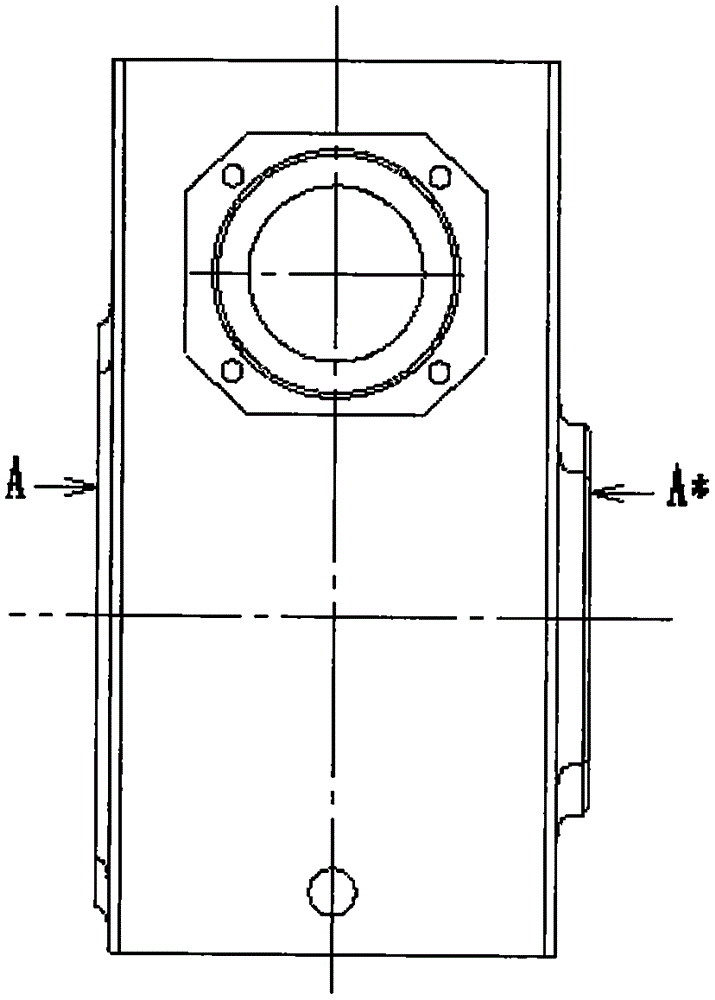

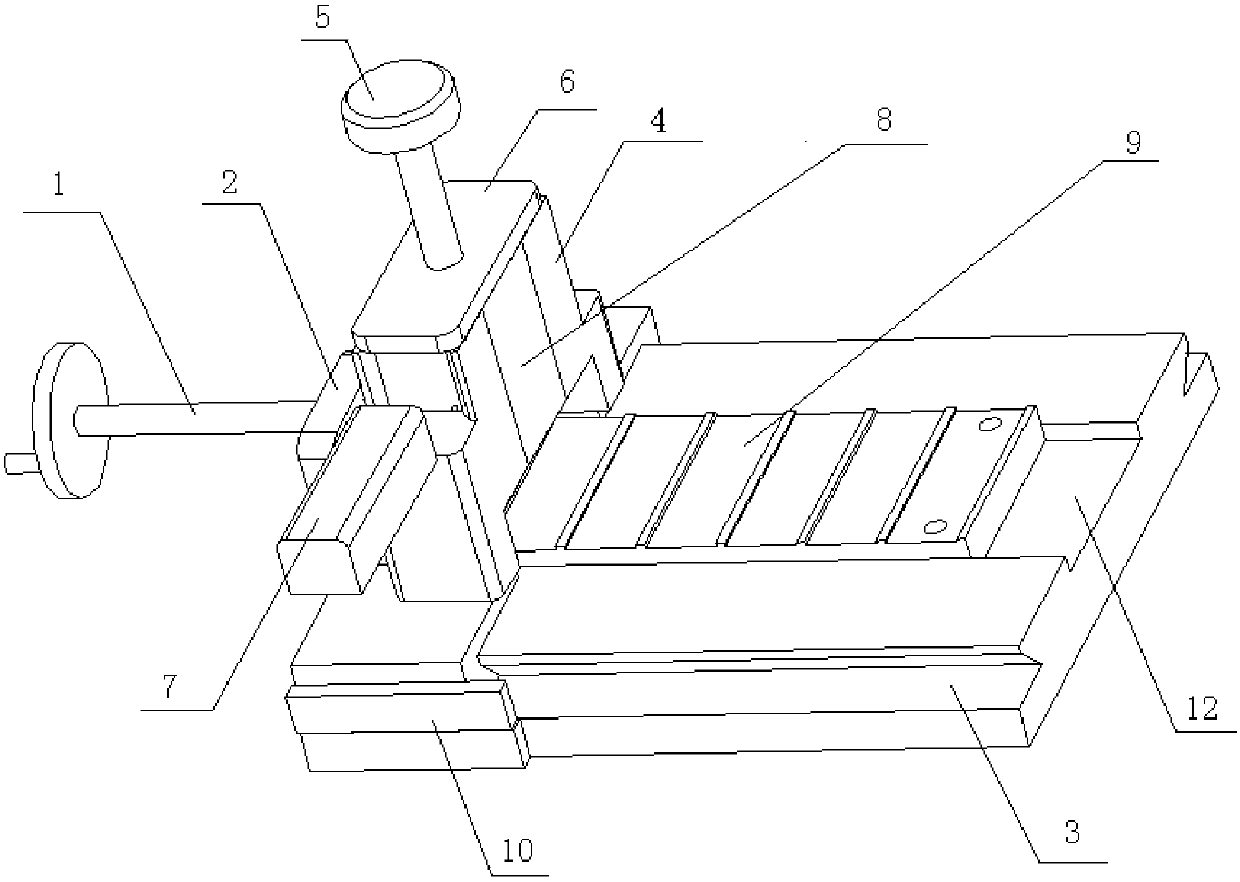

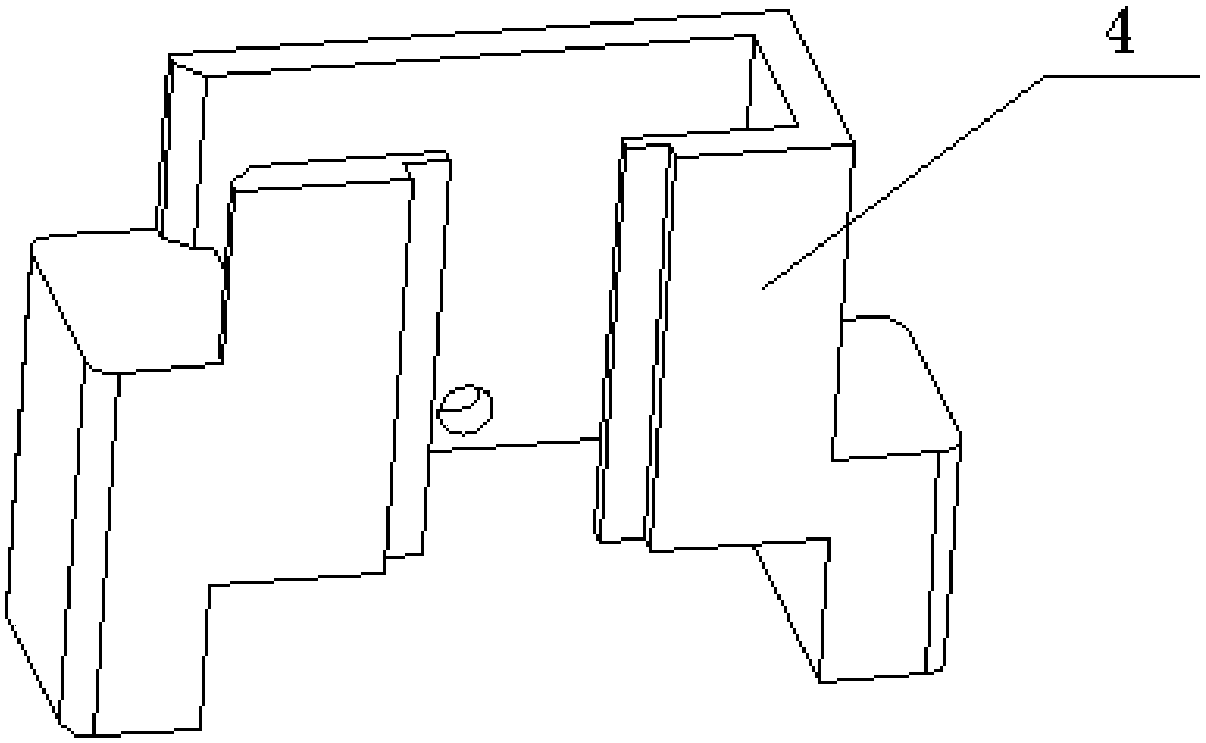

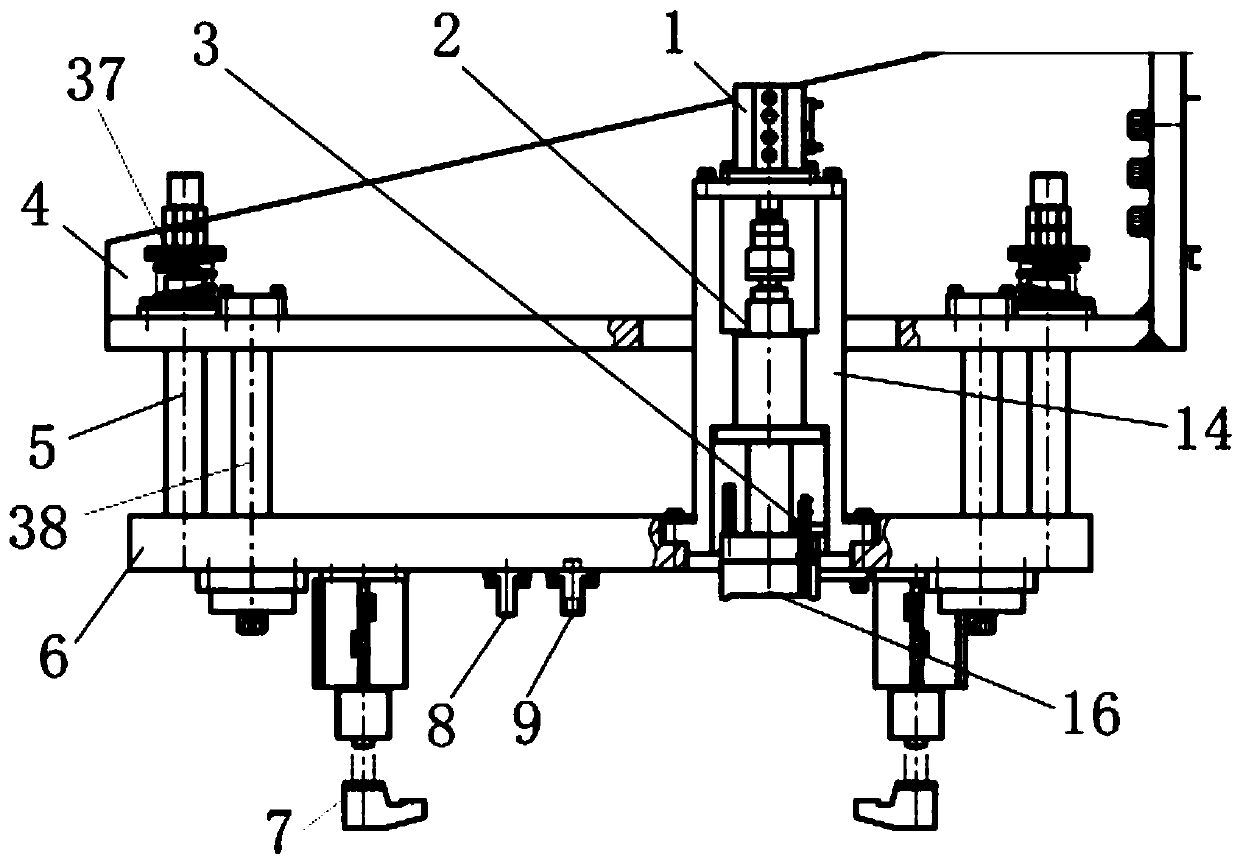

Tool for machining box and machining technology of tool

ActiveCN105479123AReduce the number of clampingGuaranteed Position Accuracy RequirementsOther manufacturing equipments/toolsPositioning apparatusEngineeringMachining

The invention discloses a tool for machining a box. The tool comprises a stand column arranged on a rotary working table of a horizontal machining center, a box tool body I and a box tool body II. The box tool body I and the box tool body II are symmetrically arranged on the two sides of the stand column. According to the box tool body I, positioning is carried out through a positioning mechanism I with the B face and the M face of a workpiece as machining standards, and the N face, the L face and the Q face of the workpiece are tightly pressed through a clamping mechanism I for fixing. According to the box tool body II, positioning is carried out in the mode that a positioning mechanism II is matched with a J hole and a K hole in the workpiece, and the M face of the workpiece is tightly pressed by a clamping mechanism II for fixing. A box machining technology in which the tool is used includes the steps that the workpiece is installed on the box tool body I and the box tool body II in sequence, a required tool is installed in a tool magazine in advance, a machining program is compiled in advance, and then a machine is started to machine the workpiece. According to the tool and the technology, box machining can be completed only through two times of clamping, the machining technology is simplified, machining quality is guaranteed, the labor intensity of an operator is reduced, and machining efficiency is improved.

Owner:SHANDONG FUYUAN TRACK MACHINERY CO LTD

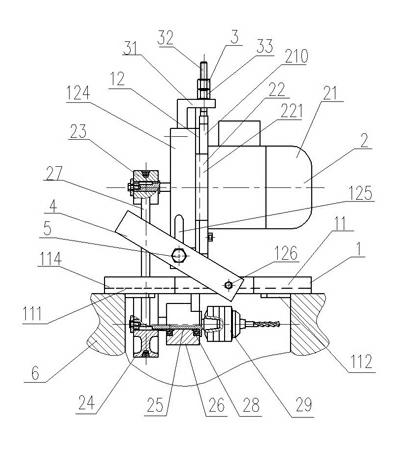

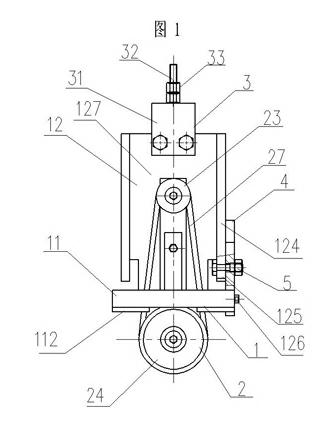

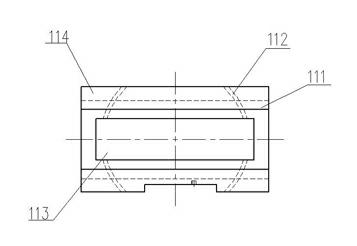

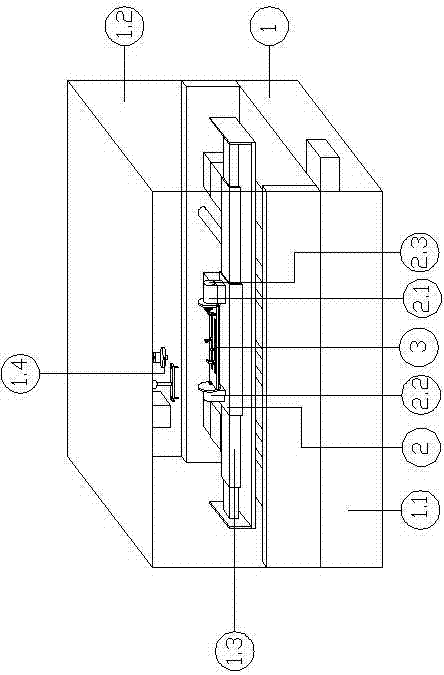

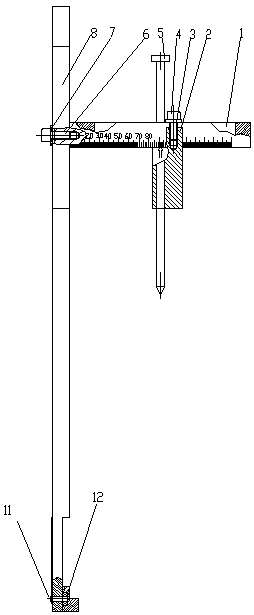

Horizontal drilling device

ActiveCN102198528AGuaranteed Position Accuracy RequirementsLower skill requirementsBoring/drilling componentsBoring/drilling machinesDrilling machinesDrill hole

The invention discloses a horizontal drilling device which comprises a guide mechanism, a drilling mechanism, a height adjusting mechanism and a push rod. The guide mechanism comprises a horizontal guide rail pair and a vertical guide rail pair vertically supporting above the horizontal guide rail, and the lower end of a vertical guide rail body is movably connected with a seat of the horizontal guide rail; the drilling mechanism comprises an electrical motor, an electrical motor mounting plate, a small belt roller, a large belt roller, a drilling machine main shaft and a supporting seat, wherein the electrical motor mounting plate is movably connected with the vertical guide rail body, the small belt roller is fixedly connected with an output shaft of the electrical motor, one end of thedrilling machine main shaft is fixedly connected with the large belt roller, and the tip of the other end of the drilling machine main shaft is fixedly connected with a drill chuck; and the height adjusting mechanism comprises a fixing plate, a screw rod and a lock nut, wherein the lower end of the screw rod is fixedly connected with the upper end of the electrical motor mounting plate. The invention has the advantages of simple structure, convenience in operation, reliable and accurate positioning, no drilling deviation phenomenon occurred during drilling and high work efficiency.

Owner:CSSC MARINE POWER

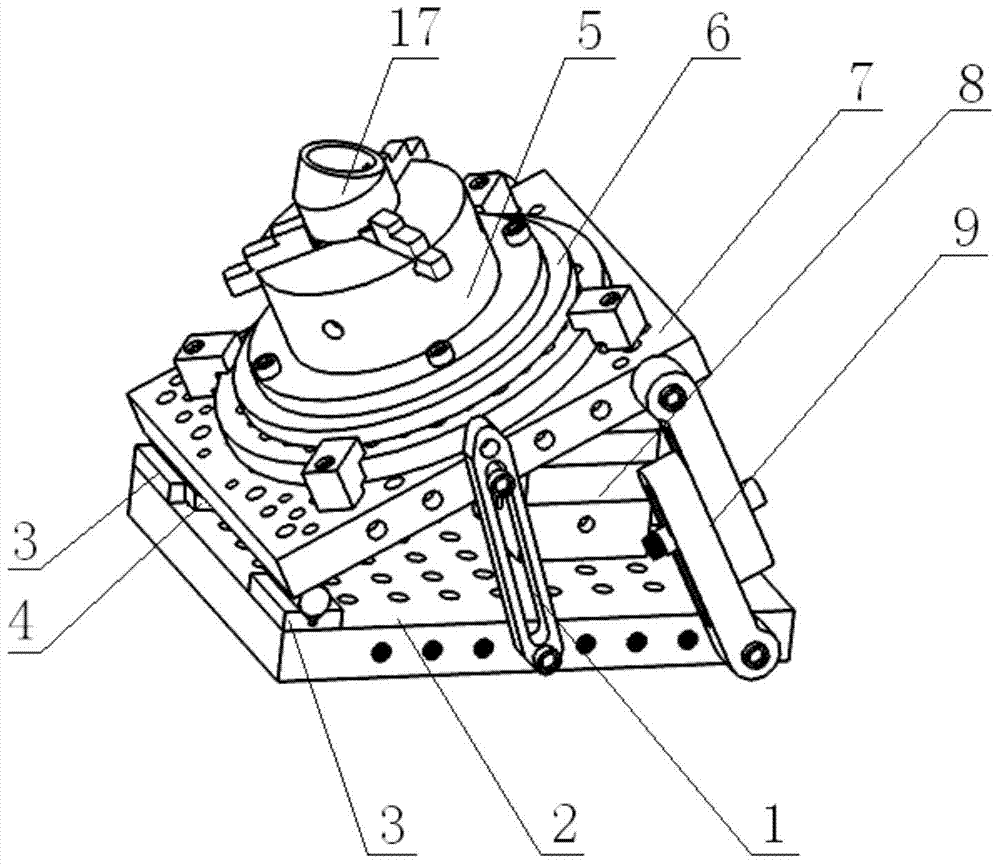

270-degree machining device and technology for sewing machine head shell

PendingCN107962424AFast productionEasy to fixLarge fixed membersPositioning apparatusEngineeringMachine tool

The invention discloses a 270-degree machining device for a sewing machine head shell. The 270-degree machining device comprises a vertical machining center machine tool and a positioning clamp. A rotary table and a rotary table tail base are fixed to the vertical machining center machine tool. A positioning clamp is fixed between the rotary table and the rotary table tail base, wherein the rotarytable is driven by a power part to rotate by 360 degrees. According to the 270-degree machining device, multi-face machining can be finished on one device, carrying is not needed, and the component production speed is high.

