A Ground Treatment Method for Eliminating Negative Frictional Resistance

A ground treatment and negative friction technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of single and backward treatment and solution methods, and achieve the effects of facilitating promotion, reducing settlement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

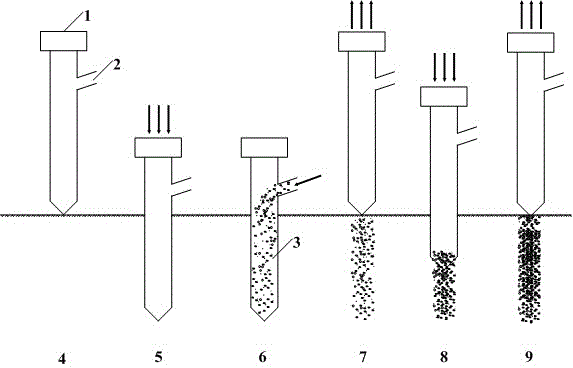

Method used

Image

Examples

Embodiment Construction

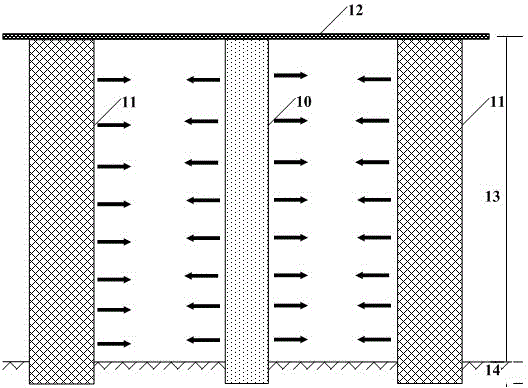

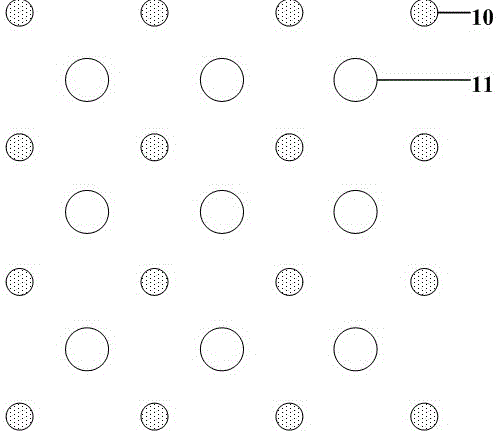

[0040] The foundation treatment method of the present invention is a composite foundation combining loose piles and flexible piles, including loose piles and flexible piles, the loose piles and flexible piles are arranged in separate rows, and the surface of the foundation on the upper part of the loose piles and flexible piles is laid. Body pile drainage cushion.

[0041] The arrangement of the row arrangement can be that each row of loose piles and flexible piles is aligned front and back, and the overall arrangement is square; or each flexible pile is located on the center line of the line connecting two adjacent loose piles in the adjacent row Each flexible pile forms a triangular arrangement with two adjacent loose piles. Through the criss-cross combined drainage channels of the loose piles and the drainage cushion, the soil between the piles can be quickly drained and consolidated, so as to further reduce the consolidation settlement and negative frictional resistance ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com