Prefabricated core column type self-insulating exterior wall plate, connecting structure and construction method thereof

A technology of self-insulation and external wall panels, applied in the direction of manufacturing tools, walls, building components, etc., can solve the problems of high rigidity, poor ductility, easy damage and falling off of the additional insulation layer, safety of connection, hidden dangers, etc., and achieve the improvement of bearing capacity and earthquake resistance , Reduce the process of thermal insulation system, improve the effect of ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

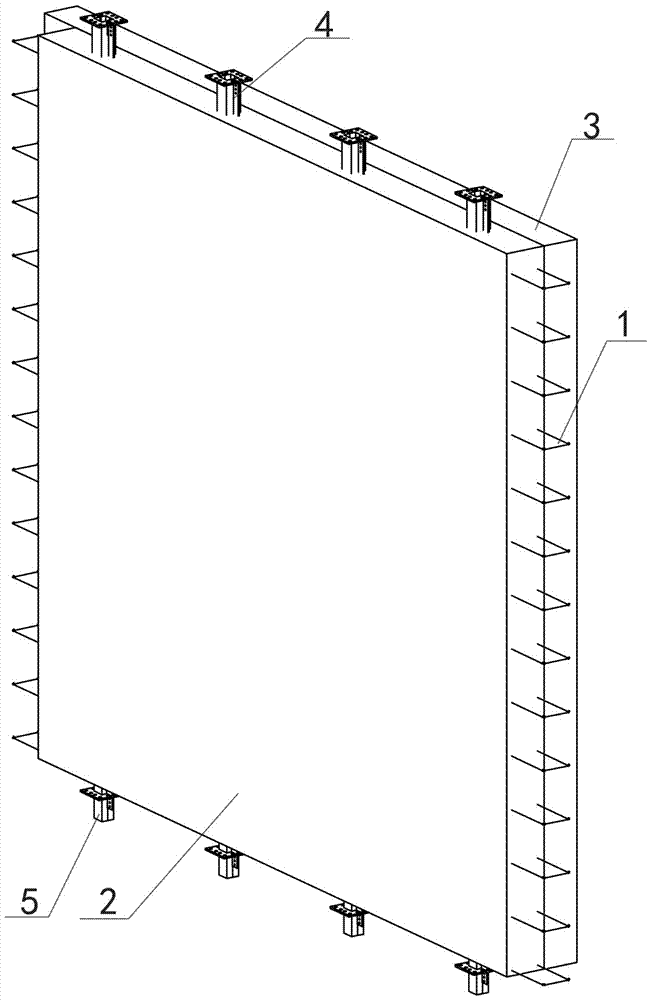

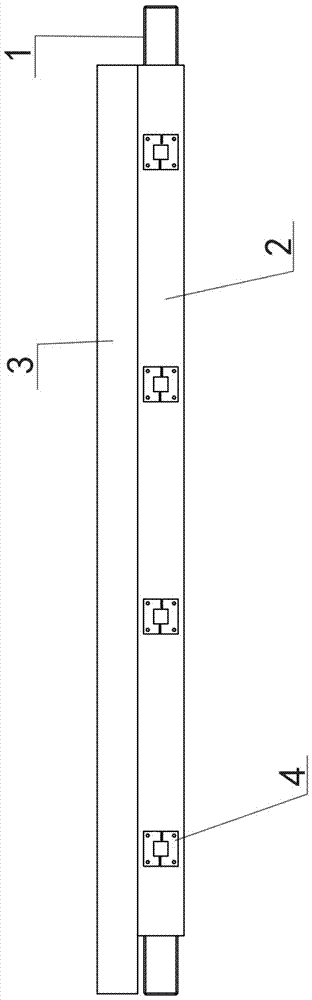

[0050] Examples see figure 1 , 3 As shown in and 4, a prefabricated core column type self-insulating exterior wall panel includes a wall and a wall vertical splicing connector embedded in the wall, and the wall is insulated by a reinforced concrete structure layer and a foam concrete The reinforced concrete structural layer includes structural layer steel skeleton 1 and structural layer concrete 2, and the material of the foam concrete insulation layer 3 is foam concrete. In this embodiment, the foamed concrete adopts a strength above 4MPa and a thermal conductivity of 0.2w / (m 2 k) Foamed concrete below.

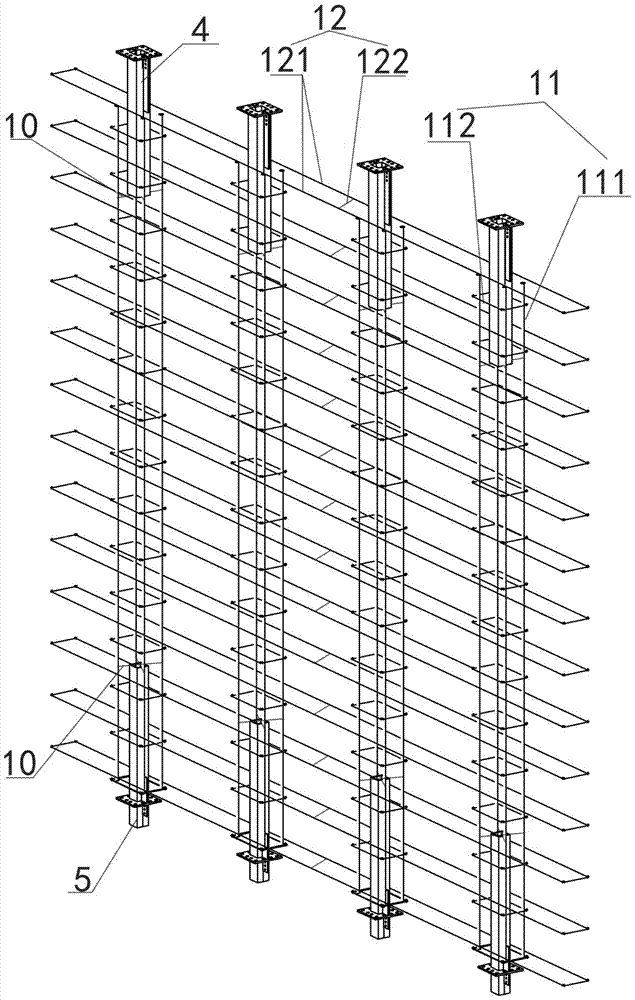

[0051] see Figure 2-4 As shown, the structural layer steel skeleton 1 includes a group of vertical core column reinforcement cages 11 arranged at intervals along the height direction of the wall and along the width direction of the wall body. The height of the core column reinforcement cages 11 is not greater than the height of the wall. The core column reinforcement c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com