Motion platform of lithography machine, micro-motion platform and control method thereof

A motion platform and micro-motion technology, applied in opto-mechanical equipment, micro-lithography exposure equipment, optics, etc., can solve the problems of voice coil motor insufficiency, high power consumption, and unable to replace the voice coil motor actuator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

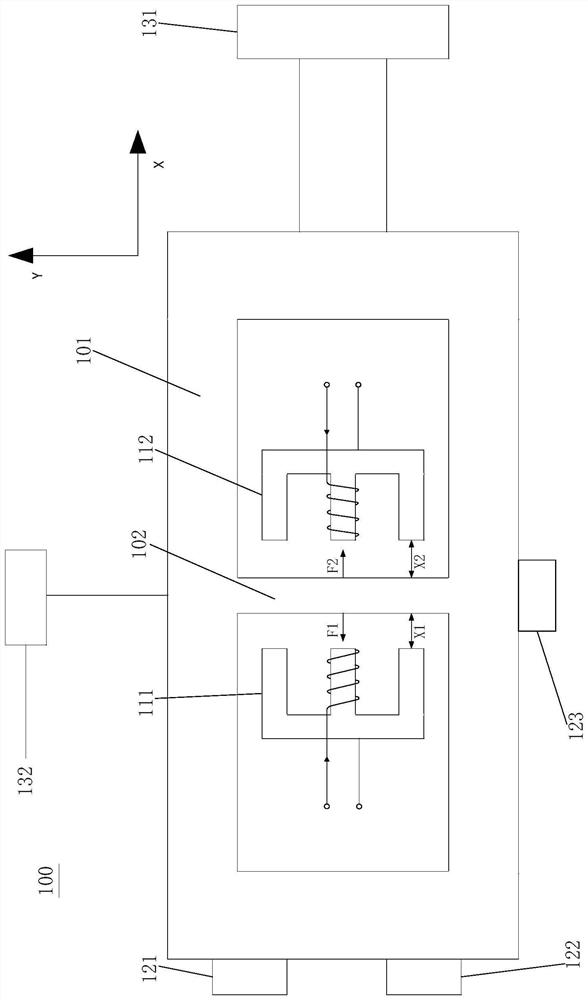

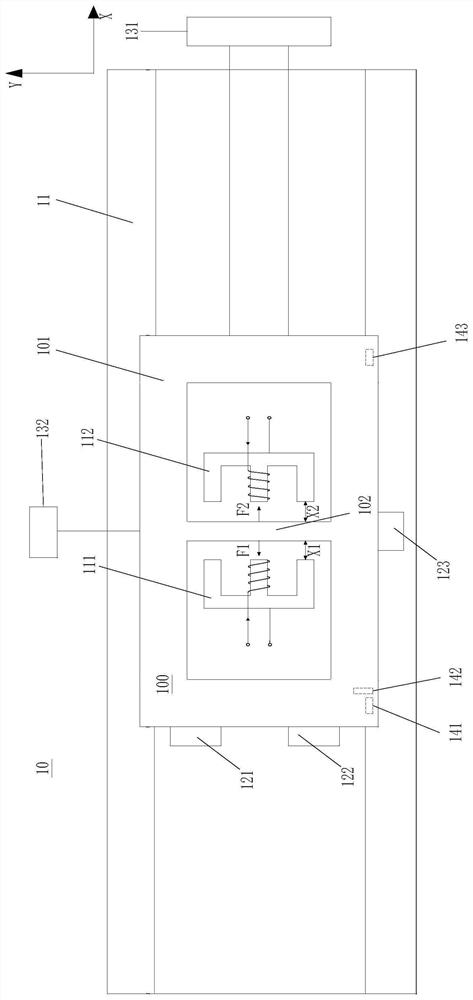

Embodiment 1

[0049] according to figure 1 , the figure shows a three-degree-of-freedom micro-motion platform 100, including a first micro-motion stage 101, two reluctance motors 111 and 112, three voice coil motors 121, 122 and 123, and two laser interferometers 131 and 132. The reluctance motors 111 and 112 share an I-type center 102 as a mover, and the two electromagnets of the reluctance motors 111 and 112 are symmetrically arranged on both sides of the I-type center 102, and the I-type center 102 and the first micro-motion Platform 101 has an integrated structure. The voice coil motors 121 and 122 are arranged on the same side of the first micro-motion table 101 , and the voice coil motor 123 is arranged on an adjacent side of this side. The laser interferometers 131 and 132 are respectively arranged on adjacent two sides of the first micro-motion stage 101 .

