Light steel assembly type composite wall board, light steel framework, manufacturing method and installing method thereof

A composite wall panel, assembled technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

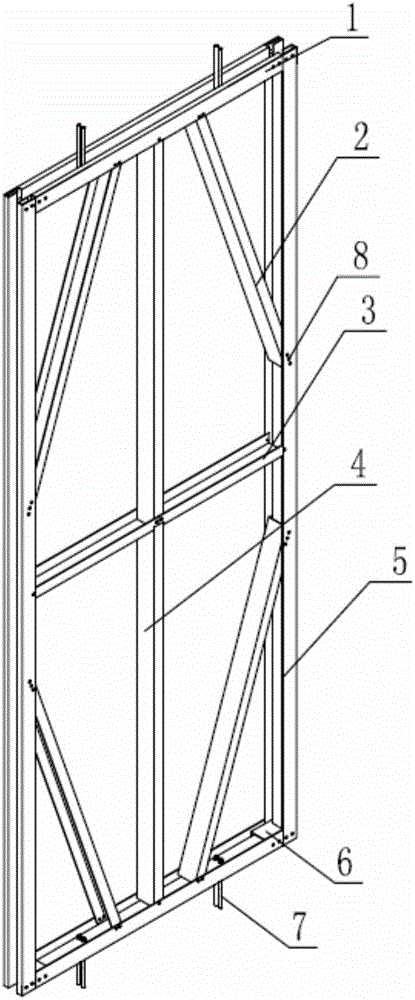

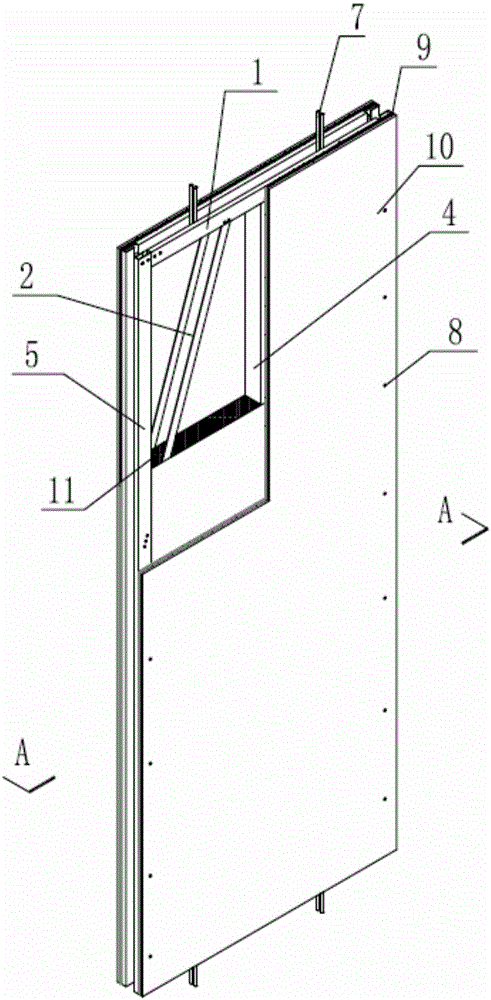

[0071] The present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

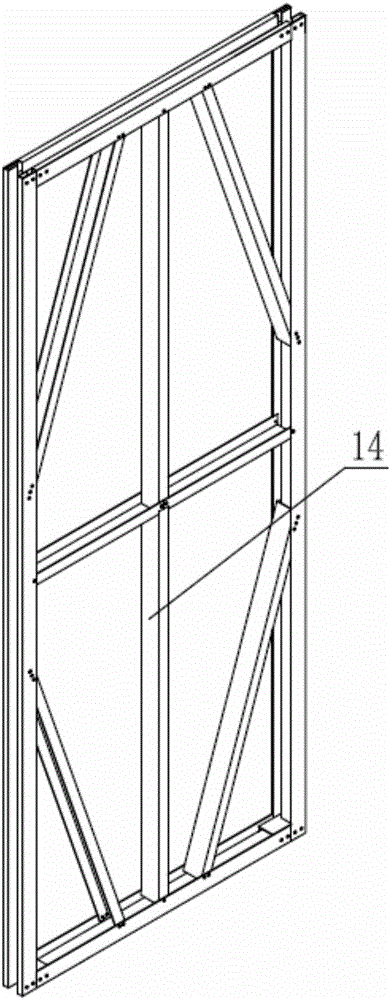

[0072] Such as Figure 1-7 As shown, a light steel assembled composite wall panel and its installation method, wherein the light steel assembled composite wall panel includes a horizontal M-shaped steel 1, a diagonal brace 2, a horizontal C-shaped steel 3, a vertical C-shaped steel 4, and a vertical M-shaped steel 5. C-type connector 6, turnbuckle screw 7, self-tapping screw 8, heat insulation layer 9, outer maintenance plate 10, sandwich insulation layer 11, square steel pipe 12, truss beam 13, light steel frame 14, connection between wall panels Structure 15, connection structure 16 between the wallboard and the main board.

[0073] The middle of the light steel frame 14 is filled with a sandwich insulation layer 11, the inner surface of the heat insulation layer 9 and the outer surface of the sandwich insulation layer 11 are bonded by polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com