Precise five-hole positioning and drilling clamp for rectangular cylinder workpiece

A drilling jig and precise positioning technology, which is applied to the drilling dies for workpieces and other directions, can solve the problems of large out-of-tolerance probability, low work efficiency, and high production costs, saving two processes of proofing and punching, and improving production efficiency. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

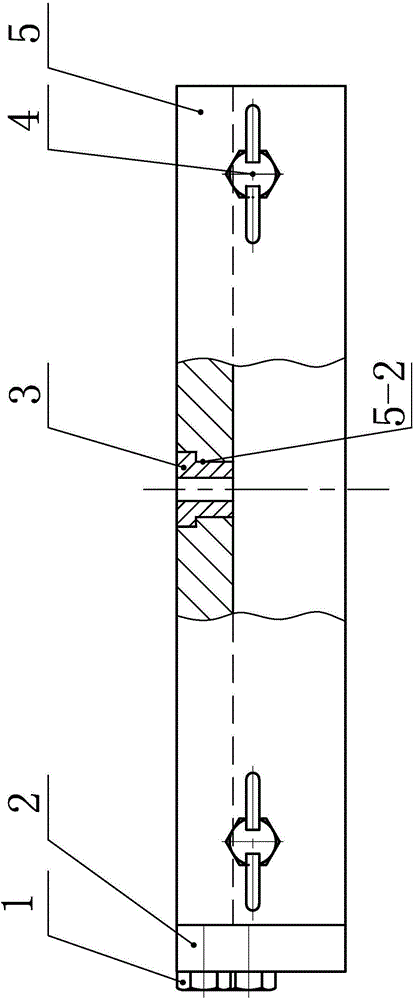

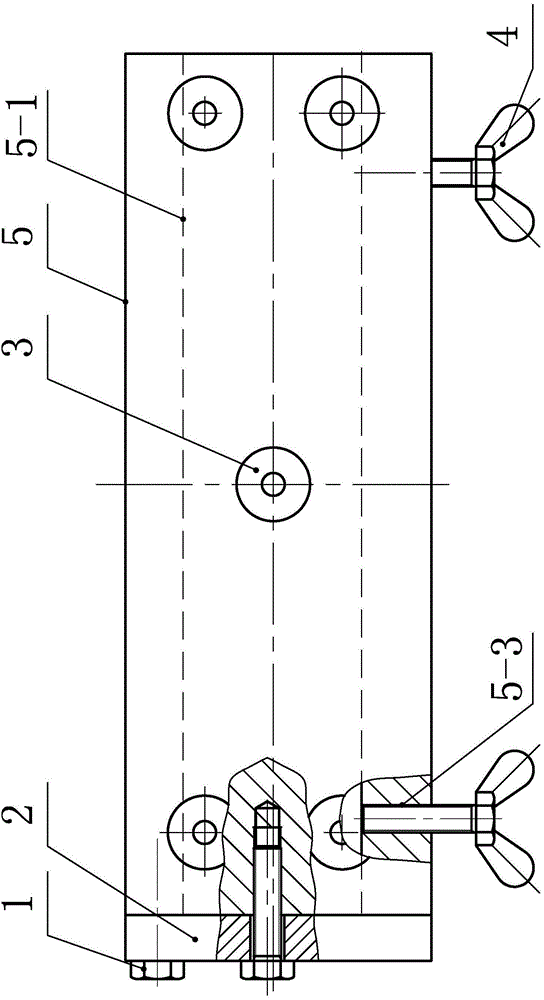

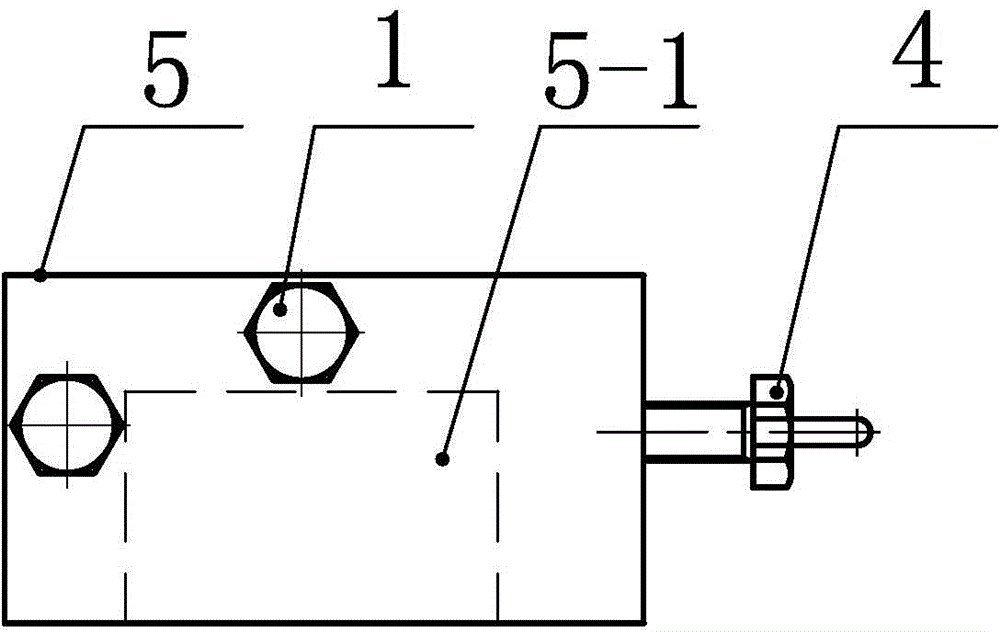

[0014] Such as Figure 1 to Figure 6 As shown, the five-hole precise positioning drilling jig of the rectangular tube workpiece includes a clamp body 5, a baffle plate 2, two connecting bolts 1, five drill sleeves 3 and two wing bolts 4; the clamp body 5 It is a rectangular plate, and the middle part of the lower surface of the clamp body 5 is processed with a through groove 5-1 for fixing the rectangular tube workpiece along its length direction, and the depth of the through groove 5-1 is smaller than that of the rectangular tube workpiece. Height, the width of the through groove 5-1 is consistent with the width of the rectangular tube workpiece, one end surface of the clamp body 5 and the baffle plate 2 are fixedly connected by two connecting bolts 1, and the baffle plate 2 is used for surface positioning of the rectangular tube workpiece , to ensure that the five drill holes on the upper surface of the rectangular tube workpiece and the five drill holes on the lower surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com