[0050] The reluctance motors 111 and 112 can push the first micro-motion stage 101 along the X coordinate axis (coordinate ...

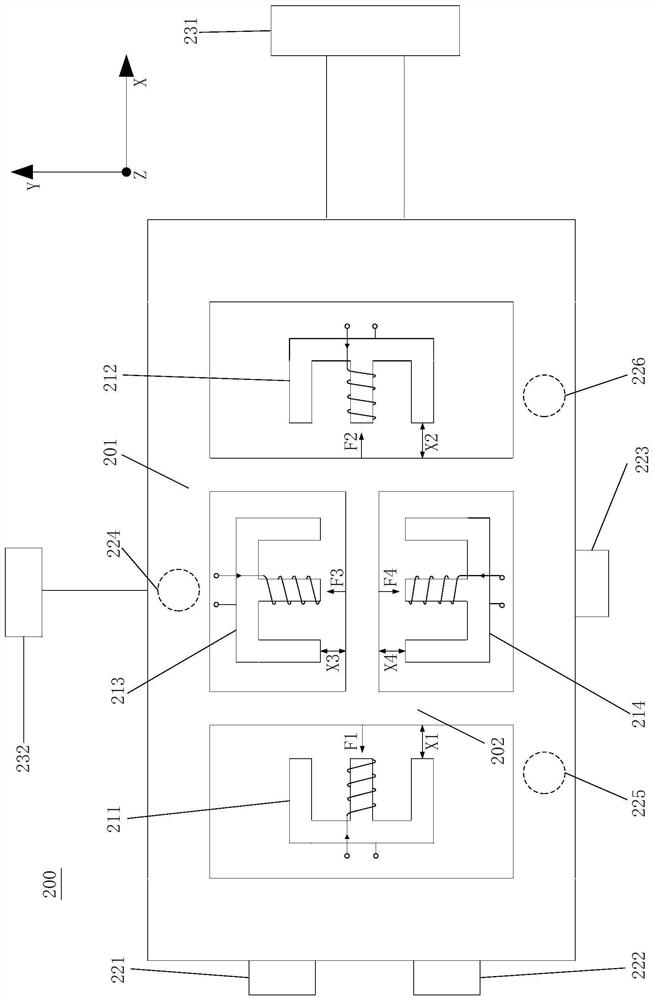

Embodiment 2

[0076] according to figure 2 , the figure shows a six-degree-of-freedom micro-motion platform 200, including a second micro-motion stage 201, four reluctance motors 211, 212, 213 and 214, six voice coil motors 221, 222, 223 and 224, 225, 226, and two laser interferometers 231 and 232. The reluctance motors 211, 212, 213 and 214 share an H-shaped center 202 as a mover, and the four electromagnets of the reluctance motors 211, 212, 213 and 214 are symmetrically arranged on four sides of the H-shaped center 202. The type center 202 and the second micro-motion table 201 are integrally structured. The setting of the voice coil motors 221, 222, 223 is the same as that of the voice coil motors 121, 122, 123 in the first embodiment. The linear movement and rotational movement and positioning of the platform 200 along the direction of six degrees of freedom (as shown in Figure 2). Other structural designs and control methods of the six-degree-of-freedom micro-motion platform 200 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com