Owner:湖南凯斯机械股份有限公司

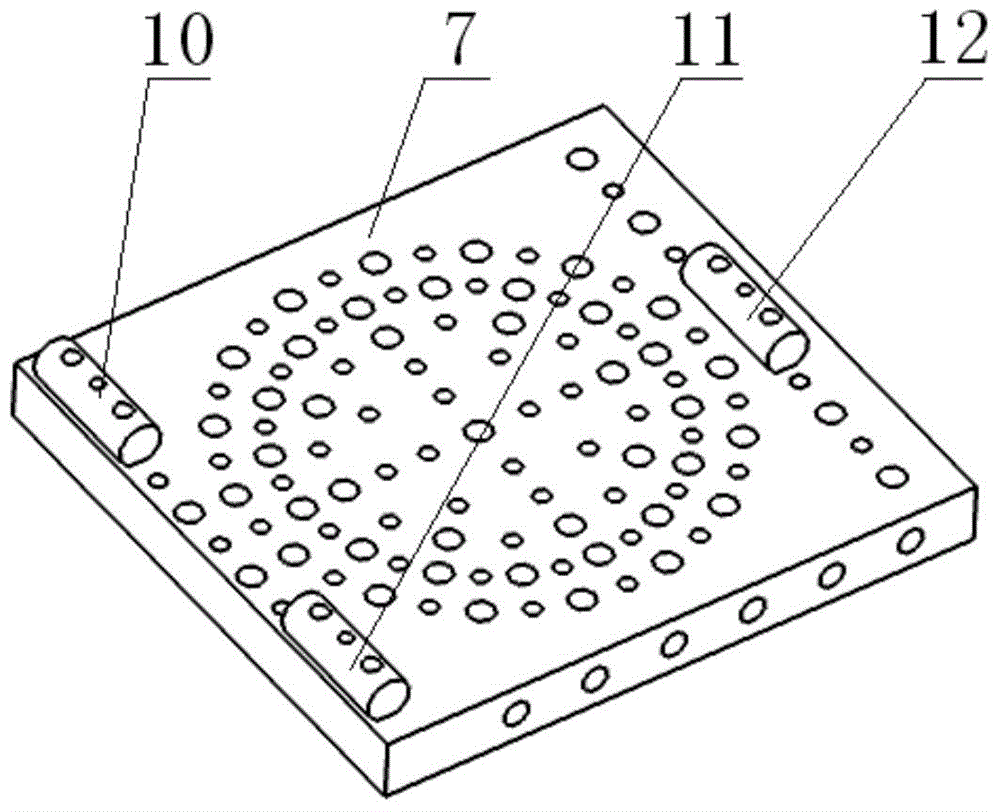

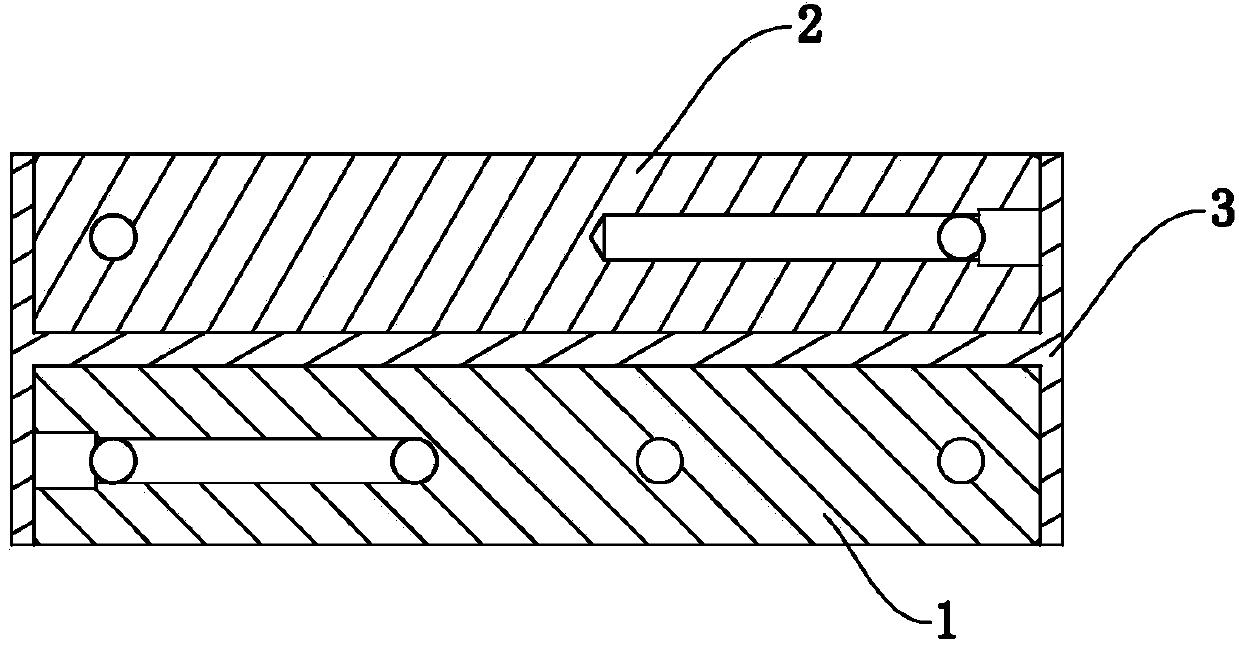

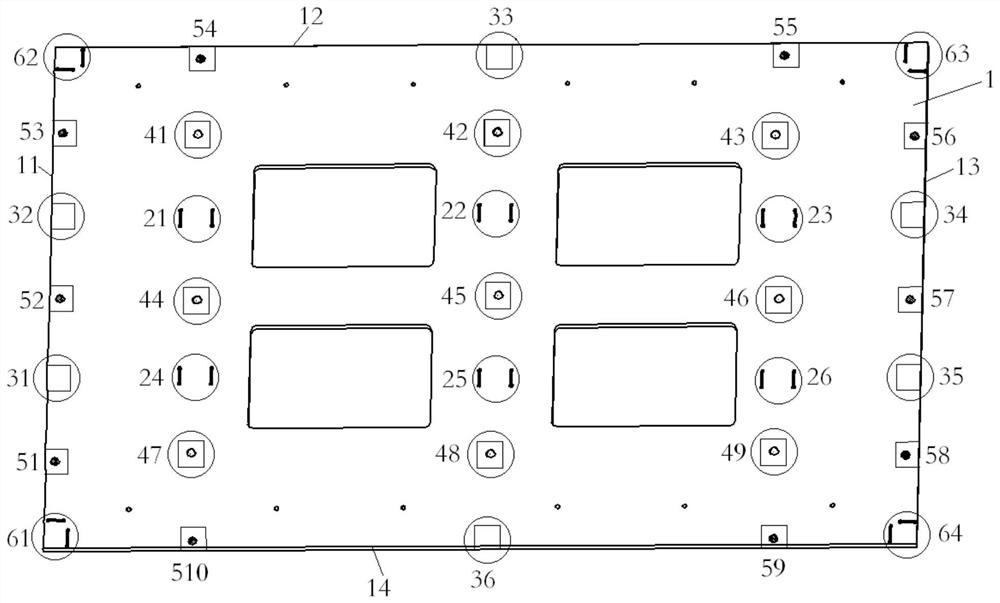

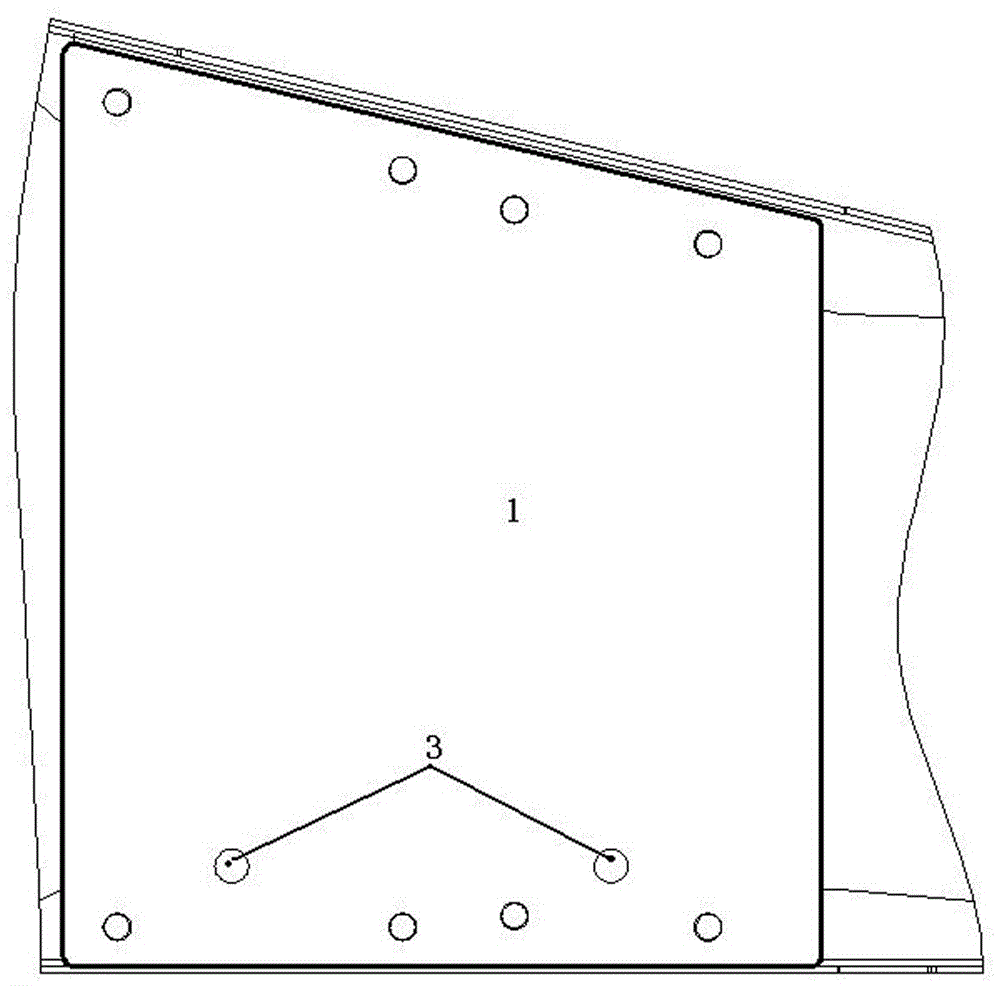

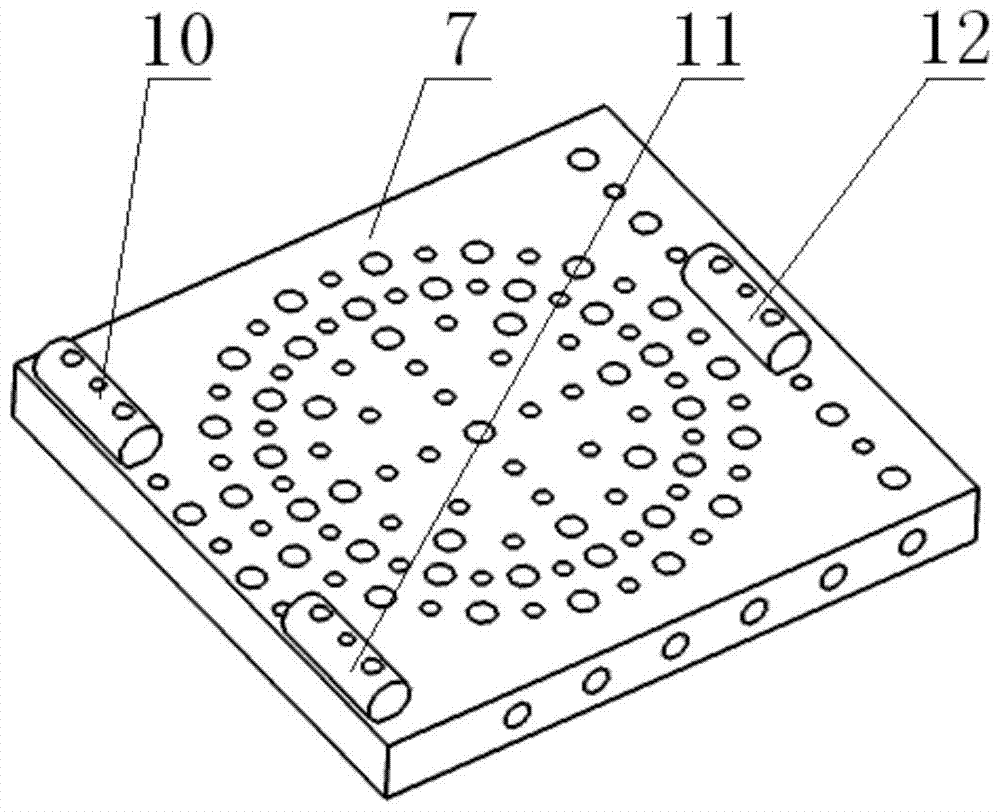

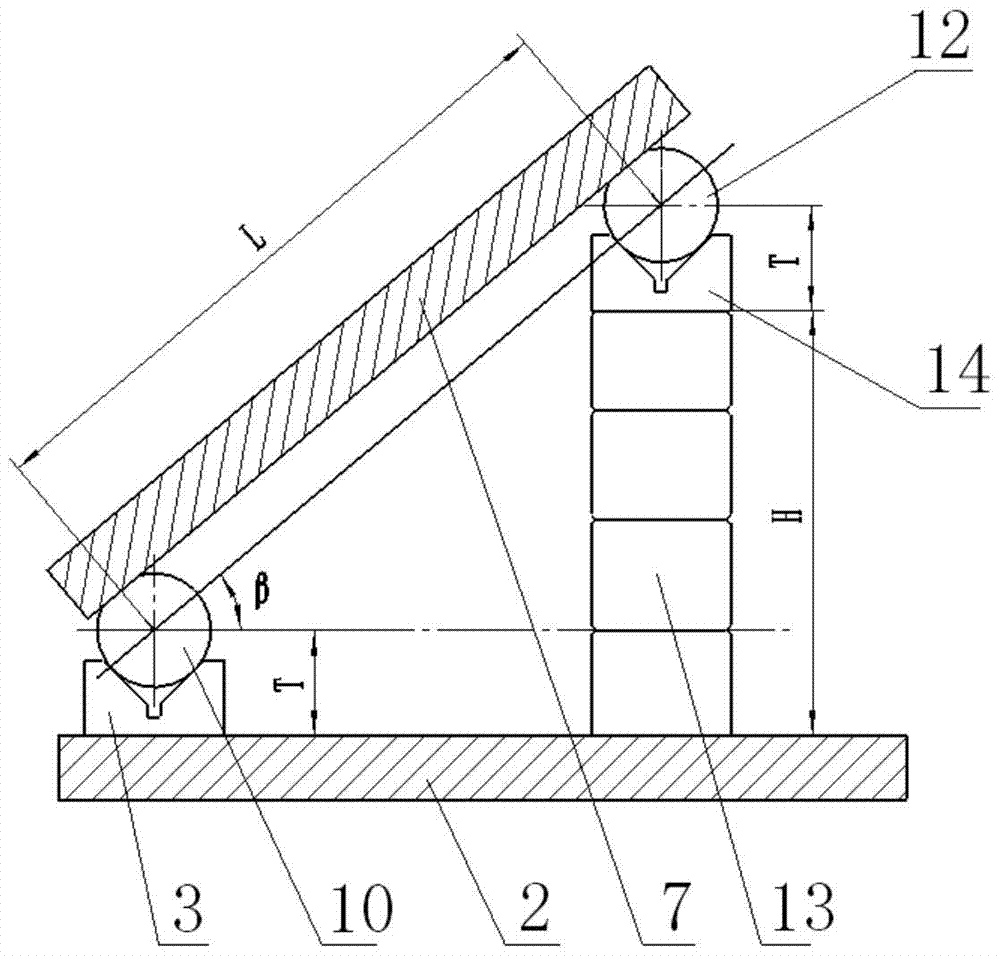

Planar-location vacuum absorption fixture used for cutting flat-plate-like parts

InactiveCN103802158APrevent throwingPrecise positioningMetal working apparatusComputer moduleMachining process

The invention provides a planar-location vacuum absorption fixture used for cutting flat-plate-like parts. The planar-location vacuum absorption fixture comprises a base plate. A sucker is arranged on the base plate. An adjustable locating module is arranged on the periphery of the sucker. A blocking pin is arranged on the outer edge of the base plate. A ventilation pipeline is arranged on the base plate. A port used for being connected with a mechanical hand is arranged in the middle position of the base plate. The device overcomes the defects in the prior art, absorbs workpieces and provides auxiliary support simultaneously, enables the fixture to provide accurate location in certain directions at workpiece clamping time, so that requirements for position accuracy in the moving or machining process are ensured, and the phenomenon that the workpieces deviate from original positions due to the fact that the workpieces are separated or deform in the multiple machining processes is reduced to the greatest extent.

