Welding experiment chamber for simulating medium-pressure liquid or gas environment

A technology of gas environment and experimental cabin, which is applied in the field of welding experimental cabin, can solve the problems of difficult replacement of components in the cabin, single pressure medium, and low simulated pressure, so as to facilitate experimental operation and maintenance of equipment in the cabin, improve integrity, improve The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

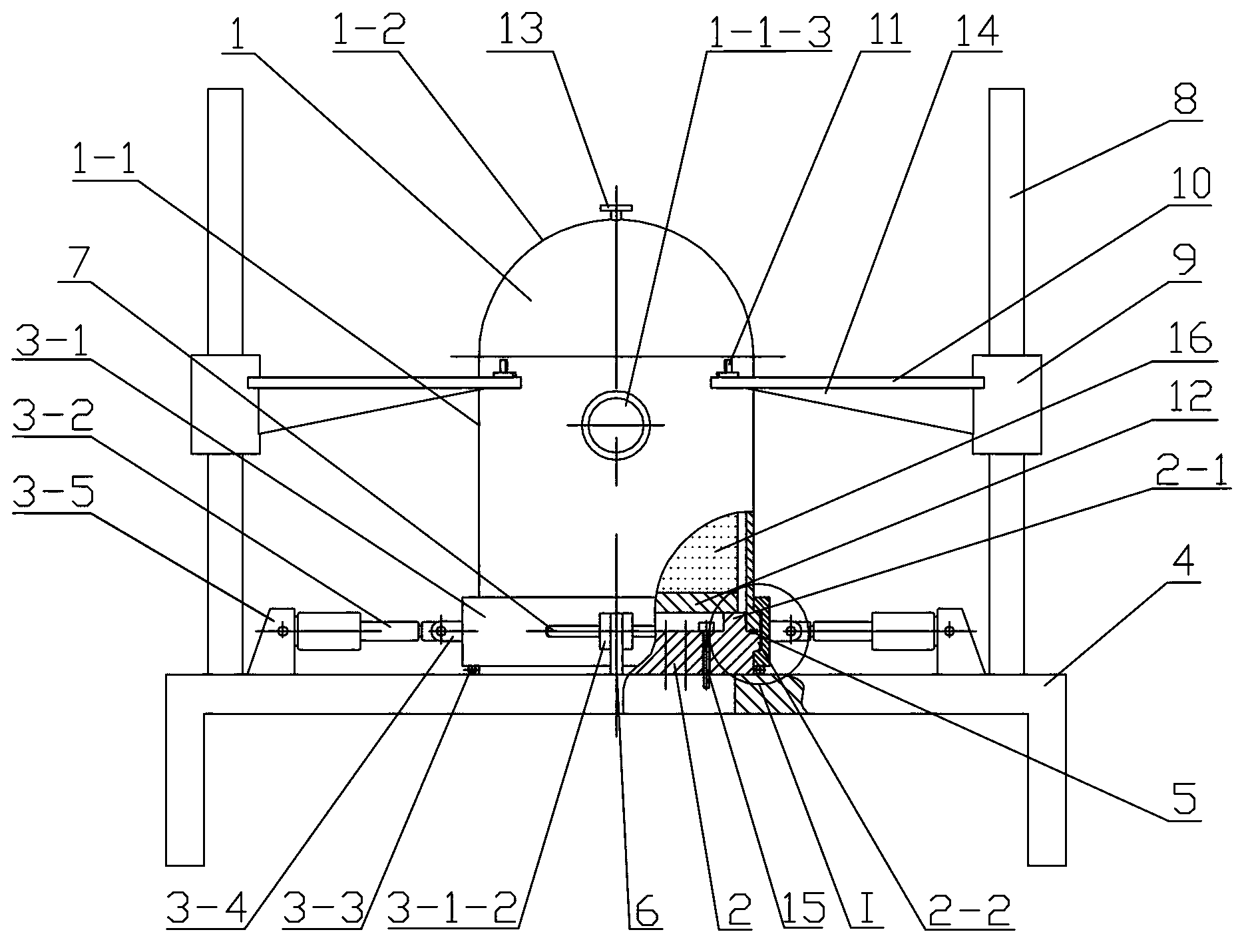

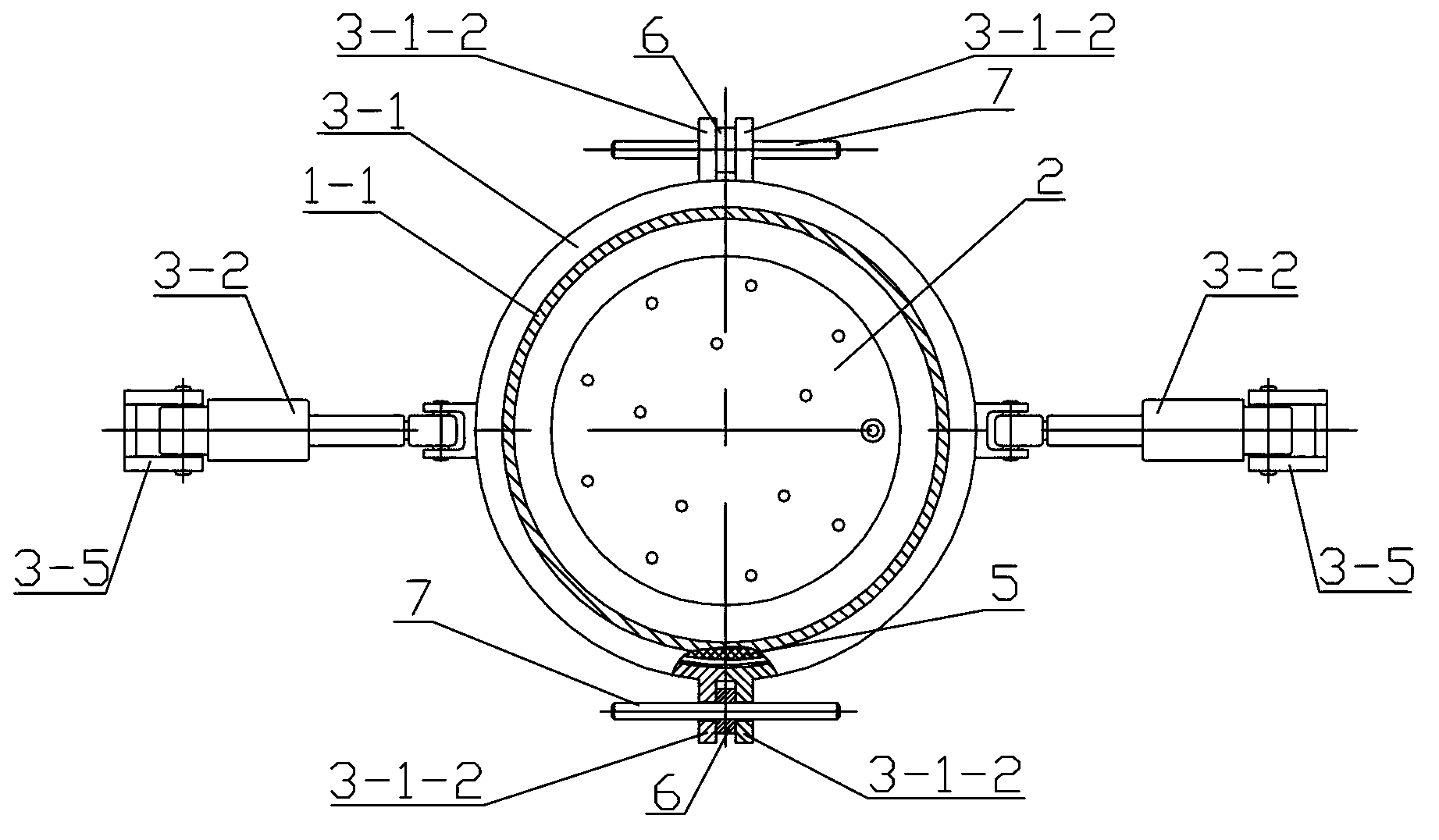

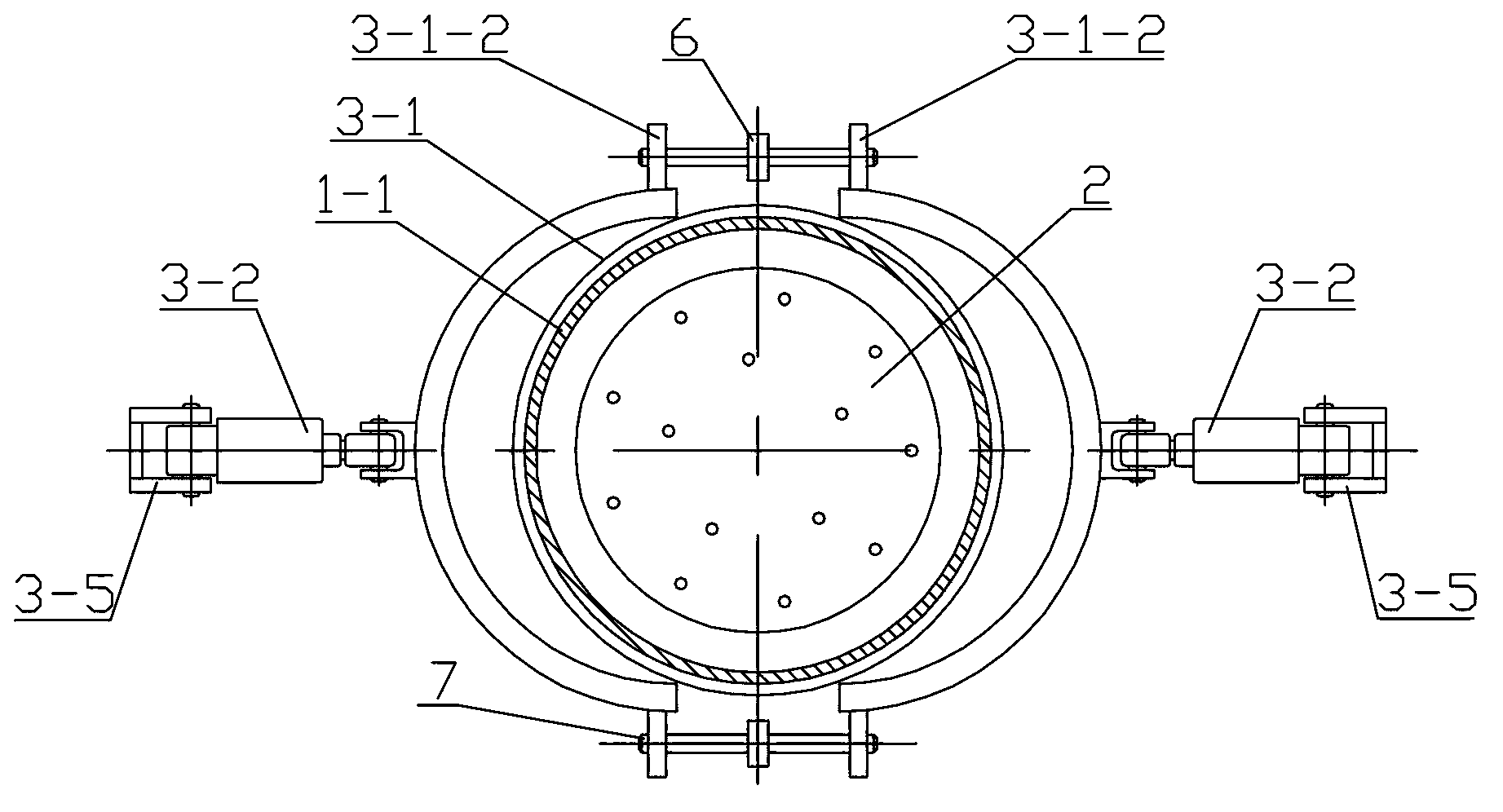

[0013] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, this embodiment includes a cabin body 1, a bilge 2, a platform support 4, an annular sealing ring 5, a welding platform 12, two clamp devices 3, two guide