Composite coating on the surface of a magnesium alloy biological implant material and its preparation method

An implant material and composite coating technology, which is applied in the field of biomedical metal implant materials, can solve problems such as difficult protective effects, and achieve the effects of controllable coating structure, excellent film-base binding force, and improved biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

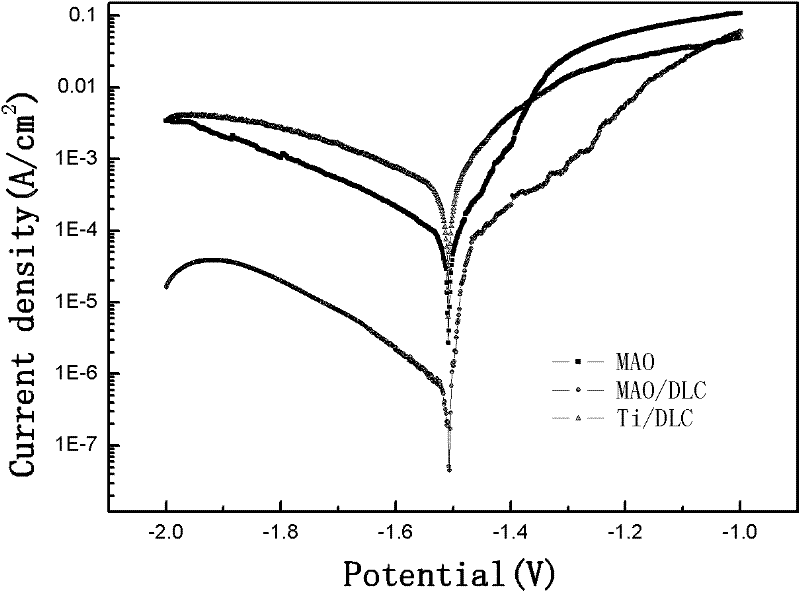

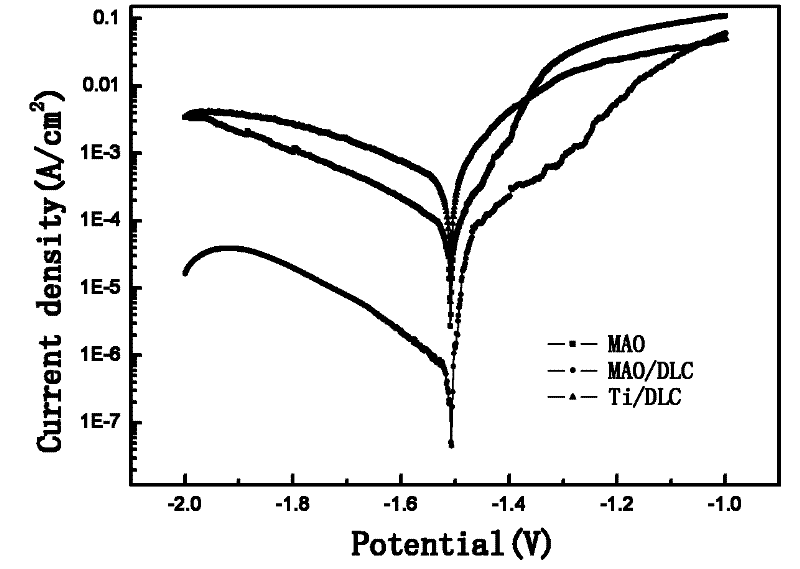

[0031] In this embodiment, the composite coating on the surface of the magnesium alloy biological implant material is a MAO / DLC composite coating, that is, there is a transition layer between the surface of the magnesium alloy substrate and the DLC film layer, and the transition layer utilizes micro-arc oxidation technology to make An oxide porous film formed in situ by magnesium atoms on the surface of the magnesium alloy substrate, and the maximum surface pore diameter of the oxide porous film is 500nm, the thickness of the transition layer is 5μm, and the thickness of the DLC film layer is 600nm.

[0032] The preparation method of the composite coating on the surface of the above-mentioned magnesium alloy biological implant material comprises the following steps:

[0033] Step 1: The magnesium alloy substrate is mechanically polished, and chemical reagents without the introduction of harmful elements are selected to prepare a silicate-based micro-arc oxidation electrolyte su...

Embodiment 2

[0039] In this embodiment, the composite coating on the surface of the magnesium alloy biological implant material is a MAO / N-DLC composite coating, that is, between the surface of the magnesium alloy substrate and the nitrogen-doped DLC film layer (abbreviated as the N-DLC film layer). There is a transition layer, which is an oxide porous film formed in situ by magnesium atoms on the surface of the magnesium alloy substrate using micro-arc oxidation technology, and the maximum surface pore diameter of the oxide porous film is 400nm, and the thickness of the transition layer is The thickness of the N-DLC film layer is 3 μm, and the thickness is 500 nm.

[0040] The preparation method of the composite coating on the surface of the above-mentioned magnesium alloy biological implant material comprises the following steps:

[0041] Step 1: The magnesium alloy substrate is mechanically polished, and chemical reagents without the introduction of harmful elements are selected to prep...

Embodiment 3

[0047] In this embodiment, the composite coating on the surface of the magnesium alloy biological implant material is MAO / Ti-DLC composite coating, that is, between the magnesium alloy substrate surface and the titanium-doped DLC film layer (abbreviated as Ti-DLC film layer). There is a transition layer, which is an oxide porous film formed in situ by magnesium atoms on the surface of the magnesium alloy substrate using micro-arc oxidation technology, and the maximum surface pore diameter of the oxide porous film is 800nm, and the thickness of the transition layer is The thickness of the Ti-DLC film layer is 12 μm, and the thickness is 800 nm.

[0048] The preparation method of the composite coating on the surface of the above-mentioned magnesium alloy biological implant material comprises the following steps:

[0049] Step 1: The magnesium alloy substrate is mechanically polished, and chemical reagents without the introduction of harmful elements are selected to prepare a sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com