Owner:DONGHUA UNIV

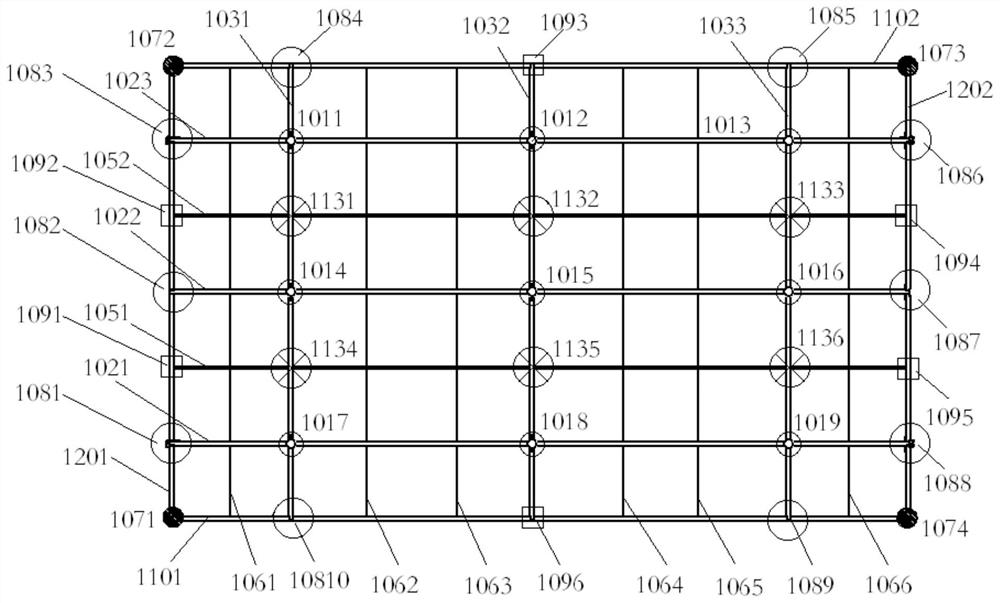

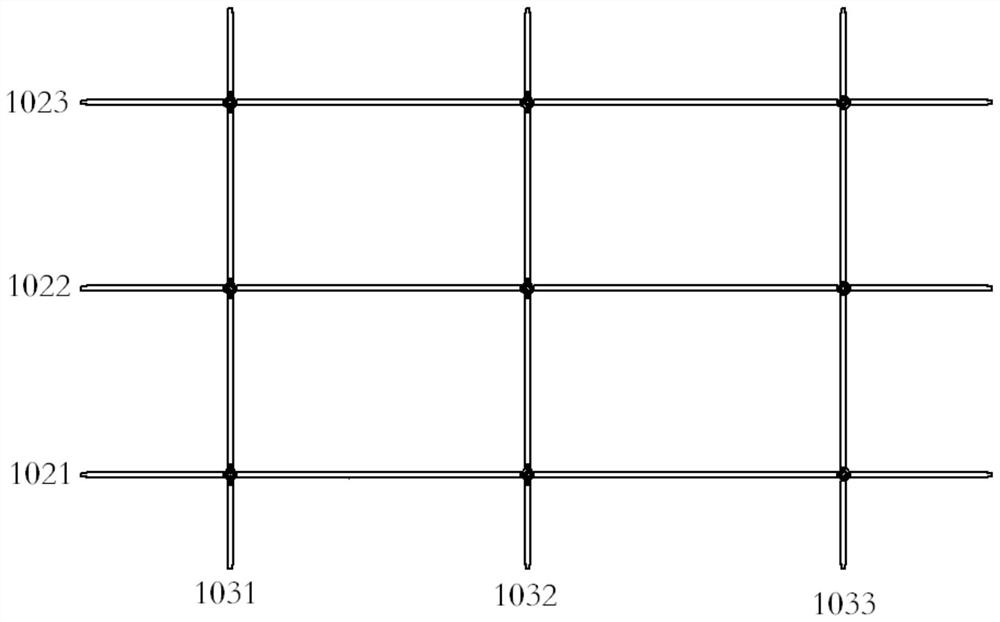

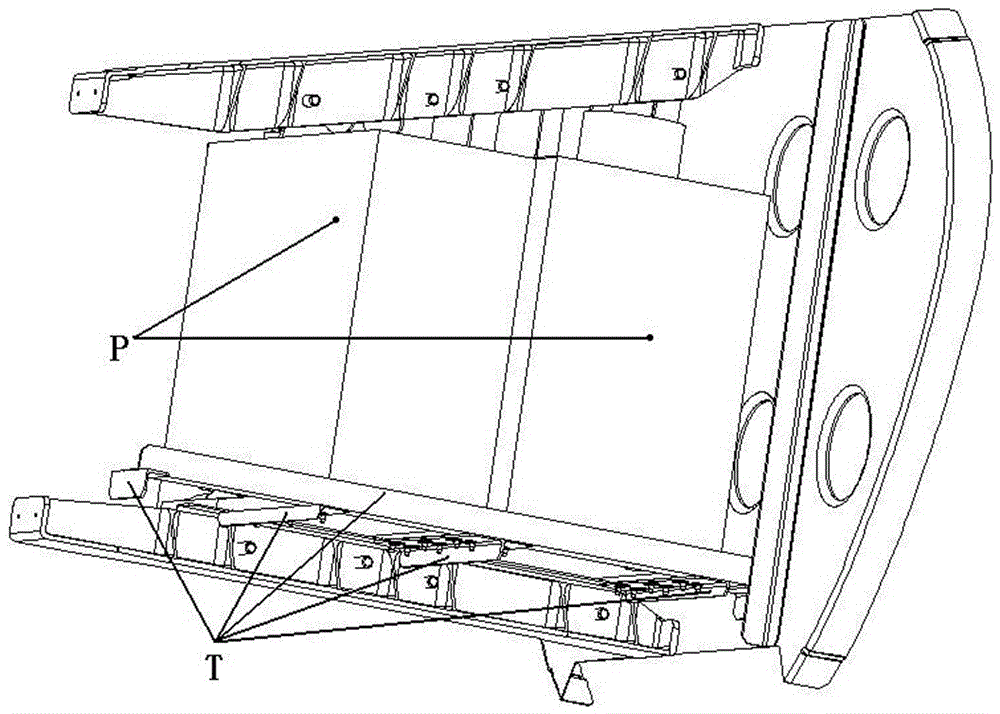

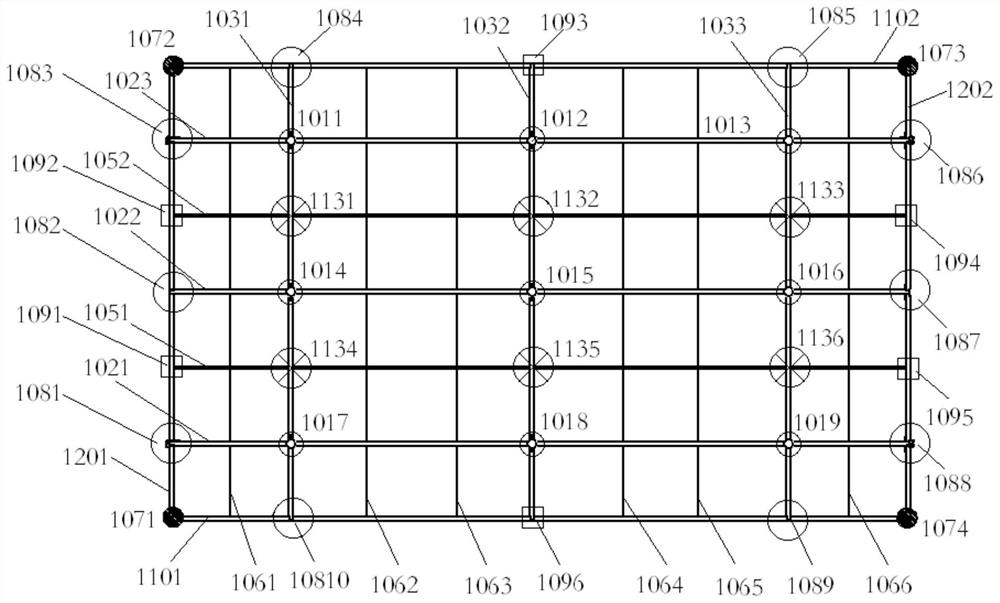

Glue joint assembly process method for string-stretching type semi-rigid substrate frame

ActiveCN112343907AGuaranteed mechanical propertiesGuarantee the mechanical properties of the compression pointMaterial gluingMechanical engineeringComposite material

The invention discloses a glue joint assembly process method for a string-stretching type semi-rigid substrate frame. The glue joint assembly process method comprises the steps that a center frame issubjected to glue joint; reinforcing beams and limiting beams are mounted, and trial assembly is conducted; an outer frame is subjected to glue joint; and angle boxes and angle pieces are subjected toglue joint, and the string-stretching type semi-rigid substrate frame is obtained. According to the glue joint assembly process method, the problems that an existing glue joint process method for thestring-stretching type semi-rigid substrate frame is compact in glue joint construction period, poor in assembly precision, large in assembly stress and the like are solved.

Owner:BEIJING SATELLITE MFG FACTORY

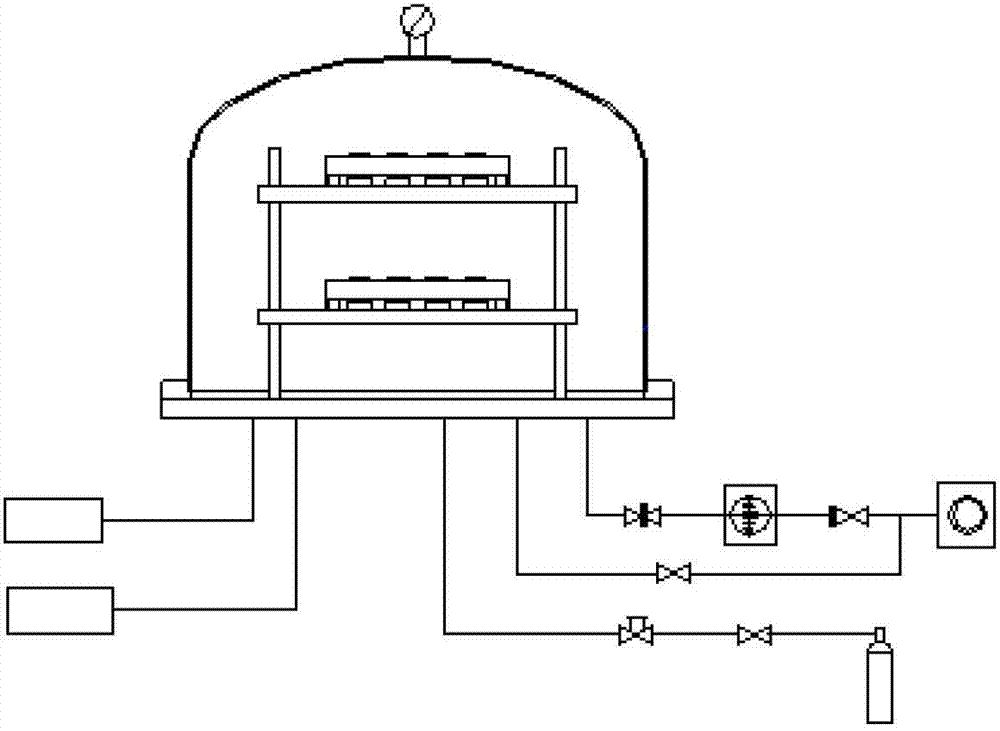

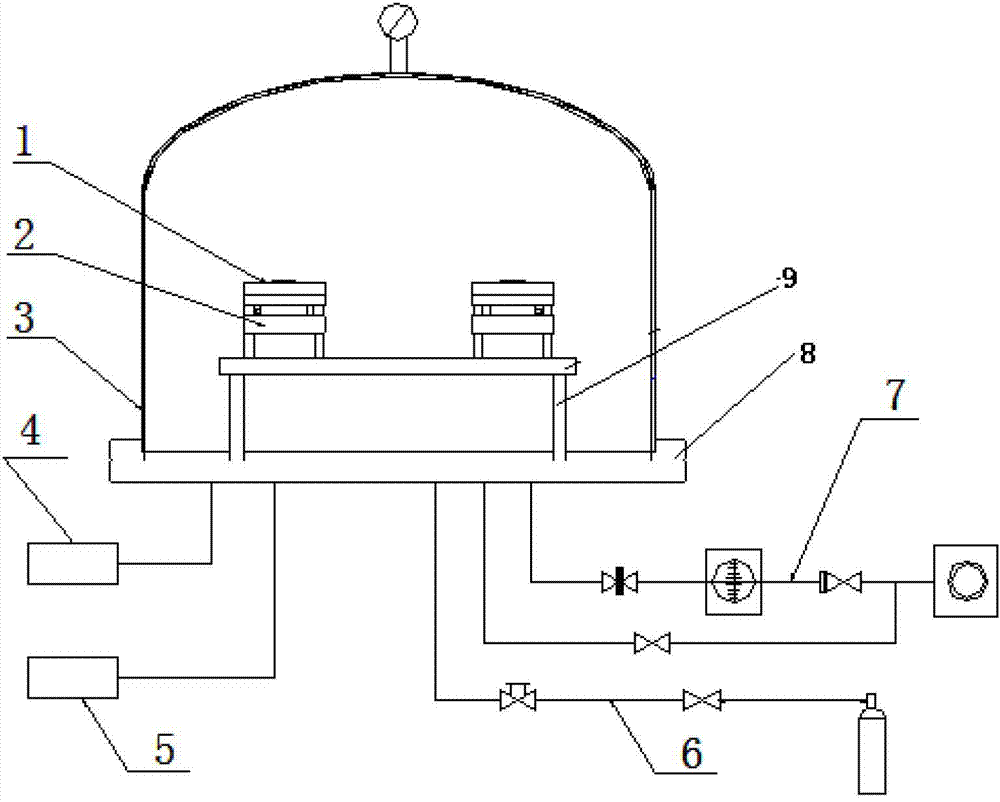

Thermal vacuum outgassing testing apparatus

ActiveCN102818815AGuaranteed design accuracyGuaranteed Position Accuracy RequirementsMaterial thermal conductivityVacuum pumpingControl system

The invention discloses a thermal vacuum outgassing testing apparatus. The apparatus mainly comprises a vacuum cover (including an outgassing collecting device and a sample groove, etc.), a vacuum pumping system, a high guarantee system, a low temperature guarantee system, a temperature vacuum degree measurement and control system and an auxiliary system. The vacuum pumping system provides vacuum degree required by the testing apparatus; and the high temperature guarantee system and the low temperature guarantee system are respectively a high temperature device and a low temperature circulating device, and provide a sample heating temperature of 125+ / -1 DEG C and a temperature of 25+ / -1 DEG C required by a collecting plate. The apparatus provided by the invention guarantees effective conduction of cooling capacity between the collecting plate and a cooling plate; and the collecting plate and the cooling plate have same and uniform temperature, and employ a double-row parallel structure to avoid mutual interference of the released gas. The operation is quick and convenient, so as to improve the accuracy of the test result.

Owner:VACREE TECH +1

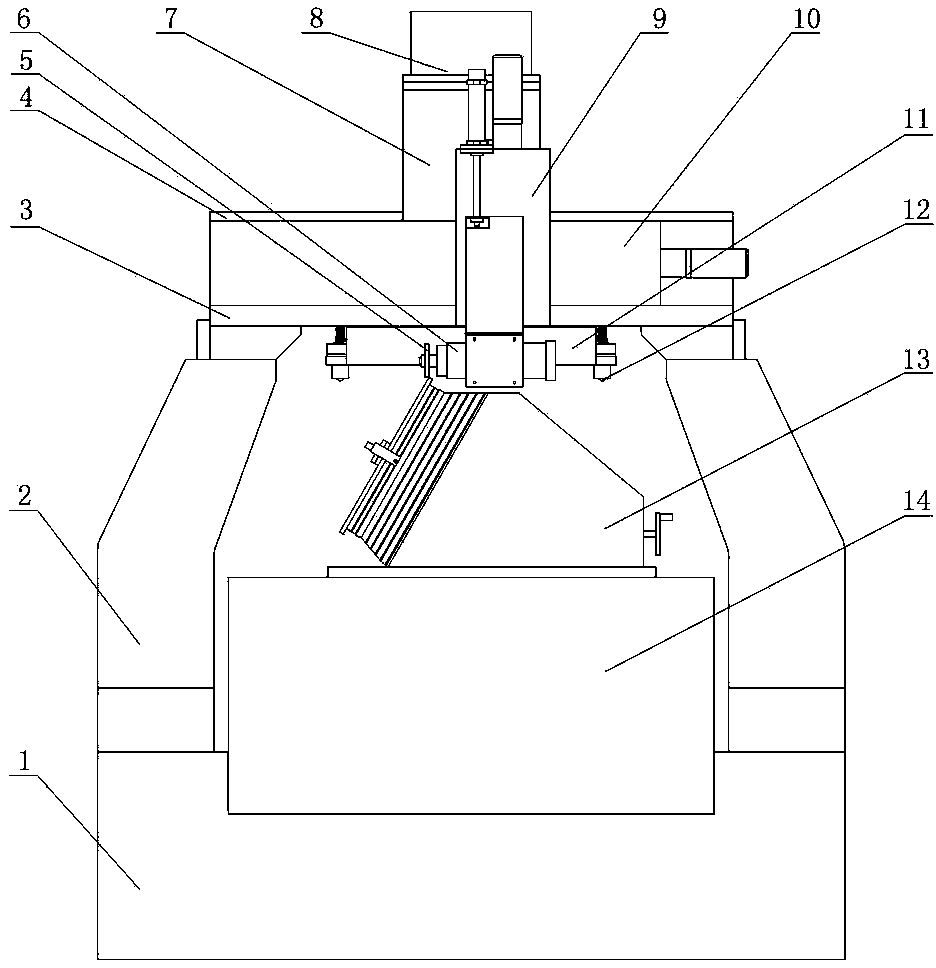

Optical machining grinding and fly-cutting combined machine tool body

InactiveCN103802003AGuaranteed accuracy requirementsGuaranteed Position Accuracy RequirementsEdge grinding machinesFine working devicesOptical processingMachine tool

The invention provides an optical machining grinding and fly-cutting combined machine tool body. The machine tool body has two machining capabilities of grinding and fly cutting, the cutting depth of grinding is relatively large, and then the grinding as rough machining can remarkably improve the machining efficiency, the cutting depth of fly cutting is relatively small, and then the fly cutting as fine machining can effectively guarantee to meet the requirements of shape accuracy and position accuracy of a machined workpiece, one machine tool body has two machining means of grinding and fly cutting, the machined workpiece is located only once, the problem of locating error caused by the repeated location of the machined workpiece is solved, and the requirements on the shape accuracy and position accuracy of the machined workpiece are met. The optical machining grinding and fly-cutting combined machine tool body can meet the requirements like surface figure accuracy, surface quality, surface defects and the like of parts while machining chamfered edge of a KDP crystal to improve the efficiency.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

