High-temperature high-strength high-conductivity high-wear-resistant copper-based composite material and preparation method thereof

A copper-based composite material, high-strength technology, applied in the field of non-ferrous metal alloys, can solve the problems of poor electrical conductivity, strength, wear resistance and other comprehensive properties, poor bonding between the micro-nano particle reinforced phase and the copper matrix interface, etc., to achieve convenient preparation. , Reduce inclusion and gas content, increase the effect of mechanical bite force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

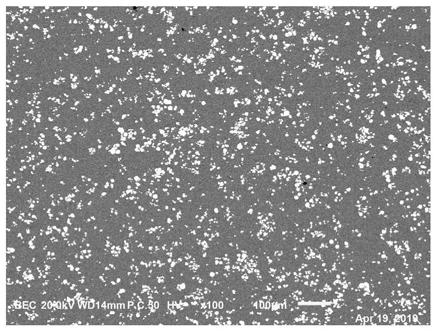

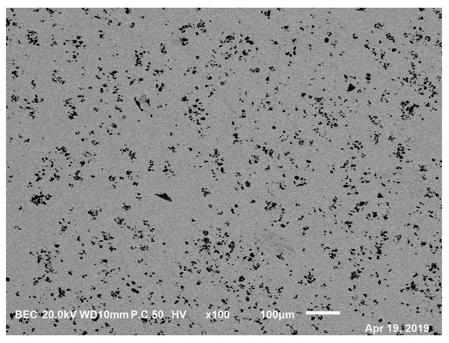

Image

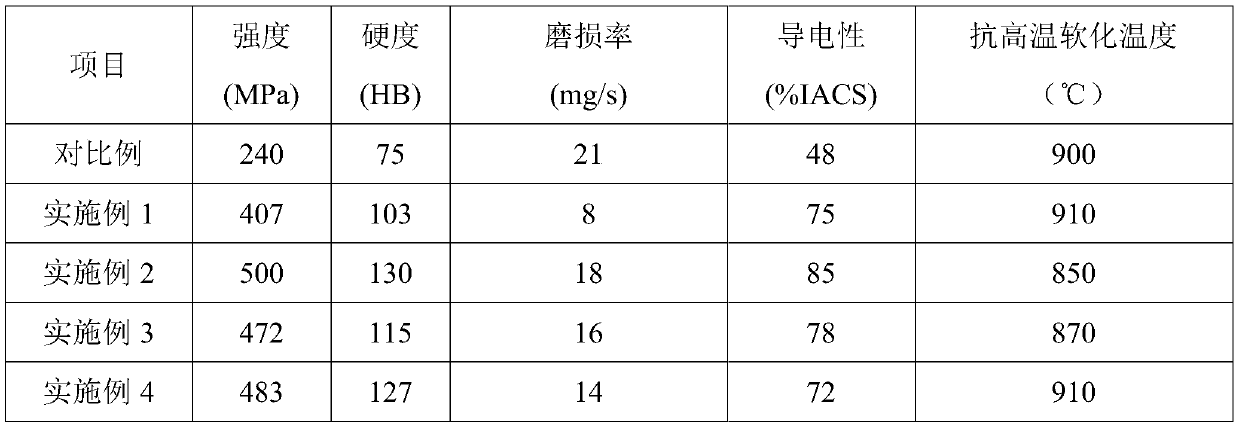

Examples

Embodiment 1

[0042] The preparation method of the high-temperature, high-strength, high-conductivity, and wear-resistant copper-based composite material of this embodiment uses WC / Cu-Al 2 O 3 Take the preparation of composite material as an example, WC / Cu-Al 2 O 3 In composite materials, the mass of WC accounts for 16.3%, and the rest is Cu and Al 2 O 3 , Al 2 O 3 The mass percentage of Cu is 1%; the specific preparation process is as follows:

[0043] (1) Preparation of copper-based electrodes

[0044] 1) Press WC / Cu-Al 2 O 3 The composition of the composite material prepared the following raw materials: WC powder 3.26kg (particle size 0.5μm), Cu 2 O powder 0.926kg (particle size is 2μm; 1.2 times the theoretical required mass), Cu-Al alloy powder 16.74kg (particle size is 10μm, Al content is 0.58%); put each raw material in the mixer Mix, and the mixing time is 2h to obtain mixed powder;

[0045] 2) Put the mixed powder into the rubber sleeve and perform mechanical vibration for 40 seconds, rol...

Embodiment 2

[0050] The method for preparing the high-temperature, high-strength, high-conductivity, and wear-resistant copper-based composite material of this embodiment is based on La 2 O 3 / Cu-TiB 2 Take the preparation of composite materials as an example, La 2 O 3 / Cu-TiB 2 In composite materials, La 2 O 3 The mass percentage is 5%, the rest is Cu and TiB 2 , TiB 2 The mass percentage of Cu is 0.5%; the specific preparation process is as follows:

[0051] (1) Preparation of copper-based electrodes

[0052] 1) Press La 2 O 3 / Cu-TiB 2 The composition of the composite material prepares the following raw materials: La 2 O 3 Powder 1kg (particle size of 2μm), Ti powder 0.065kg (particle size of 1μm), B powder 0.029kg (particle size of 0.5μm), Cu powder 18.9kg (particle size of 10μm); put each raw material in the mixer Internal mixing, the mixing time is 8h to obtain mixed powder;

[0053] 2) Put the mixed powder into the rubber sleeve and perform mechanical vibration for 60 seconds, roll the mat...

Embodiment 3

[0058] The method for preparing the high-temperature, high-strength, high-conductivity, and wear-resistant copper-based composite material of this embodiment uses TiB 2 / Cu-ZrB 2 Take the preparation of composite materials as an example, TiB 2 / Cu-ZrB 2 In composite materials, TiB 2 The mass percentage is 8%, the rest is Cu and ZrB 2 , ZrB 2 The mass percentage of Cu is 0.5%; the specific preparation process is as follows:

[0059] (1) Preparation of copper-based electrodes

[0060] 1) Press TiB 2 / Cu-Al 2 O 3 The composition of the composite material prepares the following raw materials: TiB 2 Powder 1.6kg (particle size 5μm), Zr powder 0.088kg (particle size 1μm), B powder 0.744kg (particle size 1μm), Cu powder 18.59kg (particle size 10μm); put each raw material in the mixer Internal mixing, mixing time is 16h, to obtain mixed powder;

[0061] 2) Put the mixed powder into the rubber sleeve and sequentially perform mechanical vibration for 70s, roll the material for 8 minutes, and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com