A Construction Method for Reducing Negative Frictional Resistance of Pipe Pile

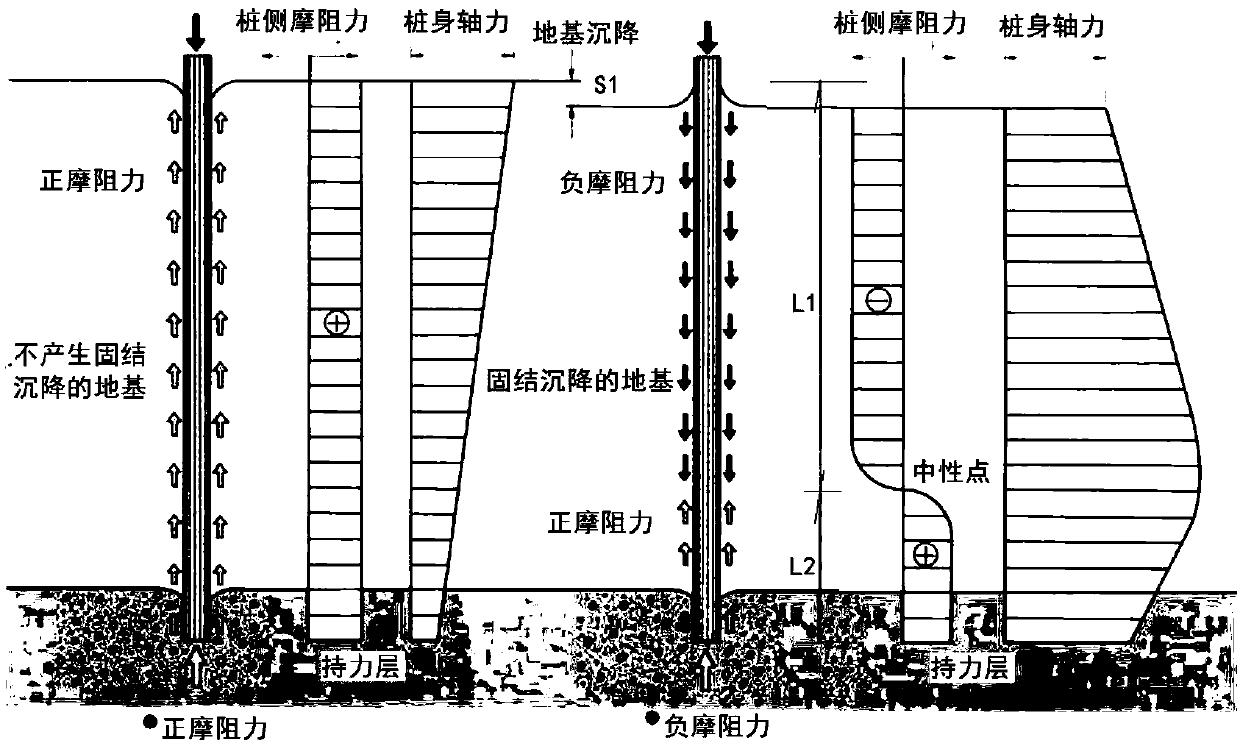

A technology of negative friction resistance and construction method, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., to achieve good use value and promotion value, eliminate negative friction resistance, and stabilize the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