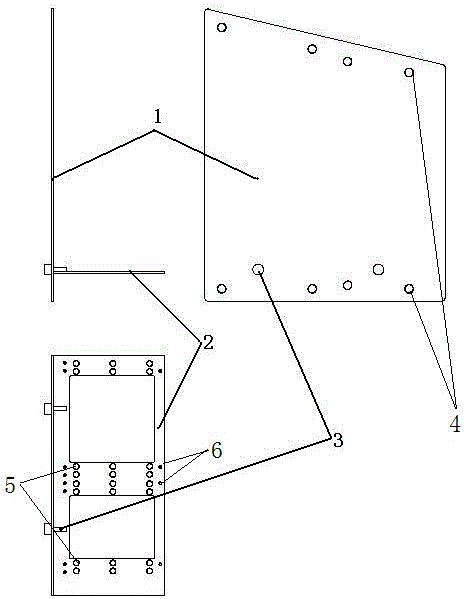

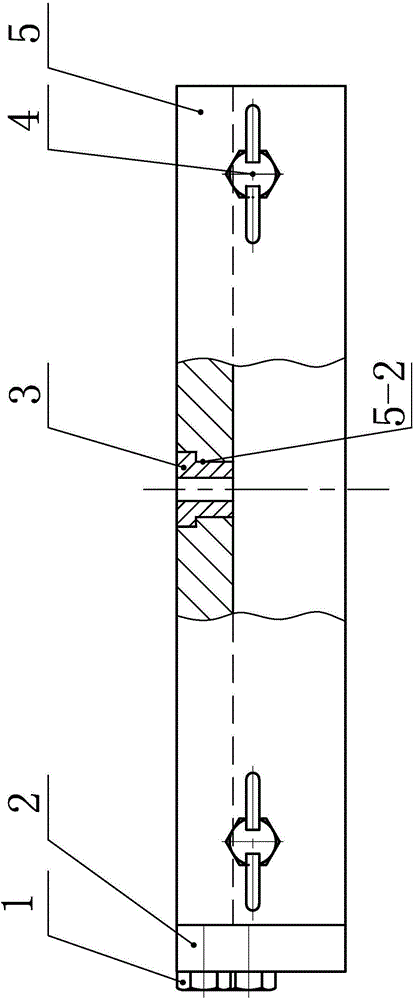

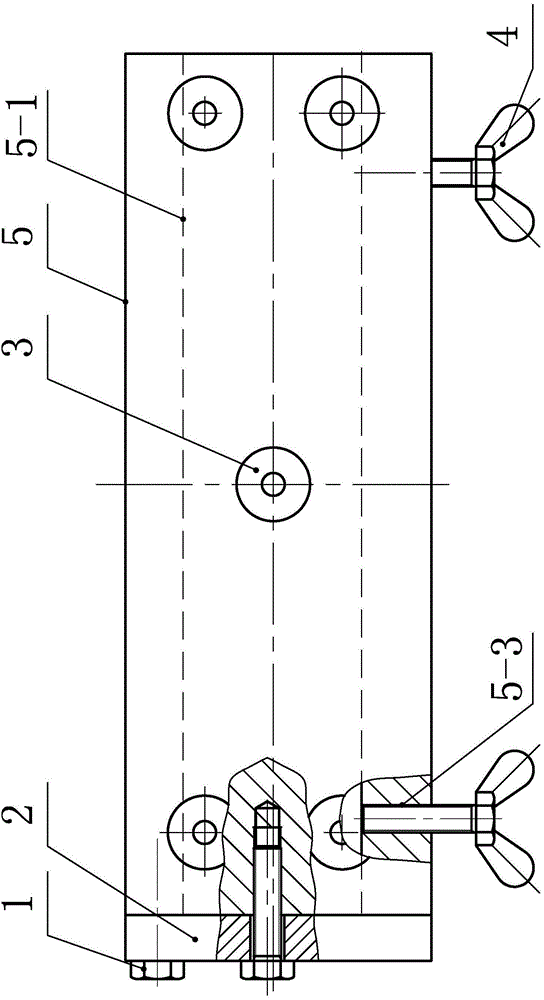

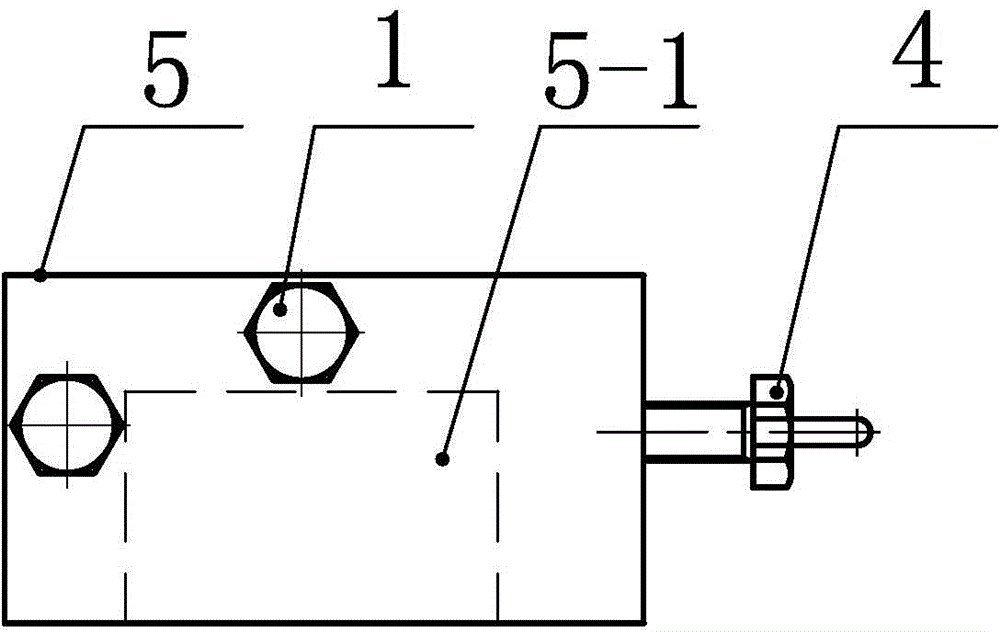

Combined positioning drilling tool for airplane structure

InactiveCN106475602ASimple structureGuaranteed Position Accuracy RequirementsMetal-working feeding devicesPositioning devicesJet aeroplaneEngineering

The invention relates to combined positioning drilling tool for an airplane structure, belongs to the positioning drilling tools which are designed for modifying the airplane structure, and aims to meet positioning drilling requirements of parts. The combined positioning drilling tool comprises three parts, namely a first sample plate, a second sample plate and a dowel pin, wherein the dowel pin is fixedly arranged on the first sample plate and is used for limiting the up-down position, relative to the first sample plate, of the second sample plate; the second sample plate is arranged on the lower surface of the dowel pin, so that the upper surface of the dowel pin clings to the dowel pin, the edge of the dowel pin clings to the surface of the first sample plate, and the left edge and the right edge of the dowel pin are guaranteed to be aligned to the first sample plate; and an included angle between the first sample plate and the second sample plate is 90 degrees. The combined positioning drilling tool can guarantee positioning precision requirements of parts, and can guarantee relative position precision of holes; and moreover, the tool is simple in structure, can be quickly manufactured, reduce preparation time, is simple and convenient in use, and can meet the refitting needs.

Owner:JIANGXI HONGDU AVIATION IND GRP

Precise five-hole positioning and drilling clamp for rectangular cylinder workpiece

InactiveCN105642955AGuaranteed Position Accuracy RequirementsIncrease productivityDrill jigsInterference fitRejection rate

The invention discloses a precise five-hole positioning and drilling clamp for a rectangular cylinder workpiece and belongs to the technical field of machining. By the adoption of the precise five-hole positioning and drilling clamp for the rectangular cylinder workpiece, the problems that when an existing technique is used for drilling five threaded bottom holes in each of two opposite side walls of the rectangular cylinder workpiece, the probability that the location degrees of the five threaded bottom holes in each side wall are out of tolerance is large, the rejection rate is large, the production cost is high, and the working efficiency is low are solved. A clamp body is a rectangular plate. A through groove is machined in the middle of the lower surface of the clamp body in the length direction of the clamp body. One end face of the clamp body is fixedly connected with a baffle through two connecting bolts. Five shoulder holes of the clamp body communicate with the through groove. One shoulder hole is located in the position of the geometrical center of the clamp body, and the other four shoulder holes are arranged in a rectangle mode. The geometrical center lines of the four shoulder holes arranged in the rectangle mode coincide with the geometrical center line of the clamp body. A drill sleeve is assembled in each shoulder hole, wherein the drill sleeve is in interference fit with the shoulder hole. Two threaded holes of the clamp body communicate with the through groove and are connected with butterfly bolts in a threaded mode. The precise five-hole positioning and drilling clamp is used for precise positioning and clamping when the five holes in each side wall of the rectangular cylinder workpiece are drilled.

Owner:HARBIN JIANCHENG GRP

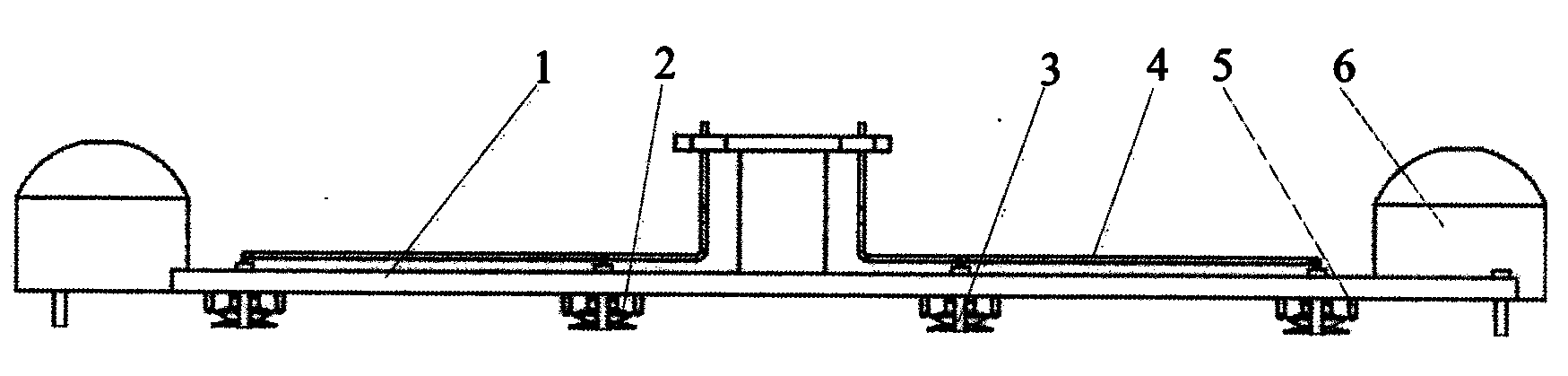

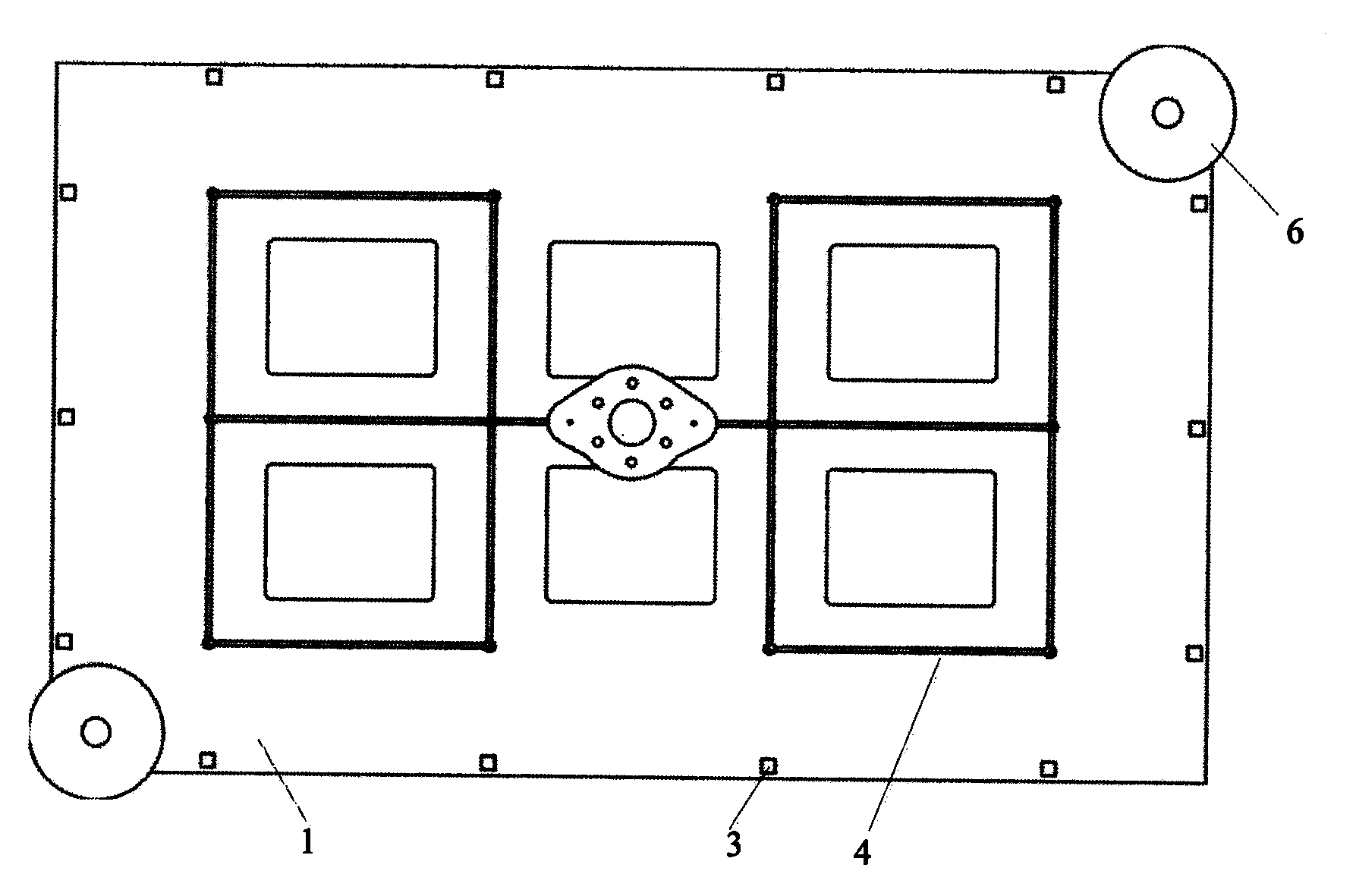

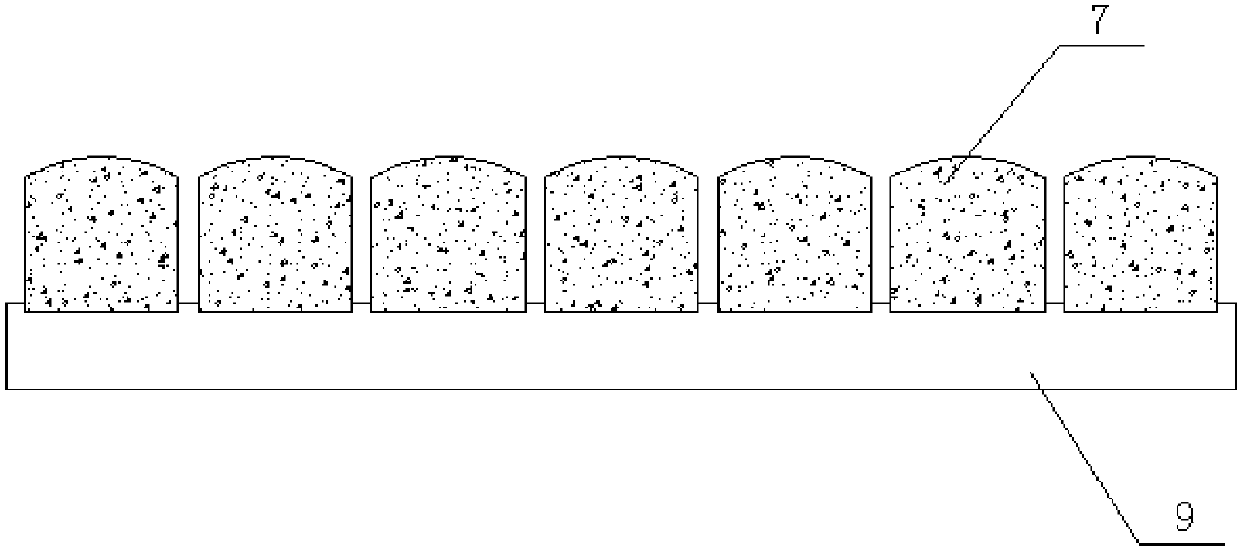

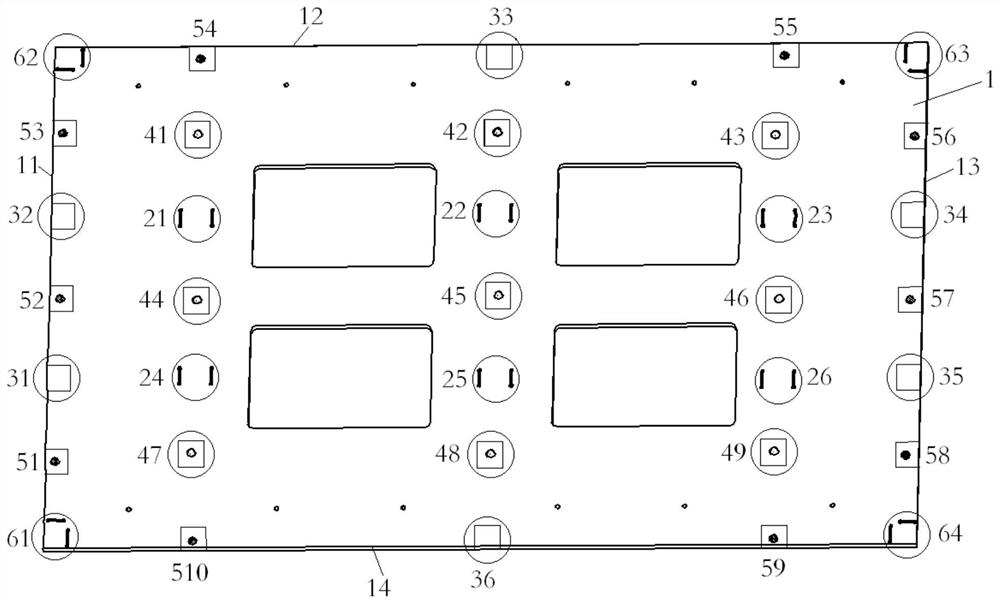

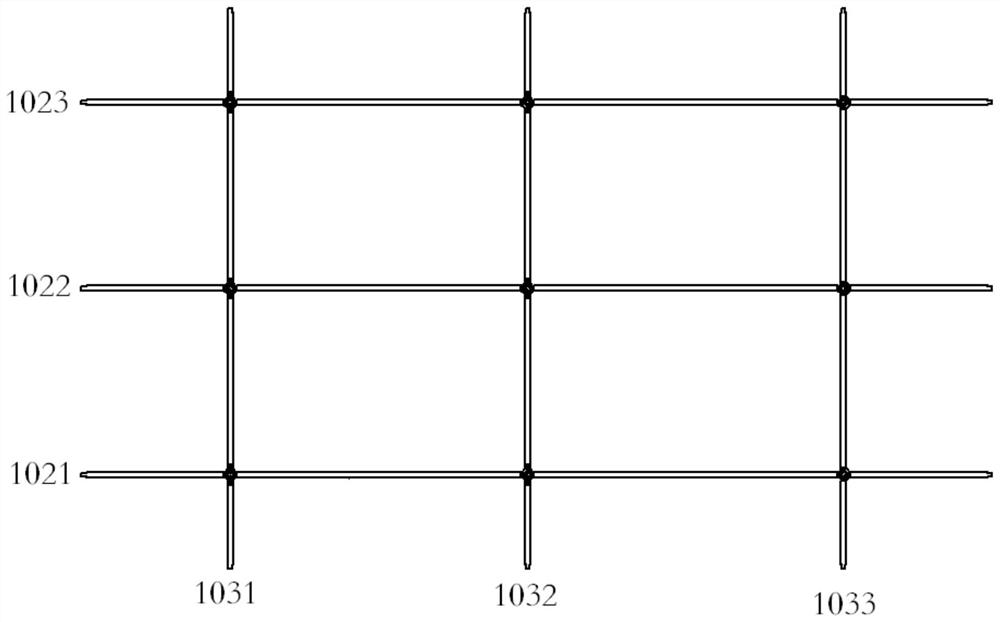

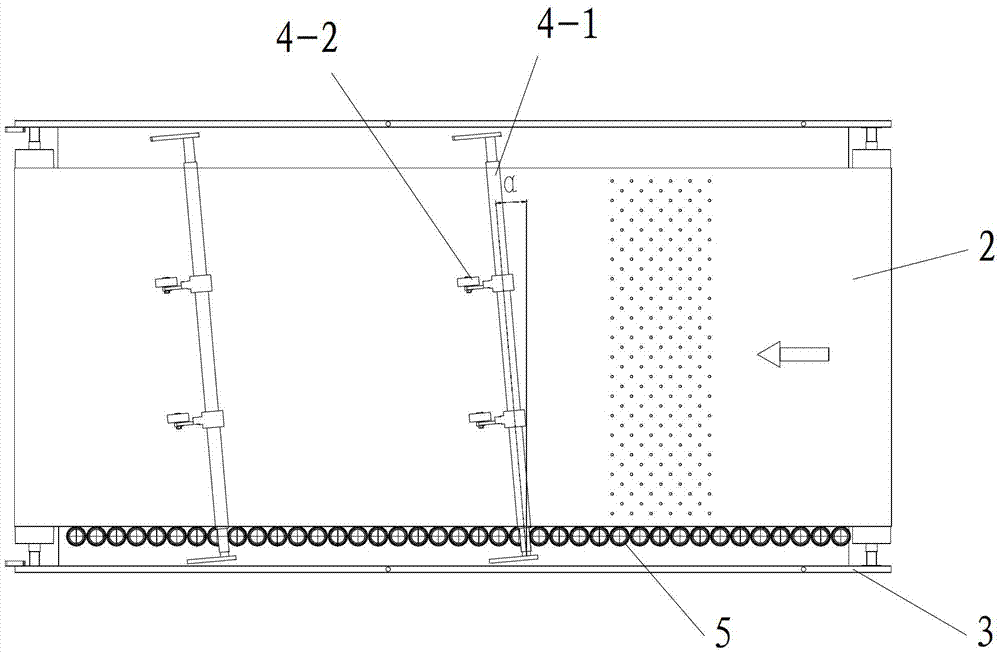

A linear motor array magnetic steel precision bonding device

ActiveCN105846648BDisplacement fine adjustmentHigh bonding displacement accuracyManufacturing stator/rotor bodiesPropulsion systemsMetallurgyBonding process

