Construction method for eliminating collapsibility of cement stirring insertion pile in collapsible loess area

A technology of collapsible loess and cement mixing piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low foundation bearing capacity, long construction time, limited depth of water injection holes, etc., to improve bearing capacity , The effect of improving the bearing capacity of the pile and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

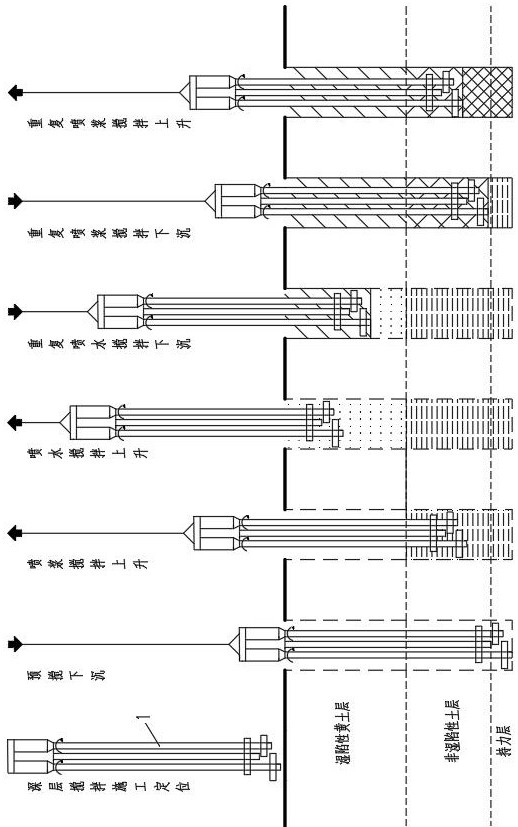

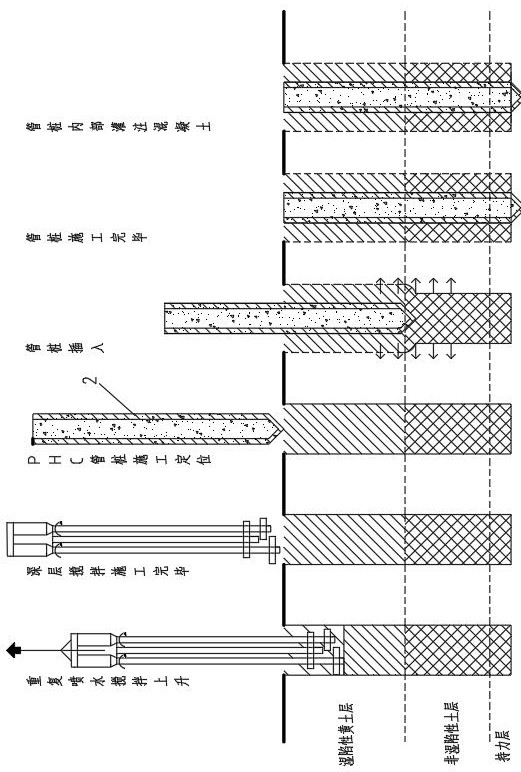

[0032] A construction method for eliminating collapsibility by inserting piles into cement mixing piles in collapsible loess areas, specifically according to the following steps:

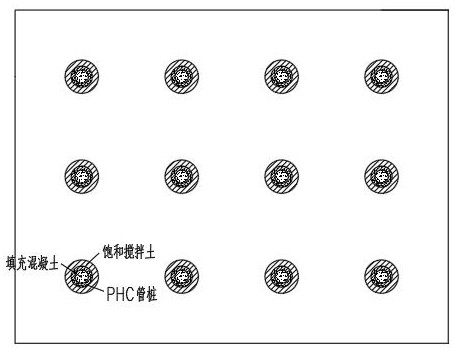

[0033] 1) Level the site before construction, measure and stake out according to the design drawings, and calibrate the position of each cement mixing pile (such as figure 1 shown).

[0034] 2) According to the geological survey report and superstructure requirements, according to the "Technical Specifications for Building Pile Foundations" (JGJ94-2008) and "Building Standards for Collapsible Loess Areas" (GB50025-2018), determine the elimination of negative friction resistance on the side of the cement mixing pile inserted into the pile In order to determine the collapsible loess layer collapsible treatment area, depth and remaining collapsible amount around the pile.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com