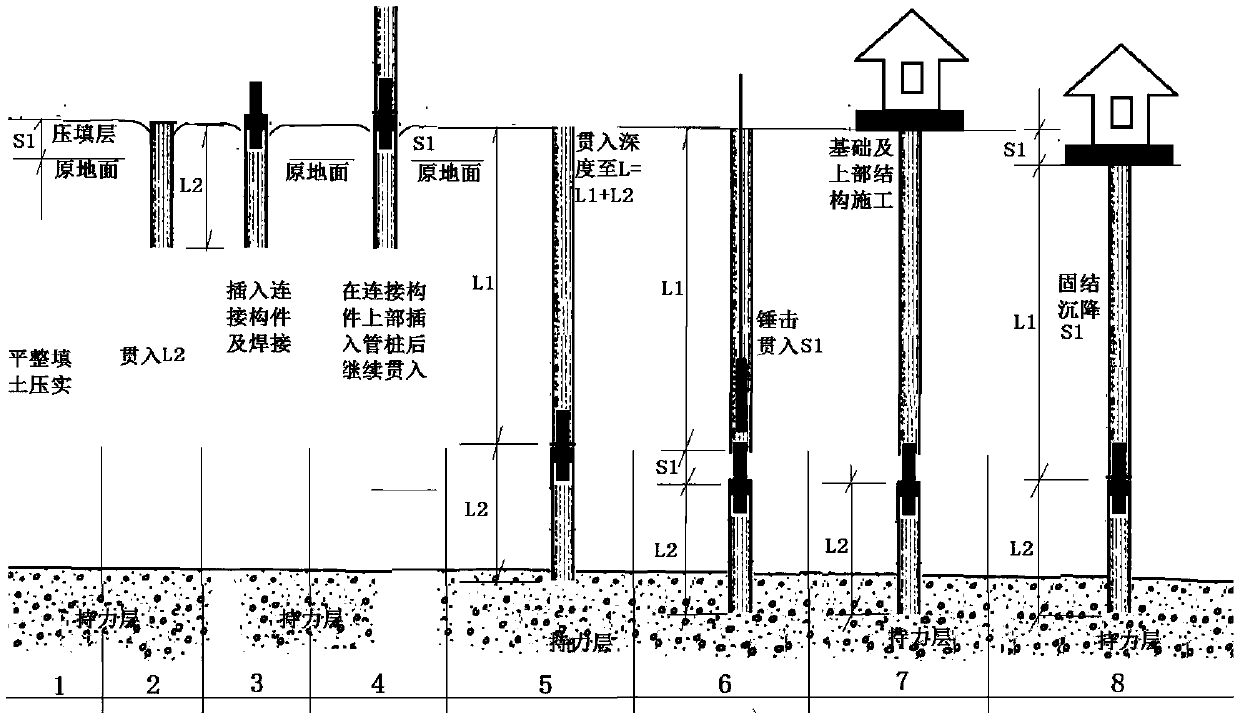

[0028] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0029] image 3 It is the construction step diagram of the construction method for reducing the negative friction resistance of pipe piles in the present invention, and the method comprises the following steps:

[0030] Step 1. Estimating the depth of the neutral point of negative friction resistance, prefabricating or processing the connecting components;

[0031] a) Calculate the post-construction settlement S1 of the soft soil layer and the depth L1 of the neutral point where negative friction resistance occurs according to the basic parameters such as the filling load on the surface of the soft soil and the thickness of the soft soil layer;

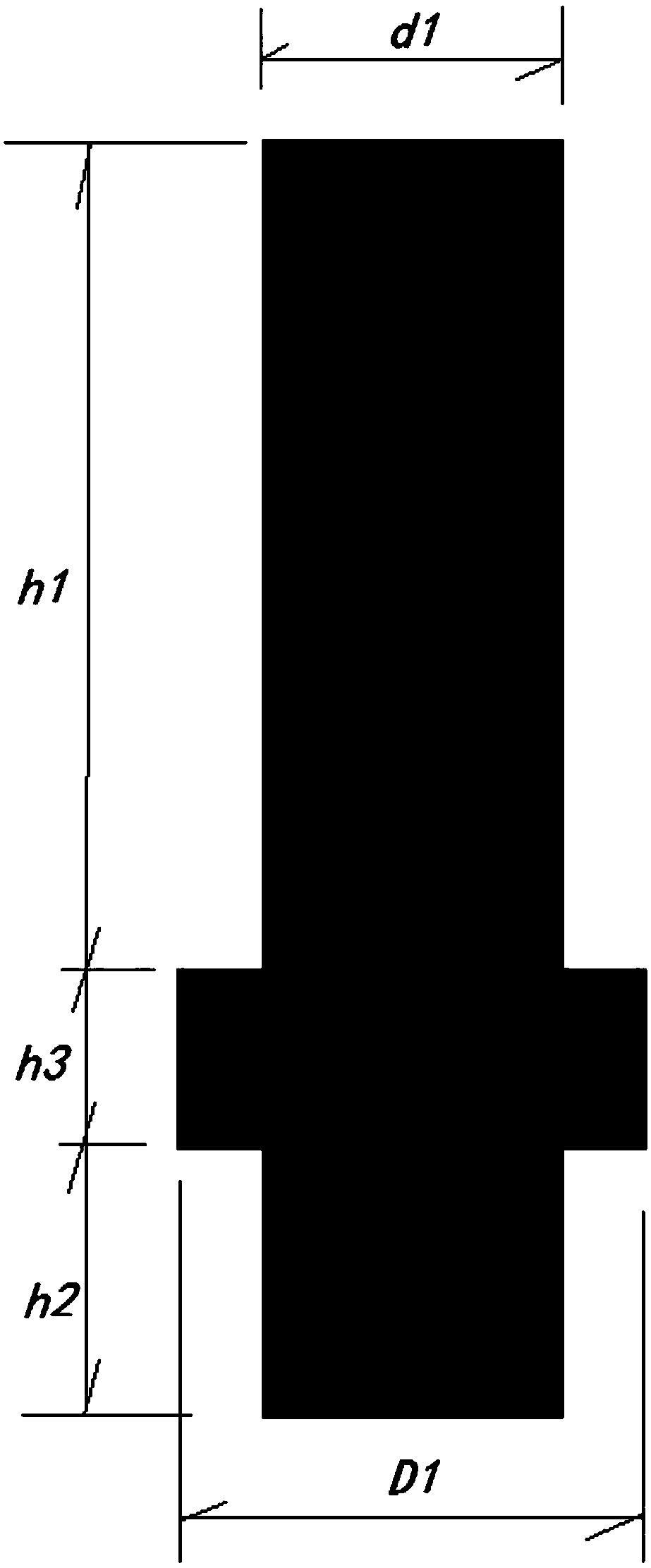

[0032] b) According to the inner and outer diameters of the pipe piles used in the piling area and the final settlement of the soft soil layer above the neutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com