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

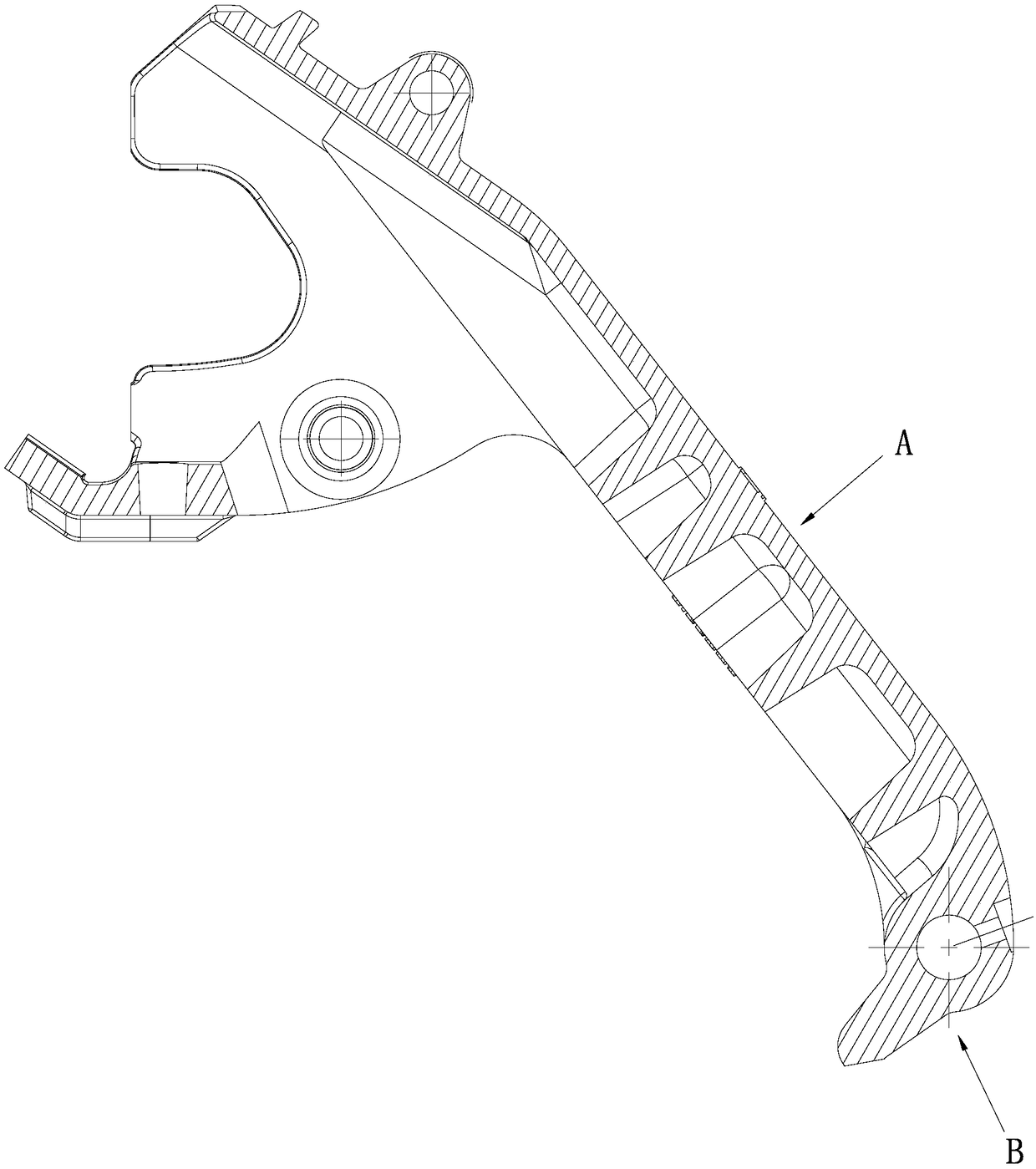

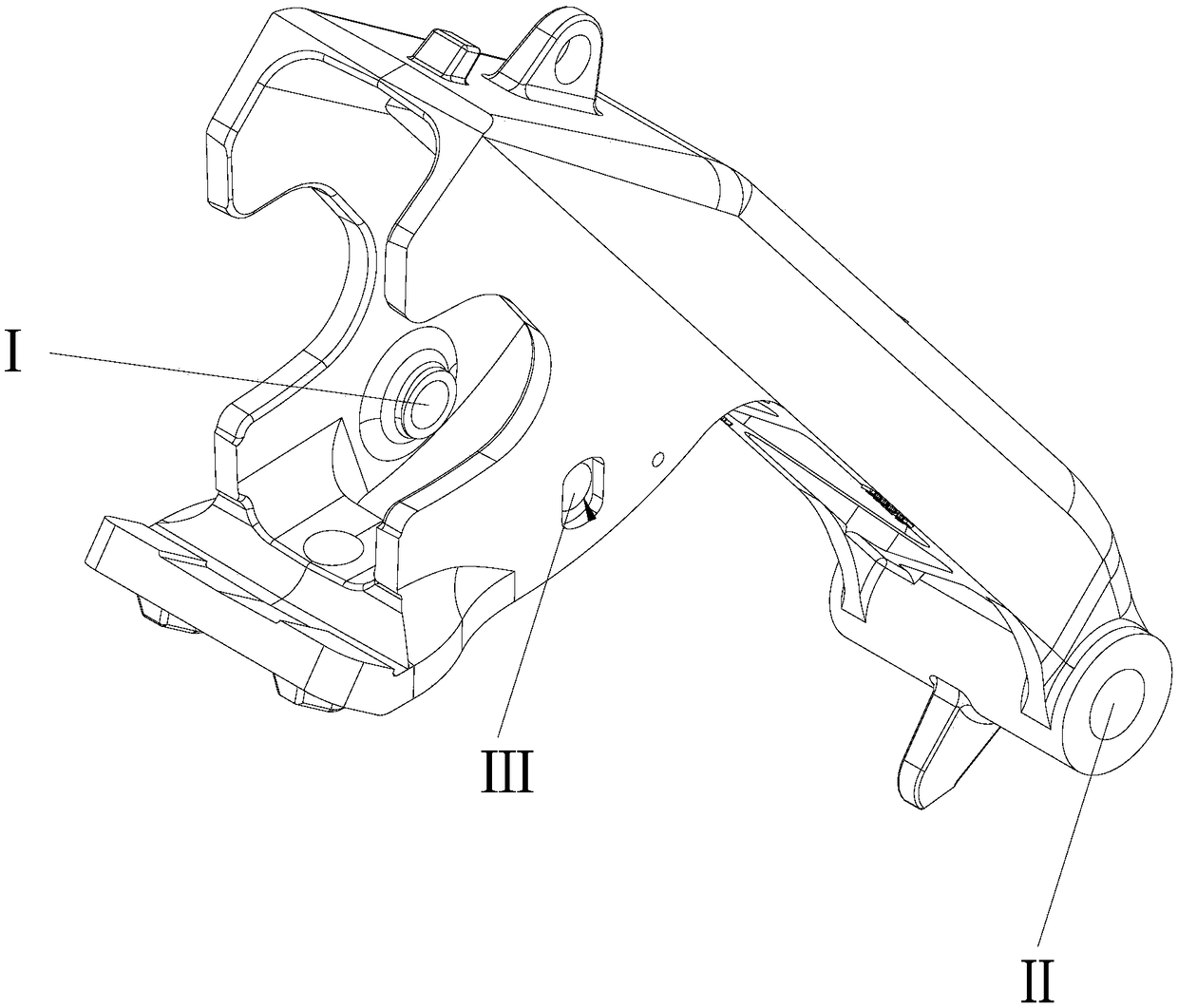

Machining tool and technology for small control arm

InactiveCN109333116AReduce the number of clampingReduce auxiliary timePositioning apparatusMetal-working holdersControl armStructural engineering

The invention relates to a machining tool for a small control arm. The machining tool comprises a vertical machining center and a horizontal machining center; a first vertical positioning plate is arranged on the vertical machining center; a first positioning bolt is arranged on the first vertical positioning plate; two second vertical positioning plates are arranged on the vertical machining center; two second positioning bolts and a plurality of threaded holes are formed in the side surfaces of each second vertical positioning plate; fixing components are further arranged; and two threaded holes, screws and nuts are arranged on the horizontal machining center. The machining tool is high in machining precision, low in labor intensity, low in cost and high in efficiency, the clamping timescan be reduced during machining, special and universal technological equipment can be saved, and the occupied workshop area can be saved.

Owner:SHANDONG FUYUAN TRACK MACHINERY CO LTD

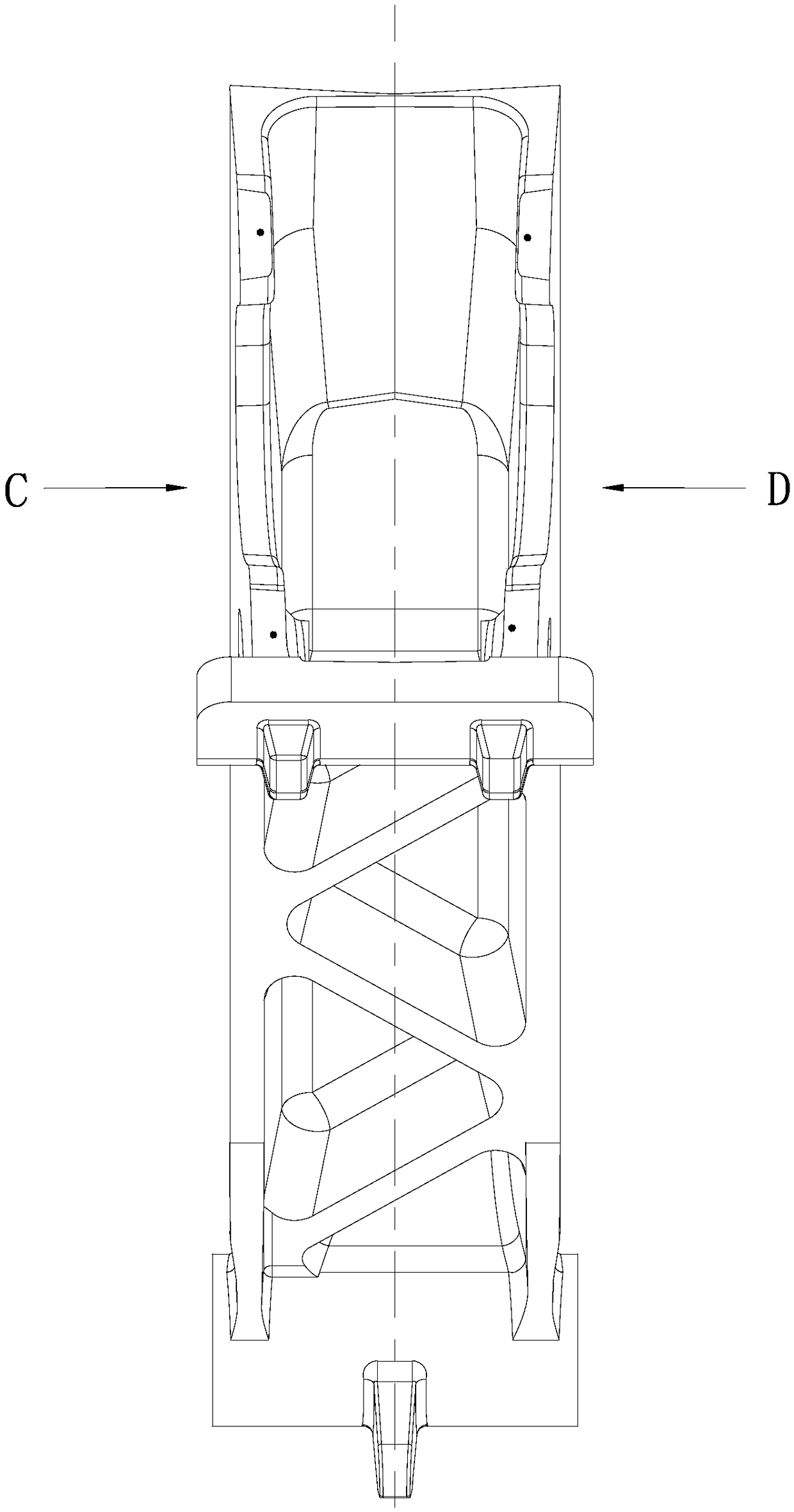

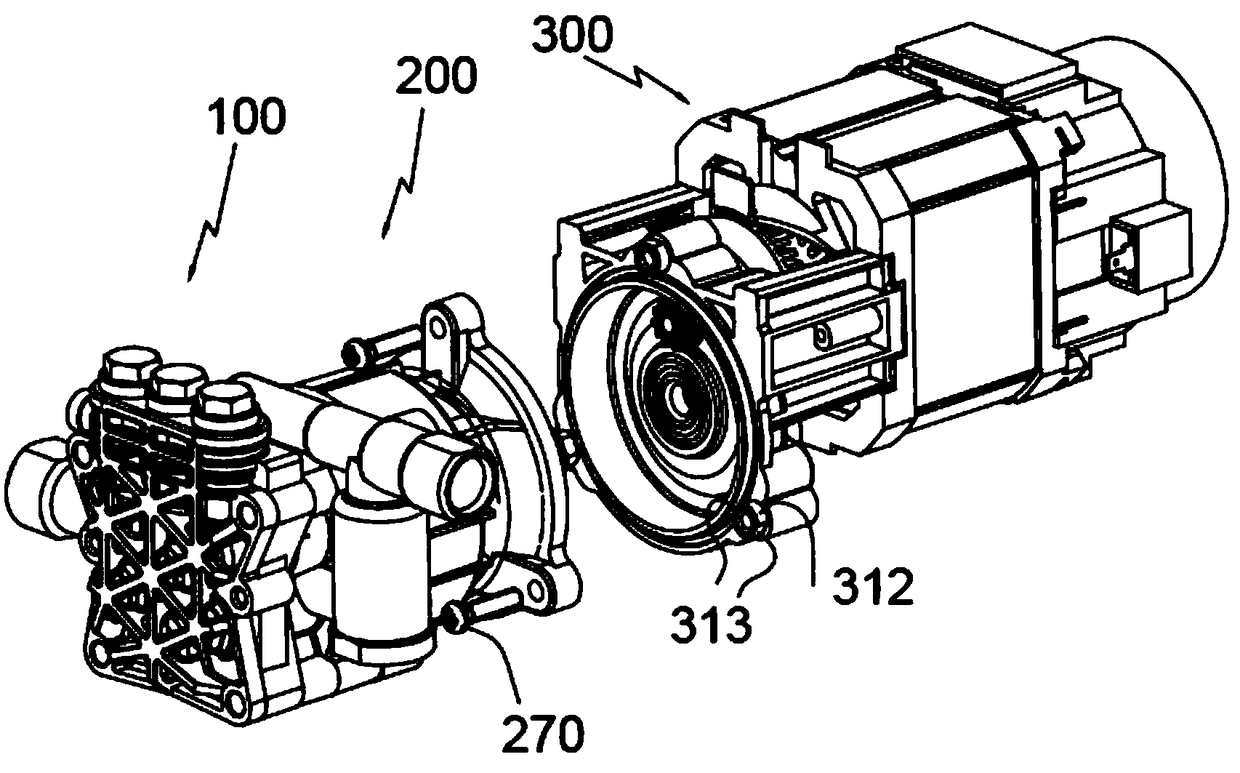

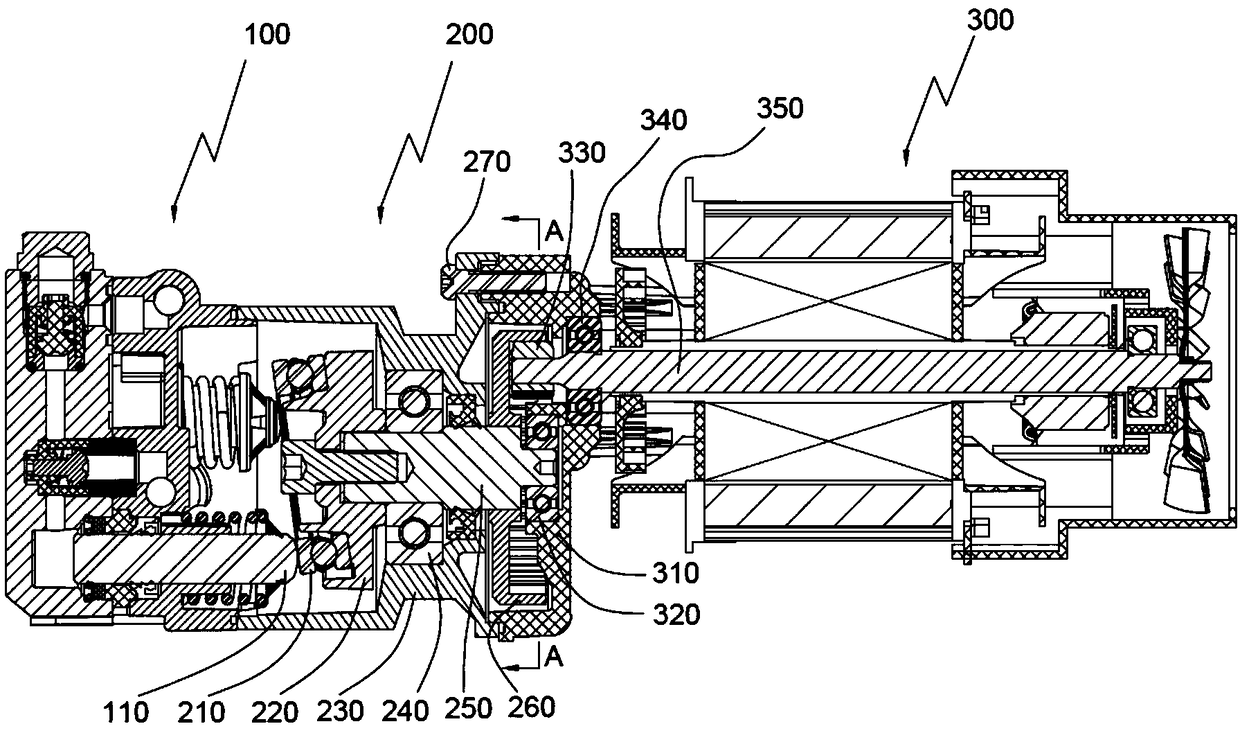

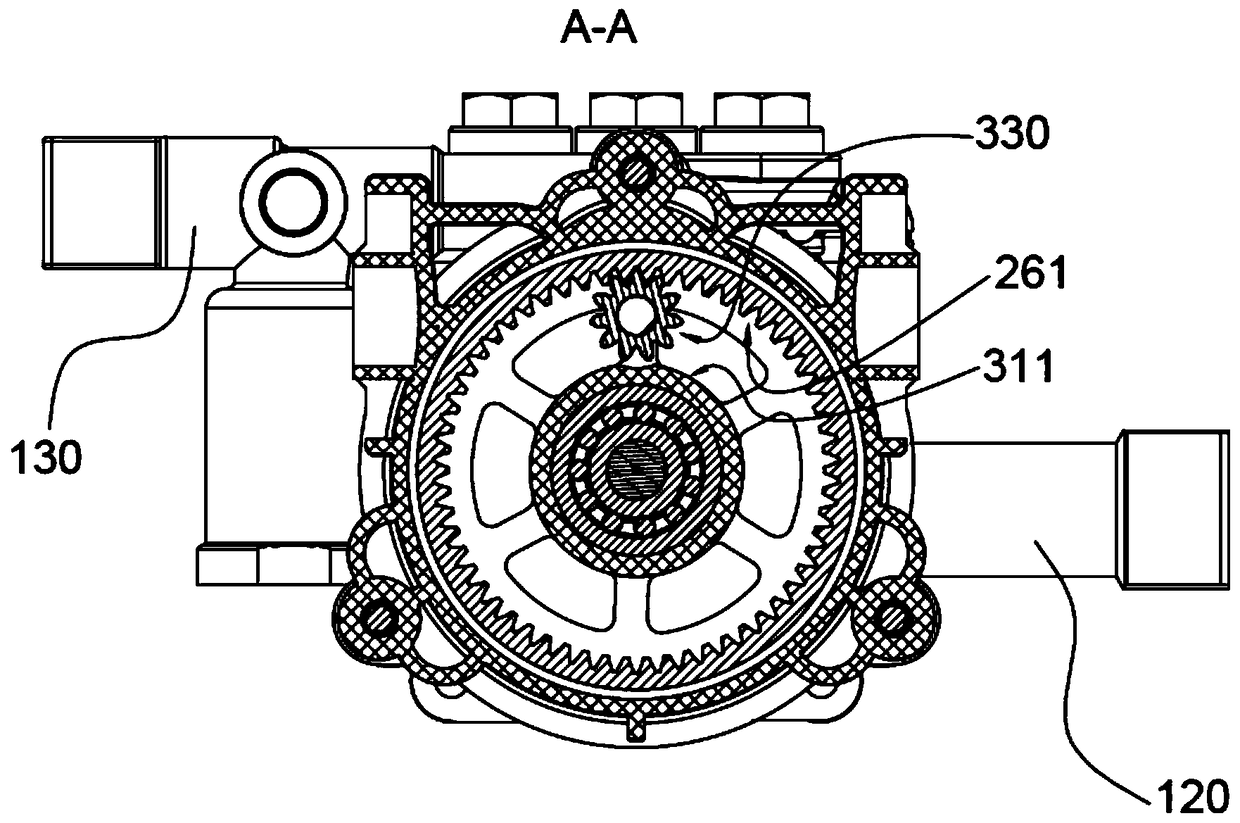

Motor pump unit

PendingCN109209809AHigh coincidenceSmooth transmissionPositive displacement pump componentsPositive-displacement liquid enginesDrive shaftEngineering

