A kind of glued assembly process method of stretched string semi-rigid substrate frame

An assembly process and semi-rigid technology, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve problems such as poor assembly accuracy and large assembly stress, and achieve the effects of improving development efficiency, reducing development costs, and reducing combined processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments disclosed in the present invention will be described in further detail below with reference to the accompanying drawings.

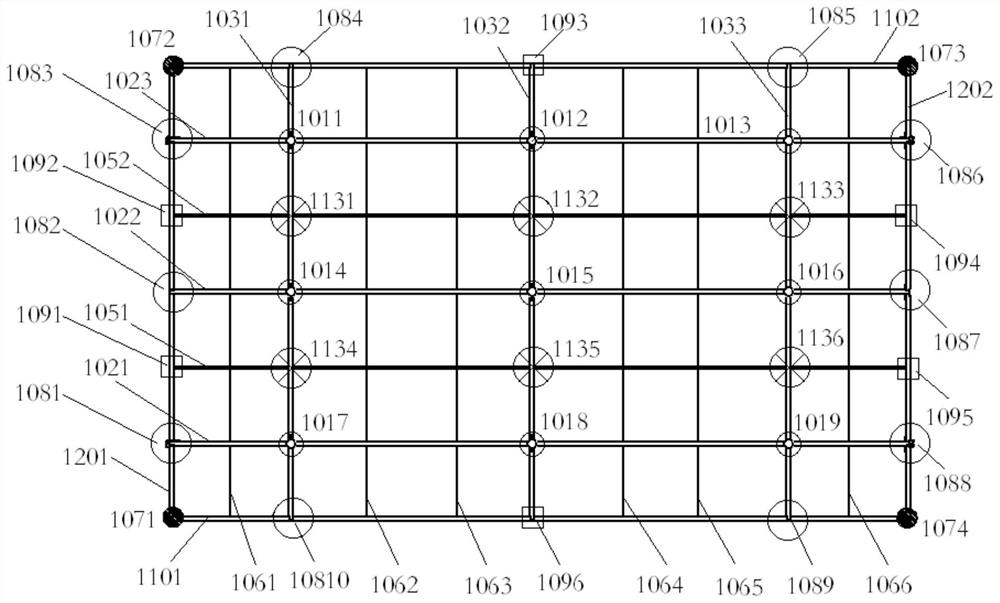

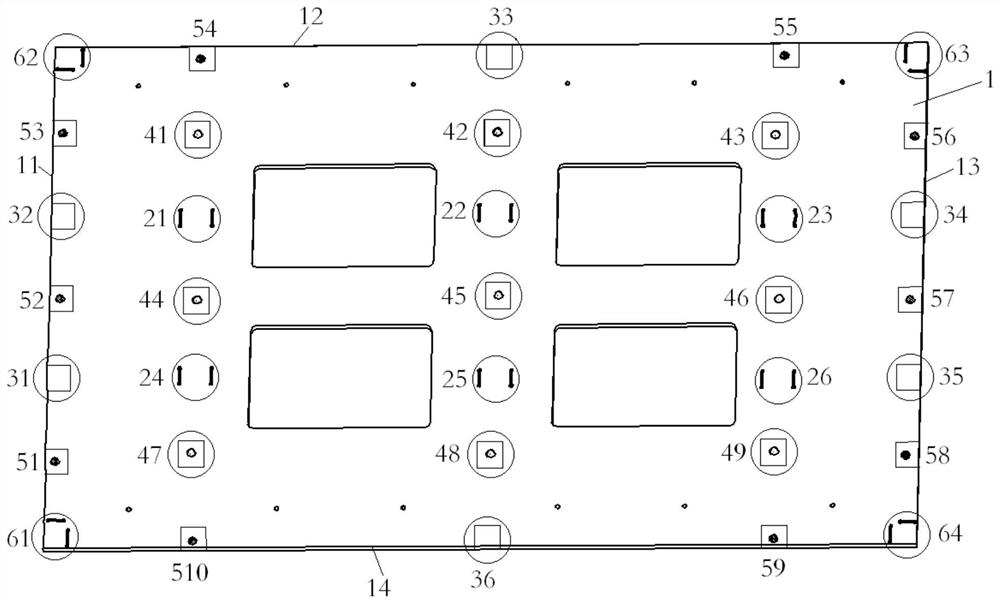

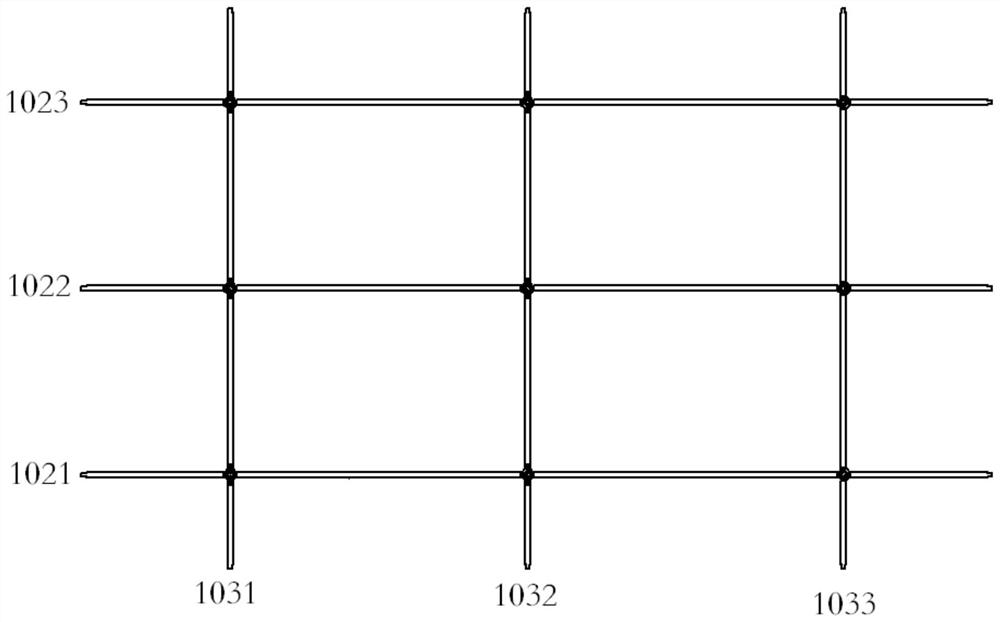

[0070] Due to the large number of compression point joints, hinge joints, frame joints, and embedded parts in the stretched semi-rigid substrate, the dimensional and positional accuracy requirements are high, and the dimensions are linked to each other. Inaccurate assembly at one location will affect the surrounding dimensions. positioning accuracy. In view of the above features, the present invention discloses a method for gluing and assembling a string-tensioned semi-rigid substrate frame. The method of wrapping carbon filaments is used to control the gluing gap of each assembly position. Specifically, the wet carbon filaments are evenly wound on each The surface of the square tube of the glued joint ensures that the circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com