High sealing device of hydraulic cylinder for engineering

A hydraulic cylinder, high-sealing technology, applied in the direction of engine seals, engine components, piston rings, etc., can solve the problems of large elastic deformation of sealing gaskets, inability to ensure installation dimensional accuracy, and increased equipment maintenance time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

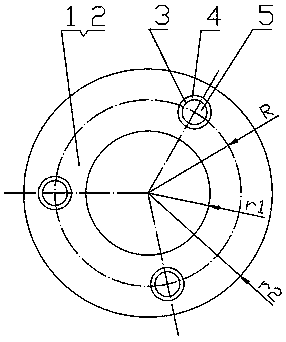

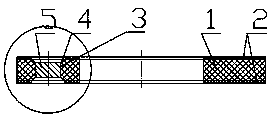

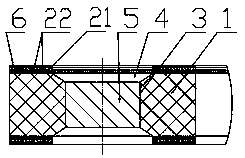

[0023] exist figure 1 , figure 2 with image 3 In the high sealing device for engineering hydraulic cylinders shown, the gasket body 1 is a ring-shaped sheet made of elastic asbestos rubber material. Three positioning hole 3 are arranged on the gasket body 1, and the positioning piece The holes 3 are evenly distributed between the inner ring and the outer ring of the annular gasket body 1 along the circumferential direction. The radius of the inner ring of the annular gasket body 1 is r1, the radius of the outer ring is r2, and the circumference of each positioning member hole 3 is The center of the circle is set concentrically with the center of the ring-shaped gasket body 1, and the radius R of the circle where the positioning member hole 3 is located is between 3 / 8-5 / 8 (r1+r2). A chamfer 4 is provided at the opening of the positioning member hole 3 . A positioning piece 5 is embedded in each positioning piece hole 3. The positioning piece 5 is a rigid body of steel mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com