The invention provides a motor pump unit which comprises a pump assembly, a transmission box device and a motor assembly. The transmission box device comprises an inner gear part. The inner gear partat least comprises three end faces, the first end face, the second end face and the third end face, in the thickness extending direction. The inner gear part comprises an inner gear ring portion, a connecting portion and a fixed ring portion from outside to inside in the radial direction, wherein the inner gear ring portion, the connecting portion and the fixed ring portion are connected in sequence. The inner gear ring portion comprises an inner gear ring. The fixed ring portion comprises a driven shaft mounting hole. A driven shaft is relatively fixedly mounted in the driven shaft mounting hole in the circumferential direction and is connected with the pump assembly. An outer gear is relatively fixedly mounted on a motor shaft included in the motor assembly in the circumferential direction. The outer gear is mounted on the inner gear ring portion in an eccentric engagement manner. In the motor pump unit, due to the fact that inner engagement is adopted by large and small gear engagement, the overlap ratio of the two gears is higher than that of outer engagement, transmission is more stable, and noise is lower.

Owner:SHANGHAI YILI ELECTRIC

Piercing die for simultaneously punching five direction holes by using two different cam mechanisms, and operating method thereof

InactiveCN106734552AGuaranteed Position Accuracy RequirementsPerforating toolsThin shellsEngineering

The invention relates to a piercing die for simultaneously punching five direction holes by using two different cam mechanisms, and an operating method thereof, and is characterized in that the piercing die for simultaneously punching five direction holes by using two different cam mechanisms comprises an upper die, a lower die, and a piercing lower die sleeve disposed over the middle of the lower die; a to-be-punched hood-shaped thin shell workpiece is disposed at an upper portion of the piercing lower die sleeve; a lower portion of the upper die is provided with motion cam punches and a single-action double-faced cam punch; the lower die is provided with three radial punch pin sliding seats which can be driven by the three sets of motion cam punches to move and a couple of opposite punch pin sliding seats which can be driven by the single-action double-faced cam punch to move; inner end portions of the radial punch pin sliding seats are provided with radial hole punch pins; and inner end portions of the opposite punch pin sliding seats are provided with opposite hole punch pins. Position accuracy requirements of to-be-machined holes of the hood-shaped thin shell workpiece can be satisfied.

Owner:FUZHOU UNIV

A kind of glued assembly process method of stretched string semi-rigid substrate frame

ActiveCN112343907BGuaranteed mechanical propertiesGuarantee the mechanical properties of the compression pointMaterial gluingStructural engineeringMechanical engineering

The invention discloses a method for gluing and assembling a string-tensioned semi-rigid base plate frame, comprising: gluing a central frame; installing a reinforcing beam and a limit beam for trial assembly; gluing an outer frame; gluing a corner box and a corner sheet to obtain a stretched-string semi-rigid substrate frame. The invention solves the problems of the existing stretched string type semi-rigid substrate frame gluing process method, such as compact gluing period, poor assembly precision, large assembly stress and the like.

Owner:BEIJING SATELLITE MFG FACTORY

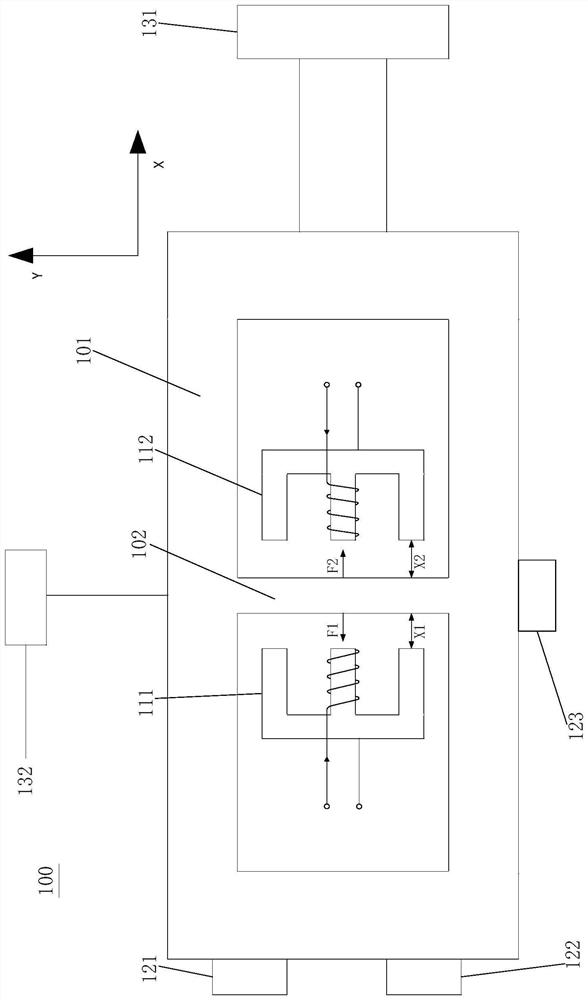

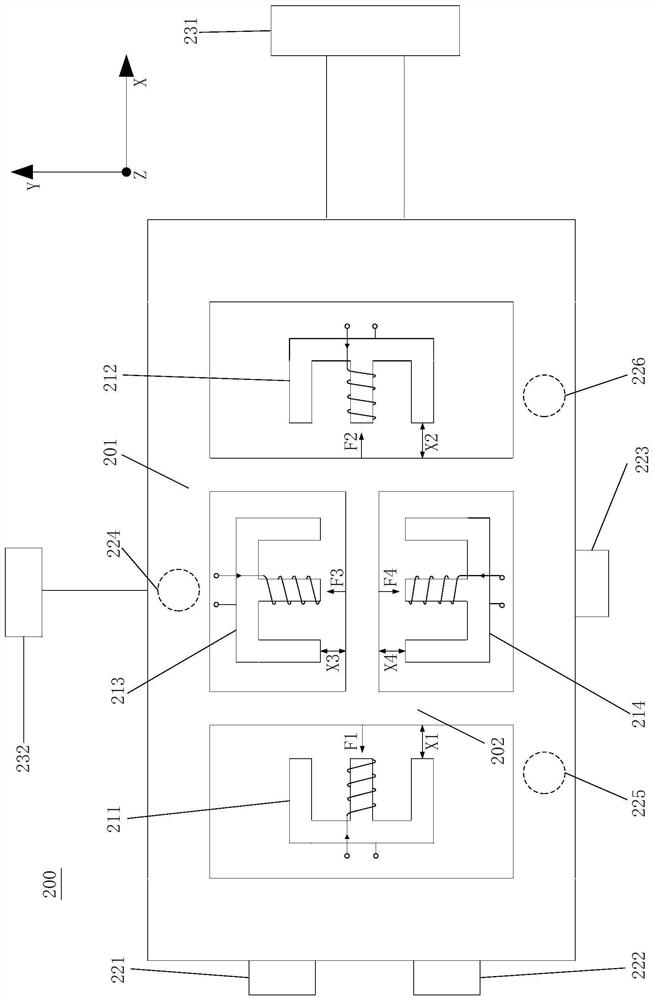

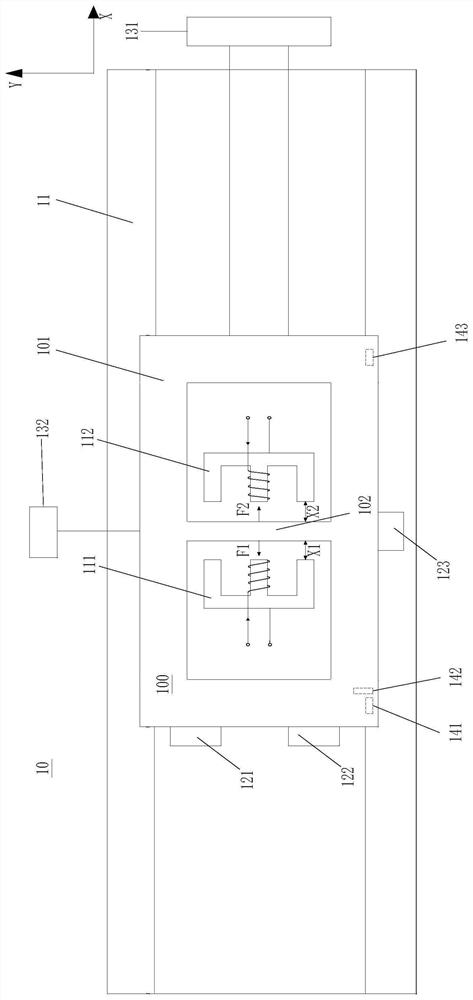

Motion platform of lithography machine, micro-motion platform and control method thereof

ActiveCN108279551BReduce volumeSmall currentPhotomechanical exposure apparatusMicrolithography exposure apparatusLoop controlMagnetic reluctance

Owner:FUDAN UNIV

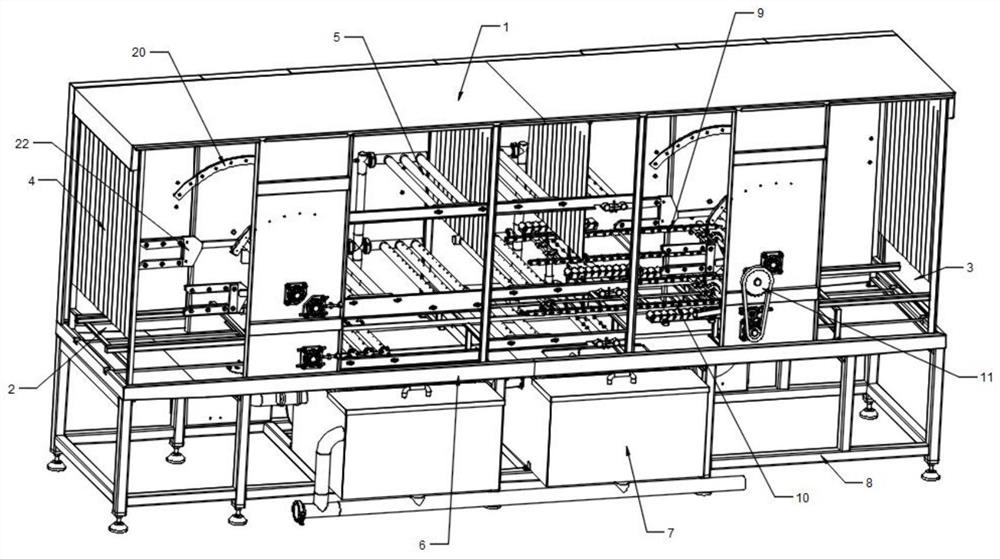

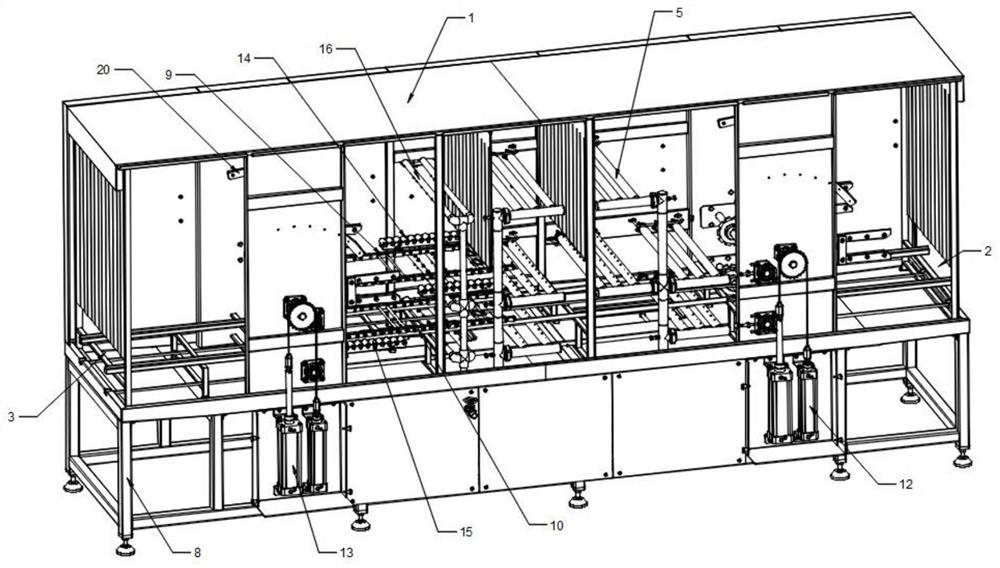

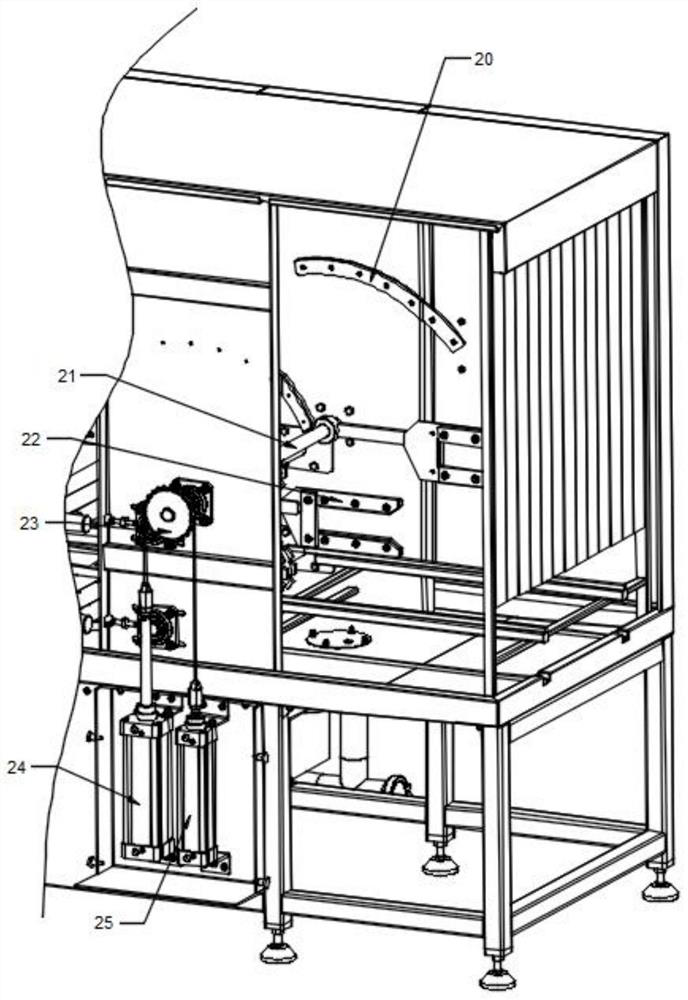

A double-layer pot washing machine for rice production line

ActiveCN110252716BPrevent deviationGuaranteed positioning accuracyHollow article cleaningCleaning using liquidsAgricultural scienceRice dishes

The invention discloses a double-layer pot washing machine for a rice production line, which belongs to the technical field of mechanical equipment and comprises a pot washer shell and a frame fixedly arranged at the bottom of the pot washer shell. The inlet of the pot washer and the outlet of the pot washer, and the inner two ends of the frame are respectively fixed with a first turning system and a second turning system, the first turning system and the second turning system both include a reset cylinder and a turning cylinder. An overturning drive sprocket movably connected with the overturning cylinder and a resetting cylinder, an overturning shaft fixedly connected with the overturning transmission sprocket, an overturning arm fixedly connected with the overturning shaft, and an overturning pot guide plate used in cooperation with the overturning arm. In the present invention, the pot cover and the pot are transported separately, and the pot cover and the pot are guided and positioned separately to ensure the position accuracy requirements of the cleaned pot cover and pot after they leave the pot washer; an automatic pot turning system is added to the pot washer , and also ensure the relative position of the pot cover and the pot after washing the pot.

