Angle workbench of high-precision combined tool

An angle worktable and combined fixture technology, which is applied in clamping, manufacturing tools, metal processing equipment, etc., can solve the problems that the positioning accuracy of the combined fixture cannot meet the requirements, it is difficult to process multiple surfaces qualified, and there are positioning errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

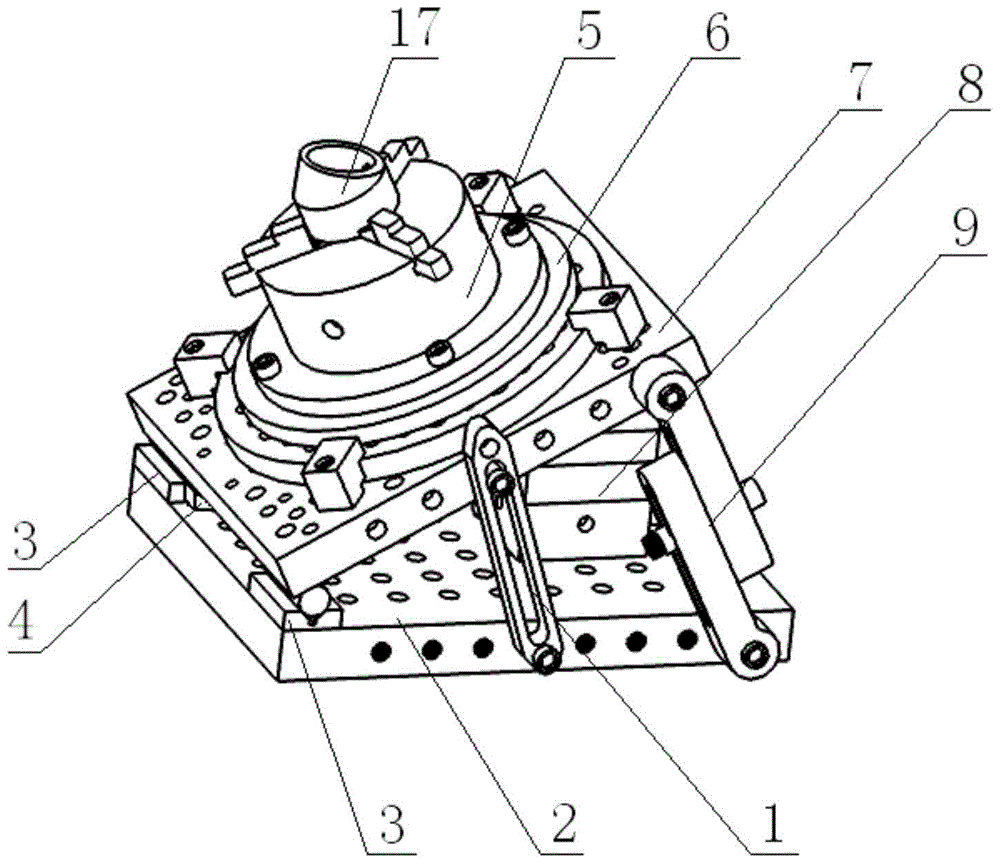

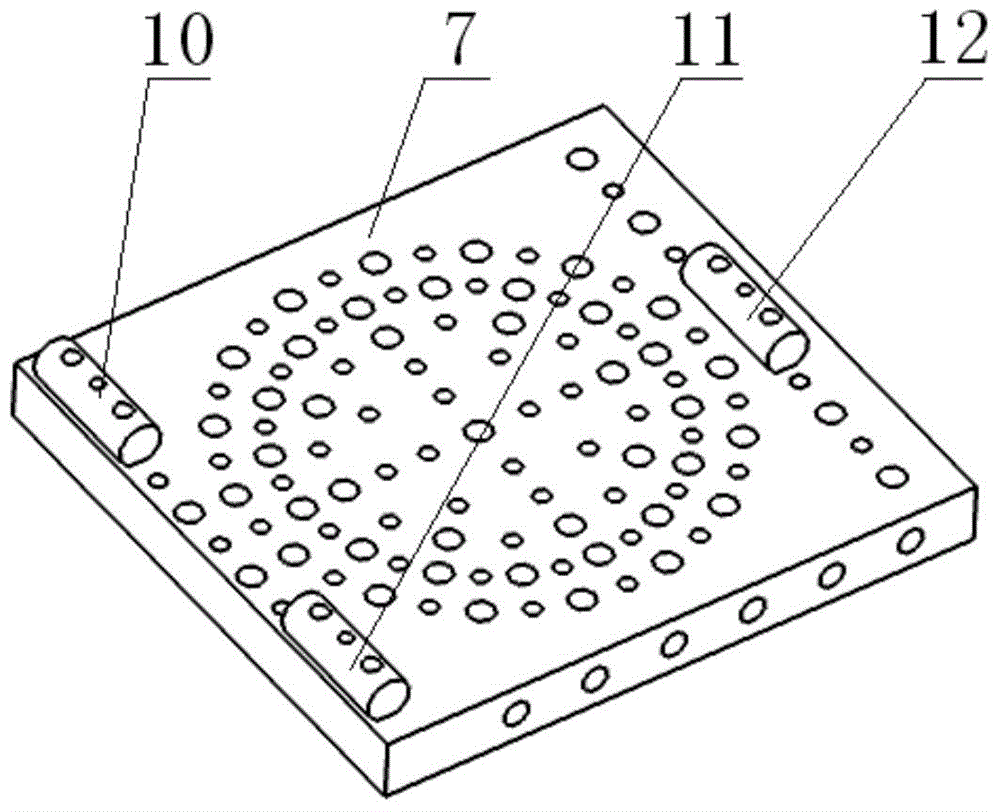

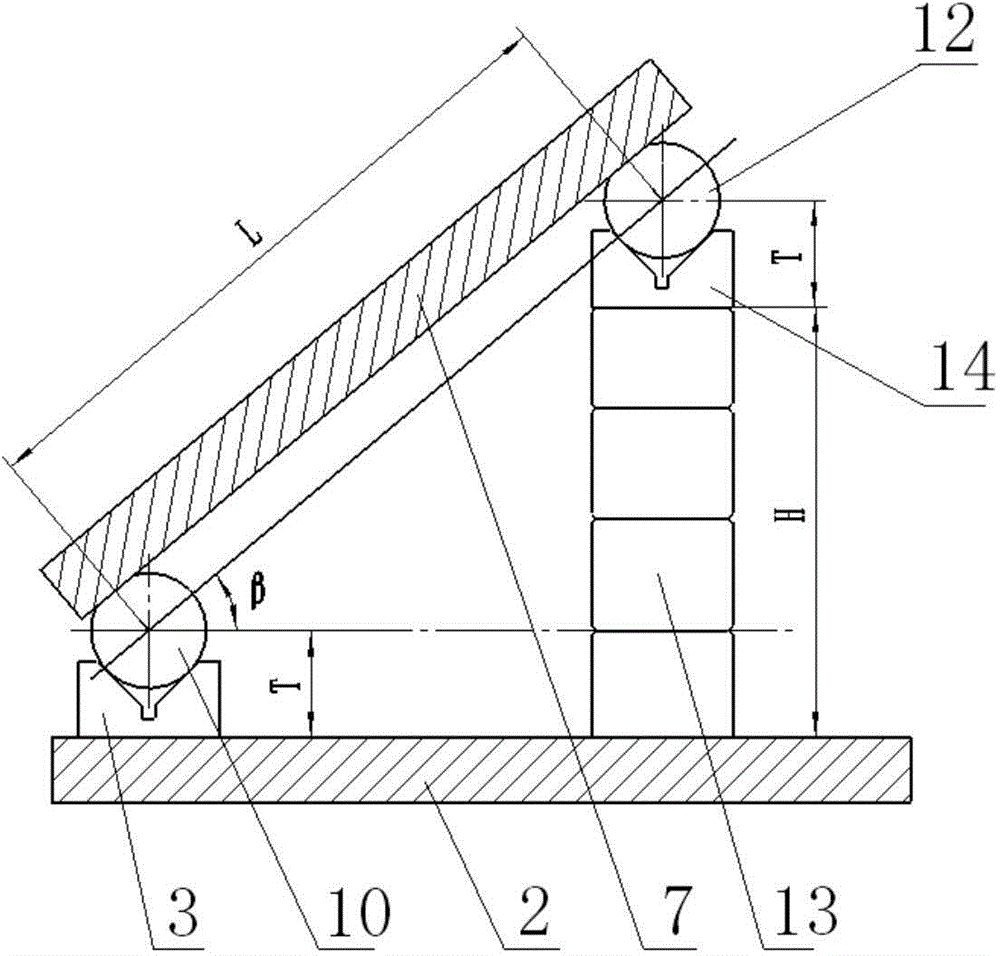

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the high-precision combined fixture includes an angle table, a three-jaw chuck 5 and an indexing plate 6, and the angle table includes a lower base plate 2, an upper base plate 7, a first connecting plate 1, a second connecting plate 9 and a support 8, the support 8 is vertically fixed on the lower base plate 2, and the lower base plate 2 is arranged with two identical low-position V-shaped support blocks 3 whose centerlines coincide on one side, and the support 8 is composed of a rectangular support element 13 and a high-position V-shaped support block. Support block 14 is made up of, high position V-shaped support block 14 is identical with low position V-shaped support block 3 structures and the center line of high position V-shaped support block 14 is parallel with the center line of two low position V-shaped support blocks 3, and the direction of upper base plate 7 The lower side is arranged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com