Thermal vacuum outgassing testing apparatus

A test device and thermal vacuum technology, applied in the direction of measurement device, material thermal analysis, material thermal conductivity, etc., can solve the problems of difficult to clear the root around the pit, affect the heat transfer effect, affect the temperature of the collecting plate, etc., so as to reduce the assembly error. , to ensure the design accuracy, to avoid the effect of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

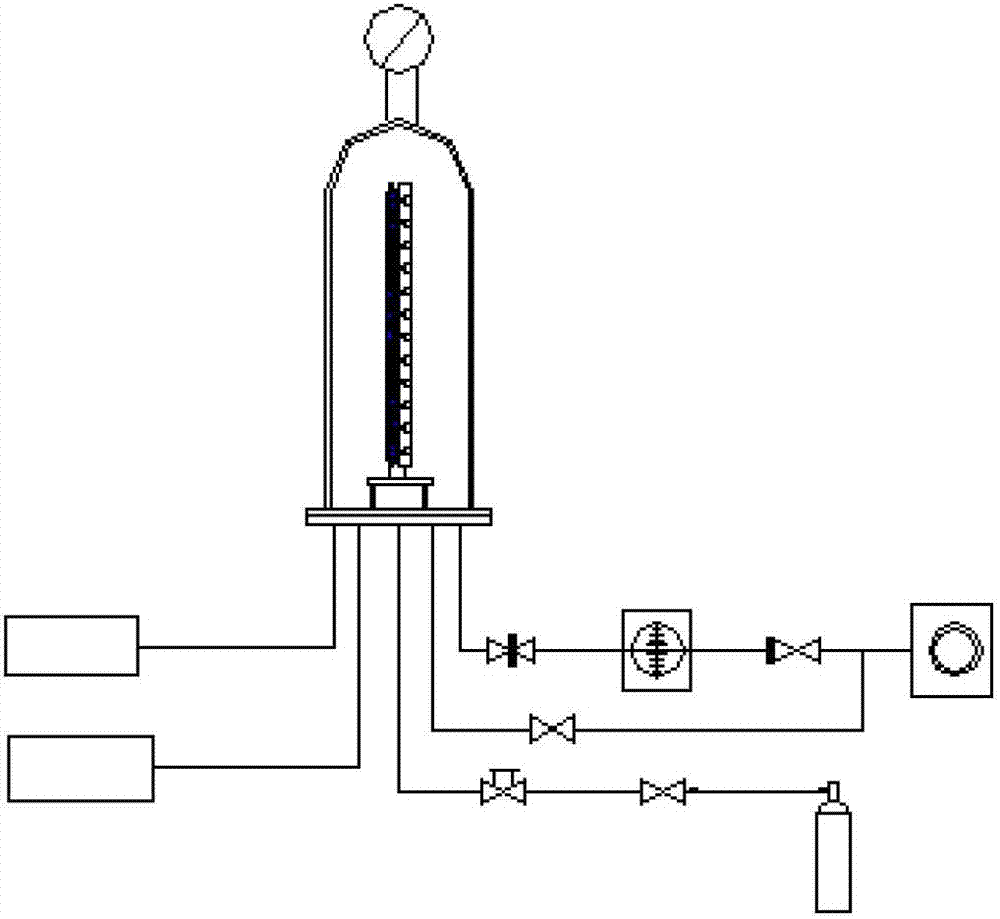

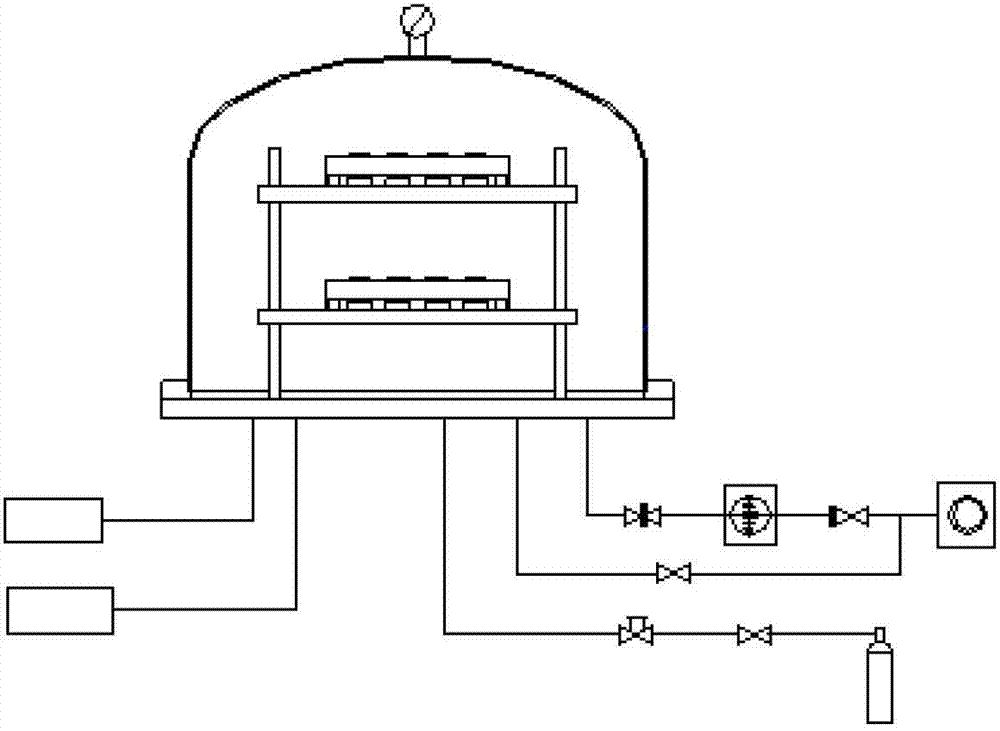

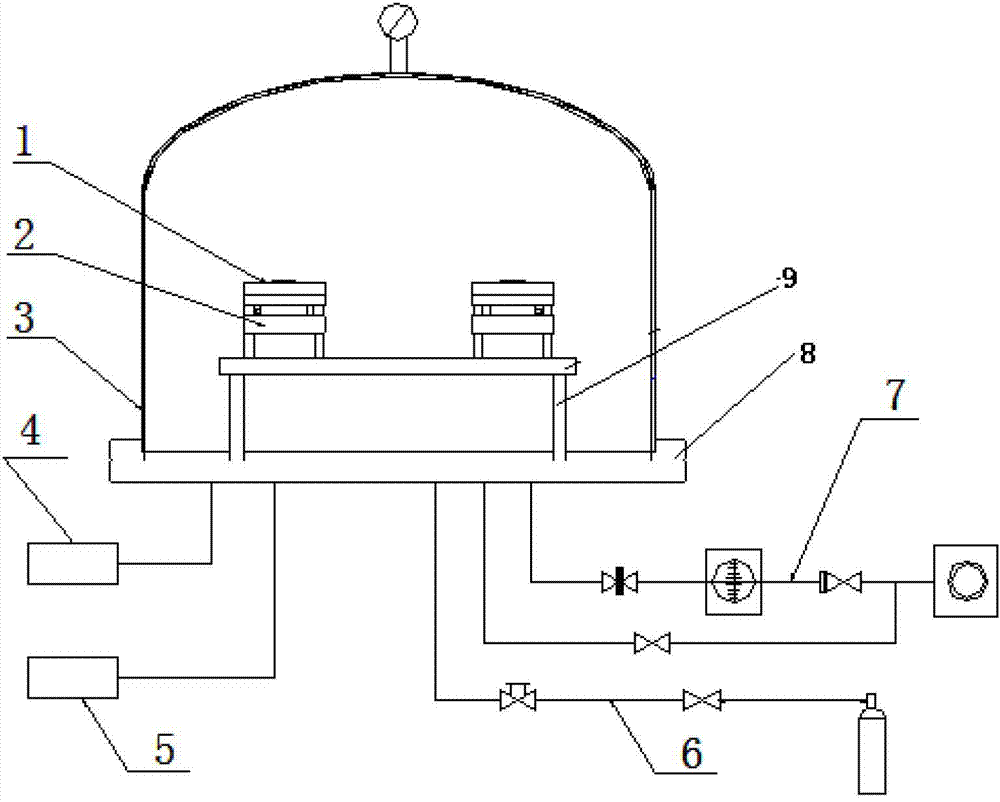

[0019] Such as image 3 , 4 As shown, a thermal vacuum outgassing test device includes an operating table 8 and a vacuum cover 3 installed above the operating table 8, and a heating plate temperature control system 4 and a cooling plate temperature control system are respectively arranged below the operating table 8 5. The inflatable device 6 and the vacuum system 7, the temperature control system accurately controls the temperature of the heating plate 1 and the cooling plate 2 respectively, the vacuum system 7 provides the vacuum degree required for the test, and the inflatable device 6 is injected into the vacuum cover 3 after the test Refilling with dry and clean nitrogen, there is an operating device in the vacuum cover 3, the operating device includes two identical devices and is distributed on the same operating plate 8 in a double-row parallel structure, and the cooling plate 2 The heating plate 1 is supported on the cooling plate 2 by a heat insulating support mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com