Owner:南京乐鹰科技股份有限公司

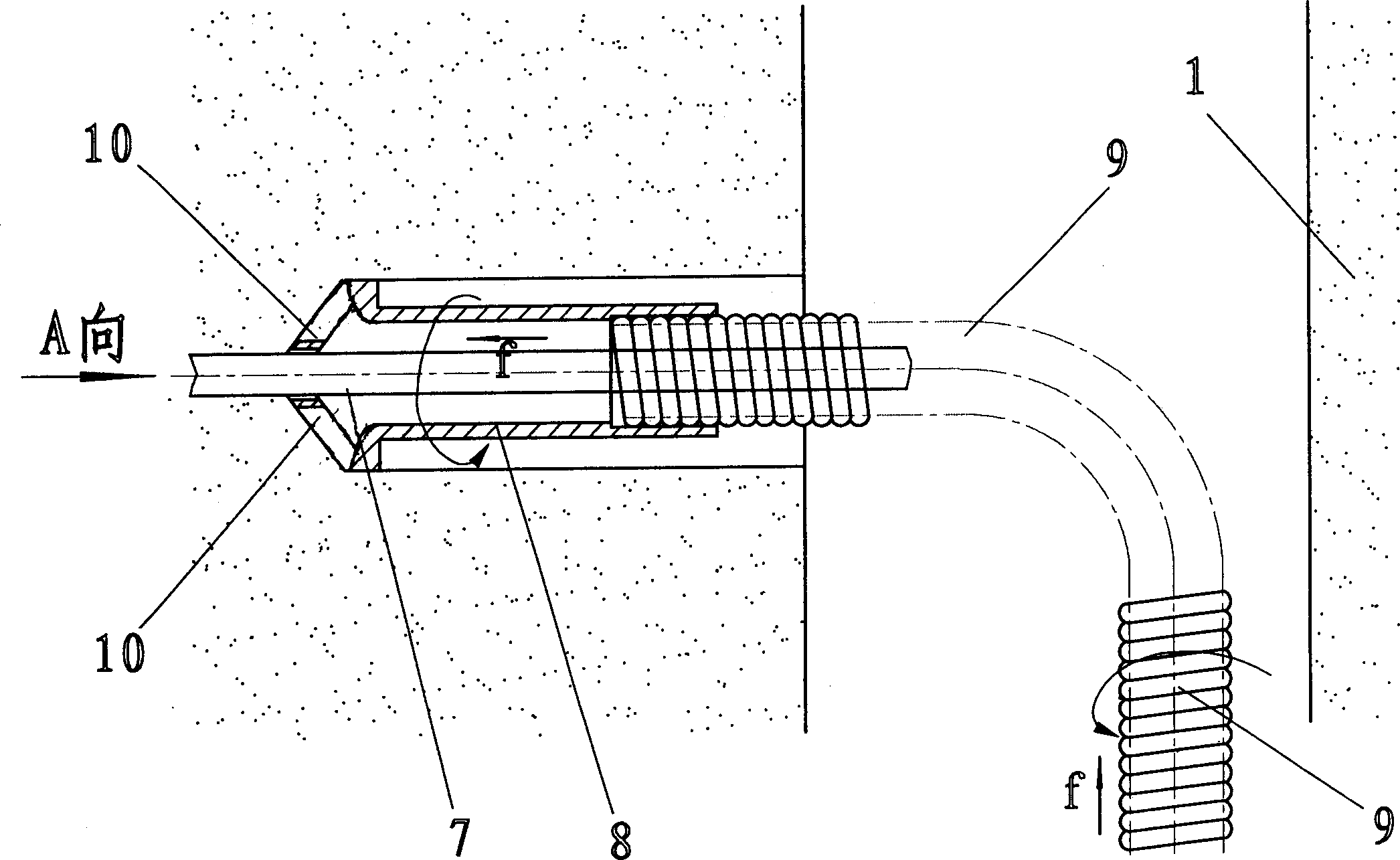

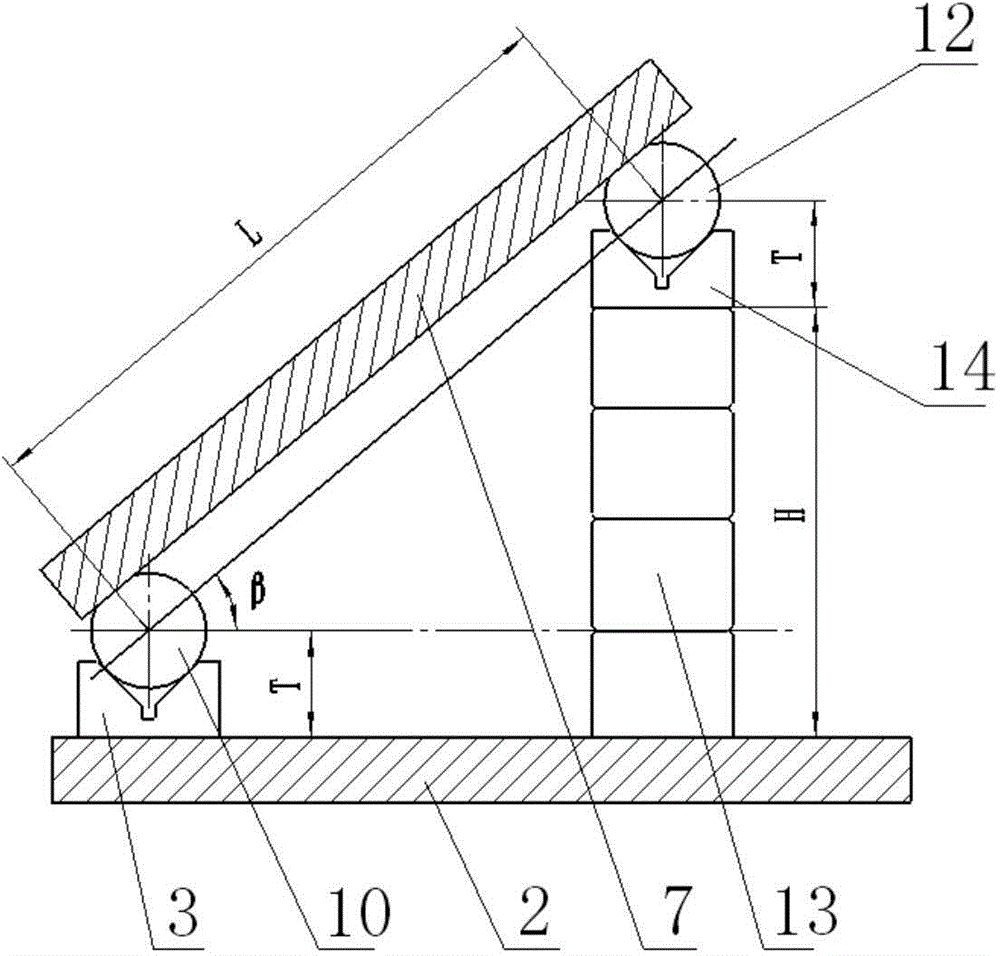

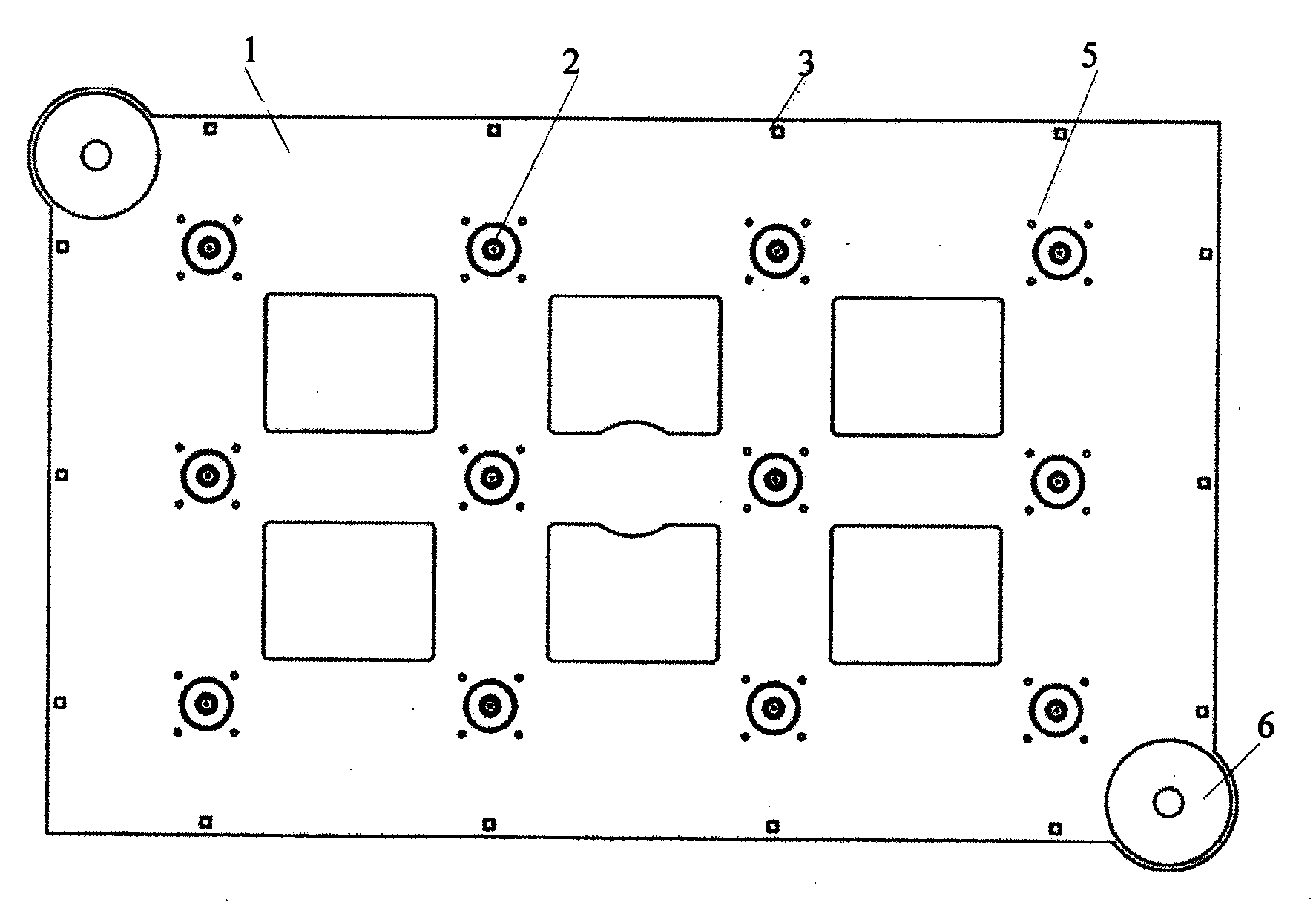

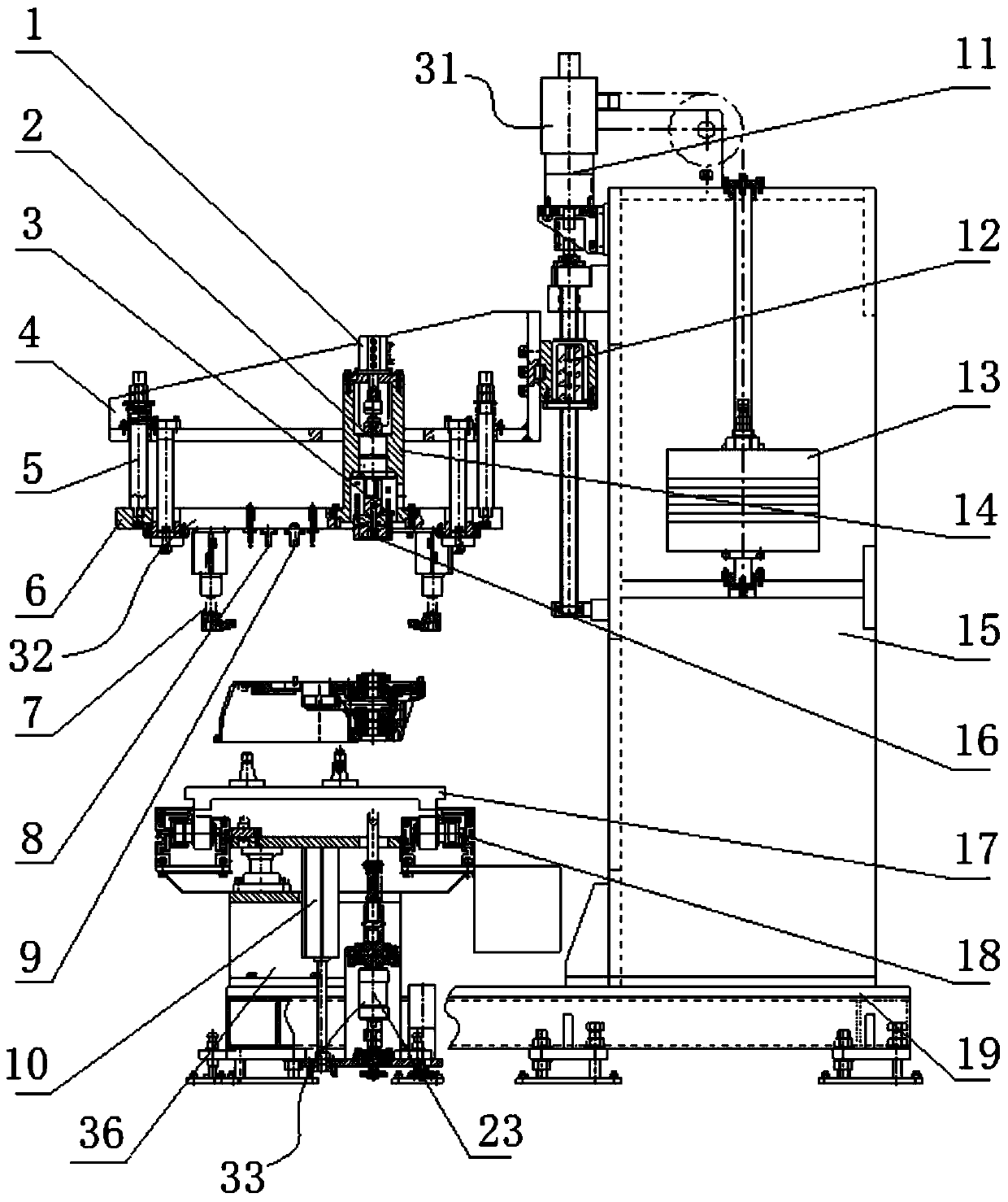

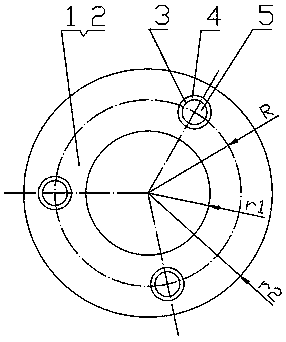

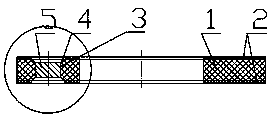

Belt correction device and working method thereof

ActiveCN102951465BPrecise positioningOvercoming the defects caused by precision errorsArticle feedersEngineeringAngle alpha

The invention provides a belt correction device. The belt correction device is characterized in that the belt consists of a pressure wheel assembly and a roller wheel flange assembly; the pressure wheel assembly presses the belt and forms an angle alpha with the shortest connecting line at the width direction of the belt; the roller wheel flange assembly is in contact with one side of the belt; the roller wheel flange assembly is used as the reference for positioning the belt. The working method comprises the following steps that the belt runs according to the working direction; in the running process of the belt, the belt laterally moves to the roller wheel flange assembly under the action of the inclined pressure wheel assembly; and one side of the belt is in contact with the roller wheel flange assembly to block the side, so that the side is tightly close to the roller wheel flange assembly to move right forwardly. The device and the method provided by the invention have the advantages that the belt positioning is accurate and stable; the defect brought by accuracy error of the belt is overcome; as the belt is positioned at single side, the requirement on positioning accuracy for a wide belt to convey printed goods for a long distance is ensured; and in addition, the inclined angle of the pressure wheel assembly is small, the belt is gradually close to the single-sided roller wheel flange assembly in the movement, so that the belt can be positioned stably.

Owner:MASTERWORK GROUP CO LTD +1

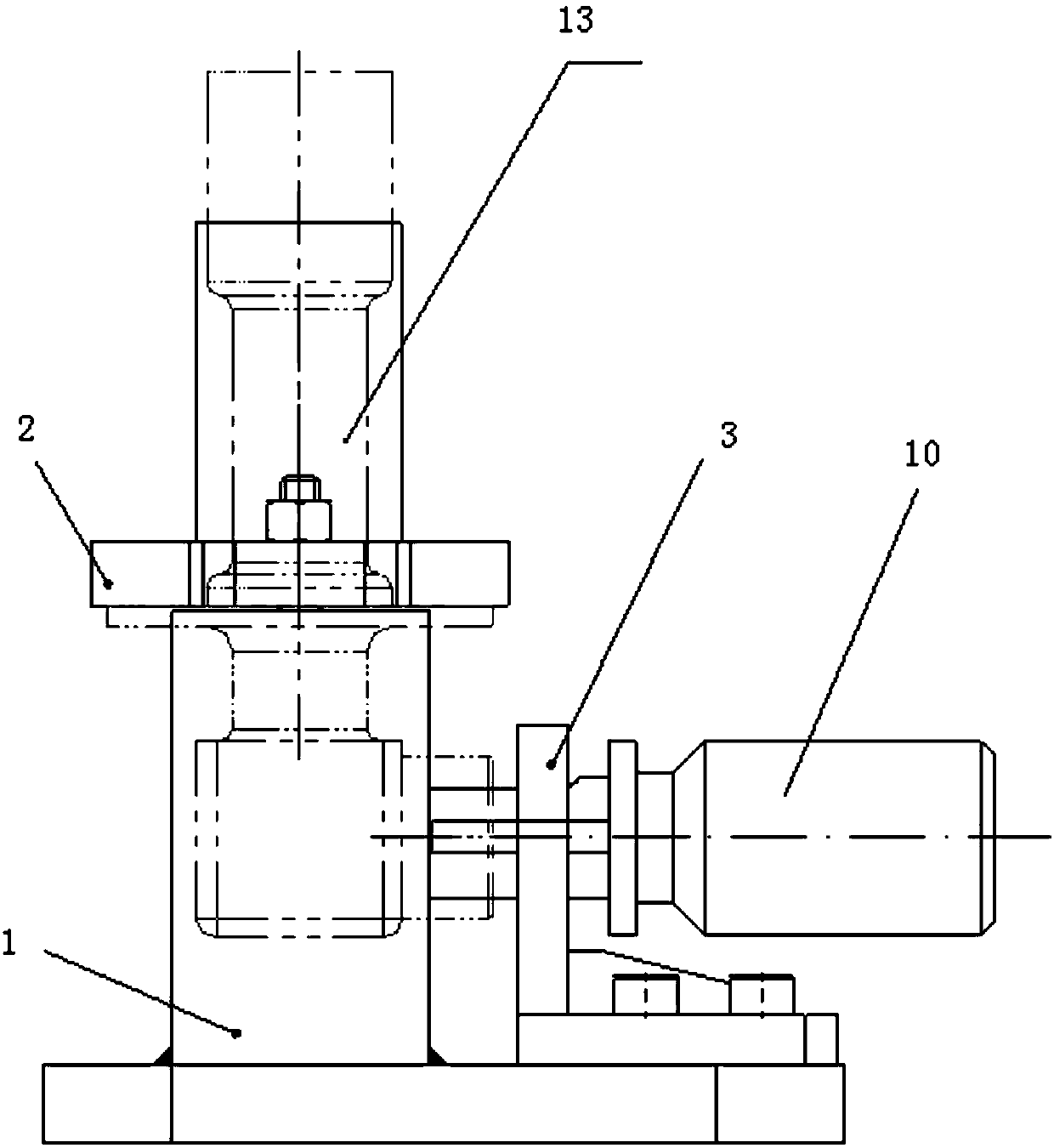

Automatic and precise measuring machine for tapered bearing shims

ActiveCN108072347BReasonable structural designGuaranteed accuracyMechanical measuring arrangementsEngineeringDeep hole

The invention relates to an automatic accurate measuring machine for a cone bearing gasket. The automatic accurate measuring machine comprises a lifting machine head, an off-shell measuring mechanism,a changing-shell measuring mechanism and a rotary simulation mechanism, wherein the off-shell measuring mechanism comprises a loading cylinder, an off-shell measuring plate and a cone bearing outer ring measuring head, the off-shell measuring plate is mounted on the lifting machine head in a floating mode, the cone bearing outer ring measuring head is driven to realize lifting through the loadingcylinder and presses against a cone bearing outer ring on an off shell during measurement, the changing-shell measuring mechanism comprises a measuring cylinder, a guide shaft, a changing-shell measuring plate and a deep hole measuring head, the changing-shell measuring plate is mounted on the lifting machine head in a floating mode, a lower end of the guide shaft penetrates through the changing-shell measuring plate, is then connected with the deep hole measuring head and is lifted through the measuring cylinder, the deep hole measuring head stretches into a to-be-measured hole during measurement when a measuring pressure plate on the guide shaft presses a displacement sensor, and the rotary simulation mechanism used for driving a differential mechanism to rotate is arranged below the lifting machine head. The automatic accurate measuring machine is advantaged in that parameters of the cone bearing gasket can be accurately measured, and actual conditions can be simulated during measurement.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

