Belt correction device and working method thereof

A working method and belt technology, which is applied in transportation and packaging, object supply, pile separation, etc., can solve problems such as difficulty in ensuring side straightness errors, large clamping force on the belt by the retaining strip, and reduced service life of the belt, etc., to achieve The effect of prolonging the service life, prolonging the life of the belt, and avoiding wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

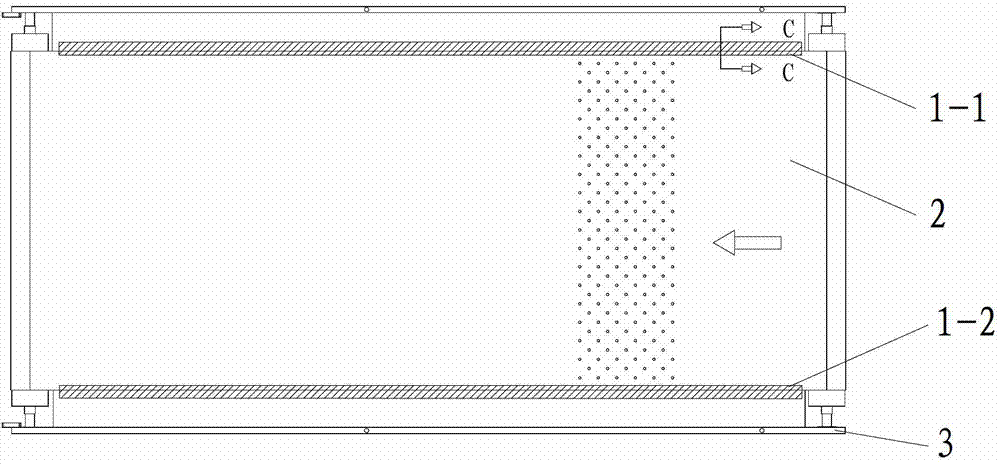

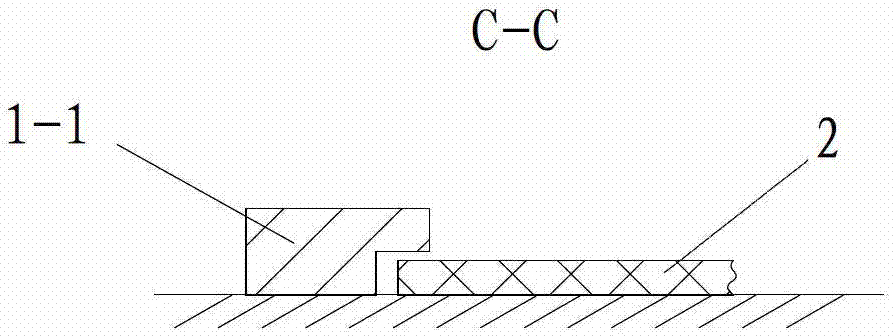

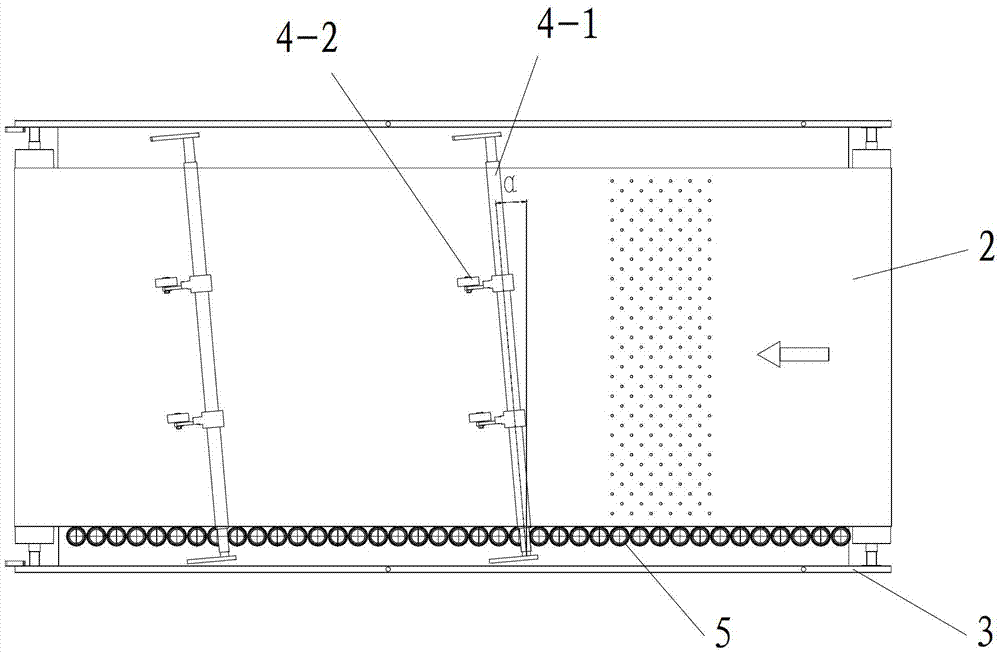

[0022] Embodiment: a kind of belt correction device (see image 3 ), which is characterized in that it consists of a pressure wheel assembly and a roller rib assembly; the pressure wheel assembly presses the belt 2 and forms an angle α with the shortest line in the width direction of the belt 2; the roller rib assembly and the belt 2 wherein Side contact, roller rib assembly is the positioning and datum of belt 2.

[0023] The pinch wheel assembly includes a bracket 4-1 and a pinch wheel 4-2; the pinch wheel 4-2 in the pinch wheel assembly is mounted on the bracket 4-1 and presses the belt 2, the bracket 4-1 and the pinch wheel 4 -2 and the shortest line in the width direction of the belt 2 form an angle α. (See image 3 )

[0024] The angle α is 15°. (See image 3 )

[0025] The pressure wheel assembly is divided into two groups. (See image 3 )

[0026] The roller rib assembly includes 39 rollers 5 . (See image 3 )

[0027] Its outer side of each roller 5 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com