Laser spot welding assembly method of magnetic circuit system of miniature loudspeaker

A micro-speaker, magnetic circuit system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unfavorable miniaturization and light weight of micro-speakers, high cost, poor durability, etc. and light weight, improve production efficiency, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

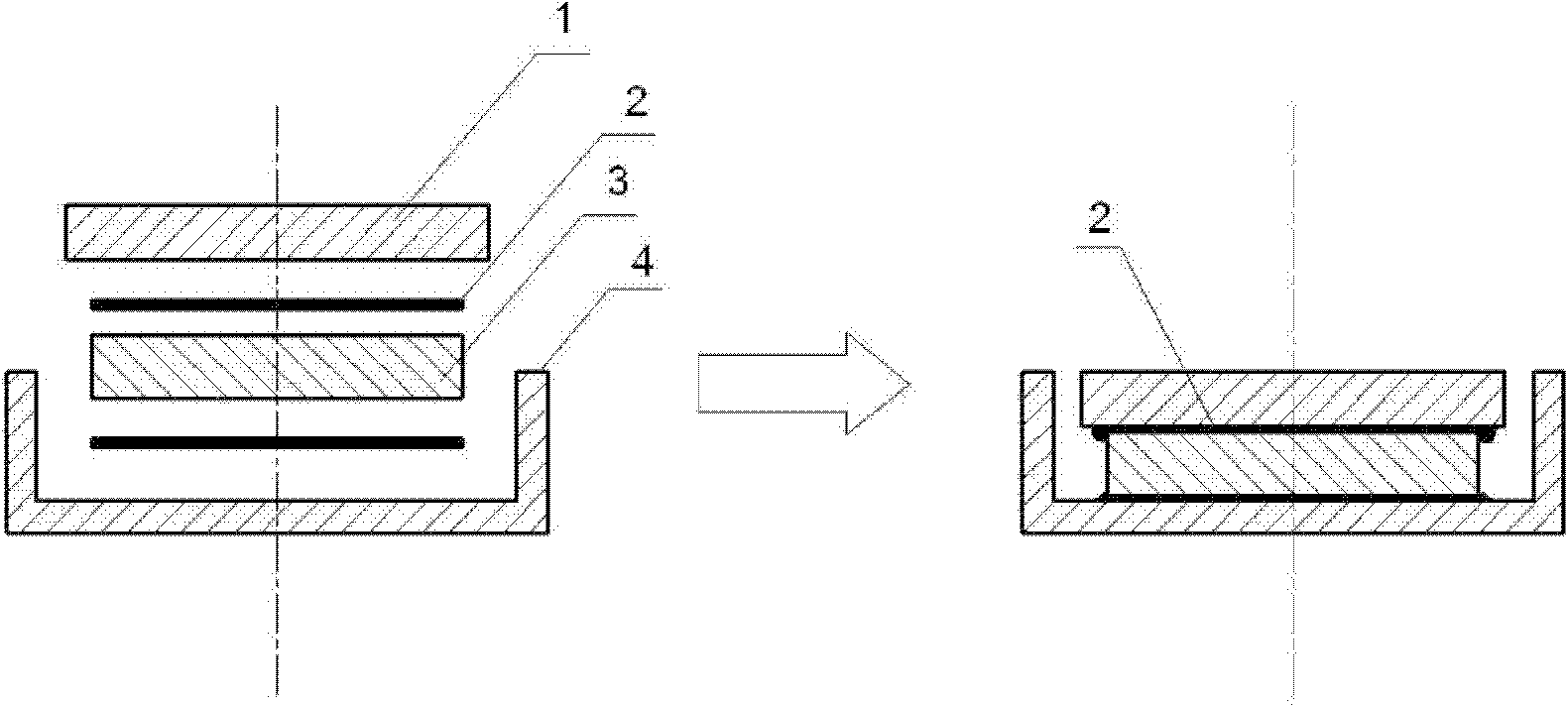

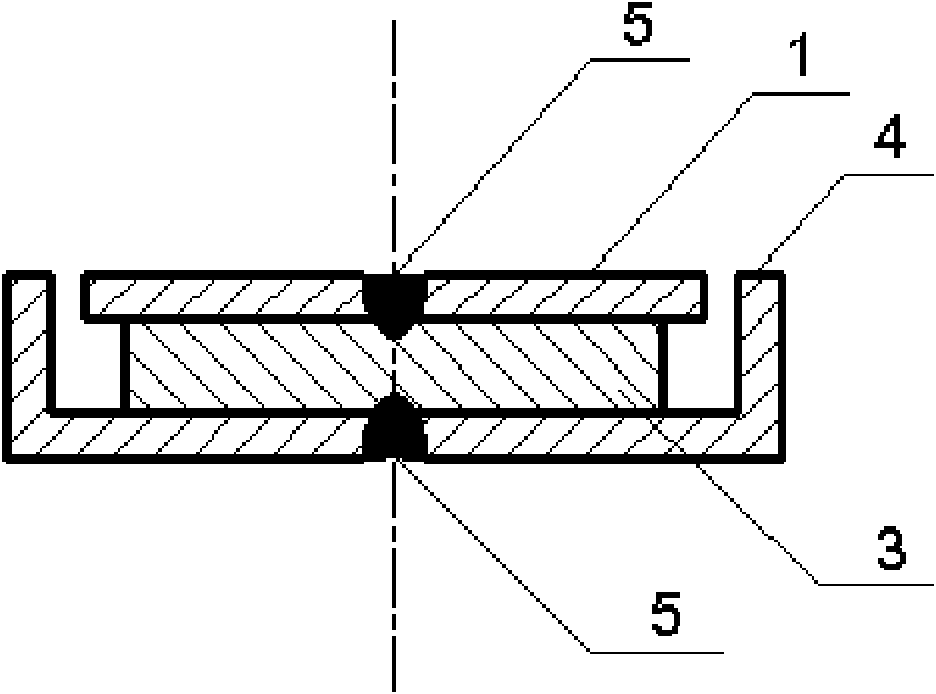

[0039] Such as image 3 , 4 As shown, for the assembly of the magnetic circuit system in which the permanent magnet 3 is circular and has a small radius, a single welding point is arranged at the respective centers of the top plate 1 and the yoke 4 for laser spot welding. Among them, the permanent magnet adopts high-performance sintered NdFeB permanent magnet N48, and the top plate 1 and the yoke 4 adopt common-quality cold-rolled low-carbon steel. Stack the top plate 1, permanent magnet 3 and yoke 4 of the magnetic circuit system in order from top to bottom; fix the stacked parts to be welded on the workbench of the Nd:YAG laser with a fixture, and move the workbench Position the laser head at the spot to be soldered on the top plate 1; turn on the laser and set the parameters of the laser as follows: the peak pulse power is 812.5W, the pulse width is 16ms, the defocus is 0mm, and argon is used as the shielding gas; Argon gas is supplied, and the spot to be welded at the ce...

Embodiment 2

[0042] Such as Figure 5 , 6 As shown, for the assembly of the magnetic circuit system in which the permanent magnet 3 is circular and has a relatively large radius, laser spot welding is performed with 4 welding spots evenly arranged on the circle centered on the respective centers of the