Device for Finding the Cooling Point of the Hot Section of the Wheel Hub Casting Side Mold and Its Application

A technology of side molds and hot joints, applied in casting molding equipment, molds, mold components, etc., can solve the problems of mold service life, low production efficiency, long operation time, etc., to solve the difficulty of finding points, improve The effect of work efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

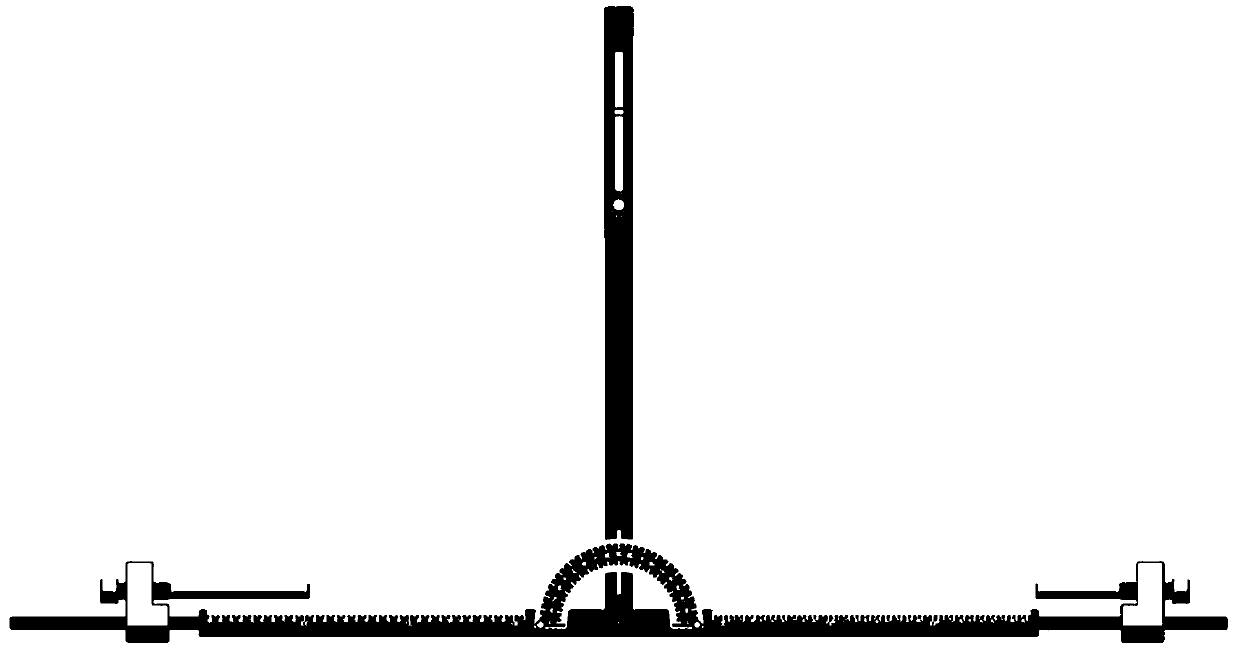

Image

Examples

Embodiment Construction

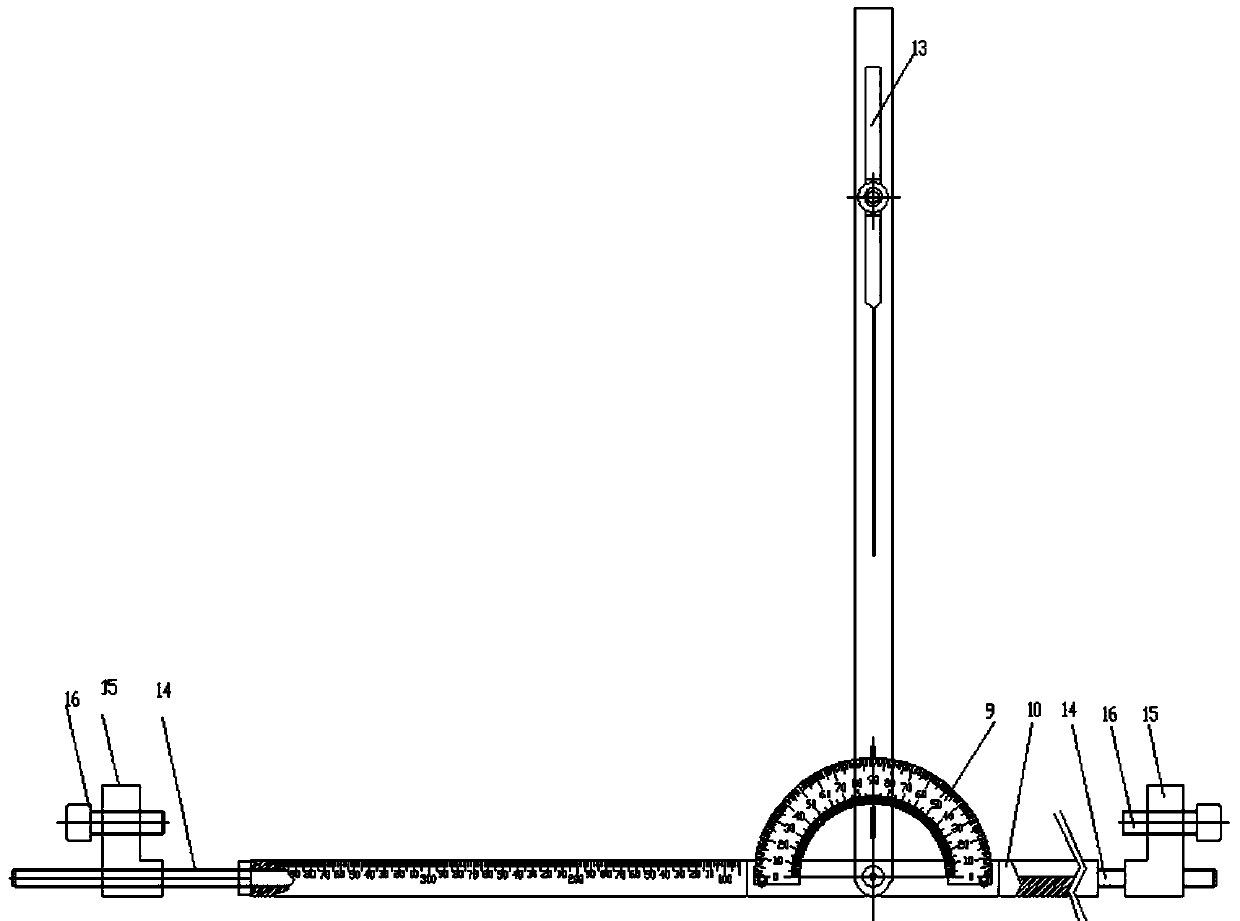

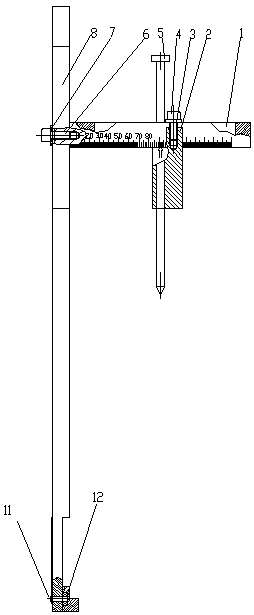

[0021] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

[0022] The device for finding the cooling point of the hot section of the aluminum alloy wheel gravity casting side mold includes a vertical connecting rod (1), a transverse connecting rod (2), a first flat pad (3), a first locking screw (4), Sample punch (5), second locking screw (6), second flat washer (7), main rod (8), angle gauge (9), ruler gauge (10), shaft (11), bearing (12 ); one end of the transverse connecting rod (2) has a T-shaped step, and a threaded hole is provided in the step, and the first locking screw (4) connects the transverse connecting rod (2) and the vertical connecting rod through the first flat pad (3) (1) Assemble, and the position of the horizontal connecting rod (2) on the vertical connecting rod (1) can be adjusted by the second locking screw, and a through hole for installing the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com