Rock reaming self-locking anchor cable comprising steel strands and manufacturing method of rock reaming self-locking anchor cable

A steel strand harness and anchor cable technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of aging resistance, single anchoring force, weak fatigue resistance, etc., to avoid high temperature resistance, anchoring force Diversification, overcoming the single effect of anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

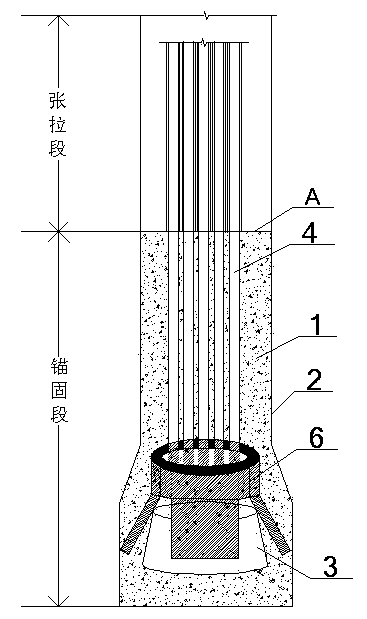

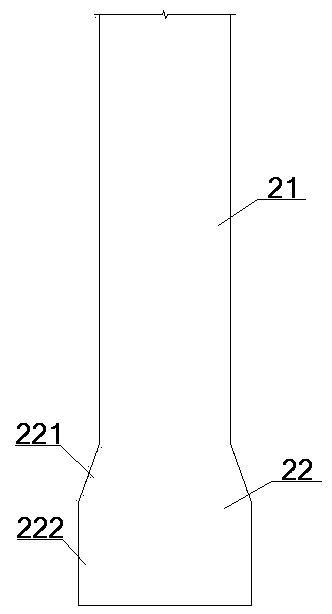

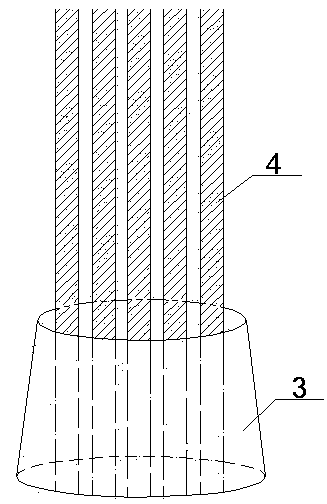

[0053] see figure 1 – Figure 5 , the rock reaming self-locking anchor cable comprising steel strands, including the outer hole 2 and the anchor cable set inside it, the lock head 3, and the petal-type circular tube 6, the anchor cable includes an anchor section and a tension section, and the top end of the anchor section It is connected with the tension section, the bottom end of the anchor section is connected with the lock head 3, and the anchor section passes through the grouting material 1 (the grouting material 1 is an inorganic micro-expansion grouting material, and its 28d compressive strength grade is greater than or equal to M50) and the outer hole 2 The inner wall of the anchor cable is connected with each other; the anchor cable is composed of multiple steel strand bundles 4, and each steel strand bundle 4 is formed by twisting a plurality of unbonded prestressed steel strands, and the steel strands in the anchorage section are removed from the anti-corrosion The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com