Grouting sleeve assembly

A technology of grouting sleeves and components, which is applied in the direction of building components, building reinforcements, structural elements, etc., and can solve problems such as the inability to ensure the density of the grout in the sleeve, material waste, connection quality, and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

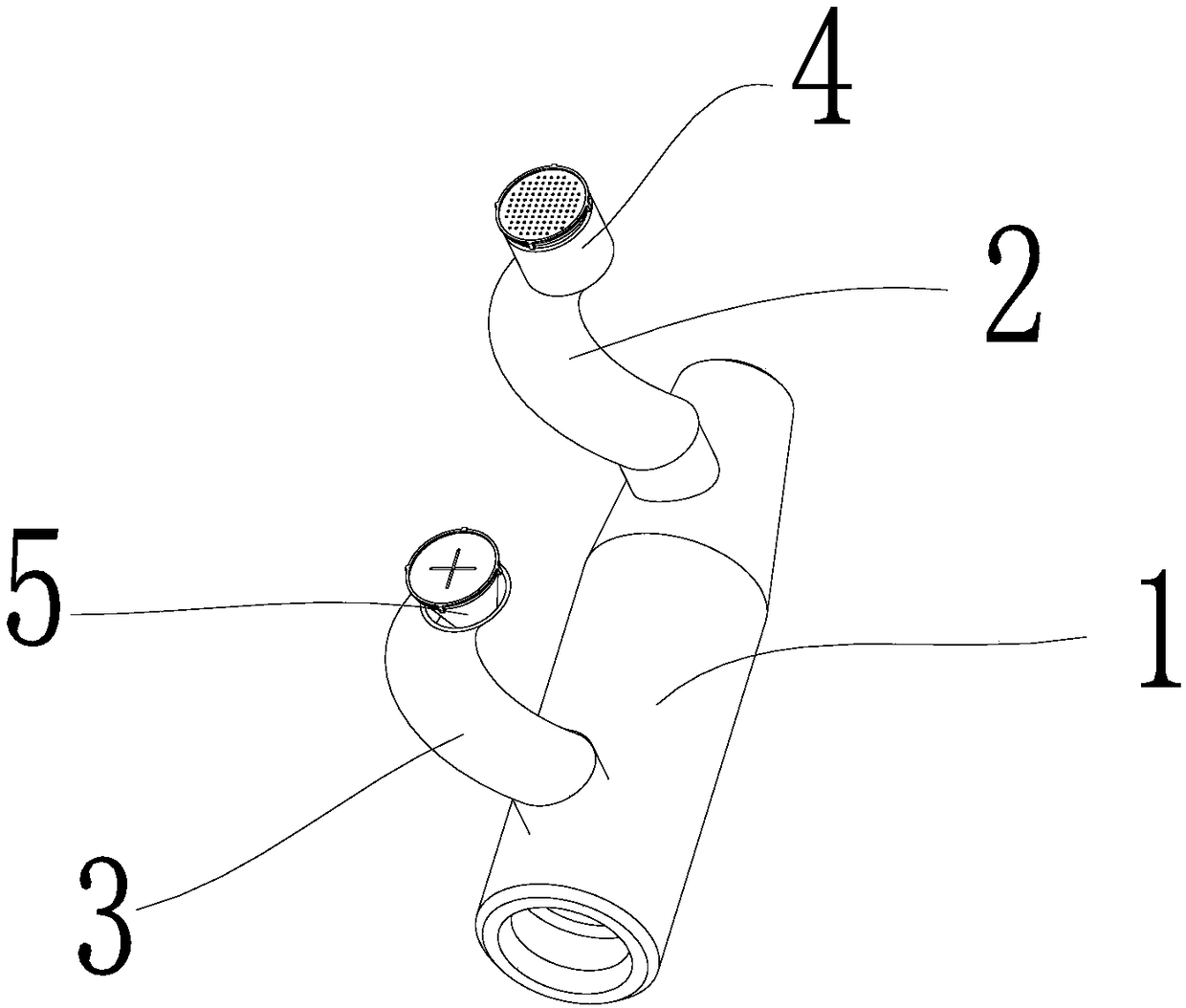

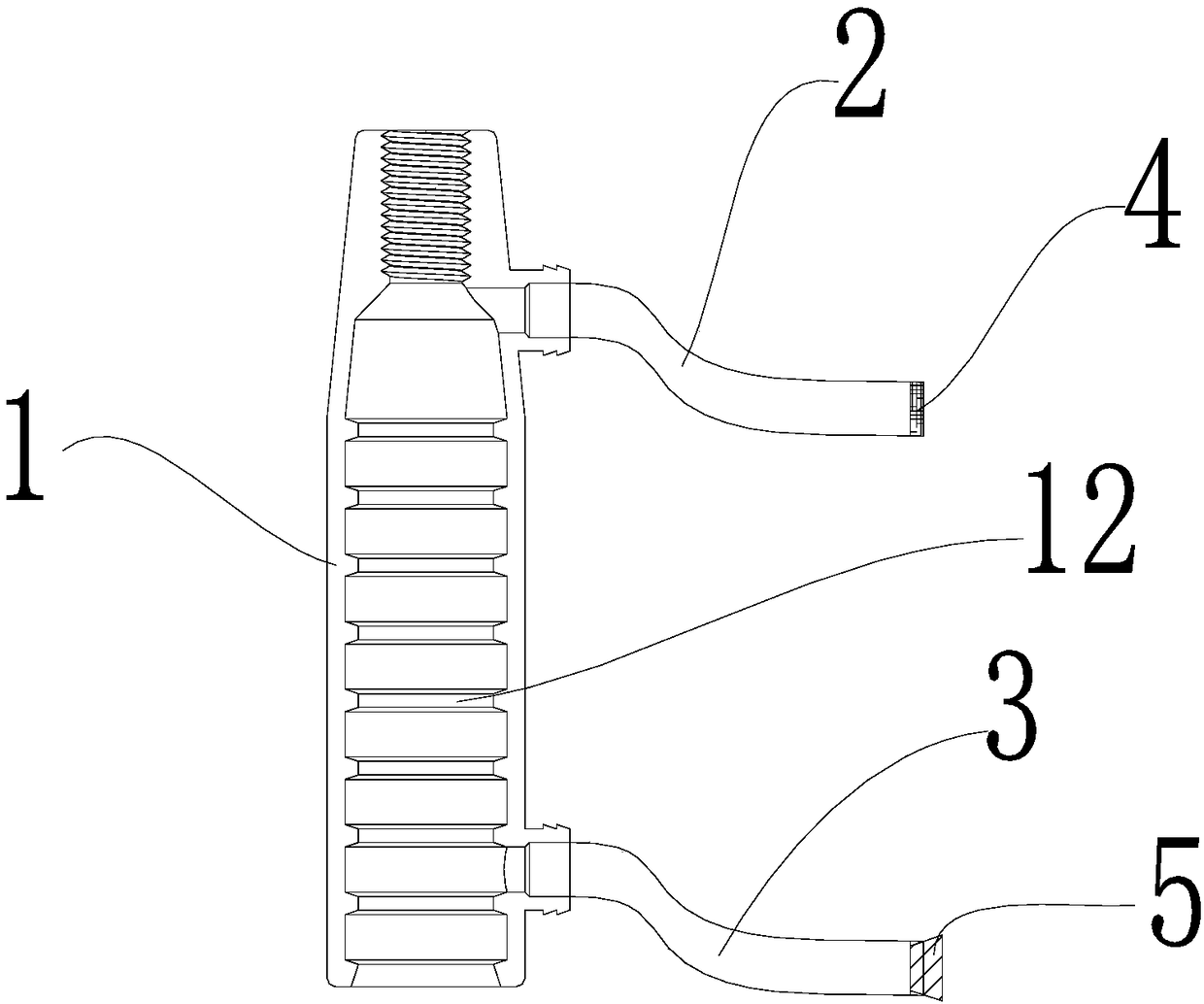

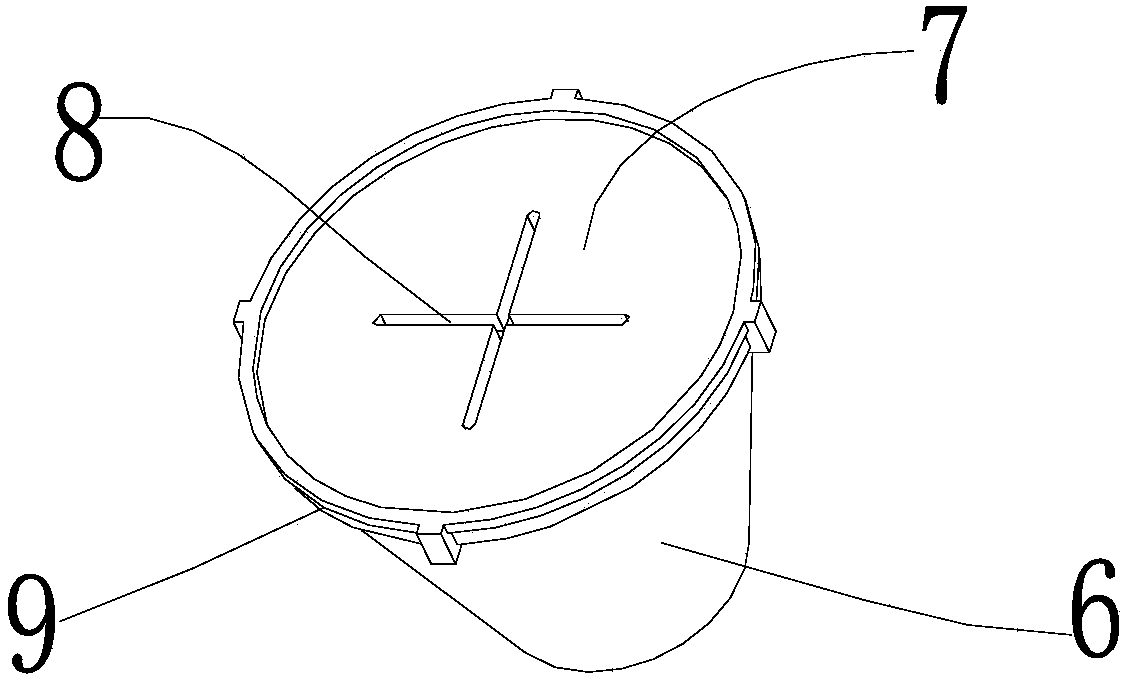

[0054] Embodiments of the present invention are as follows, with reference to figure 1 and figure 2 , a grouting sleeve assembly, including a sleeve body 1, an exhaust pipe 2 and a grouting pipe 3, the sleeve body 1 is provided with an exhaust hole and a grouting hole, and the exhaust pipe 2 and the grouting pipe 3 are respectively connected with the exhaust hole and the grouting hole, the exhaust port of the exhaust pipe 2 is provided with a ventilating sealing device 4 for preventing the grouting material from overfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com