Project beam-column joint for reverse building method

A beam-column joint and reverse method technology, which is applied in infrastructure engineering, excavation, construction, etc., can solve problems such as difficulty in connecting steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Taking the circular steel pipe concrete column as an example, other forms of steel columns can be implemented by referring to this node.

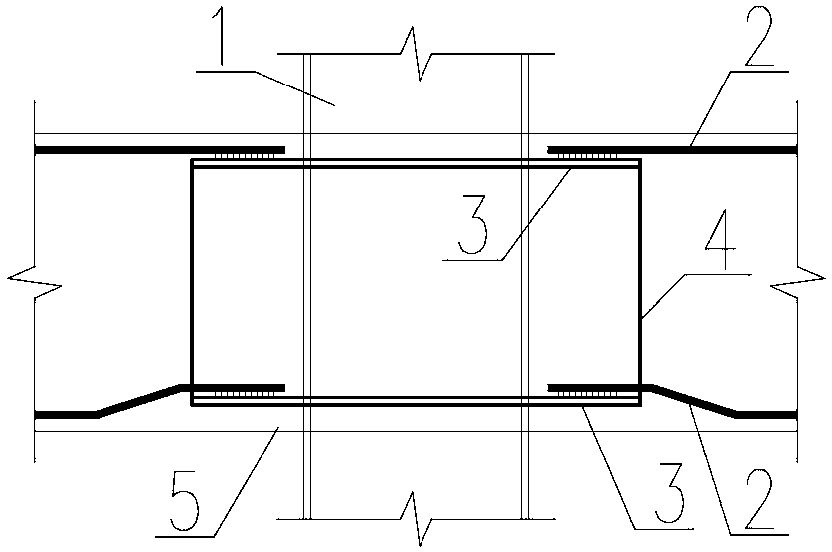

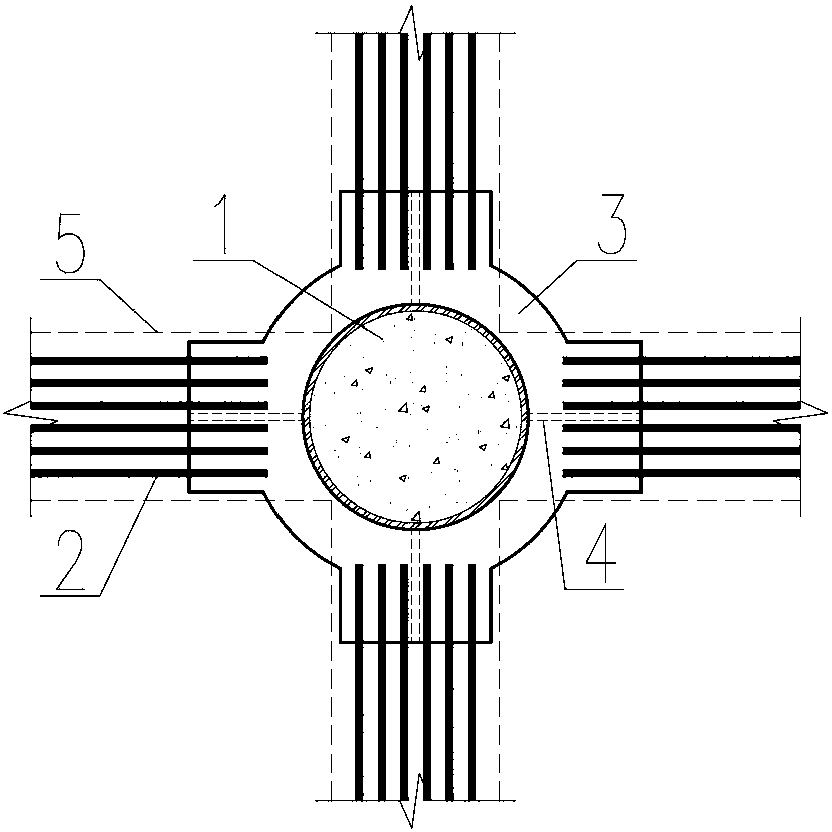

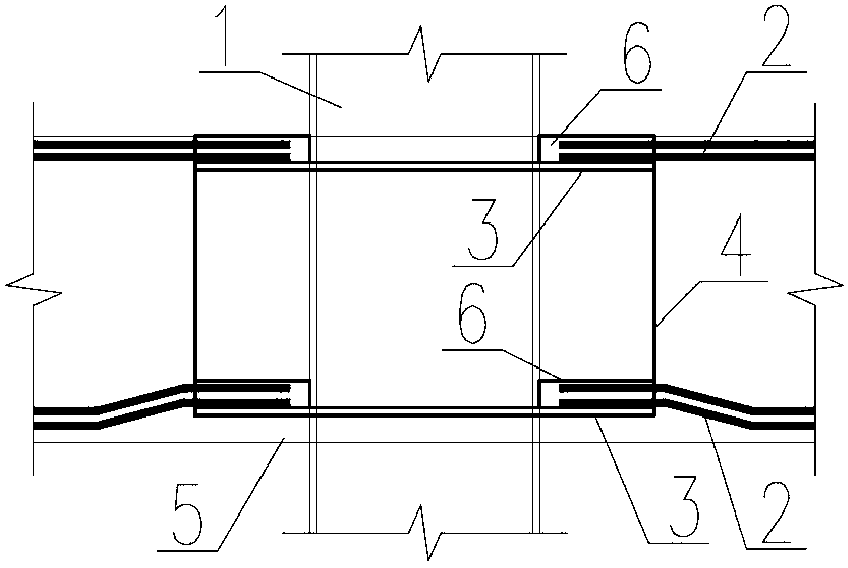

[0019] Such as figure 1 and figure 2 As shown, after the foundation pit is excavated to the elevation of the bottom of the inverted horizontal structural beam, the steel ring plate 3 is welded to the corresponding elevation of the main reinforcement 2 of the structural beam outside the steel pipe concrete column 1, and stiffeners 4 are arranged at vertical intervals. The steel ring plate 3 The width meets the welding requirements of the main reinforcement of the structural beam. If the width of the steel ring plate 1 is limited, it can be partially widened within the width of the structural beam 5. The thickness of the steel ring plate 3 needs to meet the force transmission requirements of the main reinforcement 2 of the structural beam. After the steel ring plate 3 and the stiffener 4 are welded, the structural beam main reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com