Internal and external dual-drive rotary table bearing assembly machine

A technology for slewing bearings and assembly machines, which is applied to bearing components, shafts and bearings, mechanical equipment, etc. It can solve the problems that the assembly machine cannot meet the assembly requirements of slewing bearings with a diameter of more than 4 meters, the labor intensity of workers is high, and the assembly operation is complicated. , to achieve the effect of compact structure, small footprint and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

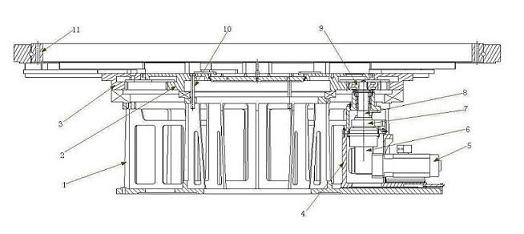

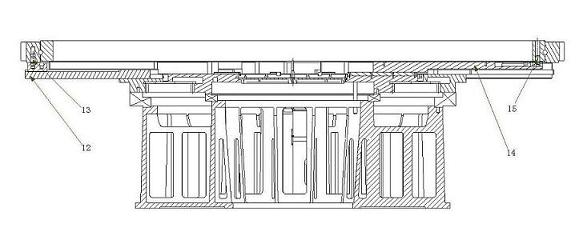

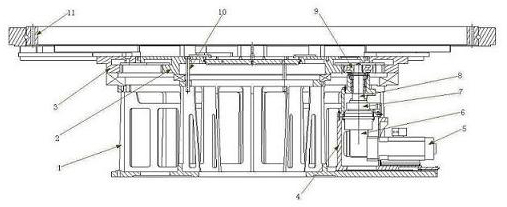

[0010] Such as figure 1 with figure 2 As shown, the internal and external dual-drive turntable bearing assembly machine of the present invention is mainly composed of a frame 1, an external gear turntable 2, an internal gear turntable 3, a movable seat 4, a frequency conversion motor 5, a precision planetary reducer 6, a torque sensor 7, The drive shaft 8, the drive gear 9, the fixed pin shaft 10, the outer telescopic arm 12, the outer drive pin 13, the inner telescopic arm 14, and the inner drive pin 15. The frame 1 supports an external gear turntable 2 and an internal gear turntable 3. The variable frequency motor 5, the precision planetary reducer 6, the torque sensor 7, the transmission shaft 8 and the driving gear 9 are installed on the movable seat 4. The workpiece 11 is supported on the outer telescopic arm 12 and the inner telescopic arm 14, and the outer drive pin 13, the inner drive pin 15 are inserted into the mounting holes of the outer ring and inner ring of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com