270-degree machining device and technology for sewing machine head shell

A processing device and sewing machine technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of insufficient accuracy, affecting work efficiency, cost waste, etc., to ensure positioning accuracy, accurate rotation angle, and production speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with accompanying drawing, the present invention is further elaborated.

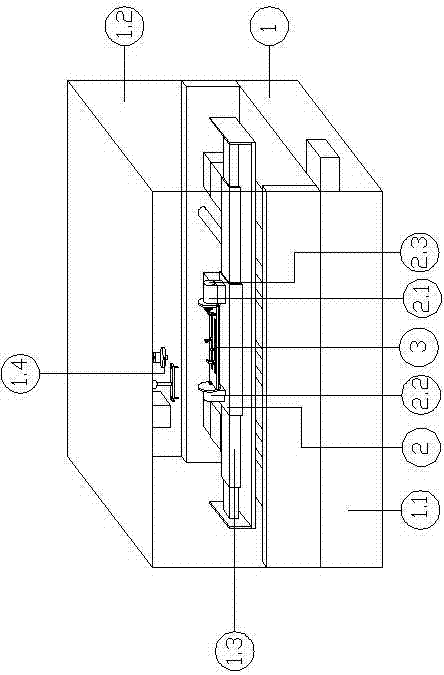

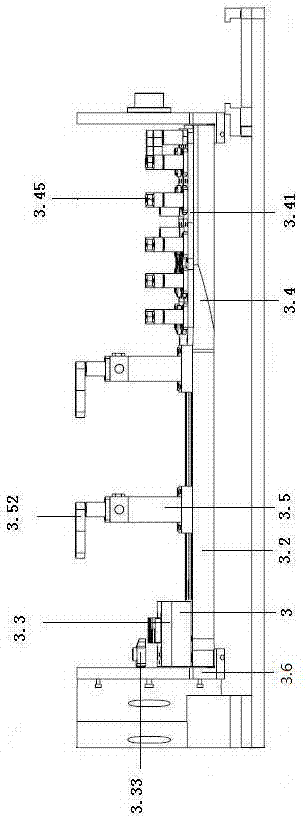

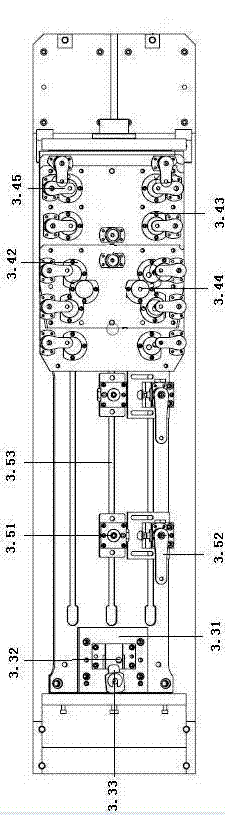

[0022] Such as Figure 1-5 As shown, the sewing machine head housing 270 ° processing device of the present invention includes a vertical machining center machine tool 1 and a positioning fixture 3, wherein the vertical machining center machine tool 1 includes a fixed base 1.1, a protective box 1.2, a sliding seat 1.3 and The rotary cutter head 1.4, wherein the edge of the fixed base 1.1 is fixed with a rectangular box-shaped protective box 1.2 by bolts and the front side of the protective box 1.2 is provided with an opening, and the fixed base 1.1 is also welded with a sliding seat 1.3, sliding The seat 1.3 includes a transverse sliding seat and an axial sliding seat, wherein the transverse sliding is located at the top of the axial sliding, and a rotary cutterhead 1.4 is fixed on the inner top surface of the protection box 1.2 through a bearing, and on one side of the rotary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com