Extension body compaction pile capable of eliminating pile foundation negative friction and construction method

A technology of negative friction resistance and compacting piles, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problem of poor treatment effect of high compressibility foundation soil, does not essentially eliminate negative friction resistance, safety threats, etc. problems, to achieve the effect of improving physical and mechanical properties, reducing foundation settlement, and high degree of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the given examples are only used to explain the present invention, and are not intended to limit the present invention. Within the principle of the present invention, the modifications, equivalent replacements and improvements all belong to the protection scope of the present invention.

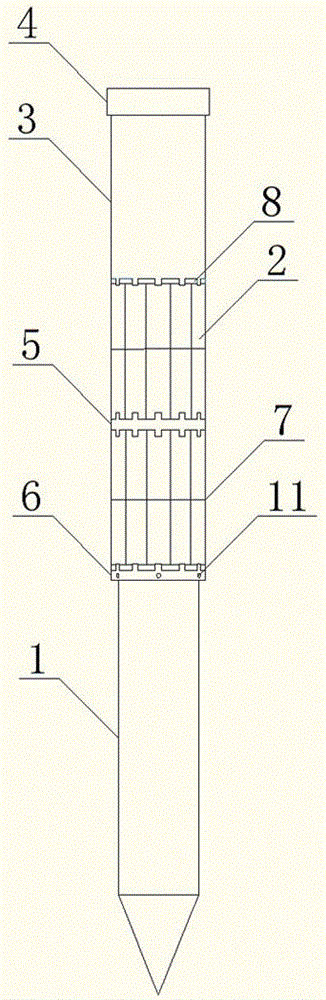

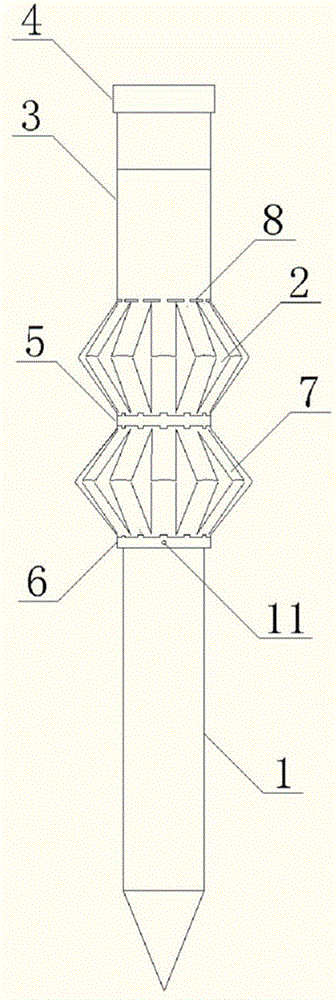

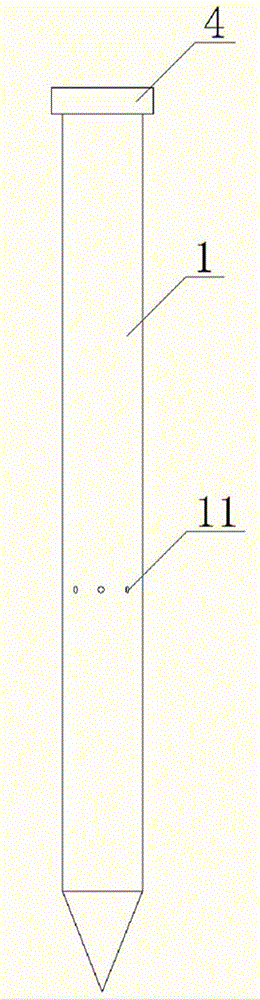

[0017] Such as Figure 1-8 Shown, the present invention is a kind of body expansion compaction pile that eliminates pile foundation negative friction resistance, and its structure comprises pile body 1, expansion device 2, sleeve 3 and cap 4; Pile body 1 is concrete steel pipe pile; Expansion The device 2 is composed of a two-way clamp 5, a one-way clamp 6, a crank connecting rod 7, and a rotating shaft pin 8. The rotating shaft pin 8 is used to connect the crank connecting rod 7 to the rotating shaft supports 9 on both sides of the two-way clamping hoop 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com