Electric conduction probe, use and manufacture method, and method for lowering electric discharge of electric conduction probe

A technology of conductive probes and probes, which is applied to the parts of electrical measuring instruments, measuring electricity, measuring electrical variables, etc., can solve the problems of probe ablation, affecting LED test light parameters and electrical parameters, etc., and achieve reliable use , reduce the smoothness requirements, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

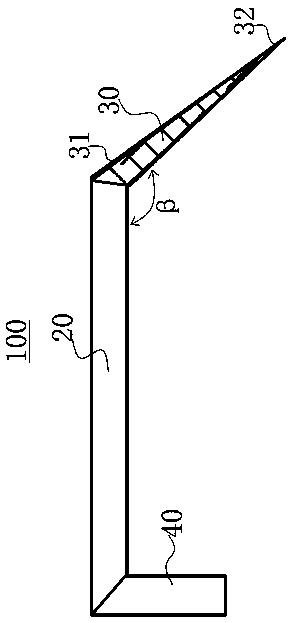

[0021] Such as figure 1 As shown, a conductive probe 100 includes a support part 20 and a bending part 30. The bending part 30 is a part that is connected to the support part 20 and will generate a discharge that affects the use of the conductive probe 100. The support part 20 is used for It is connected to the mounting seat of the conductive probe 100; one end of the support part 20 is electrically connected to the bending part 30, and the electrical signal obtained by the test of the bending part 30 is transmitted to the signal acquisition or processing module through the support part 20, and the support part The included angle between the 20 and the bent portion 30 is β, β∈(90°-180°), which ensures that the support portion 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com