Old and new concrete interface beam and plate component connection structure and construction method thereof

A technology of new and old concrete and construction methods, applied in building construction, building maintenance, construction, etc., can solve problems such as unsafe reinforcement quality, direct shear damage, and uneven chiseling quality, so as to achieve controllable and improved construction quality The effect of shear bearing capacity and improvement of force transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

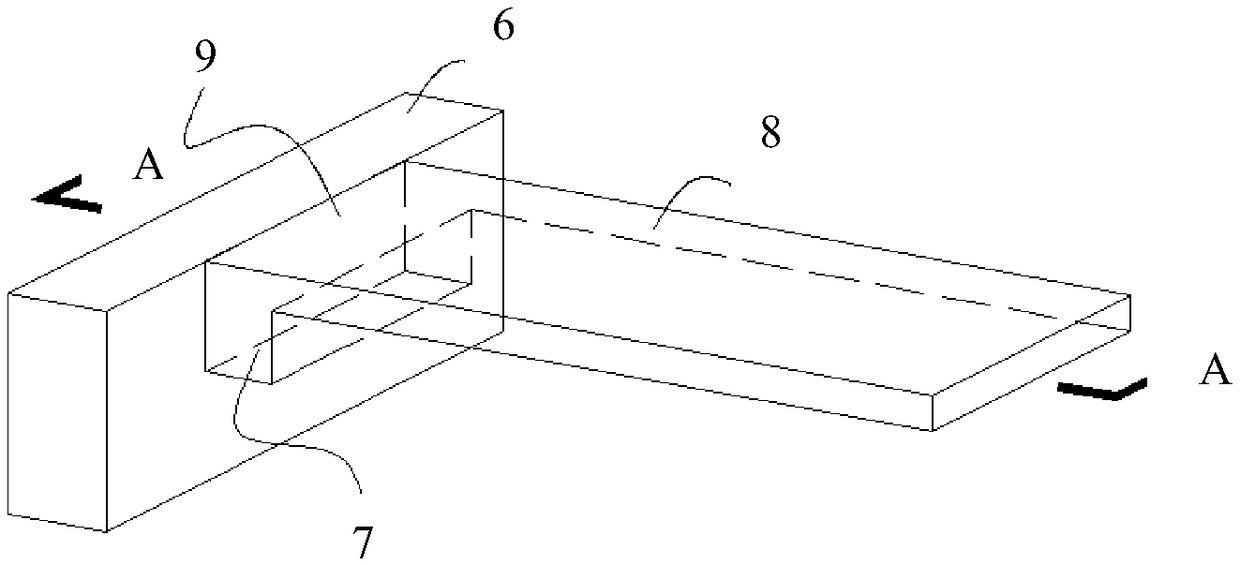

[0053] Such as Figure 3-5 Shown, is a kind of new and old concrete interface beam of the present invention, slab member handover structure, it comprises existing beam member 6, force transmission beam 7 and newly-built slab member 8, the reinforcement of force transmission beam 7 and the reinforcement of newly-built slab member 8 The force transmission beam 7 and the newly-built slab member 8 are bound together and poured in one piece. The outer surface of the force transmission beam 7 is fixed on the old and new concrete bonding surface 9 of the existing beam member 6, and the new and old concrete bonding surface 9 is chiseled. Hair treatment, the depth is 6-10mm, and the chiseling rate is greater than 90%. In addition, an interface reinforcement 10 is provided between the force transmission beam 7 and the existing beam member 6, one end of the interface reinforcement 10 is anchored into the force transmission beam 7, and the other end is anchored through the reinforcement h...

Embodiment 2

[0083] The difference between this embodiment and Embodiment 1 is that the floor slab boundary is calculated according to the fixed connection, there are reinforced concrete beams, the cross-sectional size is 300×600, the protective layer is 20mm thick, the concrete grade is C20, fc=9.6N / mm 2 ; The thickness of the new floor is 100mm, the concrete grade is C25, fcv=2ft=2.54N / mm 2 . According to the fixed calculation, the plate edge bending moment M = 8kN·m / m.

[0084] According to the structural requirements, the size of the force transmission beam is selected to be 200mm×300mm.

[0085] Select 1 linear meter slab for calculation, and only roughen the interface, the direct shear bearing capacity is 0.4×2.8×80×1000=89.6kN; after setting the force transmission beam, the direct shear bearing capacity is 1.68×280×1000=470.4 kN; for intact cast-in-place integral components, the direct shear bearing capacity is 2.8×80×1000=224.0kN.

[0086] The selected interface reinforcement is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com