Device for forming diameter-expanded prefabricated hole

A technology of prefabricated holes and driving rods, which is applied to the on-site preparation of building components, formwork/template/work frame, construction, etc., can solve problems such as weak shear strength, strengthen connection performance, increase mechanical engagement Easy and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the drawings and embodiments.

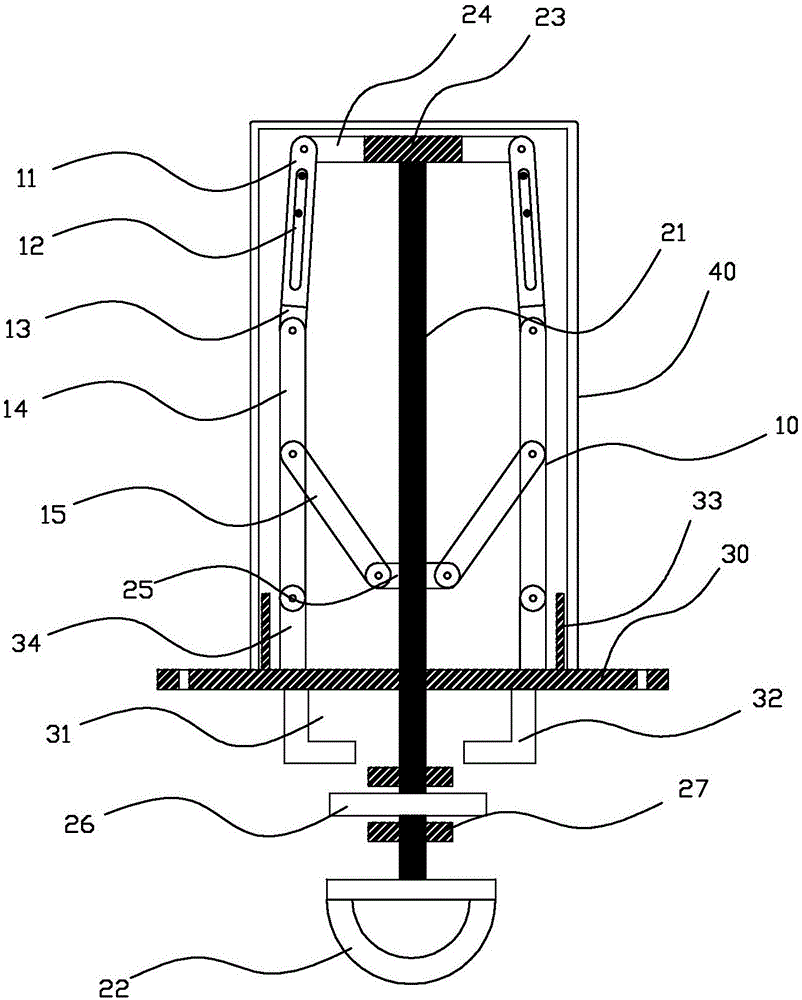

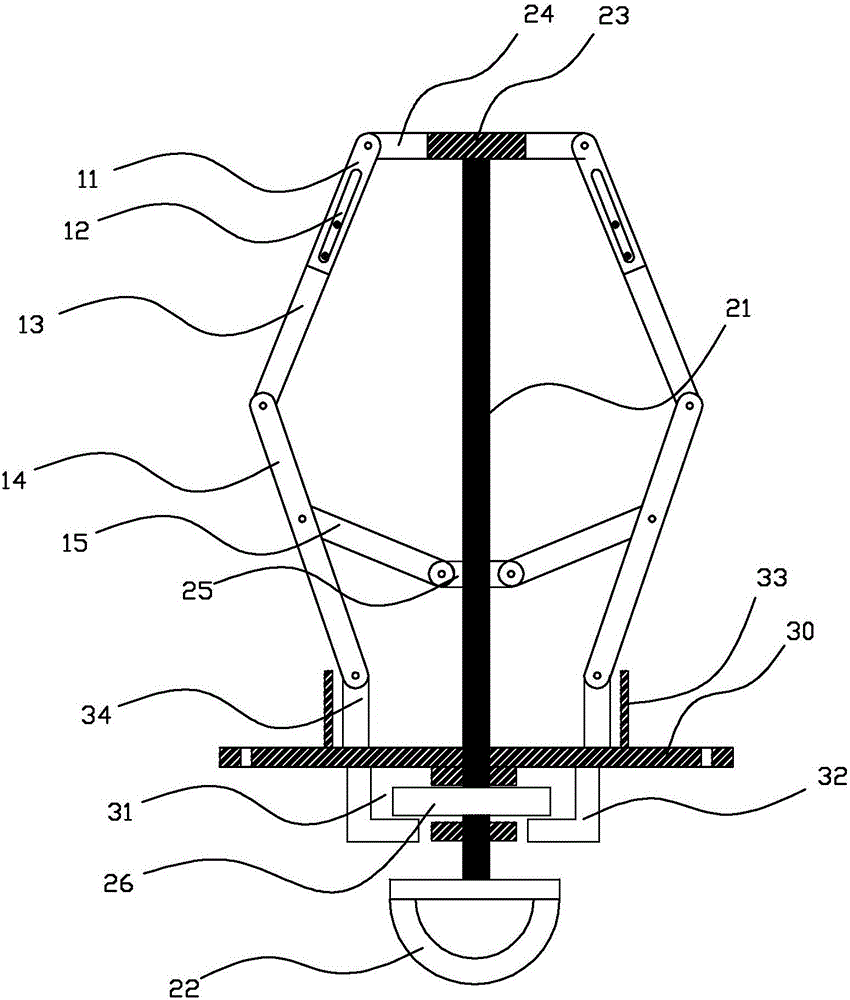

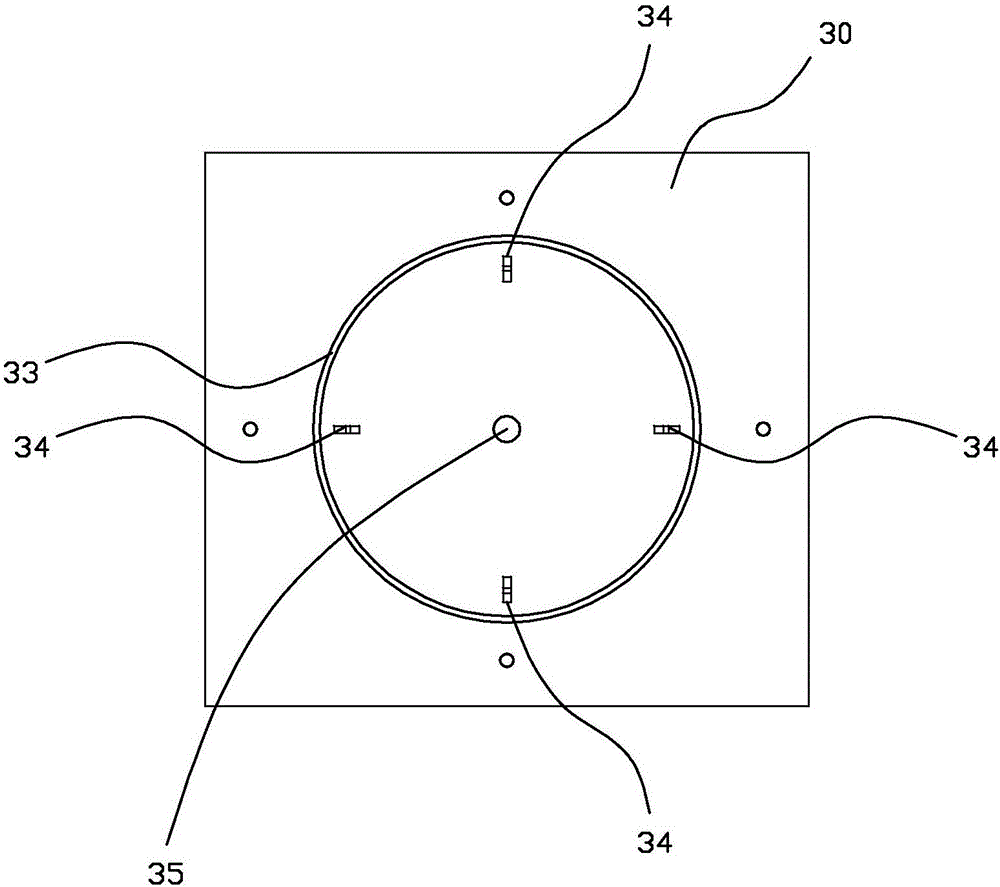

[0025] In order to solve the prior art lack of a prefabricated hole device that is convenient for installation and disassembly, and cannot balance the contradiction between convenient operation, shear strength, and grouting process, the present invention provides a device for forming expanded diameter prefabricated holes, such as figure 1 , figure 2 As shown, it includes a spreading device, an elastic sleeve 40, and a driving rod. The driving rod is connected with the spreading device, and the elastic sleeve 40 is sleeved outside the spreading device; the drive rod is pressed in, and the spreading device and the driving rod are linked to expand, from The middle position expands the elastic sleeve 40 outwards; the drive rod is drawn out, the expansion device and the drive rod are linked to contract, and the elastic sleeve 40 is reset. Before pouring concrete int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com