Optical machining grinding and fly-cutting combined machine tool body

A combined machine tool and optical processing technology, which is applied in the direction of machine tools, grinding machines, metal processing equipment, etc. suitable for grinding the edge of workpieces, to improve processing efficiency, meet shape and position accuracy requirements, and solve positioning errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

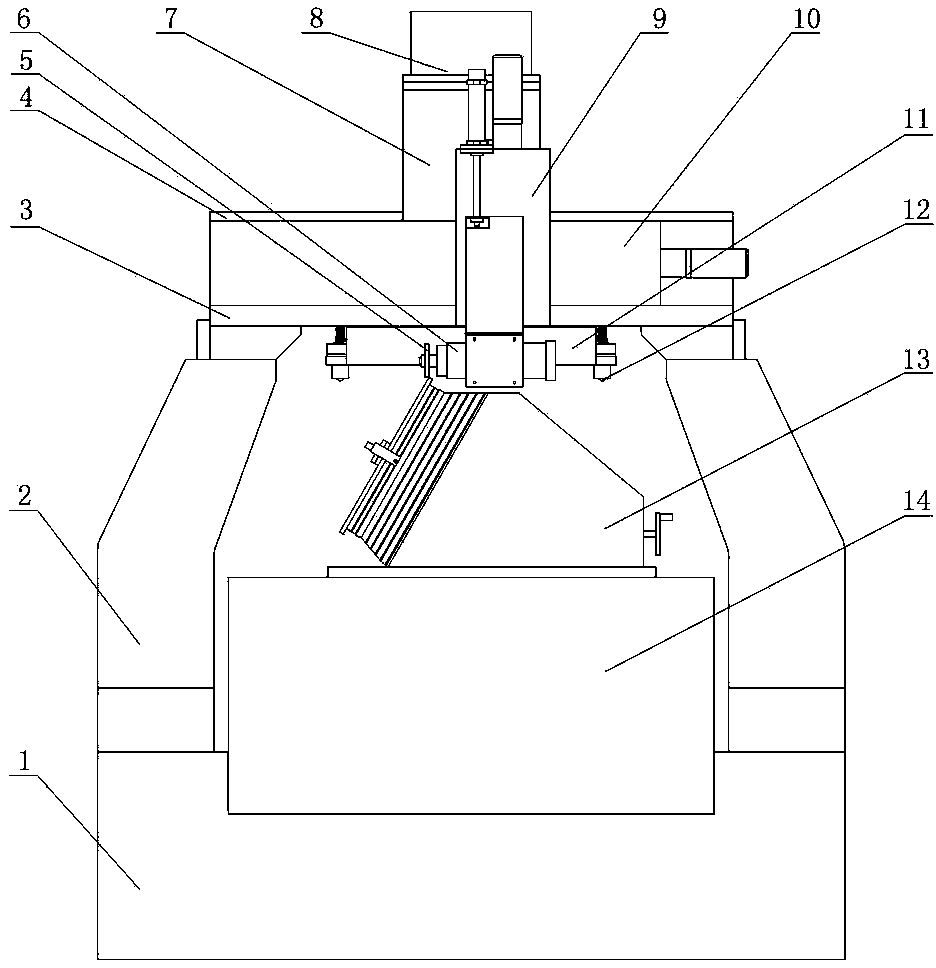

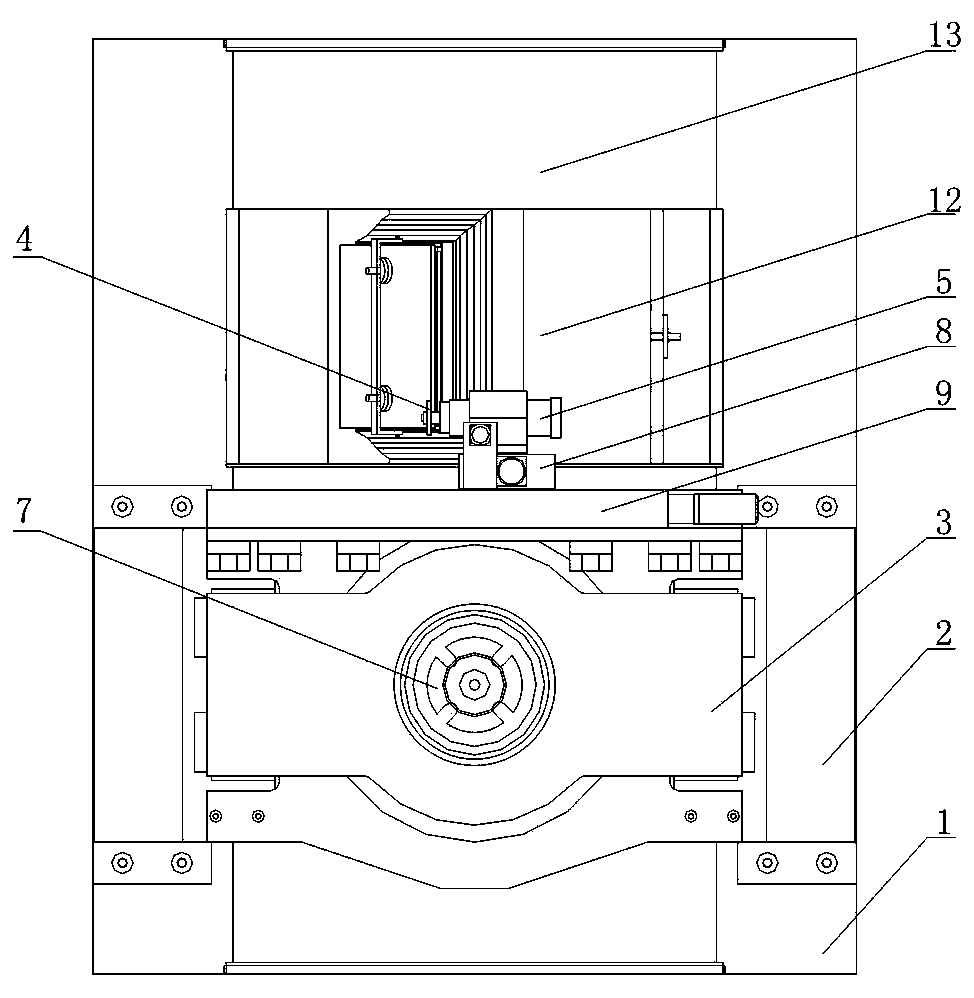

[0018] figure 1 It is the front view of the bed structure of the combined optical processing grinding and flying cutting machine tool of the present invention, figure 2 It is a top view of the bed structure of the combined optical processing grinding and flying cutting machine tool of the present invention. exist figure 1 , 2 Among them, the optical ultra-precision machining grinding and fly-cutting combined machine tool bed of the present invention includes a gantry base unit, a fly-cutting spindle unit, a grinding unit, a pitch mechanism 13, and an X guide rail 14; wherein, the gantry base unit includes Base 1, column, bracket 3, beam 4. The fly-cutting spindle unit includes a fly-cutting spindle 7, a motor 8, a cutter head 11, and a flying knife. The grinding unit includes a grinding wheel 5 , a grinding spindle 6 , a Z guideway 9 , and a Y guideway 10 . The connection relationship is that the base 1 is placed on the ground, the X guide rail 14 is fixed on the upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com