top plate 1 and the yoke 4 . Among them, the permanent magnet adopts high-performance sintered NdFeB permanent magnet N48, and the top plate 1 and the yoke 4 adopt common-quality cold-rolled low-carbon steel. Stack the top plate 1, permanent magnet 3 and yoke 4 of the magnetic circuit system in order from top to bottom; fix the stacked parts to be welded on the workbench of the Nd:YAG laser with a fixture, and move the workbench Position the laser head at the spot to be welded on the yoke 4; turn on the laser, and set the parameters of the laser as follows: the pulse peak power is 300W, the pulse width is 10ms, the defocus is 0mm, and nitrogen is used as the shielding gas; Nitrogen gas, we...

Embodiment 3

[0045] Such as Figure 9 , 10 As shown, for the assembly of the magnetic circuit system in which the permanent magnet 3 is square, two welding spots are evenly arranged on the long axis of the top plate 1 and the yoke 4 for laser spot welding. Among them, the permanent magnet adopts high-performance sintered NdFeB permanent magnet N48, and the top plate 1 and the yoke 4 adopt common-quality cold-rolled low-carbon steel. Stack the top plate 1, permanent magnet 3 and yoke 4 of the magnetic circuit system in order from top to bottom; fix the stacked parts to be welded on the workbench of the Nd:YAG laser with a fixture, and move the workbench Position the laser head at the spot to be soldered on the top plate 1; turn on the laser, and set the parameters of the laser as follows: the peak pulse power is 1000W, the pulse width is 20ms, the defocus is 3.5mm, and argon is used as the shielding gas; Argon gas is supplied, and the spots to be welded on the top plate 1 are welded in se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com