Joint of concrete-filled steel-tubular column and steel beam and architectural structure system

A technology of steel pipe concrete columns and connecting nodes, which is applied in the direction of building construction and construction, to achieve the effects of strong layout, reduced difficulty, and eased tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

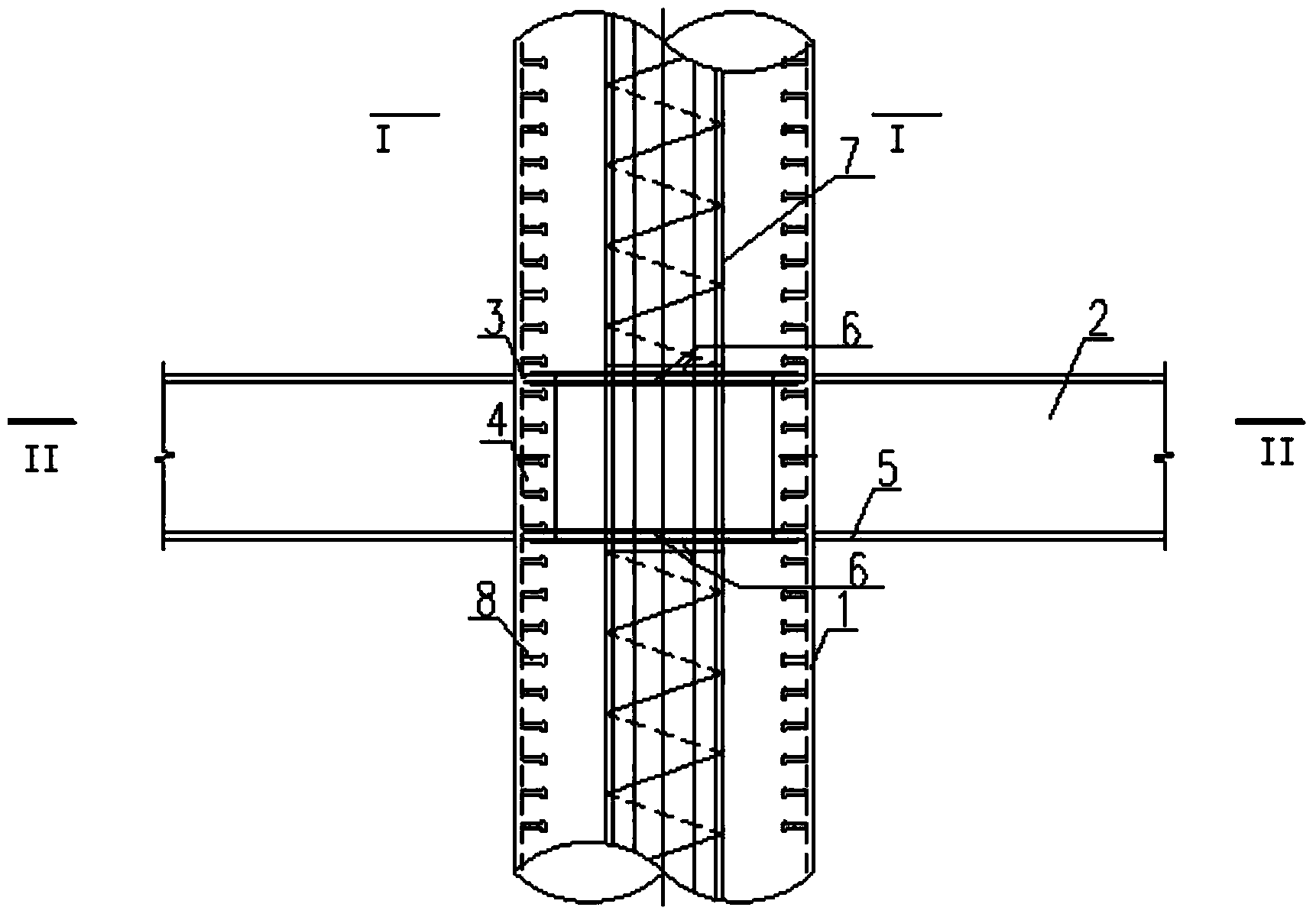

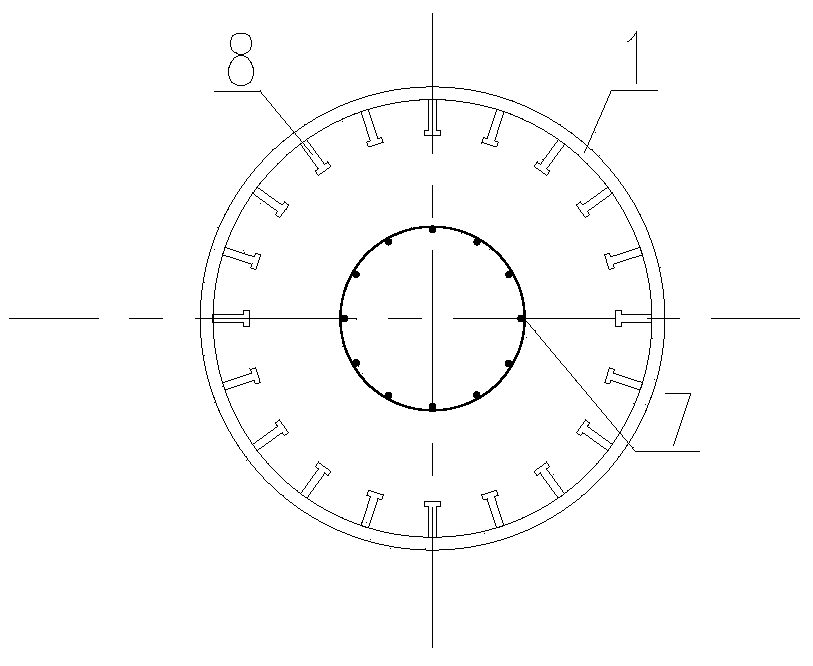

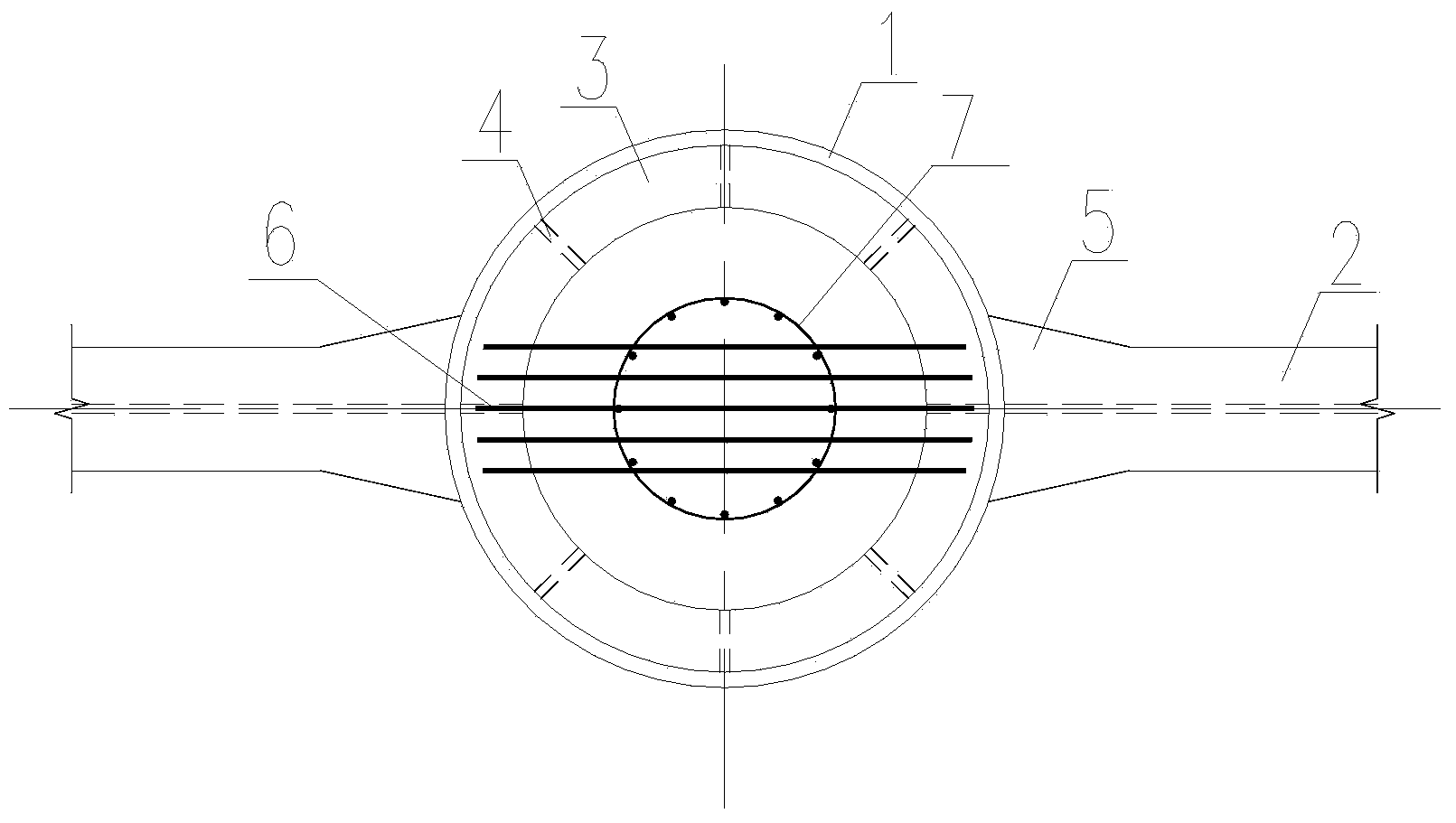

[0028] refer to Figures 1 to 3 It can be seen that the connection node between the steel pipe concrete column and the steel beam in the present invention includes the steel beam 2 and the large-diameter steel pipe 1 of the steel pipe concrete column. Steel girder 2 adopts H-shaped steel girder, and of course I-shaped steel girder can also be used. The H-shaped steel beam 2 and the steel pipe 1 of the steel tube concrete column are welded together at joints, and the width of the flange 5 of the H-shaped steel beam 2 is widened at the welding place. The inner ring plates 3 are respectively welded at positions corresponding to the upper and lower flanges 5 of the H-shaped steel beam 2 in the steel pipe 1 . In order to reduce the difficulty of pouring concrete, the width of the inner ring plate 3 is relatively small, such as less than 1 / 4 of the diameter of the steel pipe 1 . In order to improve the connection quality and increase the mechanical bite force between the steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com