post supports 6, and two clamp guide posts 7. Two lifting guide rails 8, two lifting cylinders 9, two lifting frames 10, four lugs 11 and several tank penetration connectors 15, the upper end surface of the bilge 2 is provided with an annular boss along the edge 2-1, the outer surface of the annular boss 2-1 is provided with a guide slope 2-1-1 inclined from bottom to top and from outside to inside, and the guide slope 2-1-1 plays a role in guiding and positioning the cabin body 1 during its descent ; The outer wall of the bilge 2 is provided with a lower annular flange 2-2, and the lower end surface of the lower annular flange 2-2 is a lower slope 2-2-1 inclined from the outside to the inside and from the top to the bottom, and ...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that it also has two reinforcing ribs 14, the bottom of each lifting frame 10 is equipped with a reinforcing rib 14, and an end surface of the reinforcing rib 14 is connected with the lifting frame. The frame 10 is connected, and the other end face of the rib 14 is connected with the lifting cylinder 9. Other components and connections are the same as those in the first embodiment.

[0015] Working process of the present invention:

[0016](1), before using the present invention to carry out experimental welding: start two hoop opening and closing oil cylinders 3-2 and two lifting oil cylinders 9 at the same time, hoop opening and closing oil cylinder 3-2 drives the split hoop 3-1 to separate, The lifting cylinder 9 drives the lifting frame 10 to move upward, separating the cabin body 1 from the bilge 2; the experimental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com