Character 2D code detection device

A detection equipment and two-dimensional code technology, applied in the stacking of objects, unstacking of objects, conveyors, etc., can solve the problems of low efficiency, missed detection, mixed materials, etc., achieve excellent recognition performance, improve detection efficiency, Eliminate the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

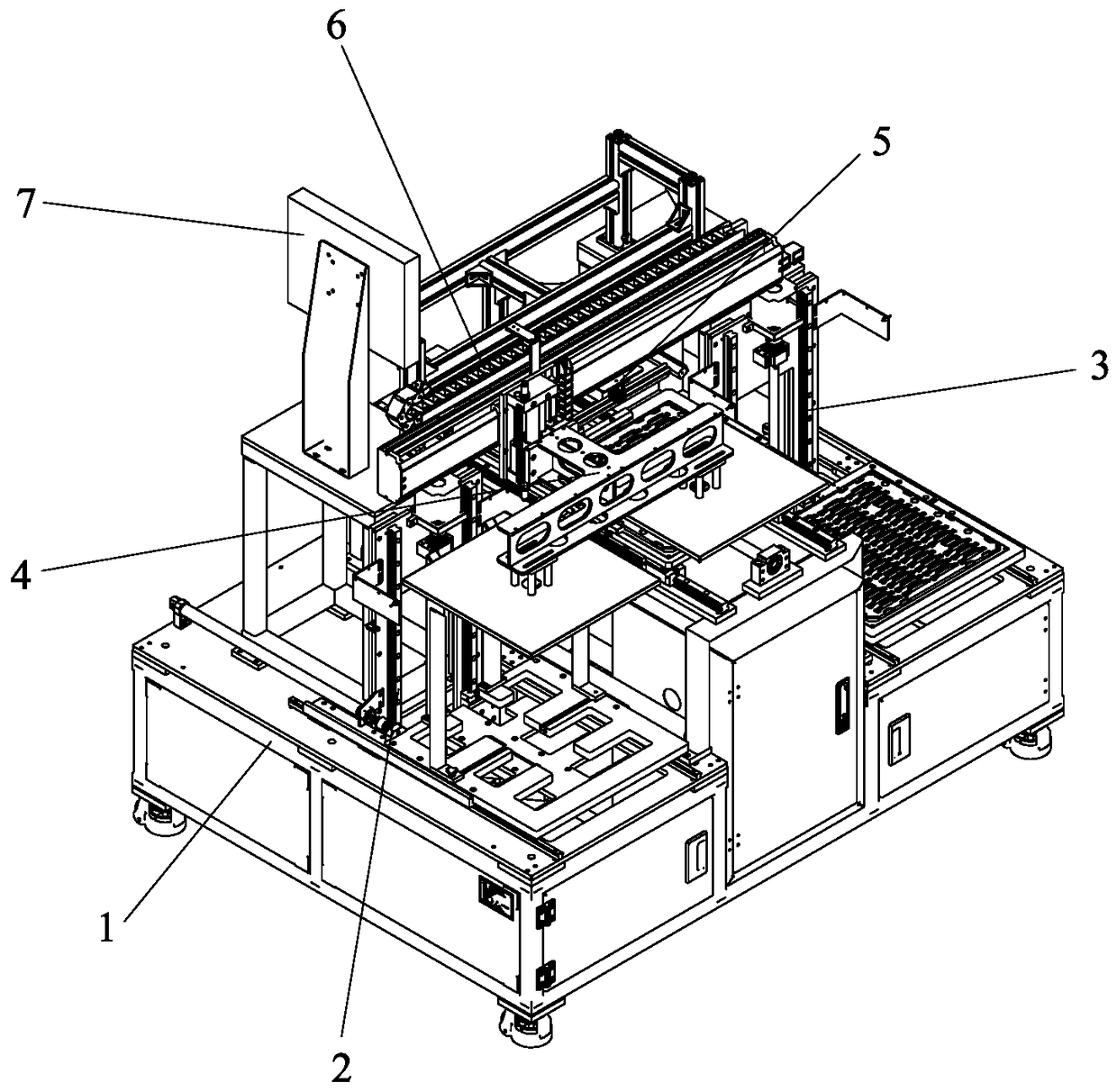

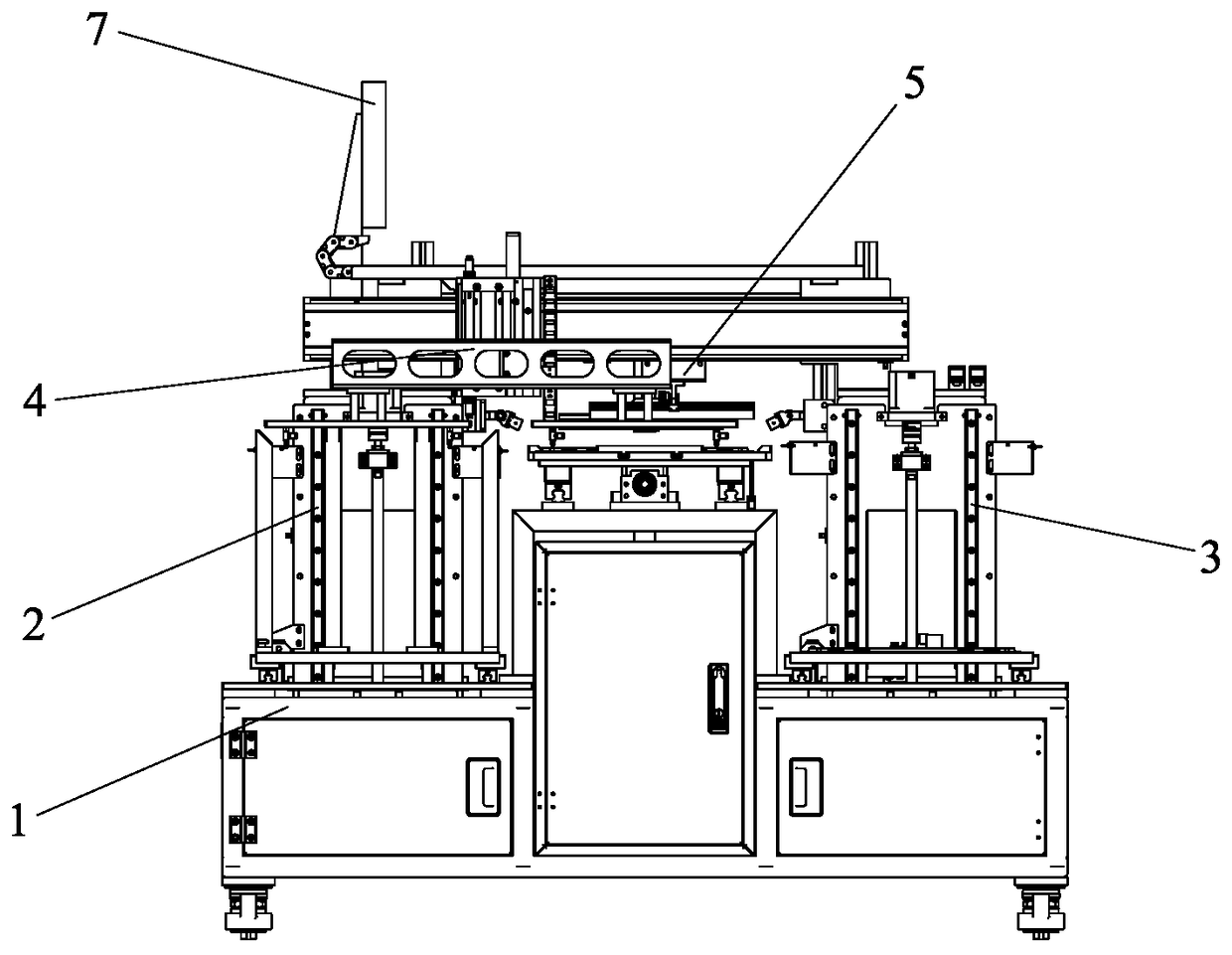

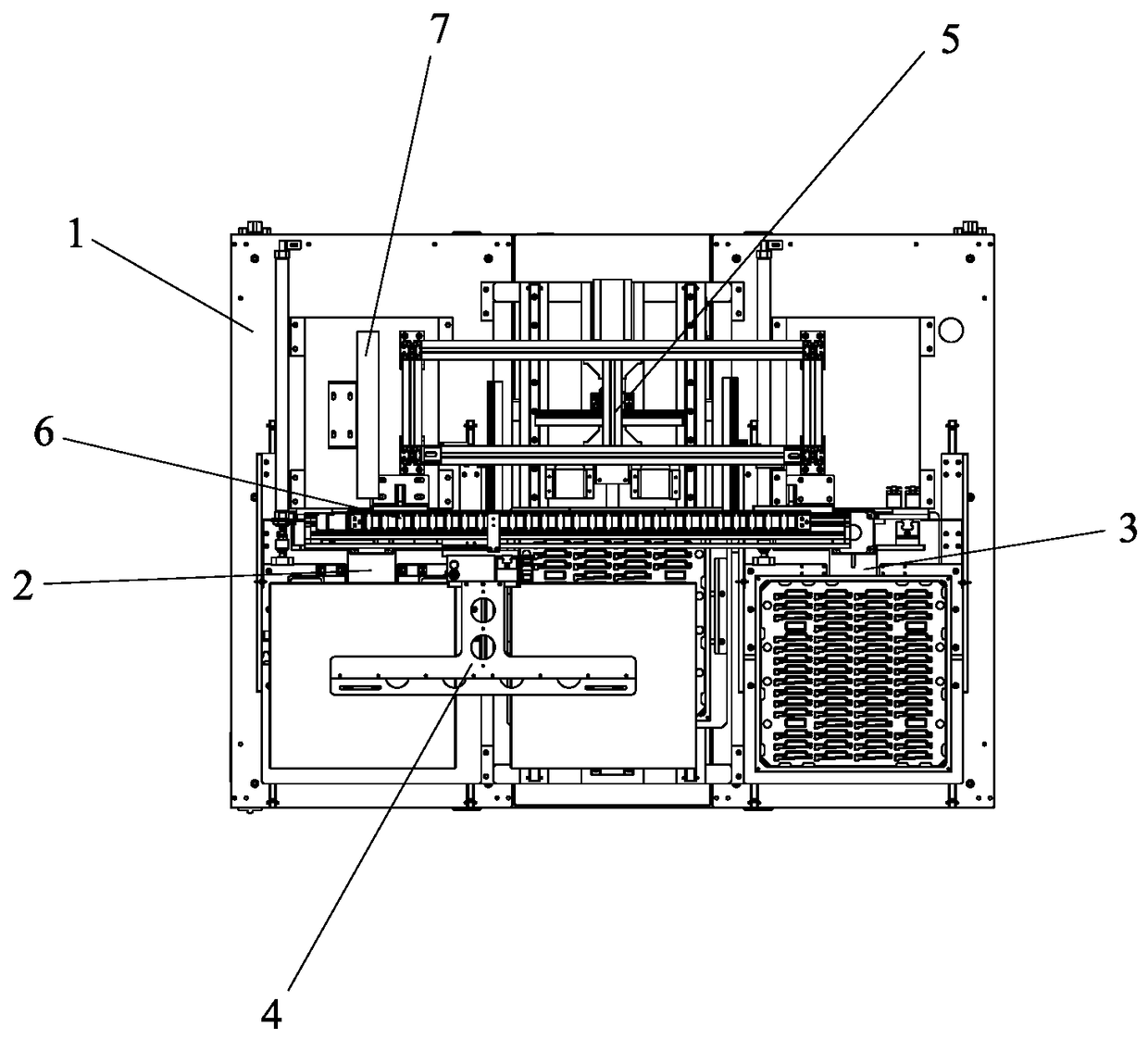

[0033] Such as Figure 1 to Figure 4 As shown, the present invention is a character two-dimensional code detection device, including a frame 1, a loading material tray buffer mechanism 2, an unloading material tray buffer mechanism 3, a suction cup mechanism 4, a detection mechanism 5, and an NG product retrieving mechanism 6 , Display 7.

[0034]The loading material tray buffer mechanism 2 and the unloading material tray buffer mechanism 3 are respectively fixed on the left and right sides of the frame 1, the detection assembly 5 is fixed on the middle area of the frame 1, and the suction cup mechanism 5 is erected and fixed on the upper frame 1. The material tray cache mechanism 2, the unloading material tray cache mechanism 3 and the detection mechanism are located above the components to be detected, the NG product retrieving mechanism 6 is fixed behind the suction cup mechanism 4, and the display 7 is fixed on the loading material tray cache mechanism 2 on.

[0035] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com