Replacement and location method of externally prestressed anchor pads for segmental beams

A technology of external prestressing and positioning method, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as the length of the steel bar hook not meeting the design requirements, the long time required for positioning, and the difficulty of increasing the binding of steel bars, etc., to achieve High practical value, large safety factor, and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

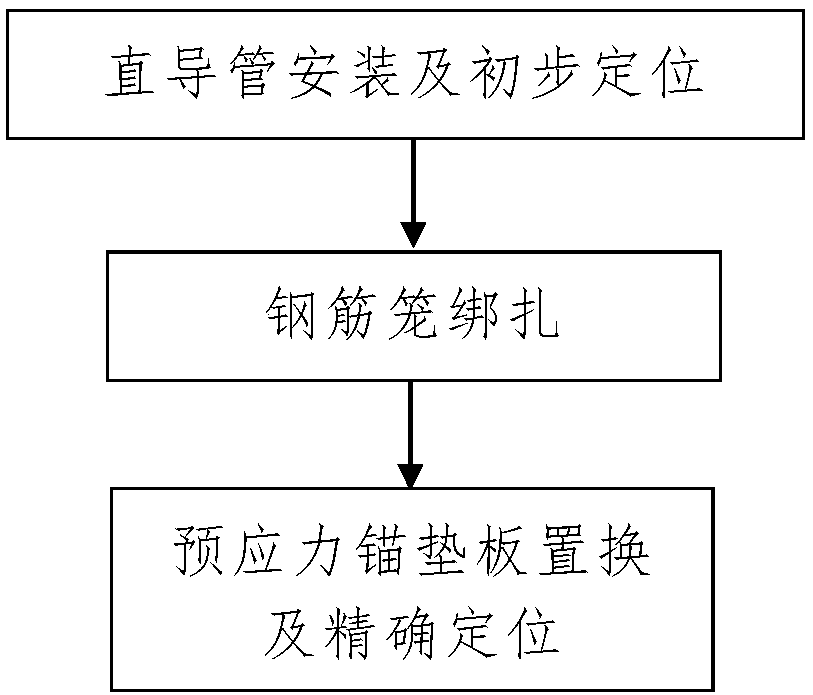

[0035] Such as figure 1 A method for replacing and positioning the external prestressed anchor plate of a segmental beam includes the following steps:

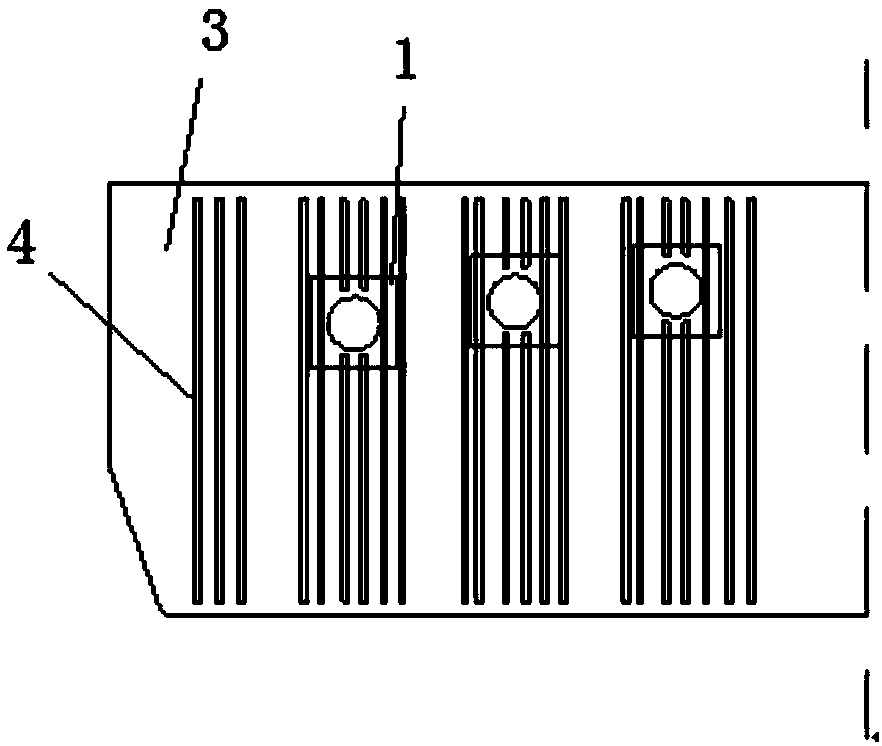

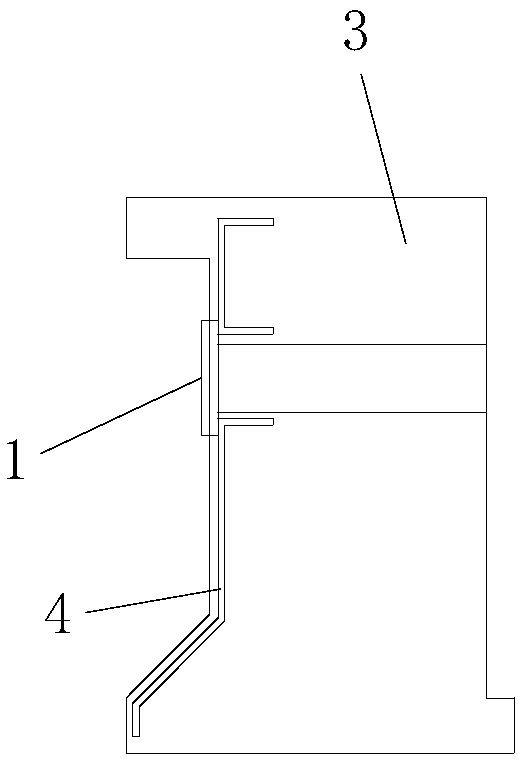

[0036] Step 1. Installation and preliminary positioning of the straight conduit: after the installation of the stiff skeleton for the construction segment beam is completed, according to the pre-designed installation position of the prestressed anchor plate 1 at the end of the segment beam, Straight conduit 2 is installed on the sex skeleton;

[0037] The straight conduit 2 is a straight circular tube arranged horizontally; the inner diameter of the straight conduit 2 is greater than the diameter of the installation hole opened on the prestressed anchor backing plate 1;

[0038] The section beam is a reinforced concrete beam section 3 supported on the bridge pier, the section beam is provided with a reinforcement cage 4, and the stiff skeleton is a support skeleton fixedly installed on the pier;

[0039] Step 2, binding the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com