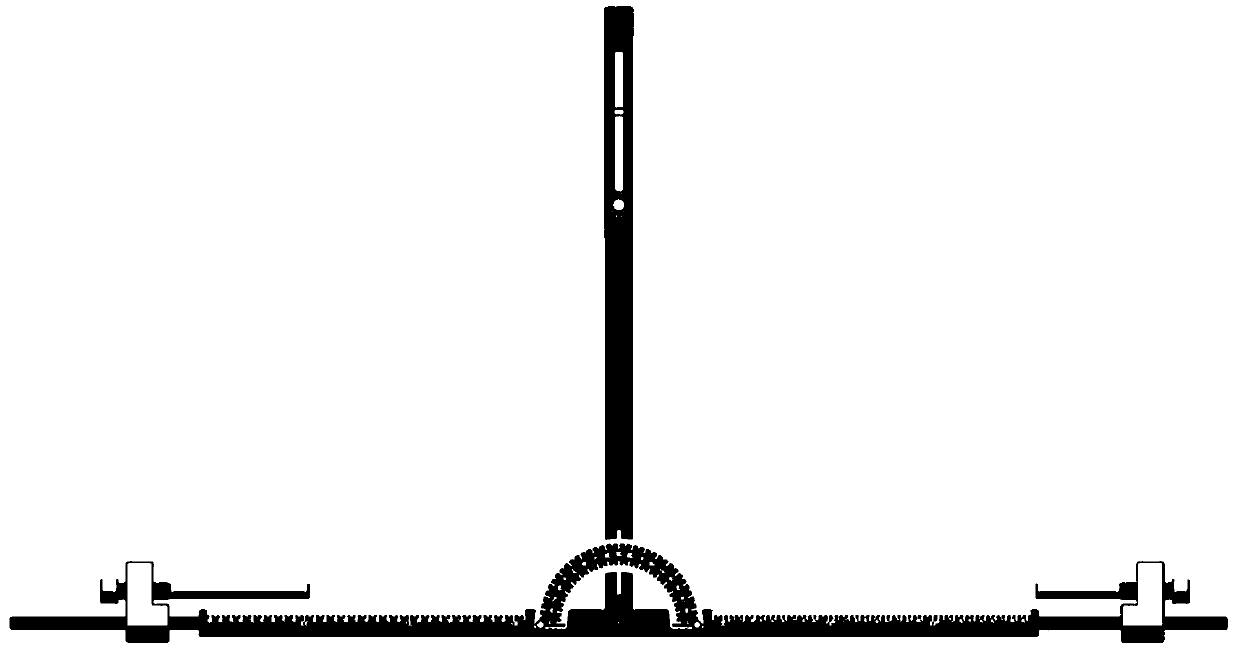

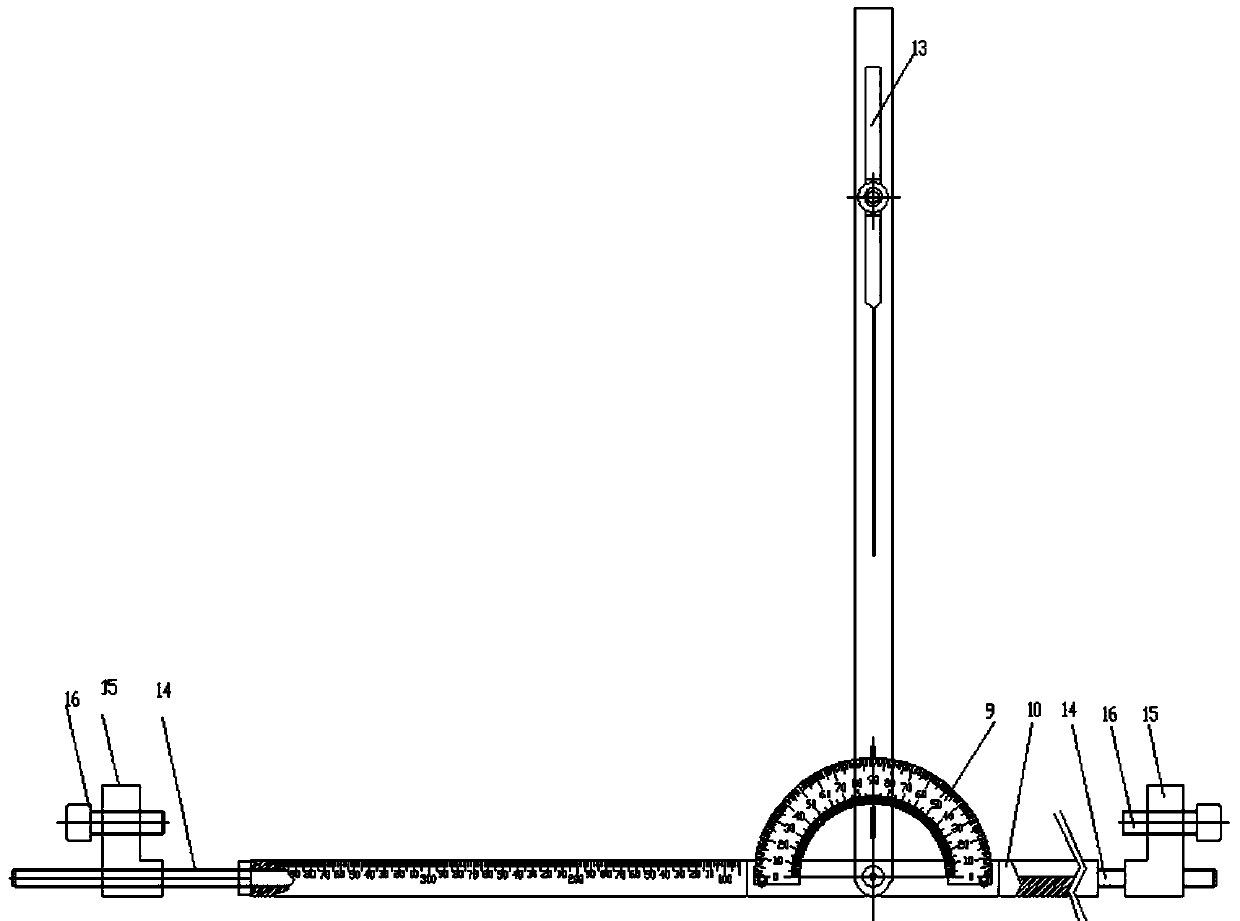

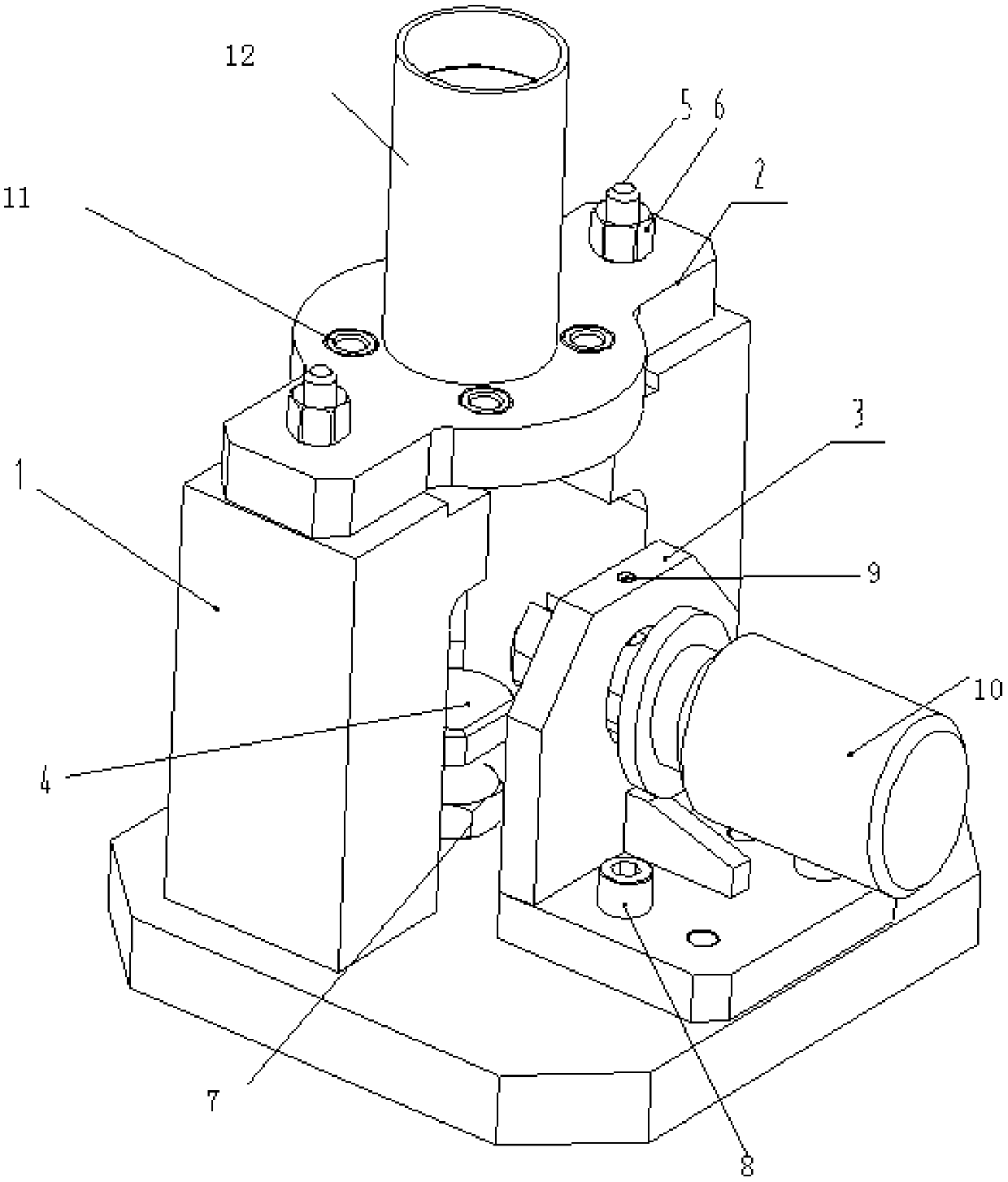

Device for Finding the Cooling Point of the Hot Section of the Wheel Hub Casting Side Mold and Its Application

ActiveCN106825439BSimple structureSimple and fast operationFoundry mouldsFoundry coresEngineeringAngle gauge

The invention relates to an aluminum alloy hub gravity casting side die hot spot cooling point seeking device. According to positions of cooling holes required by a side die and a bridging principle, the point seeking device is simple in structure and convenient to operate, and by a square groove design of a main rod 8, vertical movement of a vertical connection rod is realized, and adaptability to different hub dies is realized. Left and right locking blocks 15 adjustable in distance are further arranged at two ends of a right-angle gauge respectively, and owing to threads of the locking blocks, stability of the device in a point seeking process is improved, and simplicity and convenience in operation are further improved. The problem of difficulty in point seeking is solved, procedures are simplified while hole position precision is guaranteed, and operation efficiency is effectively improved.

Owner:苏州金瑞阳模具有限公司

Flange plate drilling clamp of L-shaped tubular part

The invention belongs to the technical field of machining, and particularly relates to a flange plate drilling clamp of an L-shaped tubular part. Holes in the flange plate of the L-shaped tubular partinterfere with the shorter end of the part, the special lengthened drill bit needs to be used, and when the drill bit is drilled, the cutter frequently inclines and slides, so that the part is scrapped. According to the flange plate drilling clamp, a pair of stand columns and a support are arranged on the base, a supporting platform is arranged on the base between the stand columns, opposite steps are arranged on the upper end face of the stand columns, the flange plate of the L-shaped tubular part is arranged in the opposite steps, a drilling template is arranged on the upper end surface, and a guide pipe which is in clearance fit with one end of the L-shaped tubular part in a sleeved mode is arranged on the drilling template, and a guide pin which is in clearance fit with the other endof the L-shaped tubular part in a sleeved mode is arranged on the support. The flange plate drilling clamp has the advantages of being accurate in positioning, simple in structure and convenient to clamp and dismount, so that the position precision and the size requirement of to-be-processed holes of the special lengthened drill bit with the suspension diameter ratio larger than 18 can be effectively ensured.

Owner:JIANGXI CHANGHE AVIATION IND

An angle table with high precision combined fixture

ActiveCN104551709BHigh precisionGuaranteed positioning accuracyLarge fixed membersPositioning apparatusStructural engineeringWorkbench

The invention discloses an angle workbench of a high-precision combined too. The angle workbench of the high-precision combined tool comprises a lower foundation plate, an upper foundation plate, a supporting part and a connecting plate; the supporting plate is vertically fixed on the lower foundation plate; two lower V-shaped supporting blocks which have the same structure are arranged close to one side of the lower foundation plate; the supporting part comprises a rectangular supporting element and an upper V-shaped supporting block; the upper V-shaped supporting block is structured the same as the lower V-shaped supporting blocks, and a central line of the upper V-shaped blocking block is parallel to the center lines of the two lower V-shaped supporting blocks; three trimming shafts which have the same structure and are integrally connected with the upper foundation plate are arranged on one downward surface of the upper foundation plate; respectively positioned on the two lower V-shaped supporting blocks and one upper U-shaped supporting block. With the adoption of the structure above, the angle workbench of the high-precision combined tool has the advantages that the precision of the combined clamp is greatly improved; a plurality of surfaces of a workpiece can be processed and qualified by one-time positioning clamping, and therefore, the processing efficiency is increased, and the manufacturing cost is decreased.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

High sealing device of hydraulic cylinder for engineering

InactiveCN107676481AGuaranteed connection dimensional accuracyGuaranteed tightnessEngine sealsPiston ringsHydraulic cylinderEngineering

The invention discloses a high sealing device of a hydraulic cylinder for engineering. The device comprises an elastic gasket body; the gasket body is provided with at least three positioning piece holes; positioning pieces are embedded in the positioning piece holes, are thinner than the gasket body, and are the same in thickness; anti-bonding layers are arranged on two side surfaces of the gasket body, and comprise base cloth; anti-bonding paint is coated on the base cloth; and the anti-bonding layers are connected with the gasket body through adhesive layers. The high sealing device of thehydraulic cylinder for engineering not only can guarantee the sealing effect, but also can guarantee the connecting size precision of two combined components, and can be repeatedly used by many times.

Owner:东台市富康机械有限公司

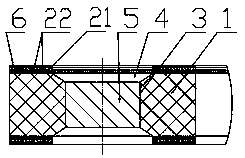

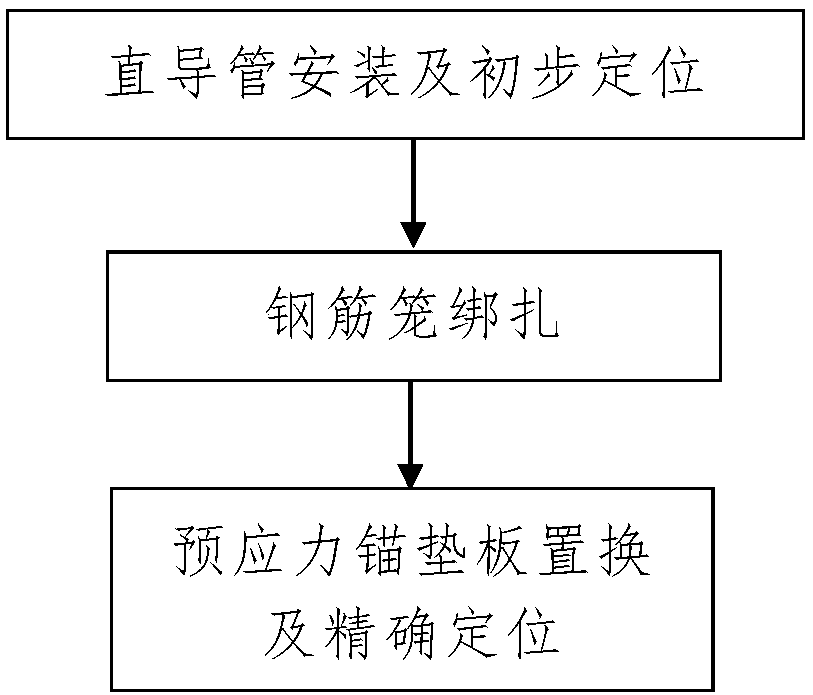

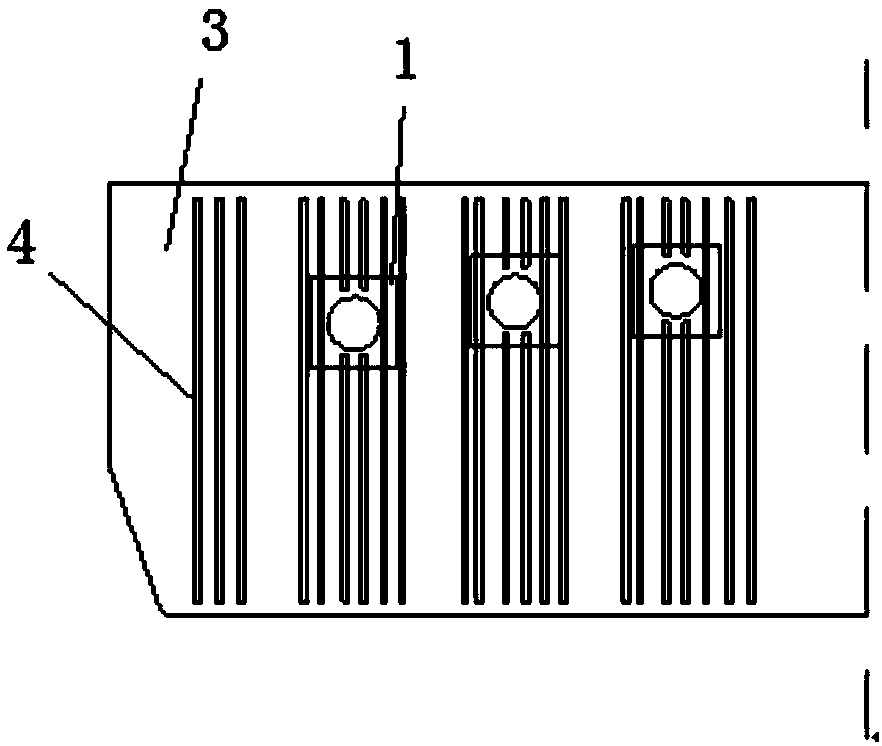

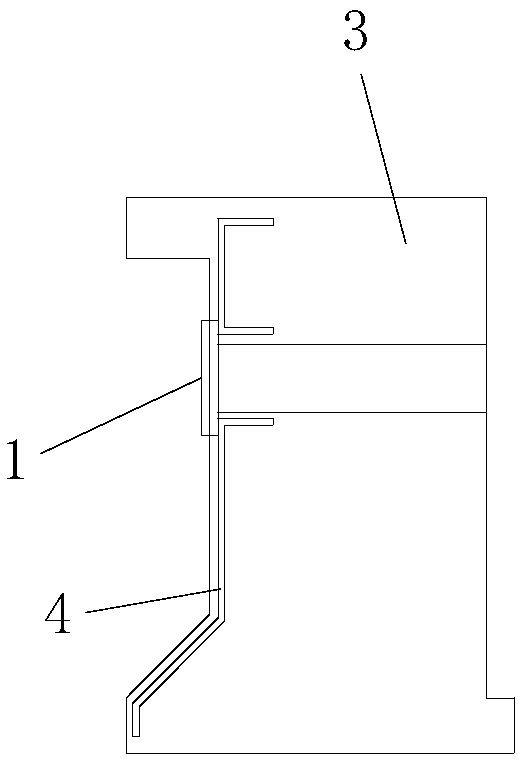

Replacement and location method of externally prestressed anchor pads for segmental beams

ActiveCN106192752BThe method steps are simpleReasonable designBridge structural detailsBridge erection/assemblyPre stressBuilding construction

The invention discloses a method for replacing and positioning an external prestressed anchor backing plate of a segmental beam, comprising steps: 1. Installation and preliminary positioning of a straight conduit: after the stiff skeleton used for construction of a segmental beam is installed, according to the pre-designed The installation position of the prestressed anchor backing plate at the end of the section beam is to install a straight conduit on the stiff skeleton; the inner diameter of the straight conduit is greater than the diameter of the installation hole opened on the prestressed anchor backing plate; two, steel cage binding ; 3. Replacement and precise positioning of the prestressed anchor backing plate: take out the straight pipe, install the prestressed anchor backing plate at the installation position of the straight pipe, and adjust the position of the prestressed anchor backing plate until the prestressed anchor backing plate is placed Backing plate installed in place. The method has the advantages of simple steps, reasonable design, convenient construction, and good application effect. It can easily and quickly complete the positioning process of the external prestressed anchor pad, and can effectively reduce the construction difficulty and greatly improve the construction efficiency.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com